Professional Documents

Culture Documents

Observation Sheet - SHEMEER

Uploaded by

Felix SamsonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Observation Sheet - SHEMEER

Uploaded by

Felix SamsonCopyright:

Available Formats

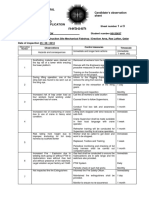

INTERNATIONAL GENERAL

CERTIFICATE Candidate’s observation

(2011 specification) sheet

IGC3 – THE HEALTH AND

SAFETY PRACTICAL APPLICATION Sheet number 1 of 3

Student name SHEMEER V C RAWTE Student number 00153640

Place inspected: Raslaffan Port Expansion Project, Ras Laffan, Qatar

Date of inspection 25 / 08 / 2012

Observation Control measures

Number Observations Timescale

Immediate and longer term actions (immediate,

Hazards and consequences

1 week, etc)

Process Area 120 Sulphur Area

Observed rusted nails protruding from Collect all timber with protruding nails and Immediately

wooden planks and no de-nailing keep in segregation area with proper sign

1 done. (Hazard of employee injury) board.

Establish de-nailing area. 1 Month

Very poor cable management found in Advise for proper cable management Immediate

welding area (Hazard of slip and trip

for employee) Advised to remove unwanted cable from

2 the work location. 1 week

Develop a program on proper cable

management 1 month

Sand Blasting performed without Advise provide wind protection Immediate

heavy wind protection (Hazard of

personal injury) Tool box training 1 Week

3

Advised that should sand material be 1 month

separated from working area.

Lifting slings were observed to be Should be removed and destroyed. Immediate

worn and torn that were to be used for

lifting operation. Tool box training and inspection of all 1 week

4 lifting gears.

Basic rigging awareness training for 1 month

mechanical crew.

Unmarked bottle of substance on one Asses eg(identify label substance or Immediate

of the work stations and cleaning dispose of)

substances left on adjacent

substances Inform staff of correct labelling of stored 1 – 3 Days

5

cleaner.

Ensure all cleaning products are put away Regular

after use.

Workers working on scaffolding which Verbal waning and ask to step down Immediate

is not inspected (RED Tag) (Hazard of

6 scaffold collapse and fall from height). Conduct Tool box talk 1 Week

Send them for working at Height training 1 month

Safe working load is displayed on the Ongoing

7 Good practice to be maintained

Pipe supports. monitoring

Reversing alarm of the forklift is not On the spot signal man has been Immediately

working. (Hazard of accident) provided.

Informed to the supervisor install reverse 1 day

8 alarm

Regular maintenance of vehicles. 1 month

Periodic Emergency drill Quarterly

INTERNATIONAL GENERAL

CERTIFICATE Candidate’s observation

(2011 specification) sheet

IGC3 – THE HEALTH AND

SAFETY PRACTICAL APPLICATION

Student name SHEMEER V C RAWTE Student number 00153640

Place inspected: Raslaffan Port Expansion Project, Ras Laffan, Qatar

Date of inspection 25 / 08 / 2012 Sheet number 2 of 3

Observation Control measures

Number Observations Timescale

Immediate and longer term actions (immediate,

Hazards and consequences

1 week, etc)

Site offices fire doors being blocked by Ensure that always emergency access Immediately

materials free from any kind of materials.

9

Proper signage to be provided. 1 day

Monitor to ensure no re-occurrence. 1 week

Crane operator started work without Advise the operator to fill the checklist Immediately

filling checklist and side window the before start the work and remove the all

cabin is covered with cloth materials. cloth materials from the cabin

10

Arrange special Tool box talk and stand 1 day

down conducted for all crane operators.

Monitoring and awareness training. 1 month

Portable grinding machine has no Confiscation of defective portable grinder Immediately

inspection tag electric cable is already

11 worn out and the guard is not installed. Carryout maintenance repair and testing 1 Day

(Electrical and mechanical hazard)

Monitoring and proper training. 1 Month

No proper PPE worn by worker during Intervened and advise to use proper PPE Immediately

grinding activity (Hazard of personal while on work.

injury)

12

Training for workers and Supervisors 1 Day

Monitoring and proper training. 1 Month

Waste food material and garbage on Make proper house keeping Immediately

the site. (Hazard of Environmental)

13

Provide waste disposal appropriate place. 1 Week

Risk of fire due to hot work activity Advised to provide Fire Blanket and Fire Immediately

(Welding) not covered with fire Extinguisher in place.

14

retardant material such as (Fire

Blanket) (Risk of fire for employee) Training to be providing all workers. 1 Month

Employees are exposed to the high Monitor the noise level Immediately

noise created due to Temporary power

generator which is installed beside the Provide personal protective equipment 1 day

15

work shop. (Noise hazard for (Ear plugs and Ear Muffs)

employees)

Provide sign boards around the area. 1 Month

Removal of extra material required Ensure that always access free from any Immediately

near to access road between North of kind of materials.

west side. (Hazard of slip and trip /

16

proper access and egress) Proper signage to be provided. 1 day

Monitor to ensure no re-occurrence. 1 Month

Pressurized cylinders being Informed the crew to always provide Immediately

transported without having cylinder cylinder caps and ensure the trolley fitted

caps and chain for the trolley (Hazard with chain to secure the cylinders.

17

of cylinder falls and injury to people)

Hazardous materials training and Toll box 1 week

talk.

INTERNATIONAL GENERAL

CERTIFICATE Candidate’s observation

(2011 specification) sheet

IGC3 – THE HEALTH AND

SAFETY PRACTICAL APPLICATION Sheet number 3 of 3

Student name SHEMEER V C RAWTE Student number 00153640

Place inspected: Raslaffan Port Expansion Project, Ras Laffan, Qatar

Date of inspection 25 / 08 / 2012

Observation Control measures

Number Observations Timescale

Immediate and longer term actions (immediate,

Hazards and consequences

1 week, etc)

A-100 Office area – Found cigarette Assigned one worker to collect on daily Immediately

buds carried by wind from smoking basis

18

shelter area. (Fire hazard)

Training on fire marshal / Fire warden 1 month

Chemical Storage area has no fire Provide fire Extinguisher from store and Immediate

extinguisher and MSDS (Risk of fire) arrange MSDS from procurement

19 Advised to keep MSDS with paint always 1 week

Hazardous materials training for store 1 month

keeper and helper

Cutting machine being used without Prohibit such kind of machine from using Immediately

proper guard protection (Mechanical

hazard) Provide protective guard for the rotating 1 day

part

20

Toolbox talk on machinery safety 1 week

Regular inspection of power tools Monthly

Vehicles are reversing in yard with Ongoing

21 Good practice to be maintained

Banksman giving proper signal monitoring

Workers are trying to lift load which is Advise them to use mechanical Immediately

(too heavy for them to lift). (Manual assistance to lift the load.

handling hazard) beyond their

capacity. Always assess the load before trying to lift 1 day

22

manually.

Manual handling training to be provide all 1 week

workers

Excavations are not protected with Provide hard berried with adequate Immediately

hard barriers, hazard of people falling signage.

into it.

23

Inspections are daily basis 1 Week

Implement excavation procedure Regular

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- 9 To 5 Props PresetsDocument4 pages9 To 5 Props Presetsapi-300450266100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Goals Editable PDFDocument140 pagesGoals Editable PDFManuel Ascanio67% (3)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The National Building Code of The PhilippinesDocument390 pagesThe National Building Code of The PhilippinesJohn Joseph EstebanNo ratings yet

- 10059-DC-K-01-A Design BasisDocument34 pages10059-DC-K-01-A Design BasisAnonymous RvIgDUNo ratings yet

- Fundamentals of Fast SwimmingDocument9 pagesFundamentals of Fast SwimmingTorcay Ulucay100% (1)

- Siemens MV Gas Insulated Switch GearDocument14 pagesSiemens MV Gas Insulated Switch GearSajesh Thykoodan T VNo ratings yet

- Piping Material Classes GuideDocument98 pagesPiping Material Classes GuideLuis Pottozen VillanuevaNo ratings yet

- Cipac MT 185Document2 pagesCipac MT 185Chemist İnançNo ratings yet

- Bentel J408Document64 pagesBentel J408Bojan MarkovicNo ratings yet

- Excel2007f TrainingManual PDFDocument270 pagesExcel2007f TrainingManual PDFFelix SamsonNo ratings yet

- Excel2007f TrainingManual PDFDocument270 pagesExcel2007f TrainingManual PDFFelix SamsonNo ratings yet

- PracticeExercise5 1Document2 pagesPracticeExercise5 1Felix SamsonNo ratings yet

- Name Rank Item Number Price Inventory VendorDocument1 pageName Rank Item Number Price Inventory VendorFelix SamsonNo ratings yet

- Excel2007f ExerciseWorkbookDocument168 pagesExcel2007f ExerciseWorkbookFelix SamsonNo ratings yet

- Top 30 Products Ranked by Name with Pricing and Inventory DataDocument1 pageTop 30 Products Ranked by Name with Pricing and Inventory DataFelix SamsonNo ratings yet

- Player Name Points Rank Team Name ScoresDocument1 pagePlayer Name Points Rank Team Name ScoresFelix SamsonNo ratings yet

- Excel: Keyboard Shortcuts Excel BasicsDocument2 pagesExcel: Keyboard Shortcuts Excel BasicsFelix SamsonNo ratings yet

- PracticeExercise5 1Document2 pagesPracticeExercise5 1Felix SamsonNo ratings yet

- PracticeExercise4 2finishedDocument2 pagesPracticeExercise4 2finishedFelix SamsonNo ratings yet

- PracticeExercise4 1Document1 pagePracticeExercise4 1Felix SamsonNo ratings yet

- North South East West Total Units Price Per Unit Sales: Product1 Product2 Product3 Product4 Product5Document1 pageNorth South East West Total Units Price Per Unit Sales: Product1 Product2 Product3 Product4 Product5Felix SamsonNo ratings yet

- Product1 Product2 Product3 Product4 Product5Document2 pagesProduct1 Product2 Product3 Product4 Product5Felix SamsonNo ratings yet

- Product1 Product2 Product3 Product4 Product5Document2 pagesProduct1 Product2 Product3 Product4 Product5Felix SamsonNo ratings yet

- PracticeExercise2 2Document1 pagePracticeExercise2 2Felix SamsonNo ratings yet

- Product1 Product2 Product3 Product4 Product5Document2 pagesProduct1 Product2 Product3 Product4 Product5Felix SamsonNo ratings yet

- Candidate Report - 00153642Document3 pagesCandidate Report - 00153642Felix SamsonNo ratings yet

- Observation Sheet - JOJODocument3 pagesObservation Sheet - JOJOFelix SamsonNo ratings yet

- Observation Sheet - JOJODocument3 pagesObservation Sheet - JOJOFelix SamsonNo ratings yet

- Candidate Report - 00153642Document3 pagesCandidate Report - 00153642Felix SamsonNo ratings yet

- Tumors of The Central Nervous System - VOL 12Document412 pagesTumors of The Central Nervous System - VOL 12vitoNo ratings yet

- Notice: Use of Segways® and Similar Devices by Individuals With A Mobility Impairment in GSA-Controlled Federal FacilitiesDocument2 pagesNotice: Use of Segways® and Similar Devices by Individuals With A Mobility Impairment in GSA-Controlled Federal FacilitiesJustia.comNo ratings yet

- Grab Go Porter S 5 ForcesDocument2 pagesGrab Go Porter S 5 ForcesUtkarsh SharmaNo ratings yet

- Position paper-MUNUCCLE 2022: Refugees) Des États !Document2 pagesPosition paper-MUNUCCLE 2022: Refugees) Des États !matNo ratings yet

- SM RSJ 420 800Document77 pagesSM RSJ 420 800elshan_asgarovNo ratings yet

- RHS NCRPO COVID FormDocument1 pageRHS NCRPO COVID Formspd pgsNo ratings yet

- Emission of Volatile Organic Compounds (Vocs) From Dispersion and Cementitious Waterproofing ProductsDocument16 pagesEmission of Volatile Organic Compounds (Vocs) From Dispersion and Cementitious Waterproofing ProductsKrishna KusumaNo ratings yet

- TSS-TS-TATA 2.95 D: For Field Service OnlyDocument2 pagesTSS-TS-TATA 2.95 D: For Field Service OnlyBest Auto TechNo ratings yet

- Aging and Elderly IQDocument2 pagesAging and Elderly IQ317537891No ratings yet

- Cell City ProjectDocument8 pagesCell City ProjectDaisy beNo ratings yet

- AAR Maintenance 001Document3 pagesAAR Maintenance 001prakash reddyNo ratings yet

- 50-Orthodontic Objectives in Orthognathic Surgery-State of The PDFDocument15 pages50-Orthodontic Objectives in Orthognathic Surgery-State of The PDFDeena A. AlshwairikhNo ratings yet

- Rapid Cycling in Bipolar DisorderDocument1 pageRapid Cycling in Bipolar Disorderdo leeNo ratings yet

- Exercise 4 Summary - KEY PDFDocument3 pagesExercise 4 Summary - KEY PDFFrida Olea100% (1)

- Esaote MyLabX7Document12 pagesEsaote MyLabX7Neo BiosNo ratings yet

- 7 Surprising Cyberbullying StatisticsDocument4 pages7 Surprising Cyberbullying StatisticsJuby Ann Enconado100% (1)

- Guide Propedevt Stomat 2c EngDocument256 pagesGuide Propedevt Stomat 2c EngJhoel Jhonatan Torres MuñozNo ratings yet

- Nursing Plan of Care Concept Map - Immobility - Hip FractureDocument2 pagesNursing Plan of Care Concept Map - Immobility - Hip Fracturedarhuynh67% (6)

- GTT Module 5Document156 pagesGTT Module 5ABDULRAHIMAN RAJEKHANNo ratings yet

- Disinfecting Water Wells Shock ChlorinationDocument3 pagesDisinfecting Water Wells Shock ChlorinationmayaNo ratings yet

- TA-Ingles IX - UAPDocument10 pagesTA-Ingles IX - UAPmanuel brennerNo ratings yet