Professional Documents

Culture Documents

Páginas Desdec Cs 50 005 Hdpe - Rev0 2

Uploaded by

Benjamin Enmanuel Mango DOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Páginas Desdec Cs 50 005 Hdpe - Rev0 2

Uploaded by

Benjamin Enmanuel Mango DCopyright:

Available Formats

Client Name: Sociedad Minera Cerro Verde S.A.A.

Specification C-CS-50-005

Project Name: Primary Sulfide Project Page 11 of 14

Project Number: PSP108 Attachment 1_Rev. 0

FLUOR

Mining & Minerals

FIELD FABRICATION AND INSTALLATION OF HDPE PIPING

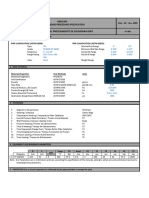

6.6 Refer to the table below for general guidelines for bead width (B) for each respective wall thickness.

Approximate Approximate

Min Wall Min. wall

Bead Width B Bead Width B

Thickness Thickness

Min. Max. Min. Max

.118” (3 mm) 5/32” (4 mm) ¼” (6 mm) 1.06” (27 mm) 19/32” (15 mm) 25/32” (19.8 mm)

.157” (4 mm) 5/32” (4 mm) 9/32” (7 mm) 1.18” (30 mm) ⅝” (16 mm) 13/16” (20.6 mm)

.197” (5 mm) 3/16” (4.8 mm) 5/16” (8 mm) 1.34” (34 mm) 21/32” (16.7 mm) ⅞” (22.2 mm)

.246” (6 mm) ¼” (6 mm) 11/32” (8.7 mm) 1.57” (40 mm) 11/16” (17.4 mm) 29/32” (23 mm)

.315” (8 mm) 9/32” (7 mm) ⅜” (9.5 mm) 1.77” (45 mm) 25/32” (19.8 mm) 1” (25.4 mm)

.354” (9 mm) 5/16” (8 mm) 7/16” (11 mm) 1.97” (50 mm) ⅞” (22.2 mm) 1-1/16” (27 mm)

.433” (11 mm) 11/32” (8.7 mm) ½” (12.7 mm) 2.16” (55 mm) 15/16” (23.8 mm) 1-3/16” (30.2 mm)

.512” (13 mm) ⅜” (9.5 mm) 9/16” (14.3 mm) 2.36” (50 mm) 1” (25.4 mm) 1 ¼” (31.7 mm)

.63” (16 mm) 7/16” (11 mm) 19/32” (15 mm) 2.56” (65 mm) 1 ⅛” (28.6 mm) 1-7/16” (36.5 mm)

.71” (18 mm) ½” (12.7 mm) ⅝” (16 mm) 2.76” (70 mm) 1-3/16” (30.1 mm) 1 ½” (38.1 mm)

.75” (19 mm) ½” (12.7 mm) 11/16” (17.4 mm) 2.95” (75 mm) 1 ¼” (31.7 mm) 1-9/16” (40 mm)

.87” (22 mm) ½” (12.7 mm) 11/16” (17.4 mm) 3.15” (80 mm) 1-5/16” (33.3 mm) 1-11/16” (42.8 mm)

.94” (24 mm) 9/16” (14.3 mm) ¾” (19 mm) 3.35” (85 mm) 1 ⅜” (34.9 mm) 1 ¾” (44.4 mm)

3.54” (90 mm) 1 ½” (38.1 mm) 1-13/16” (46 mm)

6.7 The size differential (Smax – Smin) between two single beads shall not exceed X% of the double bead

width (B).

S x 100

Where X =

B

S = Smax – Smin

For pipe to pipe max X = 10%

For pipe to fitting max X = 20%

For fitting to fitting max X = 20%

6.8 Common Reasons for Fusion Joint Rejections

A. Inadequate facing of the component – After facing the component ends, they need to be brought

together to make sure that they line up without gaps and with proper axial alignment.

Y:\103\109 ENGDOC\109.2 CONSPEC_CS\PIPING\C-CS-50-005\C-CS-50-005 ATTACHMENT 1_REV0.DOC PIPING

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hdpe Bps Sab355Document1 pageHdpe Bps Sab355Benjamin Enmanuel Mango DNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Iron-Iron Carbide Phase Diagram ExampleDocument3 pagesIron-Iron Carbide Phase Diagram ExampleBenjamin Enmanuel Mango DNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Páginas desdeC-CS-50-005 HDPE - REV0 PDFDocument1 pagePáginas desdeC-CS-50-005 HDPE - REV0 PDFBenjamin Enmanuel Mango DNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- MSS-SP-006 Standard Finishes For Contact Faces of Pipe Flanges 1996Document6 pagesMSS-SP-006 Standard Finishes For Contact Faces of Pipe Flanges 1996quack1111No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- QC Matrix - EstructurasDocument8 pagesQC Matrix - EstructurasBenjamin Enmanuel Mango DNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Bsi 5352-1981Document32 pagesBsi 5352-1981Benjamin Enmanuel Mango DNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Bsi 1868-1975Document25 pagesBsi 1868-1975Benjamin Enmanuel Mango DNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- H 99 Sec 8 D 1 App 1Document9 pagesH 99 Sec 8 D 1 App 1Benjamin Enmanuel Mango DNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Product Guide TrioDocument32 pagesProduct Guide Triomarcosandia1974No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- White Button Mushroom Cultivation ManualDocument8 pagesWhite Button Mushroom Cultivation ManualKhurram Ismail100% (4)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- HandbookDocument194 pagesHandbookSofia AgonalNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- SPC Abc Security Agrmnt PDFDocument6 pagesSPC Abc Security Agrmnt PDFChristian Comunity100% (3)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Customer Satisfaction-ICICI Bank-Priyanka DhamijaDocument85 pagesCustomer Satisfaction-ICICI Bank-Priyanka DhamijaVarun GuptaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- 3.13 Regional TransportationDocument23 pages3.13 Regional TransportationRonillo MapulaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Windsor Machines LimitedDocument12 pagesWindsor Machines LimitedAlaina LongNo ratings yet

- 950 MW Coal Fired Power Plant DesignDocument78 pages950 MW Coal Fired Power Plant DesignJohn Paul Coñge Ramos0% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cds13041 Yamaha PWC Plug-In EcuDocument1 pageCds13041 Yamaha PWC Plug-In EcuGérôme ZélateurNo ratings yet

- SC-Rape-Sole Testimony of Prosecutrix If Reliable, Is Sufficient For Conviction. 12.08.2021Document5 pagesSC-Rape-Sole Testimony of Prosecutrix If Reliable, Is Sufficient For Conviction. 12.08.2021Sanjeev kumarNo ratings yet

- Frigidaire Parts and Accessories CatalogDocument56 pagesFrigidaire Parts and Accessories CatalogPedro RuizNo ratings yet

- EE1000 DC Networks Problem SetDocument7 pagesEE1000 DC Networks Problem SetAmit DipankarNo ratings yet

- Item Description RCVD Unit Price Gross Amt Disc % Ta Amount DeptDocument1 pageItem Description RCVD Unit Price Gross Amt Disc % Ta Amount DeptGustu LiranNo ratings yet

- T3A-T3L Servo DriverDocument49 pagesT3A-T3L Servo DriverRodrigo Salazar71% (7)

- TQM BisleriDocument27 pagesTQM BisleriDishank ShahNo ratings yet

- FBW Manual-Jan 2012-Revised and Corrected CS2Document68 pagesFBW Manual-Jan 2012-Revised and Corrected CS2Dinesh CandassamyNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Microeconomics: Production, Cost Minimisation, Profit MaximisationDocument19 pagesMicroeconomics: Production, Cost Minimisation, Profit Maximisationhishamsauk50% (2)

- Rs 422Document1 pageRs 422rezakaihaniNo ratings yet

- Bea Form 7 - Natg6 PMDocument2 pagesBea Form 7 - Natg6 PMgoeb72100% (1)

- Introduction To AirtelDocument6 pagesIntroduction To AirtelPriya Gupta100% (1)

- Acevac Catalogue VCD - R3Document6 pagesAcevac Catalogue VCD - R3Santhosh KumarNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Drill String DesignDocument118 pagesDrill String DesignMohamed Ahmed AlyNo ratings yet

- Millionaire Next Door QuestionsDocument7 pagesMillionaire Next Door Questionsapi-360370073No ratings yet

- Hitt PPT 12e ch08-SMDocument32 pagesHitt PPT 12e ch08-SMHananie NanieNo ratings yet

- UCAT SJT Cheat SheetDocument3 pagesUCAT SJT Cheat Sheetmatthewgao78No ratings yet

- La Salle Lipa Integrated School Senior High School Community 1 Quarter Summative Assessment Earth Science AY 2021-2022 Household Conservation PlanDocument4 pagesLa Salle Lipa Integrated School Senior High School Community 1 Quarter Summative Assessment Earth Science AY 2021-2022 Household Conservation PlanKarlle ObviarNo ratings yet

- Principles of SOADocument36 pagesPrinciples of SOANgoc LeNo ratings yet

- Mercury 150HPDocument5 pagesMercury 150HP이영석0% (1)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- CY8 C95 X 0 ADocument32 pagesCY8 C95 X 0 AAnonymous 60esBJZIj100% (1)

- Pro Tools ShortcutsDocument5 pagesPro Tools ShortcutsSteveJones100% (1)