Professional Documents

Culture Documents

General Notes

Uploaded by

hahaerCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Notes

Uploaded by

hahaerCopyright:

Available Formats

GENERAL NOTES FOR ROOF CONSTRUCTIONS WOOD FRAMING

1. STRUCTURAL DESIGN IS IN ACCORDANCE WITH PART 9 OF THE THE 2012 ONTARIO BUILDING CODE (OBC), SUPPLEMENTED BY 1. REFER TO SPECIFICATIONS FOR ADDITIONAL REQUIREMENTS.

THE 2010 NATIONAL BUILDING CODE OF CANADA STRUCTURAL COMMENTARY.

2. UNLESS NOTED OTHERWISE, ALL WOOD FRAMING DETAILS TO BE IN ACCORDANCE WITH PART 9 OF THE REFERENCED BUILDING CODE.

2. REVIEW THESE STRUCTURAL DRAWINGS IN CONJUNCTION WITH ALL OTHER CONTRACT DOCUMENTS. THE ARCHITECTURAL,

MECHANICAL, ELECTRICAL, AND LANDSCAPING DRAWINGS AS WELL AS THE STRUCTURAL DRAWINGS ISSUED BY CIMA+ PRIOR TO 3. MATERIALS

CONSTRUCTION. REPORT DISCREPANCIES BEFORE PROCEEDING WITH THE WORK.

OSB SHEATHING: TO CSA O325.

3. COORDINATE ALL OPENINGS, SLEEVES AND EMBEDDED ITEMS IN STRUCTURE WITH ARCHITECTURAL, MECHANICAL,

ELECTRICAL, AND LANDSCAPE DRAWINGSALL OTHER CONTRACT DOCUMENTS. REPORT ANY ITEMS THAT ARE IN CONFLICT BEFORE LAMINATED STRAND LUMBER (LSL): MINIMUM GRADE 1.3E, 1700FB (FB=29.7MPA) OR BETTER

PROCEEDING WITH THE WORK.

WOOD BOLTS: ASTM A307

4. VERIFY EXISTING DIMENSIONS AND CONDITIONS ON SITE PRIOR TO CONSTRUCTION.

LAG SCREWS: CSA B34. MACHINE THREADED (NOT CAST-THREADED). PREDRILL PRIOR TO LAG SCREW INSTALLATIONS.

5. DO NOT CONSTRUCT FROM THESE DRAWINGS UNLESS MARKED “ISSUED FOR CONSTRUCTION”.

WOOD CONNECTORS: GALVANIZED STEEL FASTENERS DESIGNED FOR CAPACITIES NOTED ON DRAWINGS. INSTALL IN ACCORDANCE WITH

6. DO NOT USE INFORMATION ON THESE DRAWINGS FOR ANY OTHER PROJECTS OR WORKS. MANUFACTURER'S REQUIREMENTS.

7. DO NOT SCALE THESE DRAWINGS. HOT DIP GALVANIZING: ASTM A123/A123M, MINIMUM ZINC COATING OF 600 G/M². FOR ALL EXTERIOR STEEL TIMBER CONNECTION

COMPONENTS, UNLESS NOTED OTHERWISE.

8. FOLLOW TYPICAL DETAILS SHOWN ON DRAWING XXX, UNLESS OTHERWISE NOTED. TYPICAL DETAILS SHOW STRUCTURAL

INTENT RATHER THAN ACTUAL ACTUAL PROJECT CONDITIONS FOR THIS PROJECT. (NOTE THAT TYPICAL DETAILS ARE NOT ALWAYS 3. PROTECT ALL WOOD PRODUCTS FROM THE ELEMENTS AS REQUIRED TO MAINTAIN THEIR INTEGRITY.

REFERENCED ON PLAN.)

4. PROVIDE ALL ERECTION BRACING REQUIRED TO KEEP THE STRUCTURE STABLE AND IN ALIGNMENT DURING CONSTRUCTION.

9. ALL SECTIONS, DETAILS, AND STATEMENTS NOTED AS “TYPICAL” SHALL CONVEY THAT CONDITIONS ARE APPLY TO LIKE OR

/SIMILAR CONDITIONS IN THE STRUCTURE. 5. SUBSTITUTION OF COMMON NAILS WITH POWER DRIVEN NAILS OF THE SAME LENGTH AND DIAMETER IS ACCEPTABLE. SUBSTITUTION OF POWER

DRIVEN NAILS OF SMALLER DIAMETER MUST BE APPROVED IN WRITING BY ENGINEER PRIOR TO USE. POWER DRIVEN NAILS NOT TO BE OVER-DRIVEN INTO

10. STRUCTURAL DESIGN ASSUMES NON-LOAD RESTRICTED ULC FIRE RATED ASSEMBLIES, AND APPROPRIATE MATERIALS MUST BE WOOD OR SHEATHING.

USED.

6. MEMBER SIZES INDICATED ON DRAWINGS ARE A MINIMUM AND ARE TO BE INCREASED AS REQUIRED TO MEET DESIGN WITHOUT DETERRING FROM

11. THESE DRAWINGS SHOW THE COMPLETED STRUCTURE ONLY. THEY DO NOT SHOW TEMPORARY WORKS FOR WHICH THE ORIGINAL DESIGN INTENT.

CONTRACTOR IS RESPONSIBLE AND WHICH MAY BE REQUIRED FOR EXECUTION OF THE PROJECT ARE NOT SHOWN. CONSTRUCTION

LOADS ON THE PERMANENT STRUCTURE SHALL NOT EXCEED DESIGN LOADS INDICATED ON DRAWINGS. 7. PROVIDE ADEQUATE SUPPORT FOR VERTICAL EDGES OF SHEATHING AND FINISHES AT CORNERS, INTERSECTIONS AND ENDS OF WALLS CONSISTING OF

NOT LESS THAN 2-38X140 STUDS UNLESS OTHERWISE NOTED ON THE DRAWINGS .

12. ALL TEMPORARY WORKS WORKS SHALL BE DESIGNED AND REVIEWED BY A PROFESSIONAL ENGINEER RETAINED BY THE

CONTRACTOR, LICENSED IN ONTARIO. 8. NOTCHING AND DRILLING OF FRAMING MEMBERS THAT DO NOT CONFORM TO PART 9 OF THE REFERENCED BUILDING CODE MUST BE REVIEWED BY

THE ENGINEER RESPONSIBLE FOR THOSE FRAMING MEMBERS. SIGNIFICANT NOTCHES CONFORMING TO PART 9 MAY BE REVIEWED AND REJECTED IF THEY

13. EMBEDDED ITEMS, INCLUDING ANCHOR BOLTS, HAVE BEEN DESIGNED FOR LOADS OF THE COMPLETED STRUCTURE ONLY. THE COMPROMISE THE STRUCTURAL INTEGRITY.

USE OF THESE ELEMENTS FOR TEMPORARY SUPPORT DURING CONSTRUCTION MUST BE REVIEWED AND APPROVED BY THE

CONTRACTOR'S ENGINEER RESPONSIBLE FOR THE ERECTION PROCEDURES. 9. ALL COMPONENTS OF BUILT UP MEMBERS TO BE CONTINUOUS FOR FULL SPAN. DO NOT SPLICE OR USE BUTT JOINTS.

14. PROVIDE REASONABLE NOTICE (NOT LESS THAN 48 HOURS) PRIOR TO CONCEALING ANY WORK THAT REQUIRES INSPECTION, 10. UNLESS OTHERWISE NOTED, BUILT UP BEAMS OR LINTELS ARE TO BE FASTENED WITH A DOUBLE ROW OF 89 LONG NAILS, AT 450 C/C AND AT 125

REVIEW, OR TESTING. SCHEDULE THIS WORK TO OCCUR DURING NORMAL BUSINESS HOURS. WORK TO BE GENERALLY COMPLETE AT FROM EACH END.

THE TIME OF THE REVIEW.

11. CARRY ALL POSTS DOWN TO SUPPORTING SLAB OR FOUNDATION. PROVIDE SOLID VERTICAL BLOCKING IN LINE AND SAME SIZE OR LARGER WITH

15. JLL ENGINEERING INC. (OR REPRESENTATIVE) WILL PROVIDE PERIODIC FIELD REVIEW OF A REPRESENTATIVE SAMPLE OF THE POSTS AT FLOOR LEVELS.

STRUCTURAL WORKS DESIGNED BY JLL ENGINEERING INC. WILL BE UNDERTAKEN TO ASCERTAIN GENERAL CONFORMANCE WITH

THE STRUCTURAL DRAWINGS AND SPECIFICATIONS. THESE REVIEWS DO NOT REPLACE THE CONTRACTOR'S RESPONSIBILITY FOR 12. ALL 2 STOREY WALLS AND SPLIT LEVEL WALLS WITHOUT INTERMEDIATE FLOORS TO BE BALLOON FRAMED TO PREVENT HINGING. REFER TO PLAN FOR

QUALITY CONTROL CONTROL AND QUALITY ASSURANCE. LOCATIONS AND STUD WALL REQUIREMENTS.

16. ALL STRUCTURAL WORK DESIGNED BY PROFESSIONAL ENGINEERS RETAINED BY THE CONTRACTOR SHALL BE REVIEWED BY THE 13. ALL RIM BOARD AND BLOCKING MATERIAL TO BE LSL FOR ENGINEERED FLOOR SYSTEMS, MINIMUM THICKNESS TO BE 44 (1-3/4”) UNLESS NOTED

ENGINEERS RESPONSIBLE FOR THE DESIGN OR THEIR REPRESENTATIVE. SUBMIT CONSTRUCTION REVIEW REPORTS TO JLL ENGINEERING OTHERWISE ON DRAWINGS.

INC. FOR REVIEW.

14. ENSURE WOOD IS NOT IN DIRECT CONTACT WITH CONCRETE, PROVIDE FOAM GASKET BETWEEN WOOD AND CONCRETE, OR USE PRESSURE TREATED

WOOD. REFER TO PLANS FOR ADDITIONAL REQUIREMENTS.

DESIGN LOADS 15. PREFABRICATED WOOD ROOF TRUSSES:

1. THE VALUES FOR CLIMATIC DATA USED IN THE DETERMINATION OF DESIGN LOADS HAVE BEEN OBTAINED FROM 15.1. DESIGN TO THE REFERENCED BUILDING CODE AND THE TRUSS PLATE INSTITUTE OF CANADA (TPIC) DESIGN SPECIFICATIONS FOR LIGHT METAL

THE 2012 OBC FOR THE SPECIFIC LOCATION OF OTTAWA. PLATE CONNECTED WOOD TRUSSES FOR LOADS GIVEN ON THE STRUCTURAL DRAWINGS.

2. SELF WEIGHT (SWT) IS DUE TO THE WEIGHT OF THE STRUCTURE ITSELF. IT VARIES WITH THE STRUCTURAL

SYSTEM. 15.2. TRUSSES TO BE SUPPLIED BY A MEMBER OF THE CANADIAN WOOD TRUSS ASSOCIATION.

3. SUPERIMPOSED DEAD LOADS (SDL) ARE NON-STRUCTURAL DEAD LOADS DUE TO NON-STRUCTURAL TOPPINGS, 15.3. DESIGN TRUSSES FOR THE MAXIMUM DEFLECTIONS DUE TO THE LIVEL LOAD: L/360. TOTAL DEAD+LIVE INDUCED MAXIMUM DEFLECTION: L/240.

FINISHES, PARTITIONS, ROOFING MATERIALS, SUSPENDED EQUIPMENT, PAVERS, SOIL, ETC.

4. DEAD LOAD (DL) IS THE SELF WEIGHT OF THE STRUCTURE PLUS THE SUPERIMPOSED DEAD LOAD. 15.4. SUBMIT SHOP DRAWINGS SIGNED AND SEALED BY A PROFESSIONAL ENGINEER LICENSED IN THE PLACE WHERE THE PROJECT IS LOCATED PRIOR TO

FABRICATION. SHOP DRAWINGS TO INCLUDE MATERIAL GRADES, CALCULATIONS, LAYOUT DRAWINGS, BEARING AND ANCHORAGE DETAILS,

5. GRAVITY LOADS ARE SHOWN ON PLANS. LIVE LOAD REDUCTION HAS NOT BEEN USED. CONNECTION DETAILS BETWEEN TRUSSES AND THEIR SUPPORTS, AND TEMPORARY AND PERMANENT BRACING AND BRIDGING DETAILS AFFECTING

THE STRUCTURAL CAPACITY OF THE TRUSSES.

6. UNLESS OTHERWISE NOTED, DESIGN LOADS SHOWN ARE SPECIFIED (UNFACTORED) LOADS, TO BE USED FOR ULS

DESIGN.

15.5. PROVIDE A STAMPED MEMO FROM THE TRUSS ENGINEER CONFIRMING THEIR REVIEW OF THE LOAD INPUTS INTO THE PROGRAM USED FOR THE

TRUSS DESIGN.

7. FOR POINT LOADS, IF ONLY ONE LOAD IS GIVEN, CONSIDER IT LIVE LOAD.

8. JLL ENGINEERING INC. IS RESPONSIBLE FOR PROVIDING THE LOADING ACTIONS FROM THE SNOW AND THE WIND

TO ROOF STRUCTURAL PREFABRICATORS.

ROOF DIAPHRAGM LATERAL LOADS ARE RESISTED BY THE CANTILEVER COLUMNS ONLY, AND A 35 KN LONGITUDINAL

& 25 KN PERPENDICULAR FACTORED (PER COLUMN LATERAL LOADING IS PROVIDED BY CIMA+. JLL ENGINEERING INC. IS

RESPONSIBLE FOR THE DESIGN OF THE CONNECTIONS BETWEEN THE ROOF TRUSSES AND THEIR SUPPORTING CONCRETE

CANTILEVER COLUMNS BELOW. THE ROOF DIAPHRAGM DESIGN IS TAKEN THE GREATER OF THE LATERAL LOADING

DETERMINED FROM RD*R0 = 2.0 OR CIMA PLUS INDICATED LOADING ON DRAWING S022.

SNOW (IN ACCORDANCE WITH PART 4)

Ss = 2.5 kPa Sr = 0.4 kPa PLUS THE SNOW PILING.

JLL ENGINEERING INC.

You might also like

- Atopex Metal ENG 3Document6 pagesAtopex Metal ENG 3hahaerNo ratings yet

- Yard King Bridge Operation ManualDocument7 pagesYard King Bridge Operation ManualhahaerNo ratings yet

- Li Jun 2013Document233 pagesLi Jun 2013hahaerNo ratings yet

- Whale Seeing Nature TourDocument3 pagesWhale Seeing Nature TourhahaerNo ratings yet

- Natural Pozzolan SCM Safety Data Sheet Provides Cancer, Skin and Eye Damage WarningsDocument11 pagesNatural Pozzolan SCM Safety Data Sheet Provides Cancer, Skin and Eye Damage WarningshahaerNo ratings yet

- AISI How To Build INTERIOR WALLS With SteelDocument4 pagesAISI How To Build INTERIOR WALLS With SteeloscarNo ratings yet

- Bridge Shop Drawing SignedDocument1 pageBridge Shop Drawing SignedhahaerNo ratings yet

- Hollowcore Slab DetailsDocument17 pagesHollowcore Slab DetailshahaerNo ratings yet

- OPSS - PROV 1350 Ontario Specs 1305Document28 pagesOPSS - PROV 1350 Ontario Specs 1305hahaerNo ratings yet

- Reinforcement at Pipe Penetrations Through Steel Column TS-COL-01Document4 pagesReinforcement at Pipe Penetrations Through Steel Column TS-COL-01hahaerNo ratings yet

- 06-TC-BM-00 CombinedDocument10 pages06-TC-BM-00 CombinedhahaerNo ratings yet

- Self-Consolidating Concrete SheetDocument2 pagesSelf-Consolidating Concrete SheethahaerNo ratings yet

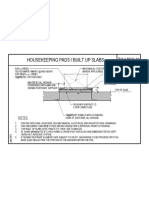

- Housekeeping Pads / Built Up Slabs TC-MISC-01: NotesDocument8 pagesHousekeeping Pads / Built Up Slabs TC-MISC-01: NoteshahaerNo ratings yet

- Tension Development Lengths and Lap Splices For Bars Grade 400 Mpa TC-REINF-01Document5 pagesTension Development Lengths and Lap Splices For Bars Grade 400 Mpa TC-REINF-01hahaerNo ratings yet

- 05-TC-SL-00 Combined PDFDocument28 pages05-TC-SL-00 Combined PDFhahaerNo ratings yet

- OCCDC Reference Guide V31 PDFDocument32 pagesOCCDC Reference Guide V31 PDFx620No ratings yet

- NRC Chemical AdmixtureDocument7 pagesNRC Chemical AdmixturehahaerNo ratings yet

- Flagpole EmbedmentDocument2 pagesFlagpole EmbedmenthahaerNo ratings yet

- 1180 002Document5 pages1180 002hahaerNo ratings yet

- 19 1 PDFDocument61 pages19 1 PDFsunitkghosh1No ratings yet

- Tremie ConcreteDocument3 pagesTremie ConcreteChae Tyng FengNo ratings yet

- DSI Canada DYWIDAG PT Anchor Bolt CA 01Document2 pagesDSI Canada DYWIDAG PT Anchor Bolt CA 01suvraNo ratings yet

- Placing Reinforcing Bars - tcm45-344165Document5 pagesPlacing Reinforcing Bars - tcm45-344165x620No ratings yet

- Specs Concrete Post FoundationDocument8 pagesSpecs Concrete Post FoundationhahaerNo ratings yet

- uNDERWATER gEOTECHNICAL fOUNDATION PDFDocument224 pagesuNDERWATER gEOTECHNICAL fOUNDATION PDFhahaerNo ratings yet

- 19 1 PDFDocument61 pages19 1 PDFsunitkghosh1No ratings yet

- Appendix A: Design Criteria: Davenport Diamond Grade Separation Feasibility Study Update (2015)Document11 pagesAppendix A: Design Criteria: Davenport Diamond Grade Separation Feasibility Study Update (2015)hahaerNo ratings yet

- CodeStandardPractice8E Jun 3 2016Document62 pagesCodeStandardPractice8E Jun 3 2016shakirhamid6687No ratings yet

- Lesson 01 - BasicModeling1 - Steel - Precast PDFDocument50 pagesLesson 01 - BasicModeling1 - Steel - Precast PDFmihai_purcaru1888No ratings yet

- QualityGuidelineFabrication2E WithCommentaryDocument42 pagesQualityGuidelineFabrication2E WithCommentaryhahaerNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chumaceras SKF Sistema ConcentricoDocument40 pagesChumaceras SKF Sistema Concentricotip312No ratings yet

- Fatigue and Bond Properties For High Performance ConcreteDocument23 pagesFatigue and Bond Properties For High Performance ConcretesakolkongNo ratings yet

- SMD - Metal-Sheet Decking DesignDocument10 pagesSMD - Metal-Sheet Decking DesignAchilles YipNo ratings yet

- B4 Stress AnalysisDocument5 pagesB4 Stress AnalysisNaNo ratings yet

- 1b Ce131-01 - Loads On StructuresDocument64 pages1b Ce131-01 - Loads On StructuresRiza Labrague YsmaelNo ratings yet

- Cub Brid Lesson02 WorksheetDocument4 pagesCub Brid Lesson02 WorksheetRichard KansinallyNo ratings yet

- Section 1630 - Minimum Design Lateral Forces and Related EffectsDocument1 pageSection 1630 - Minimum Design Lateral Forces and Related EffectsAbdul Rauf100% (1)

- Design and Analysis of Truck Chassis Frame: Monika S.AgrawalDocument10 pagesDesign and Analysis of Truck Chassis Frame: Monika S.AgrawalAloaa AlaaNo ratings yet

- Oto01070 HELYDECKDocument18 pagesOto01070 HELYDECKpicci4No ratings yet

- AEROCOMPACT - CompactFLAT SN2 - LeafletDocument5 pagesAEROCOMPACT - CompactFLAT SN2 - LeafletLaurentiuNo ratings yet

- Nord EMDocument120 pagesNord EMflasnicugNo ratings yet

- Attachment Report SubmittedDocument74 pagesAttachment Report SubmittedShepherd NhangaNo ratings yet

- General Construction in Steel - Code of Practice: Indian StandardDocument150 pagesGeneral Construction in Steel - Code of Practice: Indian Standardsunil kumar sharmaNo ratings yet

- NBCC 2015: Design Load Criteria For Steel Building SystemsDocument61 pagesNBCC 2015: Design Load Criteria For Steel Building SystemsalbertoxinaNo ratings yet

- Ac 193Document46 pagesAc 193Tiago Castelani100% (1)

- RDSO Steel Bridges Technical PaperDocument314 pagesRDSO Steel Bridges Technical PaperTarun Kant Goyal100% (7)

- Applications of Pretensioned Anchor Rods in Industrial FacilitiesDocument10 pagesApplications of Pretensioned Anchor Rods in Industrial FacilitiescharlesroberNo ratings yet

- Structural Calculation Report - BuildingDocument41 pagesStructural Calculation Report - Buildingarafat.cuet99No ratings yet

- A Comparative Study On Wind Loads Between Design Standards For The Design of Pipe-Rack StructuresDocument8 pagesA Comparative Study On Wind Loads Between Design Standards For The Design of Pipe-Rack Structuresvirat_daveNo ratings yet

- Unit I DME I 13 09 2021Document68 pagesUnit I DME I 13 09 2021Vaibhav JainNo ratings yet

- Dragon Fyp StructureDocument22 pagesDragon Fyp StructureSushrutNo ratings yet

- Michler enDocument3 pagesMichler enMiguel FuentesNo ratings yet

- E 1925 - 99 - Rte5mjutotk - PDFDocument12 pagesE 1925 - 99 - Rte5mjutotk - PDFMauricio Antonio SalgadoNo ratings yet

- Anchor WorksDocument168 pagesAnchor WorksseamaniacNo ratings yet

- Awc Nds2018 Viewonly 171117Document206 pagesAwc Nds2018 Viewonly 171117dnavarro100% (2)

- 2-Types of Foundations and Their SelectionDocument6 pages2-Types of Foundations and Their SelectionSamson Yonas0% (1)

- Staad ExampleDocument45 pagesStaad ExamplehgorNo ratings yet

- Chapter 3 - 3 OSH Mechanical SafetyDocument24 pagesChapter 3 - 3 OSH Mechanical SafetyMahes War100% (1)

- Eota TR 061 Design Method Fasteners Fatigue Loading 2018-06-11Document19 pagesEota TR 061 Design Method Fasteners Fatigue Loading 2018-06-11coolkaisyNo ratings yet

- Design of Centering For BridgesDocument18 pagesDesign of Centering For BridgesAshish Kurve100% (1)