Professional Documents

Culture Documents

Part A5 Cotter Joints

Uploaded by

N Dhanunjaya Rao BorraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Part A5 Cotter Joints

Uploaded by

N Dhanunjaya Rao BorraCopyright:

Available Formats

Prepared By

B.N.DHANUNJAYARAO, &

Dr. K.S.RAGHURAM.

Part-A-Topic_1_CAMD_ Cotter Joints

Cotter joint with sleeve, Cotter joint with socket and spigot ends & Cotter

joint with a gib.

Cotter Joints:

A cotter is a flat wedge-shaped piece, made of steel. It is uniform in thickness but tapering in width,

generally on one side; the usual taper being 1:30. The lateral (bearing) edges of the cotter and the bearing

slots are generally made semi-circular instead of straight.

Cotter joints are used to connect two rods, subjected to tensile or compressive forces along their axes.

These joints are not suitable where the members are under rotation. The following are some of the

commonly used cotter joints:

1. Sleeve and cotter joint,

2. Socket and spigot cotter joint, and

3. Gib and cotter joint.

Figure: Cotter pin (wedge shaped)

Cotter joint with sleeve:

This is the simplest of all cotter joints, used for fastening two circular rods. To make the joint, the rods

are enlarged at their ends and slots are cut. After keeping the rods butt against each other, a sleeve with

slots is placed over them. After aligning the slots properly, two cotters are driven-in through the slots,

resulting in the joint. The slots in the rods and sleeve are made slightly wider than the width of cotter.

The relative positions of the slots are such, that when a cotter is driven into its position, it permits

wedging action and pulls the rod into the sleeve.

Figure: 3D view of Cotter joint with sleeve to connect two rod ends Figure: 3D view of Cotter joint with sectional sleeve to connect two rod ends

Figure: Exploded 3D views of sleeve Cotter joint arrangement

B.N.Dhanunjayarao, Email: dhanunjayborra@gmail.com 2

Figure: Half sectional front view and top view of Cotter joint with sleeve.

Cotter joint with socket and spigot ends:

This joint is also used to fasten two circular rods. In this, the rod ends are modified instead of using a

sleeve. One end of the rod is formed into a socket and the other into a spigot and slots are cut. After

aligning the socket and spigot ends, a cotter is driven-in through the slots, forming the joint.

B.N.Dhanunjayarao, Email: dhanunjayborra@gmail.com 3

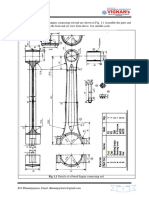

Figure: Half sectional front view and side view of Cotter joint with socket and spigot.

Cotter joint with a gib:

This joint is generally used to connect two rods of square or rectangular cross-section. To make the

joint, one end of the rod is formed into a U-fork, into which, the end of the other rod fits in. When a

cotter is driven-in, the friction between the cotter and straps of the U-fork, causes the straps to open.

This is prevented by the use of a gib.

B.N.Dhanunjayarao, Email: dhanunjayborra@gmail.com 4

Figure: Half sectional front view and side view of Cotter joint with gib.

B.N.Dhanunjayarao, Email: dhanunjayborra@gmail.com 5

DRAWING EXERCISES

1. Draw the sectional view from the front, view from the side and view from the top of a cotter

joint with sleeve used to connect two rods of 30 mm diameter each.

2. Draw the half sectional view from the front, with top half in section and the view from the side

of a cotter joint with socket and spigot ends, to connect two rods of 30 mm diameter each.

3. Two square rods of side 30 mm each, are connected by a cotter joint with a gib. Sketch the

following views of the Joint: (a) half sectional view from the front and (b) view from the side.

B.N.Dhanunjayarao, Email: dhanunjayborra@gmail.com 6

You might also like

- STEEL HOLLOW SECTION JOINT DETAILINGDocument7 pagesSTEEL HOLLOW SECTION JOINT DETAILINGsamirbendre1No ratings yet

- Ar10 Jig Instructions PDFDocument5 pagesAr10 Jig Instructions PDFterrencebelles100% (1)

- Crossbow PlansDocument4 pagesCrossbow Planssuperscribed75% (4)

- Design of Rivets & Welded JointsDocument52 pagesDesign of Rivets & Welded JointsKrishna VamsiNo ratings yet

- Sewing Machine Service ManualDocument40 pagesSewing Machine Service ManualRamon Johnson100% (2)

- Trebuchet Plans 2006 10 11Document7 pagesTrebuchet Plans 2006 10 11Sue MurphyNo ratings yet

- U2l3s Measuring ToolsDocument32 pagesU2l3s Measuring ToolspmcisissengueNo ratings yet

- Assembly DrawingsDocument15 pagesAssembly DrawingsN Dhanunjaya Rao BorraNo ratings yet

- Assembly DrawingsDocument15 pagesAssembly DrawingsN Dhanunjaya Rao BorraNo ratings yet

- Manual Saturn S-0001Document17 pagesManual Saturn S-0001Erick Hdez0% (1)

- Assembling A Can Sealer Fnh-00022Document40 pagesAssembling A Can Sealer Fnh-00022MR XNo ratings yet

- Screw ThreadsDocument37 pagesScrew ThreadsOmkaar SinghNo ratings yet

- 06 - 0010 LED Anti-Collision Lighting System A320Document12 pages06 - 0010 LED Anti-Collision Lighting System A320premica100% (1)

- Oct09 CustomCool OnlineDocument2 pagesOct09 CustomCool OnlineVivian M. Rosario Santos50% (2)

- ReversingDocument28 pagesReversingrakesh0212100% (1)

- Topic 1 Design of FastenersDocument15 pagesTopic 1 Design of FastenersSimon DavidNo ratings yet

- 8/20/2014 1 Hareesha N Gowda, DSCE, Blore-78Document77 pages8/20/2014 1 Hareesha N Gowda, DSCE, Blore-78Santosh DabholeNo ratings yet

- Advanced NDE Lesson 1Document190 pagesAdvanced NDE Lesson 1N Dhanunjaya Rao BorraNo ratings yet

- Screw Threads and Assembly Drawing Class NotesNotesDocument17 pagesScrew Threads and Assembly Drawing Class NotesNotesRay NjorogeNo ratings yet

- A Guide to Making a Leather Belt - A Collection of Historical Articles on Designs and Methods for Making BeltsFrom EverandA Guide to Making a Leather Belt - A Collection of Historical Articles on Designs and Methods for Making BeltsRating: 3 out of 5 stars3/5 (1)

- 100W Wind Turbine ManualDocument23 pages100W Wind Turbine ManualJáder França100% (1)

- Plastic Export Product CompaniesDocument47 pagesPlastic Export Product Companiessunshine7883100% (2)

- Question For Cotter and Knuckle JointDocument3 pagesQuestion For Cotter and Knuckle JointRahul PatilNo ratings yet

- Knuckle Joint Connects RodsDocument10 pagesKnuckle Joint Connects RodsSumit KumarNo ratings yet

- 4 Cotter JointDocument15 pages4 Cotter JointPranay KiranNo ratings yet

- Part A5 Cotter JointsDocument8 pagesPart A5 Cotter JointsN Dhanunjaya Rao BorraNo ratings yet

- Sleeve and Cotter JointDocument13 pagesSleeve and Cotter JointmohanNo ratings yet

- Cutting Braces With A Miter SawDocument7 pagesCutting Braces With A Miter SawSteven MichelsNo ratings yet

- Cotter JointDocument28 pagesCotter Jointsuresh krishna100% (1)

- Project 1Document5 pagesProject 1Sri KannanNo ratings yet

- Basic Warp Knitting GuideDocument8 pagesBasic Warp Knitting GuideTextile AcademiaNo ratings yet

- Cotter JointDocument2 pagesCotter JointSoumyadeep BiswalNo ratings yet

- Screw FastenersDocument17 pagesScrew FastenersZojj UliNo ratings yet

- Cad & Component DrawingDocument36 pagesCad & Component DrawingkousikkumaarNo ratings yet

- Cotter & Knuckle Joints: Prepared by Asst. ProfessorDocument15 pagesCotter & Knuckle Joints: Prepared by Asst. ProfessorTejas RavalNo ratings yet

- Chapter III-V Types of Joint and Torque Transmitting JointDocument18 pagesChapter III-V Types of Joint and Torque Transmitting JointfetenaNo ratings yet

- Cotter JointDocument7 pagesCotter Jointsarath.kumarnmk930No ratings yet

- Joint DetailDocument4 pagesJoint DetailRamesh PrajapatiNo ratings yet

- Fabricating The AdamsDocument2 pagesFabricating The AdamsRebin AliNo ratings yet

- Lec09 Knuckle CotterJointDocument33 pagesLec09 Knuckle CotterJointsunita.storage01No ratings yet

- Cotter JointDocument14 pagesCotter JointAtharva SalunkheNo ratings yet

- Miter Joint: Non-Perpendicular JointsDocument1 pageMiter Joint: Non-Perpendicular JointsMohit BauskarNo ratings yet

- Technical Drawing SS3Document36 pagesTechnical Drawing SS3Moyo DaviesNo ratings yet

- Socket and Spigot JointDocument5 pagesSocket and Spigot Jointsarath.kumarnmk930No ratings yet

- MD R19 - PART - A WordDocument120 pagesMD R19 - PART - A Wordashok junapudiNo ratings yet

- TapersDocument2 pagesTaperskundank_32No ratings yet

- By L.srikanth 17b81a03k4 A.vinay Kumar 17b81a03p3 16b81a03d6Document15 pagesBy L.srikanth 17b81a03k4 A.vinay Kumar 17b81a03p3 16b81a03d6Sunil Kumar VemulaNo ratings yet

- Manufacturing Method of Cotter JointDocument11 pagesManufacturing Method of Cotter JointlolNo ratings yet

- 0009 10enDocument2 pages0009 10enZoran DanilovNo ratings yet

- Introduction to Riveted JointsDocument52 pagesIntroduction to Riveted Jointsaparunpravin079579No ratings yet

- Miter JointDocument2 pagesMiter JointSreekar ParimiNo ratings yet

- Information Sheet No11ThreadingDocument16 pagesInformation Sheet No11ThreadingKher Bee A. PingolNo ratings yet

- 03 Cotter JointDocument22 pages03 Cotter JointTeaching ClubNo ratings yet

- Circular Machine Practical TrainingDocument70 pagesCircular Machine Practical TrainingLiyew WorkieNo ratings yet

- Cove Cutting Jigs For The BT3000 by Jim FryeDocument8 pagesCove Cutting Jigs For The BT3000 by Jim FryeozilogNo ratings yet

- Knuckle Cotter JointDocument10 pagesKnuckle Cotter JointpriyankarNo ratings yet

- Manufacturing Method of Cotter JointDocument11 pagesManufacturing Method of Cotter JointSiddiqui Adil Adnan71% (7)

- MD R19 - Part - ADocument116 pagesMD R19 - Part - Aashok junapudiNo ratings yet

- Pattern Durable Solstice Round Macrame Cushion EngDocument9 pagesPattern Durable Solstice Round Macrame Cushion Engcarolinajuzgado26No ratings yet

- Typical Joint Detailing of Steel Hollow SectionsDocument7 pagesTypical Joint Detailing of Steel Hollow SectionsSyed Mohd MehdiNo ratings yet

- Engineering Graphics and Drawing: "Semester Project Cad"Document12 pagesEngineering Graphics and Drawing: "Semester Project Cad"Xodab21683No ratings yet

- Knuckle Joint & Cotter JointDocument10 pagesKnuckle Joint & Cotter JointSanthosh SekarNo ratings yet

- MEC-307 Design of Machine Element 6 Semester (3 Year) : Name: Chirag Shetty Urn No: 2020-B-26101996Document18 pagesMEC-307 Design of Machine Element 6 Semester (3 Year) : Name: Chirag Shetty Urn No: 2020-B-26101996Siddharth SinghNo ratings yet

- Caps All SizesDocument1 pageCaps All SizesSmrutiNo ratings yet

- Design of Riveted JointDocument12 pagesDesign of Riveted JointYogesh DandekarNo ratings yet

- Power Screws - Types and Uses ExplainedDocument6 pagesPower Screws - Types and Uses ExplainedDeepak KrishnanNo ratings yet

- MCMT Unit-2 PPQDocument2 pagesMCMT Unit-2 PPQN Dhanunjaya Rao BorraNo ratings yet

- MCMT Mid-2 Mech 3-1 R13Document1 pageMCMT Mid-2 Mech 3-1 R13N Dhanunjaya Rao BorraNo ratings yet

- Fundamentals of Machining TechniquesDocument2 pagesFundamentals of Machining TechniquesN Dhanunjaya Rao BorraNo ratings yet

- MCMT Mid-2 Mech 3-1 R13Document1 pageMCMT Mid-2 Mech 3-1 R13N Dhanunjaya Rao BorraNo ratings yet

- MCMT Mid-1 Mech 3-1 R13Document1 pageMCMT Mid-1 Mech 3-1 R13N Dhanunjaya Rao BorraNo ratings yet

- Mid 2Document6 pagesMid 2N Dhanunjaya Rao BorraNo ratings yet

- Supplementary Examinations Tool Wear Cutting Fluid Lathe Attachments Planer Shaper DrillingDocument5 pagesSupplementary Examinations Tool Wear Cutting Fluid Lathe Attachments Planer Shaper DrillingN Dhanunjaya Rao BorraNo ratings yet

- Supplementary Examinations Tool Wear Cutting Fluid Lathe Attachments Planer Shaper DrillingDocument5 pagesSupplementary Examinations Tool Wear Cutting Fluid Lathe Attachments Planer Shaper DrillingN Dhanunjaya Rao BorraNo ratings yet

- New Microsoft Excel WorksheetDocument3 pagesNew Microsoft Excel WorksheetN Dhanunjaya Rao BorraNo ratings yet

- Robotics Course Objectives and ApplicationsDocument5 pagesRobotics Course Objectives and ApplicationsN Dhanunjaya Rao BorraNo ratings yet

- Mid 2Document6 pagesMid 2N Dhanunjaya Rao BorraNo ratings yet

- New Text DocumentDocument1 pageNew Text DocumentN Dhanunjaya Rao BorraNo ratings yet

- Study of Continuous Carbon Fiber Epoxy Polymer Composite Under Prestress ConditionDocument1 pageStudy of Continuous Carbon Fiber Epoxy Polymer Composite Under Prestress ConditionN Dhanunjaya Rao BorraNo ratings yet

- Ucmp QBDocument1 pageUcmp QBN Dhanunjaya Rao BorraNo ratings yet

- Study of Continuous Carbon Fiber Epoxy Polymer Composite Under Prestress ConditionDocument1 pageStudy of Continuous Carbon Fiber Epoxy Polymer Composite Under Prestress ConditionN Dhanunjaya Rao BorraNo ratings yet

- New Text DocumentDocument1 pageNew Text DocumentN Dhanunjaya Rao BorraNo ratings yet

- Composite Materials QuotationDocument1 pageComposite Materials QuotationN Dhanunjaya Rao BorraNo ratings yet

- Part-B-Topic AB 1 CAMD Petrol Engine Connecting - RodDocument8 pagesPart-B-Topic AB 1 CAMD Petrol Engine Connecting - RodN Dhanunjaya Rao BorraNo ratings yet

- CAMD QuestionsDocument3 pagesCAMD QuestionsN Dhanunjaya Rao Borra100% (1)

- Part A4 Keyed JointsDocument8 pagesPart A4 Keyed JointsN Dhanunjaya Rao BorraNo ratings yet

- Part A4 Keyed JointsDocument8 pagesPart A4 Keyed JointsN Dhanunjaya Rao BorraNo ratings yet

- Part-A5-Cotter Joints PDFDocument6 pagesPart-A5-Cotter Joints PDFN Dhanunjaya Rao BorraNo ratings yet

- Intro To NDTDocument34 pagesIntro To NDTkbldamNo ratings yet

- Part-B1-Petrol Engine Connecting RodDocument5 pagesPart-B1-Petrol Engine Connecting RodN Dhanunjaya Rao BorraNo ratings yet

- Technical Data Demag Hoist Units Volume 2: Double-Rail Crab EZDH 600 - EZDH 1000 Double-Rail Crab EZLDH 600 - EZLDH 2000Document88 pagesTechnical Data Demag Hoist Units Volume 2: Double-Rail Crab EZDH 600 - EZDH 1000 Double-Rail Crab EZLDH 600 - EZLDH 2000mohammad khoraminiaNo ratings yet

- UL-ES-AC-Contractors52-WH19 Owner's ManualDocument24 pagesUL-ES-AC-Contractors52-WH19 Owner's ManualCeCy UMNo ratings yet

- Chapter 39 Tires, Wheels and Hubs Maintenance, Diagnosis and ServiceDocument40 pagesChapter 39 Tires, Wheels and Hubs Maintenance, Diagnosis and ServiceROSAN YUMANGNo ratings yet

- Directional Controls: Wet Armature Solenoid Operated Directional Control ValvesDocument11 pagesDirectional Controls: Wet Armature Solenoid Operated Directional Control ValvesNíkolas BorgesNo ratings yet

- UNIT-5 MLAN (Troubleshooting)Document23 pagesUNIT-5 MLAN (Troubleshooting)bala smileyNo ratings yet

- Work Holding Devices-Milling, Shaping, Planing & Slotting MachinesDocument25 pagesWork Holding Devices-Milling, Shaping, Planing & Slotting MachinesMukhil Rajasekaran33% (3)

- Honda Goldwing GL1200 1984 To 1985 Honda Parts Manual-A023BDocument280 pagesHonda Goldwing GL1200 1984 To 1985 Honda Parts Manual-A023Bjoe_2005No ratings yet

- Kem Tc101 STDDocument51 pagesKem Tc101 STDnalasekaranNo ratings yet

- Trinity 64 Refrigerated BoxCar BrochureDocument16 pagesTrinity 64 Refrigerated BoxCar BrochureBassam SayedNo ratings yet

- Sunday MaintDocument33 pagesSunday MaintRonnel Delos ReyesNo ratings yet

- UM9401 / UM9402 / UM9415: Key Features DescriptionDocument7 pagesUM9401 / UM9402 / UM9415: Key Features DescriptionRafael CamposNo ratings yet

- McCloskey J40v2 Track Crusher SpecsDocument5 pagesMcCloskey J40v2 Track Crusher Specsмаргарита100% (1)

- 10-6320 For EMS - 30-6320Document13 pages10-6320 For EMS - 30-6320Alexandru AvrigeanuNo ratings yet

- Training Report On VerilogDocument25 pagesTraining Report On VerilogSohail AnsariNo ratings yet

- Electromagnetic Brakes ClutchesDocument8 pagesElectromagnetic Brakes Clutchesfsilassie8012100% (1)

- Tru TracDocument8 pagesTru TracJavier SaavedraNo ratings yet

- FaultDocument3 pagesFaultSandeep KumarNo ratings yet

- Users Manual KD21C KDSDocument25 pagesUsers Manual KD21C KDSSora GamerNo ratings yet

- C4020 AllegroMicroSystemsDocument1 pageC4020 AllegroMicroSystemsChristian Torres DavilaNo ratings yet

- TM100 ManualDocument2 pagesTM100 Manualefrain rivasNo ratings yet

- D1780 - EN - 02 (Signets) GL314F3 - AlstomDocument224 pagesD1780 - EN - 02 (Signets) GL314F3 - Alstomtuantz206No ratings yet

- Experiment No. 7 SensorsDocument8 pagesExperiment No. 7 SensorsJonelNo ratings yet

- Snap Disc Thermostats by Utiliti ControlsDocument2 pagesSnap Disc Thermostats by Utiliti ControlsSiddarthNo ratings yet

- RT530E-2 Load ChartDocument16 pagesRT530E-2 Load Chartburak cikirkanNo ratings yet

- #Milling Presentation 2011Document47 pages#Milling Presentation 2011HABTAMU FEKADUNo ratings yet