Professional Documents

Culture Documents

Distance/force: Series Touch Screen Quick Start User'S Guide

Uploaded by

anthonyMOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Distance/force: Series Touch Screen Quick Start User'S Guide

Uploaded by

anthonyMCopyright:

Available Formats

SERIES TOUCH SCREEN

QUICK START USER’S GUIDE TOUCH SCREEN NUMERIC KEYPAD

distance/force On power up, after the Windows OS is loaded, the

the Language Selection screen will be displayed.

Used for numeric and alphanumeric entry of

values for selected parameters.

Here you may select the language to be displayed on In Numeric mode, INC (+), and DEC (-) become

the Power Supply menus. The Visual Quality screen inactive when a number digit is pressed. Once

POWER POWER LEVEL % INDICATOR will be shown briefly. Then either the Weld Results or the INC or DEC buttons are pressed, the number

Press to turn the Indicates the power used either during the Main Menu screen will be displayed. The screen digits are inactive. The INC or DEC will increment

system On and Off. last weld cycle or when TEST is running. displayed is chosen in System Configuration >Start or decrement the Current Value field by 1 each

The button depresses Screen. All other menus are accessed from the time it is pressed.

and it lights to indicate Navigation Buttons at the bottom of all screens.

power is On.

FREQ OFFSET

Main Menu Pg1of2

100 % Freq Offset[Hz]

Current Value /# ABC DEF

distance

80 %

Weld Setup System Configuration +0 1 2 3

GHI JKL MNO

New Value

Screen Setup System Information

4 5 6

60 %

View Current Setup Diagnostics

- PQR STU VWX

7 8 9

Reset 40 % Horn Down Weld History Min Value +0 + YZ -

Max Value +400 INC 0 DEC

RESET 20 % ESC . ENT

Press to reset Test >>

Alarms. 0%

Weld Results Main Menu Weld Setup Graphs

Weld Results Main Menu Weld Setup Graphs

TEST WELD RESULTS MAIN MENU WELD SETUP GRAPHS ESC ENT

Press to display a Displays 4 parameters Use this menu to Use this menu to Access graphs to view Touching ESC will Touching ENT will

menu to test the from the last 7 weld access all functions access the 3 pages or print from this menu. erase all digits in the close the pop-up and

ultrasonic power supply, cycles to be monitored on the Main Menu. of parameters on the in the New Value field. return you to the Weld

horn, booster, and from Weld Results screen. (shown above) Weld Setup Menu. Setup screen.

converter.

WELD RESULTS Print WELD SETUP Pg1of3 GRAPHS

Preset1 Tm=1.000s RUN:TIME = 1.000

Weld Mode > Time Trig Force = 10 lb View Graphs

Cycle# Time Freq Chg Energy Total Col

[s] [Hz] [J] [in]

18 1.000 +15 160.9 0.0083 Weld Time = 0.010s Amplitude > Fixed

Auto Scale = On

17 1.000 +16 162.1 0.0082

16 1.000 +15 161.8 0.0083 Hold Time = 0.010s Amplitude = 100%

X Scale =***

15 1.000 +15 163.4 0.0082

14 1.000 +14 163.2 0.0088

Visual Quality Screen > Afterbust > On

13 1.000 +13 163.1 0.0089 Auto Refresh =Off

12 1.000 +13 152.3 0.0089

Column Setup >> ***X Scale can only be selected if Auto Scale = Off

Weld Results Main Menu Weld Setup Graphs Weld Results Main Menu Weld Setup Graphs Weld Results Main Menu Weld Setup Graphs

2000X d/f Touch Screen

Quick Start User Guide v. 11.0 Rev. 4

EDP 100-412-169 March 2011

Copyright © Branson Ultrasonics Corp.

Basic Menu Map

d/f Power Up

The Power Supply will display the Language Selection screen at Power Up.

On this screen you may select the language to be displayed on the Power Supply menus.

Power Supply

OR

WELD RESULTS (Set Start Screen MAIN MENU WELD SETUP GRAPHS

in Sys Config)

Preset 0 Run Time 1.000 Save/Recall Presets Weld Mode > View Graphs

Diagnostics †Weld Time = Auto Scale =

Screen displays, (for the last 7 weld cycles), Weld Setup †Peak Power = X Scale =

the 4 parameters selected from Column Horn Down †Absolute = Auto Refresh =

Setup in the Weld Results Screen. Print Menu †Weld Energy =

System Information †Collapse =

Screen Setup †Scrub Time = VIEW GRAPHS

PRESETS Sequencing Presets †Scrub Amp =

Calibration Power

Recall Hold Time = Frequency

Save Print Now Trig Force =

Weld History Amplitude

Clear Amplitude > Force

Verify View Current Setup Amplitude =

PRINT MENU System Configuration Visual Quality Setup

Velocity

View Quality Screen Col Distance

Printing = Afterburst >

DIAGNOSTICS Printer Offline Pretrigger >

Digital Tune Abort Printing PRINT NOW Reject Limits >

Start Freq Choose Printout > Setup Suspect Limits >

Horn Signature Setup Printer > Weld History SYS CONFIG Energy Brake =

Cold Start Weld Data Units = Power Match Curve =

Actuator Cold Start SYSTEM INFO Power Graph Password = Save/Recall Presets >

F Memory [ ] Amp Graph Start Screen = *Force >

PS Life = Freq Graph RS232 > *Weld Force =

F Actual [ ] Gen Alarm = USB Data >

Run Seek Col Graph *Hold Force =

Calibration = Vel Graph Welder Addr = *Rapid Traverse =

Clear Store P/S = Cycle Counter >

Force Graph *Downspeed =

Actuator = Gen Alarm Reset = *Force Ramps >

S/W Version = Time >

HORN DOWN Act S/N = CALIBRATION Date >

Post Weld Seek =

Beepers > Act Clr Output =

*Set Pres = Cal Actuator Write In Fields >

Horn Down Clamp= Cyl Stroke = Cal Full System P/S Settings >

*HD Force = Amp Control = Frequency Offset >

Overloads = Control Limits >

*Downspeed = Frequency & Power Act Settings >

*Rapid Traverse = SEQUENCING Extra Cooling = Cycle Aborts >

Date Run = Ext Presets = Ext U/S Delay = *Applies to 2000X f only

*RT@ D = †Availability dependant on Weld Mode

P/S Version = Sequencing User I/O > Digital UPS >

Control Level = Erase Sequence Bargraph Scales > †Timeout =

P/S S/N = Define/Edit Sequence Digital Filter = The “>” symbol indicates additional

Welder Addr = Freq Offset = sub-menus available.

Cyl Dia = Column Setup >

SBC Version = SCREEN SETUP Screen Setup > 2000X d/f Touch Screen

P/S Presets Screen Alignment Windows Setup Quick Start User Guide v. 11.0 Rev. 4

View IP Address Color Setup > EDP 100-412-169 March 2011

Copyright © Branson Ultrasonics Corp.

You might also like

- Guide 100 412 175 2000xea Quick Start Rev 05 en 5283264Document2 pagesGuide 100 412 175 2000xea Quick Start Rev 05 en 5283264martin JeongNo ratings yet

- User Manual: DIN Rail Smart Energy Meter For Single and Three Phase Electrical SystemsDocument2 pagesUser Manual: DIN Rail Smart Energy Meter For Single and Three Phase Electrical SystemsAnggara KusumaNo ratings yet

- LDR Short FormDocument4 pagesLDR Short FormOrhan DenizliNo ratings yet

- Decimator UI Help GuideDocument19 pagesDecimator UI Help GuideEduard LembaNo ratings yet

- 9IS54271.08_EWCM_EO_InstructionSheet_EN_0921 Eliwell do Clint MEA/KDocument20 pages9IS54271.08_EWCM_EO_InstructionSheet_EN_0921 Eliwell do Clint MEA/KzydradeeNo ratings yet

- Connections, Displays and Operating Elements: G F MN HDocument10 pagesConnections, Displays and Operating Elements: G F MN HdogasanchesNo ratings yet

- On-Screen Keys and Their Functions: Scanned by CamscannerDocument1 pageOn-Screen Keys and Their Functions: Scanned by CamscannerSoluciones EspecializadasNo ratings yet

- Kontrolleri Koefficienta Moshnosti RVT Pamphlet EN PDFDocument12 pagesKontrolleri Koefficienta Moshnosti RVT Pamphlet EN PDFNisar AhmedNo ratings yet

- 7segment Control PanelDocument12 pages7segment Control Panelhunt huntNo ratings yet

- Elmeasure Multifunction Meter Multifunctionlcd Programming GuideDocument2 pagesElmeasure Multifunction Meter Multifunctionlcd Programming GuideP.p. Arul IlancheeranNo ratings yet

- 8900 Diagnostic Flow ChartsDocument17 pages8900 Diagnostic Flow ChartsMiguel MartinezNo ratings yet

- User's Manual: Titel - pm6 13.07.2004, 10:37 1Document122 pagesUser's Manual: Titel - pm6 13.07.2004, 10:37 1Amel HamzicNo ratings yet

- Matrix 430Document16 pagesMatrix 430Dani GrigorNo ratings yet

- Program setting flow chart EST120Document3 pagesProgram setting flow chart EST120Adito JunandaNo ratings yet

- Em 300Document6 pagesEm 300Frizal Akbar BudiatmoyoNo ratings yet

- Alcatel 4038 4039 4068 Operator ManualDocument16 pagesAlcatel 4038 4039 4068 Operator ManualSerious DoubtsNo ratings yet

- WaveRunner Xi QRG RevBDocument16 pagesWaveRunner Xi QRG RevBRanz KopaczNo ratings yet

- Bizhub c287 c227 Quick Reference en 1 0 0Document4 pagesBizhub c287 c227 Quick Reference en 1 0 0Badr BiuoNo ratings yet

- Eastron SDM630MCT-Lora Series User Manual V1Document2 pagesEastron SDM630MCT-Lora Series User Manual V1Luiz Fernando AlvesNo ratings yet

- Vari Flex Drive BroDocument7 pagesVari Flex Drive Brohicham plastNo ratings yet

- Gipam 2000Document6 pagesGipam 2000hoangepuNo ratings yet

- Brief Instructions: Acoustic, Digital Current Meter OTT ADCDocument6 pagesBrief Instructions: Acoustic, Digital Current Meter OTT ADCM Nurman HidayahNo ratings yet

- GK B5 User Guide v12Document5 pagesGK B5 User Guide v12CarecaIIINo ratings yet

- Axe MRTDocument5 pagesAxe MRTmanzoor9603302No ratings yet

- Axe Microprocess 5 Digital Panel Meter: Key Introduce Operation ManualDocument3 pagesAxe Microprocess 5 Digital Panel Meter: Key Introduce Operation ManualMOREENo ratings yet

- ALTIVAR 28 Quick Reference GuideDocument1 pageALTIVAR 28 Quick Reference GuideAshok PatelNo ratings yet

- Rca L37WD250 L42WD250 L46WD250 SMDocument33 pagesRca L37WD250 L42WD250 L46WD250 SMFidelio AdonisNo ratings yet

- PowerXL DG1 Quick Start Guide - MN040012ENDocument32 pagesPowerXL DG1 Quick Start Guide - MN040012ENcoldebelladNo ratings yet

- Uzu2 Series: Led Digital Display High Functionality Pressure SensorsDocument11 pagesUzu2 Series: Led Digital Display High Functionality Pressure SensorsJose Luiz QuerubinNo ratings yet

- Op - Rem 308 - Rem C 312 - Op597 V01Document13 pagesOp - Rem 308 - Rem C 312 - Op597 V01Superintending EngineerNo ratings yet

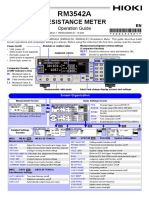

- Resistance Meter: Operation GuideDocument2 pagesResistance Meter: Operation GuideEko SutjiptoNo ratings yet

- Sturtevant Richmont: ExactaDocument4 pagesSturtevant Richmont: ExactaJuan SiviraNo ratings yet

- FFT OperationDocument5 pagesFFT OperationFaizan MalikNo ratings yet

- Dwyer MSX-W12Document6 pagesDwyer MSX-W12Jack MayNo ratings yet

- Elmeasure Accl Accl300 Programming GuideDocument2 pagesElmeasure Accl Accl300 Programming GuideaymaanfkNo ratings yet

- Cat TM82 8300manual PDFDocument2 pagesCat TM82 8300manual PDFbuddhika MadusankaNo ratings yet

- Tech+Guide+Yaskawa+J1000-V1000-GA500+Basic+User+Guide+v1 0 9Document11 pagesTech+Guide+Yaskawa+J1000-V1000-GA500+Basic+User+Guide+v1 0 9Klemen KavčičNo ratings yet

- User Manual: QX Connect SeriesDocument16 pagesUser Manual: QX Connect SeriesEL BAY abdelfattahNo ratings yet

- Display and Operation Board For Compusave and Svs Protect 4Document26 pagesDisplay and Operation Board For Compusave and Svs Protect 4LP J AleNo ratings yet

- SVG Installation Guide v10Document24 pagesSVG Installation Guide v10Jas SinghNo ratings yet

- OPTALIGNsmart guideNV PDFDocument2 pagesOPTALIGNsmart guideNV PDFElinton De Jesus SarmientoNo ratings yet

- 11a Vs300 Quick Guide en v2.10 EagDocument4 pages11a Vs300 Quick Guide en v2.10 Eagmoh taNo ratings yet

- 7000 118-364, D1, R5 SUPREME AIS Operator Short InstructionDocument4 pages7000 118-364, D1, R5 SUPREME AIS Operator Short Instructionchefradio CFCARTHAGENo ratings yet

- pCO Universal Stage Controller: User ManualDocument32 pagespCO Universal Stage Controller: User ManualVinod LAmbadeNo ratings yet

- Eaton-IQ200X-Electronic Power Meter-User Manual-EN-USDocument2 pagesEaton-IQ200X-Electronic Power Meter-User Manual-EN-USAlan leví TeleguarioNo ratings yet

- JD740A User Manual R09.0 (401-480)Document80 pagesJD740A User Manual R09.0 (401-480)halfonsoNo ratings yet

- E1005 SpecDocument4 pagesE1005 SpecMakombe RonnyNo ratings yet

- Man 000008Document2 pagesMan 000008Angelo CotradoNo ratings yet

- Fusion Splicer T-400SDocument2 pagesFusion Splicer T-400SNicolaie NicusorNo ratings yet

- CJ4 Avionics 1.01Document36 pagesCJ4 Avionics 1.01Jose Otero De Santiago100% (1)

- 90 (J)Document28 pages90 (J)fdsfdsfsdNo ratings yet

- Quick guide to temperature indicator outputsDocument2 pagesQuick guide to temperature indicator outputsPuneet BachalNo ratings yet

- Um1m820bna Rev P Acu Controller 79228 1Document198 pagesUm1m820bna Rev P Acu Controller 79228 1Alex Bueno de OliveiraNo ratings yet

- SOP-20-CP Smart Operation Panel User Guide Components and FunctionsDocument2 pagesSOP-20-CP Smart Operation Panel User Guide Components and FunctionsTrinnatee ChotimongkolNo ratings yet

- Operation Guide: Graphing CalculatorDocument34 pagesOperation Guide: Graphing Calculatorguillermo garciaNo ratings yet

- Fas3000 FlowchartsDocument204 pagesFas3000 FlowchartsBe HappyNo ratings yet

- ArchivosDocument2 pagesArchivosAlfredo Renteria MezaNo ratings yet

- SLC Cube 3+: User'S ManualDocument16 pagesSLC Cube 3+: User'S ManualJose CaceresNo ratings yet

- Manual Rack Presses 2020Document14 pagesManual Rack Presses 2020anthonyMNo ratings yet

- Traveler or Crew Member Iden Fica On: Traveler S Health A Davit (MSP-DJSV-01)Document1 pageTraveler or Crew Member Iden Fica On: Traveler S Health A Davit (MSP-DJSV-01)LaenetGalumetteJosephJuniorPaulNo ratings yet

- Distance/force: Series Touch Screen Quick Start User'S GuideDocument2 pagesDistance/force: Series Touch Screen Quick Start User'S GuideanthonyMNo ratings yet

- Distance/force: Series Touch Screen Quick Start User'S GuideDocument2 pagesDistance/force: Series Touch Screen Quick Start User'S GuideanthonyMNo ratings yet

- Distance/force: Series Touch Screen Quick Start User'S GuideDocument2 pagesDistance/force: Series Touch Screen Quick Start User'S GuideanthonyMNo ratings yet

- Apéndice B: B.4 Valores Críticos de La Distribución F en Un Nivel de Significancia de 5%Document2 pagesApéndice B: B.4 Valores Críticos de La Distribución F en Un Nivel de Significancia de 5%anthonyMNo ratings yet

- 1 Sem CFA Question Solving, Objective Question and Dos Command PDFDocument50 pages1 Sem CFA Question Solving, Objective Question and Dos Command PDFSabin AcharyaNo ratings yet

- Murphy pv101C Users GuideDocument47 pagesMurphy pv101C Users GuideRafael StriederNo ratings yet

- Huawei E5372 Mobile Router GuideDocument32 pagesHuawei E5372 Mobile Router GuidehumenzNo ratings yet

- Voice Controlled Wheel Chcomplete Pptair PrototypeDocument28 pagesVoice Controlled Wheel Chcomplete Pptair PrototypeAnubhuti SharmaNo ratings yet

- P43AL Series Manual en V1.0Document74 pagesP43AL Series Manual en V1.0Cel Groaznic PimNo ratings yet

- Future Logic GEN2 Course UpdatedDocument25 pagesFuture Logic GEN2 Course Updatedpablo bulzomiNo ratings yet

- GE Renewal Parts: Contactor Model 17Cm53E10ADocument3 pagesGE Renewal Parts: Contactor Model 17Cm53E10ARafael Dutil LucianaNo ratings yet

- Ee321 Chap01 ReviewDocument60 pagesEe321 Chap01 ReviewMohamed Ouail CHARAOUINo ratings yet

- Clevo m740t M740tu m760t M760tuDocument118 pagesClevo m740t M740tu m760t M760tuBigadicManiaNo ratings yet

- MBDCDocument2 pagesMBDCRachel RobinsonNo ratings yet

- S&S Make: RRM For 6000 RPMDocument16 pagesS&S Make: RRM For 6000 RPMABVSAI100% (1)

- Cypress - Training Doc 7Document8 pagesCypress - Training Doc 7Anonymous J92vDtSNo ratings yet

- Microsoft Virtual Machine Converter Administration GuideDocument21 pagesMicrosoft Virtual Machine Converter Administration GuidesamuefonNo ratings yet

- How To Replace A Processor On A Dell Latitude D620Document37 pagesHow To Replace A Processor On A Dell Latitude D620g10vann1castelazoNo ratings yet

- 2N2369Document7 pages2N2369Martín SayagoNo ratings yet

- Sartech ARG5410 EPIRB TesterDocument3 pagesSartech ARG5410 EPIRB TesterEric PskdNo ratings yet

- SR-1000 S7-1200 Om 600F51 GB WW 1114-2Document10 pagesSR-1000 S7-1200 Om 600F51 GB WW 1114-2BaroszNo ratings yet

- eCAD Manual PDFDocument11 pageseCAD Manual PDFichrakNo ratings yet

- July2008 - Geodin Training FmeDocument62 pagesJuly2008 - Geodin Training FmeDewa Midi100% (1)

- Spoke PovDocument82 pagesSpoke PovJefferson Huerta OlivaresNo ratings yet

- Parts Book P20-P50/51-P75/76-P315 Gear Pumps and Motors: Distributor ProgramDocument37 pagesParts Book P20-P50/51-P75/76-P315 Gear Pumps and Motors: Distributor ProgramEddy OrtegaNo ratings yet

- 7.0 Synchroscope ManualDocument3 pages7.0 Synchroscope ManualAyan MajiNo ratings yet

- The Intel PentiumDocument10 pagesThe Intel Pentiummani_vlsiNo ratings yet

- Transpose Rows To ColumnDocument34 pagesTranspose Rows To ColumnAmit Sharma100% (1)

- APD4 Install E RevFDocument66 pagesAPD4 Install E RevFPepe SantosNo ratings yet

- HH Spares Price ListDocument716 pagesHH Spares Price ListAnkit Agarwal100% (1)

- Bildr Use The Easydriver Stepper Motor Driver..Document5 pagesBildr Use The Easydriver Stepper Motor Driver..fayazrashNo ratings yet

- Windows Ginune ErrorDocument6 pagesWindows Ginune ErrorMandis ShahNo ratings yet

- Actia MDO + VCI ManualDocument54 pagesActia MDO + VCI ManualItrescuer ItrNo ratings yet

- ADA MP-1 Level Switch ModDocument5 pagesADA MP-1 Level Switch ModAndrei PopaNo ratings yet

- The Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumFrom EverandThe Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumRating: 3 out of 5 stars3/5 (12)

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveFrom EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveNo ratings yet

- Defensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityFrom EverandDefensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityRating: 5 out of 5 stars5/5 (1)

- Algorithms to Live By: The Computer Science of Human DecisionsFrom EverandAlgorithms to Live By: The Computer Science of Human DecisionsRating: 4.5 out of 5 stars4.5/5 (722)

- CompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideFrom EverandCompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideRating: 5 out of 5 stars5/5 (2)

- Generative AI: The Insights You Need from Harvard Business ReviewFrom EverandGenerative AI: The Insights You Need from Harvard Business ReviewRating: 4.5 out of 5 stars4.5/5 (2)

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldFrom EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldRating: 4.5 out of 5 stars4.5/5 (54)

- Digital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyFrom EverandDigital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyRating: 4 out of 5 stars4/5 (51)

- Chip War: The Quest to Dominate the World's Most Critical TechnologyFrom EverandChip War: The Quest to Dominate the World's Most Critical TechnologyRating: 4.5 out of 5 stars4.5/5 (227)

- ChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessFrom EverandChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessNo ratings yet

- 8-Bit Apocalypse: The Untold Story of Atari's Missile CommandFrom Everand8-Bit Apocalypse: The Untold Story of Atari's Missile CommandRating: 3.5 out of 5 stars3.5/5 (10)

- AI Superpowers: China, Silicon Valley, and the New World OrderFrom EverandAI Superpowers: China, Silicon Valley, and the New World OrderRating: 4.5 out of 5 stars4.5/5 (398)

- The E-Myth Revisited: Why Most Small Businesses Don't Work andFrom EverandThe E-Myth Revisited: Why Most Small Businesses Don't Work andRating: 4.5 out of 5 stars4.5/5 (708)

- The Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldFrom EverandThe Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldRating: 4.5 out of 5 stars4.5/5 (107)

- The Future of Geography: How the Competition in Space Will Change Our WorldFrom EverandThe Future of Geography: How the Competition in Space Will Change Our WorldRating: 4.5 out of 5 stars4.5/5 (4)

- The Corporate Startup: How established companies can develop successful innovation ecosystemsFrom EverandThe Corporate Startup: How established companies can develop successful innovation ecosystemsRating: 4 out of 5 stars4/5 (6)

- Blood, Sweat, and Pixels: The Triumphant, Turbulent Stories Behind How Video Games Are MadeFrom EverandBlood, Sweat, and Pixels: The Triumphant, Turbulent Stories Behind How Video Games Are MadeRating: 4.5 out of 5 stars4.5/5 (335)

- Data-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseFrom EverandData-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseRating: 3.5 out of 5 stars3.5/5 (12)

- Reality+: Virtual Worlds and the Problems of PhilosophyFrom EverandReality+: Virtual Worlds and the Problems of PhilosophyRating: 4 out of 5 stars4/5 (24)