Professional Documents

Culture Documents

Ordering Ready Mixed Concrete

Uploaded by

aaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ordering Ready Mixed Concrete

Uploaded by

aaCopyright:

Available Formats

CIP 31 - Ordering Ready Mixed Concrete

WHAT is Ready Mixed Concrete

Concrete is a mixture of cementitious materials, water, aggregate,

usually sand and gravel or crushed stone. Chemical admixtures

and other products are used to enhance its fresh and hardened

properties.

Ready mixed concrete is that which is manufactured and

delivered to the customer in a freshly mixed and unhardened

state. The customer is typically a concrete contractor. Ready

mixed concrete is manufactured and delivered in accordance with

ASTM C94, Specification for Ready Mixed Concrete.

There is no typical recipe for concrete mixtures. Concrete mixture

materials and quantities vary depending on the required properties

of fresh and hardened concrete. Concrete mixture composition is

best developed by the concrete producer based on the project. The purchaser should provide a copy of project

requirements for specific applications as stated by the purchaser. specifications if such applies to the project.

Ready mixed concrete should have properties in its fresh state that

When ordering concrete include the following information:

will facilitate handling, placing and finishing. In its hardened

state, concrete should achieve the strength and durability Size of coarse aggregate—the nominal maximum size of

properties required by the designer of the structure. These would aggregate should be smaller than the narrowest dimension

depend on the anticipated loads, environmental exposure, and through which concrete should flow, such as the thickness of

service conditions. the section, space between embedments and formwork, and

spacing of the reinforcing steel, if any. For most applications,

The materials for a concrete mixture are accurately weighed and nominal maximum size of coarse aggregate is 3/4 or 1 in. (19.0

mixed, either in a mixer at the concrete plant or in a concrete

or 25.0 mm).

truck mixer. It is typically delivered in a truck mixer, which keeps

the concrete uniformly mixed until it is discharged at the Slump—is a measure of consistency of concrete when it is

placement location. Concrete remains in a fluid or unhardened delivered. For most applications slump required is 3 to 5 inches

condition for a sufficient period of time for it to be placed and (75 to 100 mm). For slip-form construction maximum slump of

finished. Concrete normally sets or hardens within two to eight 2 inches (50 mm) is applicable, while higher slump of 7 – 9

hours after mixing and continues to gain strength for months or inches (175 – 225 mm) may be needed for basement walls,

even years if it is properly cured during the first few days. pumped concrete or when there is congested reinforcement.

ASTM C94 states tolerances for slump. Adjustments are

WHY Use Ready Mixed Concrete permitted at the jobsite to achieve the slump within tolerances.

Water addition requested should not be excessive so as to cause

Concrete is a popular, economical, and versatile building segregation or reduce the quality of concrete to less than that

material. Concrete mixtures can be customized to provide color, required. Jobsite water addition can increase air content.

texture, shape, strength and other properties required for various Air Content—Air-entrained concrete is required for concrete

applications. It can be delivered at varying consistency exposed to freezing temperatures in service. Air-entrained

appropriate to the placement methods. It can be proportioned to concrete is the default option for exterior concrete in many

achieve a wide range of strength levels and to be durable in regions. When non air-entrained concrete is required this

diverse environmental exposures and service conditions. should be clearly stated. Target air content depends on the size

Concrete can serve its function for several years with minimum of the coarse aggregate and the typical range is 4 to 6% of the

maintenance, provided the proper mixture relative to the concrete volume. The tolerance on air content as delivered is

application and established construction practices are used. ±1.5%. The concrete supplier is permitted to make an

adjustment for air content at the jobsite.

HOW to Order Ready Mixed Concrete Quality required—The purchaser specifies the quality amd

performance requirements for concrete.

When placing an order for ready mixed concrete it is important to The preferred method for ordering concrete is by specifying

provide the basic information and to keep the requirements as performance requirements that can be measured by a standard

simple as possible and relevant to the application. There may be test. Concrete strength is commonly specified. Other

different concrete mixtures needed for the different parts of a performance characteristics, such as permeability, shrinkage or

structure being constructed. The ready mixed concrete producer other durability requirements may be specified when

maintains several mixture formulations for a variety of appropriate to the exposure and service conditions. The

applications and can help with selecting the right mixture for the concrete producer is best equipped to develop concrete

mixtures, mix and supply concrete for the desired performance. WHAT are the Responsibilities

The strength level is generally established by the design of the

structure based on the design loads or durability requirements. The responsibilities of the various parties involved in the con-

Specified strength of 3500 to 5000 psi (25 to 35 MPa) is typical struction process should be addressed at a pre-construction

for most concrete applications and generally ensures durable meeting, especially on a large project. These responsibilities

concrete, such as resistance to wear, abrasion, and freezing and should be documented and distributed to all concerned for

thawing cycles. reference during the construction.

Alternatively, concrete can be ordered by prescription The purchaser is responsible for communicating all

whereby the purchaser states details on the materials and information to the producer that is necessary to comply with a

quantities that make up the concrete mixture. Frequently, this project specification and other project needs.

approach is used when prescriptive mixture formulations have The concrete producer is responsible for the concrete slump

worked well in the past. This approach does not allow the as specified for a period of 30 minutes after the requested time

producer much flexibility thereby cannot assume responsibility or the time the truck arrives at the site, whichever is later.

on the actual performance of concrete. The concrete producer is required to deliver concrete at the

A mixture designation should be established for each type of requested slump and air content, within tolerances, as measured

mixture required on a project to ensure that concrete is placed at the point of discharge from the transportation unit.

in the correct location. When placing procedures can potentially alter the characteris-

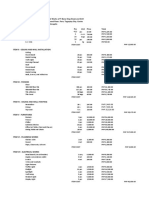

Quantity of concrete—Concrete is sold by volume, in cubic tics of the fresh concrete, it is the responsibility of the pur-

yards (cubic meters), in a freshly mixed unhardened state as chaser to inform the producer of changes to the mixture require-

discharged from the truck mixer. The basis of sale is addressed ments to accommodate these effects. An example is pumping

in ASTM C94. The capacity of a truck mixer is between 8 to 12 concrete in place.

cubic yards (5 to 9 cubic meters). When a job uses more than one type of concrete mixture, it is

Quantity of concrete ordered should be 4% to 10% more than the purchaser’s responsibility to verify the mixture delivered,

an estimate from the plan dimensions to account for based on pre-established designation, and direct it to the

contingencies such as waste, over-excavation, spreading of correct placement location.

forms, etc. See CIP 8. Make a good estimate of concrete The purchaser should check and sign the delivery ticket and

required for the job before placing an order and reevaluate the document any special occurrences on the ticket.

quantity required to complete a placement. Avoid ordering The concrete producer cannot be responsible for the quality

excessive concrete or small clean-up loads less than 4 cubic of concrete when any modification or additions are made to

yards (2.5 cubic meters). the mixture at the jobsite. These include addition of excessive

Additional Items—A variety of value-added options are water, admixtures, fibers or special products, or if the purchaser

available from the ready mixed concrete producer. Chemical is not ready to accept the concrete in the placement location.

admixtures can modify the setting characteristics of concrete to When strength tests are used for acceptance of concrete, the

aid in placing and finishing during hot or cold weather. Water samples should be obtained at the point of discharge from the

reducing admixtures can increase slump without adding water transportation unit. The purchaser or his representative should

and reducing strength. Admixtures can be used to retain ensure that facilities are available for curing test specimens at

workability for longer periods if needed. Synthetic fibers can the jobsite and that standard practices are fol-lowed for

reduce the potential for plastic shrinkage cracking. Color or subsequent curing and testing. Certified personnel should

special aggregates can enhance aesthetic characteristics. The conduct the tests. Test reports should be forwarded to the

concrete contractor is a resource for decorative options. producer in a timely manner so that deficiencies are rectified.

Scheduling delivery—Schedule the delivery of concrete to

support the construction schedule. Inform the producer of the References

correct address, location and nature of the pour, rate of delivery

based on placement methods, and estimated delivery time and 1. ASTM Standards, ASTM Book of Standards, Volume 04.02,

pour duration. Call and place the order with the ready mixed ASTM International, West Conshohocken, PA.

concrete producer well in advance of the required delivery date. www.astm.org

Concrete is a perishable product and the construction crew 2. Ready Mixed Concrete, Gaynor, R.D. & Lobo, C.L., NRMCA

should be ready for concrete placement when the truck arrives. Publication 186, NRMCA, Silver Spring, MD,

Notify the producer of any schedule changes or work stoppage www.nrmca.org.

immediately. 3. Users Guide to ASTM C94, Daniel, D.G. & Lobo, C.L.,

Ensure that the truck mixer has proper access to the placement NRMCA Publication 2PMNL49, 2nd edition, NRMCA,

location. A loaded concrete truck weighs about 80,000 lbs. Silver Spring, MD, www.nrmca.org.

(36,000 kg) and may not be able to maneuver on loose dirt and 4. Guide for Measuring, Mixing, Transporting and Placing Con-

residential curbs and pathways. Consider alternative conveying crete, ACI 304R, American Concrete Institute, Farmington

and placing methods when access is limited Hills, MI, www.concrete.org

CAUTION

Fresh concrete can cause severe chemical burns to skin and eyes. Keep fresh concrete off your skin. When working with concrete use

rubber work-boots, gloves, protective eyeglasses, clothing and knee-boards. Do not let concrete or other cement products soak into

clothing or rub against your skin. Wash your skin promptly after contact with fresh concrete with clean water. If fresh concrete gets into

your eyes, flush immediately and repeatedly with water and consult a doctor immediately. Keep children away from dry cement powder

and all freshly mixed concrete.

2000, 2016

You might also like

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Constatnt Head Permabeality TestDocument1 pageConstatnt Head Permabeality TestaaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- PMP Cheat SheetDocument11 pagesPMP Cheat Sheetsachin.nate525782% (11)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Quarterly Progress Report Top 5 ProductsDocument4 pagesQuarterly Progress Report Top 5 ProductsaaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Qdoc - Tips Fidic Users Guide A Practical ApproachDocument24 pagesQdoc - Tips Fidic Users Guide A Practical ApproachaaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Clause 13 PDFDocument28 pagesClause 13 PDFChamin SubhawickramaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Specificatin For Fasteners-Washers For Overhead Bolts Nuts WashersDocument34 pagesSpecificatin For Fasteners-Washers For Overhead Bolts Nuts WashersaaNo ratings yet

- 65 Civata Torklama Tablosu PDFDocument1 page65 Civata Torklama Tablosu PDFÜstün Onur BaktırNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- B2 C1Document46 pagesB2 C1aaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Pipe GuideDocument48 pagesPipe GuideaaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- CBDG TG 14 - Best Construction Methods For Concrete Bridge Decks - Cost DataDocument130 pagesCBDG TG 14 - Best Construction Methods For Concrete Bridge Decks - Cost DataimamtaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Programming On AutoCadDocument25 pagesProgramming On AutoCadRaul AndresNo ratings yet

- HDPE - LLDPE Geomebrane Installation Manual Revised 2011 Final PDFDocument29 pagesHDPE - LLDPE Geomebrane Installation Manual Revised 2011 Final PDFaaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- B2 C1Document46 pagesB2 C1aaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Introduction VBA For AutoCAD (Mini Guide) - HyperPicsDocument53 pagesIntroduction VBA For AutoCAD (Mini Guide) - HyperPicsmourad117No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Determine soil density using a sand cone testDocument3 pagesDetermine soil density using a sand cone testaaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Landfill Project Bratislava SlovakiaDocument286 pagesLandfill Project Bratislava SlovakiaaaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Summary of Main Changes For Applicators and SpecifiersDocument20 pagesSummary of Main Changes For Applicators and Specifiersمحمد مقلدNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Moisture - Content - Ocr Rms Kadar AirDocument9 pagesMoisture - Content - Ocr Rms Kadar AirPali MeitaNo ratings yet

- Significance of The Formation of Calcium Carbonate Minerals in The Pedogenesis and Management of Cracking Clay Soils (Vertisols) of IndiaDocument16 pagesSignificance of The Formation of Calcium Carbonate Minerals in The Pedogenesis and Management of Cracking Clay Soils (Vertisols) of IndiaaaNo ratings yet

- Exercise 4 Converting Numbers To Words and Word To Numbers Jan 2005Document7 pagesExercise 4 Converting Numbers To Words and Word To Numbers Jan 2005Dali Soares De Sá NardeliNo ratings yet

- IPC-1 IPC-1 IPC-1: DOC No.6 DOC No.6 DOC No.6Document1 pageIPC-1 IPC-1 IPC-1: DOC No.6 DOC No.6 DOC No.6aaNo ratings yet

- Fore KazıkDocument1 pageFore KazıkaaNo ratings yet

- An Innovative Design For Leachate Collection Pipes To Eliminate Clogging of Geotextiles PDFDocument29 pagesAn Innovative Design For Leachate Collection Pipes To Eliminate Clogging of Geotextiles PDFaa0% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Landfill Project Bratislava SlovakiaDocument286 pagesLandfill Project Bratislava SlovakiaaaNo ratings yet

- Rescued Document 2Document1 pageRescued Document 2aaNo ratings yet

- QualityDocument28 pagesQualityaaNo ratings yet

- Attachment (1) Annex 4 ESIA EBRD Leachate Treatment 140902Document28 pagesAttachment (1) Annex 4 ESIA EBRD Leachate Treatment 140902aaNo ratings yet

- Stormwater/Wetland Pond Construction Inspection Checklist: C S S / U C Pre-Construction/Materials and EquipmentDocument22 pagesStormwater/Wetland Pond Construction Inspection Checklist: C S S / U C Pre-Construction/Materials and EquipmentaaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Significance of The Formation of Calcium Carbonate Minerals in The Pedogenesis and Management of Cracking Clay Soils (Vertisols) of IndiaDocument16 pagesSignificance of The Formation of Calcium Carbonate Minerals in The Pedogenesis and Management of Cracking Clay Soils (Vertisols) of IndiaaaNo ratings yet

- Step by Step Guide To Dumpy Level SurveyDocument5 pagesStep by Step Guide To Dumpy Level Surveyandysupa100% (1)

- G-00-1169 - Grade Designation For Low Carbon Hot Rolled Steel Sheets Used in Automotive Applications - Rev 4Document7 pagesG-00-1169 - Grade Designation For Low Carbon Hot Rolled Steel Sheets Used in Automotive Applications - Rev 4Prince Ali50% (2)

- Annular Cutter Feeds and SpeedsDocument1 pageAnnular Cutter Feeds and SpeedsAnonymous JzEb8CXErNo ratings yet

- Advantages of Bubble Deck Slab Over RCC Slab: Presentation On Project Review - IIDocument25 pagesAdvantages of Bubble Deck Slab Over RCC Slab: Presentation On Project Review - IIsumitNo ratings yet

- Metals: Vacuum Die Casting Process and Simulation For Manufacturing 0.8 Mm-Thick Aluminum Plate With Four Maze ShapesDocument14 pagesMetals: Vacuum Die Casting Process and Simulation For Manufacturing 0.8 Mm-Thick Aluminum Plate With Four Maze Shapesrekyts31No ratings yet

- Interior Fitting Out Works Bill of MaterialsDocument15 pagesInterior Fitting Out Works Bill of MaterialsAnn MoralesNo ratings yet

- Syllabus - CBB - CP ExamDocument7 pagesSyllabus - CBB - CP ExamRAJKUMARNo ratings yet

- Chemistry Project MannyDocument12 pagesChemistry Project Mannyabhishekhembrom89No ratings yet

- Joint Design RequirementsDocument21 pagesJoint Design RequirementskhudubaNo ratings yet

- Assignment 2, Flat Slab Flexural DesignDocument1 pageAssignment 2, Flat Slab Flexural DesignKelly Obrien0% (1)

- Construction Terminologies BT2Document53 pagesConstruction Terminologies BT2Joyce CulloNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Final Bhiwadi EffluentDocument53 pagesFinal Bhiwadi EffluentRajendra MittalNo ratings yet

- Din 8074 HdpeDocument18 pagesDin 8074 Hdpesomeshangale100% (4)

- Sheet1 - AGAY NATIONAL HIGH SCHOOL SMAW Training MatrixDocument2 pagesSheet1 - AGAY NATIONAL HIGH SCHOOL SMAW Training Matrixfernando m comedoy jr100% (2)

- Mill Certificate Juno 13 Ags 22Document1 pageMill Certificate Juno 13 Ags 22Constantia ArthiaNo ratings yet

- X17CrNi16-2 HTTP - WWW - Steelnumber.com - en - Steel - Composition - Eu - PHP - Name - IdDocument2 pagesX17CrNi16-2 HTTP - WWW - Steelnumber.com - en - Steel - Composition - Eu - PHP - Name - IddabarcinaNo ratings yet

- TDS Contite FCW 010 Jul11Document4 pagesTDS Contite FCW 010 Jul11พศิน จันทะสิมNo ratings yet

- Tetra PakDocument13 pagesTetra PakPriya Subramanian0% (1)

- Notes of CH 6 Physical and Chemical Changes Class 7th ScienceDocument3 pagesNotes of CH 6 Physical and Chemical Changes Class 7th ScienceVicky SharmaNo ratings yet

- Cable Glands CrossreferenceDocument8 pagesCable Glands CrossreferenceerstendrainNo ratings yet

- Prestressing Techniques: The Extract About A of Prestressed Concrete The Box. 9 PtsDocument2 pagesPrestressing Techniques: The Extract About A of Prestressed Concrete The Box. 9 Ptsfahimaomar IbrahimNo ratings yet

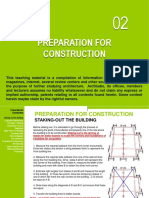

- 02 Preparation For Construction PDFDocument61 pages02 Preparation For Construction PDFMiguel David100% (2)

- Goodreach Wilcox Weld 9781631263286 - ch11Document30 pagesGoodreach Wilcox Weld 9781631263286 - ch11Anonymous nw5AXJqjdNo ratings yet

- Elems 15Document101 pagesElems 15Reynald de VeraNo ratings yet

- Green Building Materials Guide: Characteristics, Selection & CategoriesDocument23 pagesGreen Building Materials Guide: Characteristics, Selection & Categoriessusmita sethiNo ratings yet

- Durability Studies On Concrete by Using Groundnut Shell Ash As Mineral AdmixtureDocument5 pagesDurability Studies On Concrete by Using Groundnut Shell Ash As Mineral AdmixtureIJIRSTNo ratings yet

- ASTM A 802 Standard Practice For Steel Castings, Iron Castings, Surface Acceptance, Visual ExaminationDocument10 pagesASTM A 802 Standard Practice For Steel Castings, Iron Castings, Surface Acceptance, Visual ExaminationlodraprabowoNo ratings yet

- 092116Document7 pages092116kupaloidNo ratings yet

- Structural Design of Swimming PoolsDocument12 pagesStructural Design of Swimming Poolsale hopeju200975% (20)

- Lecture 6 - BricksDocument28 pagesLecture 6 - BricksVanessa AlexanderNo ratings yet

- Nucleotec 2222Document2 pagesNucleotec 2222Marco MorenoNo ratings yet

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetFrom EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetRating: 4.5 out of 5 stars4.5/5 (10)

- Cable Supported Bridges: Concept and DesignFrom EverandCable Supported Bridges: Concept and DesignRating: 5 out of 5 stars5/5 (1)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- Summary of Neil Postman's Amusing Ourselves to DeathFrom EverandSummary of Neil Postman's Amusing Ourselves to DeathRating: 4 out of 5 stars4/5 (2)