Professional Documents

Culture Documents

Jde 10030

Uploaded by

X800XLOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jde 10030

Uploaded by

X800XLCopyright:

Available Formats

Ottumwa Works FACTORY

Engineering Standards SPECIFICATIONS

________________________________________________________________________

General Default Tolerances

SCOPE:

This standard provides a general tolerance for dimensions on part drawings where a specific tolerance is

not specified. JDS-G25 applies to all old drawings adopted before 01 June 1994.

APPLICATION OF TOLERANCES:

All attempts should be made to tolerance every dimension on the drawing. If any

dimension is not properly toleranced then this standard must be specified in the general

notes of the part drawing to apply.

Example: UNLESS OTHEWISE SPECIFIED

TOLERANCES PER JDE 10030

This standard will not override any other standard called out on the part drawing.

Example: Reference to hardware standard, sprocket standard, etc.

GENERAL TOLERANCES:

1. Formed or Fabricated

Linear Dimensions +/- 1mm

Bend Radius Dimensions:

Note: If inside Radius is distorted verification of Radius can be made

from external Bend form,

Note: If tooling marks are not allowed (i.e. from Hammerle Type Press)

note must be added:

MARK NOT TOLERATED

John Deere Ottumwa:

Regardless of material thickness: +1.5mm; -1mm

John Deere Arc Les Gray:

Material thickness <= 6mm (+1mm; -2mm)

Material thickness > 6mm (+1mm; -3mm)

Angular Dimensions:

Bend Angles - material thickness <2 mm (+/- 3 deg)

JDE10030 DESIGN CNTL DECISION DECISION DECISION DECISION

E 34094 321782 325549 382477

INTERFACTORY DATE DATE DATE DATE

Page 1 of 3

NO 18 July 2002 22 Oct 2004 26 Mar 2006 30 Jul 2010

Bend Angles - material thickness >=2 and <3.5 mm (+/- 1.5 deg)

Bend Angles - material thickness >= 3.5 mm (+/- 1 deg)

Angles other than bends +/-1 deg.

When no radius is specified, a sharp corner to 1.5 mm max chamfer or radius is allowed,

unless otherwise specified.

The notes "BREAK CORNER" and "FREE FROM BURRS" - allow a 0.2mm min. to 1.5mm max.

corner break. A corner break may be either a chamfer or a radius.

2. Hole Tolerance

a. General Hole Tolerance

Material thickness <= 5mm (+0.25mm; -0.25mm)

Material thickness > 5mm (+0.4mm; -0.25mm)

b. Drilled Holes

Hole tolerances specified with “DRILL” or “REAM” on the part drawing should follow tolerances

listed in the chart below unless otherwise specified.

HOLE SIZE NON HEAT TREATED AFTER HEAT

mm TOLERANCE TREATED

Over TO & Incl. Plus Minus Plus Minus

--- 6 0.2 0.05 0.3 0.1

6 19 0.25 0.05 0.4 0.1

19 32 0.3 0.08 0.46 0.15

32 --- 0.5 0.08 0.76 0.25

3. Castings (Steel and Aluminum)

Steel - See JDM B2

Iron - See JDM B15

Aluminum – See ISO 8062

4. Machine Finished Dimensions

Turned or bored diameter or length +/- 0.5mm

Planed, shaped or milled surface

For dimensions from another finished surface +/- 0.5mm

For dimensions from a locating point on an unfinished surface +/- 0.8mm

For dimensions without locating points on an unfinished surface +/- 1.0mm

Fillet radii +/- 0.5

When no radius is specified, a sharp corner to 1.5 mm max chamfer or radius is allowed.

The notes "BREAK CORNER" and "FREE FROM BURRS" - allow a 0.2mm min. to 1.5mm max.

corner break. A corner break may be either a chamfer or a radius.

Angles and Chamfers +/- 5 deg.

JDE10030 DESIGN CNTL DECISION DECISION DECISION DECISION

E 34094 321782 325549 382477

INTERFACTORY DATE DATE DATE DATE

Page 2 of 3

NO 18 July 2002 22 Oct 2004 26 Mar 2006 30 Jul 2010

Default surface finish for surfaces designated with finish mark shall be max. 3.2 mircometers, unless

otherwise specified.

5. Welding

Feature Location Dimensions (+1.5mm, -1.5mm)

Refer to JDV 20 for information on Welding Tolerances.

6. Distortion

The maximum permissible distortion due to fabrication operations (punching, shearing, bending,

and laser) other than cross breaks on sheet metal and bend intersections shall be 1.5mm. This

permissible distortion shall be in addition to the commercial form tolerances for steel as described

in JDM, ASTM, AISI, and ISO or DIN manuals. All parts with distortion greater than 1.5mm shall

be flattened in the distortion area with no drawing note required.

For parts were distortion greater than 1.5mm can be allowed, then “DISTORTION PERMISSIBLE” or

“XX MAX DISTORTION PERMISSIBLE” shall be noted on drawing. All distortion notes applying to a

limited area shall use a leader line to indicate the area to which the note applies.

All parts requiring closer control of flatness or straightness than commercial form tolerances

and/or distortion less than 1.5mm shall be noted on the drawing.

Distortion is permissible on all cross breaks and bend intersections on all parts unless otherwise

specified.

JDE10030 DESIGN CNTL DECISION DECISION DECISION DECISION

E 34094 321782 325549 382477

INTERFACTORY DATE DATE DATE DATE

Page 3 of 3

NO 18 July 2002 22 Oct 2004 26 Mar 2006 30 Jul 2010

You might also like

- JDM A24 John DeereDocument5 pagesJDM A24 John Deerergi178No ratings yet

- JDM F17X3: Relationships Between Various John Deere Paint Performance Standards and QualificationsDocument8 pagesJDM F17X3: Relationships Between Various John Deere Paint Performance Standards and QualificationsX800XLNo ratings yet

- JDM F11Document5 pagesJDM F11X800XLNo ratings yet

- JDN 200Document14 pagesJDN 200qualidadesiderNo ratings yet

- Y14 43Document1 pageY14 43Adrian JoelNo ratings yet

- JDM A20 - Rev. 11-2009Document11 pagesJDM A20 - Rev. 11-2009Romulo EduardoNo ratings yet

- Saej1459v004 PDFDocument9 pagesSaej1459v004 PDFvishalNo ratings yet

- JDM F20Document8 pagesJDM F20X800XLNo ratings yet

- JDM A28: Specification For Fluid Line Tubing of Carbon and Low Alloy SteelsDocument4 pagesJDM A28: Specification For Fluid Line Tubing of Carbon and Low Alloy SteelsGANESH GNo ratings yet

- JDM B8: Ductile (Spheroidal Graphite) Cast Irons - SpecificationDocument17 pagesJDM B8: Ductile (Spheroidal Graphite) Cast Irons - SpecificationthiagoNo ratings yet

- AN834 Rev9Document36 pagesAN834 Rev9MAI_QualityNo ratings yet

- Jde 10050Document20 pagesJde 10050X800XLNo ratings yet

- Mil PRF 81733DDocument34 pagesMil PRF 81733DHenryNo ratings yet

- Jdma17 2Document8 pagesJdma17 2qualidadesider0% (1)

- BasicCAM2 SmartInspect Basic v1.2 - FaroArm and FARO Gage Training Workbook - November 2014Document166 pagesBasicCAM2 SmartInspect Basic v1.2 - FaroArm and FARO Gage Training Workbook - November 2014raseen pNo ratings yet

- Engineering Materials Data SheetDocument6 pagesEngineering Materials Data Sheetrajarao1234No ratings yet

- Engineering Material Specification: Approval From The Sheet Metal Tech ClubDocument8 pagesEngineering Material Specification: Approval From The Sheet Metal Tech ClubaldairlopesNo ratings yet

- Secondary Paint Process Qualification FormDocument13 pagesSecondary Paint Process Qualification FormRajwinder SinghNo ratings yet

- Sae J200-Epdm-Ts5 - Google SearchDocument2 pagesSae J200-Epdm-Ts5 - Google SearchJessica ApalinNo ratings yet

- JDM B3 - Rev. 07-2015Document17 pagesJDM B3 - Rev. 07-2015Romulo EduardoNo ratings yet

- SAE J1926, MS 16142 - CuttersDocument11 pagesSAE J1926, MS 16142 - CutterspbsurfNo ratings yet

- Engineering Material SpecificationDocument10 pagesEngineering Material SpecificationMike FiorenNo ratings yet

- Esbm5a-B 1n261-s Aa RSWDocument37 pagesEsbm5a-B 1n261-s Aa RSWChandrajeet Shelke50% (2)

- GM Approved Finishers - ApplicatorsDocument3 pagesGM Approved Finishers - ApplicatorsScott Kramer0% (1)

- ISO 10243.die SpringsDocument12 pagesISO 10243.die SpringsКонстантин Косарев100% (1)

- JDM F17 Pintura IJDDocument14 pagesJDM F17 Pintura IJDcharssx100% (1)

- Material Specification Metals Gmw4: Impressão Não ControladaDocument17 pagesMaterial Specification Metals Gmw4: Impressão Não ControladaLucas MlbNo ratings yet

- VW13705 en 2003-08-01Document32 pagesVW13705 en 2003-08-01koalaboi100% (1)

- Asme B18.18.2M R1999Document16 pagesAsme B18.18.2M R1999Gerardo Rivera100% (1)

- Geometric Dimensioning and Tolerancing (GD&T) : Part Production Communication ModelDocument76 pagesGeometric Dimensioning and Tolerancing (GD&T) : Part Production Communication Modelmariappan128No ratings yet

- Rule #1 Explained: 2.7.1 Variations of Form (Rule #1: Envelope Principle)Document6 pagesRule #1 Explained: 2.7.1 Variations of Form (Rule #1: Envelope Principle)Anonymous 7ZTcBnNo ratings yet

- Din 8140 AmecoilDocument1 pageDin 8140 Amecoiljuanpalomo74No ratings yet

- ASME ISO ComparisonDocument1 pageASME ISO Comparisonsachoo17No ratings yet

- Danh Sách Tiêu Chuẩn HesDocument2 pagesDanh Sách Tiêu Chuẩn HesanhthoNo ratings yet

- Guia de Materiales - MatricesDocument11 pagesGuia de Materiales - MatricesGracielaNo ratings yet

- ASTM E 505 Cast DefectsDocument3 pagesASTM E 505 Cast DefectsMario Moura JrNo ratings yet

- 3 Surface Roughness SymbolsDocument7 pages3 Surface Roughness SymbolsAMIRHUSAIN MOMINNo ratings yet

- Source: Https://assist - Dla.mil - Downloaded: 2017-12-05T21:08Z Check The Source To Verify That This Is The Current Version Before UseDocument6 pagesSource: Https://assist - Dla.mil - Downloaded: 2017-12-05T21:08Z Check The Source To Verify That This Is The Current Version Before UseJoey ThomannNo ratings yet

- DIN 3016 P-Clip Form DDocument2 pagesDIN 3016 P-Clip Form Dsrushti100% (1)

- Engineering Material Specification: Printed Copies Are UncontrolledDocument6 pagesEngineering Material Specification: Printed Copies Are UncontrolledRicardo VitorianoNo ratings yet

- GMW16536 Sealer-In Welded Struct Aug2011Document9 pagesGMW16536 Sealer-In Welded Struct Aug2011Taofiq AbiolaNo ratings yet

- Geometric Dimensioning and Tolerancing: Procedure / Drafting FNHA-3-B-072.00Document69 pagesGeometric Dimensioning and Tolerancing: Procedure / Drafting FNHA-3-B-072.00003689% (9)

- The New Y14.5: We've Improved The Gold StandardDocument9 pagesThe New Y14.5: We've Improved The Gold StandardVignesh PanneerselvamNo ratings yet

- Sae J49-2018 PDFDocument10 pagesSae J49-2018 PDFNastyNo ratings yet

- Mat1140 PDFDocument4 pagesMat1140 PDFGustavo C. FerreiraNo ratings yet

- Ford-WSS-M1A365-A11A23 - (2017-09) - (Steel-CR-HR-Low Carbon) 9pgDocument9 pagesFord-WSS-M1A365-A11A23 - (2017-09) - (Steel-CR-HR-Low Carbon) 9pgdpfloresNo ratings yet

- TSB1503G 9 P 1Document18 pagesTSB1503G 9 P 1kk_pammu_915176926No ratings yet

- WSS M1P94 ADocument9 pagesWSS M1P94 AAleks SenaNo ratings yet

- Sae J500 Estriados PDFDocument2 pagesSae J500 Estriados PDFMarcel DandaroNo ratings yet

- Jis G0558 1977Document7 pagesJis G0558 1977Tuanbk NguyenNo ratings yet

- Jis G3113 1990Document11 pagesJis G3113 1990TUAN NGUYEN VANNo ratings yet

- Hes B008-03 Hexagon NutsDocument5 pagesHes B008-03 Hexagon NutsPreetam KumarNo ratings yet

- VW 011 03Document22 pagesVW 011 03Alexandre UrquizaNo ratings yet

- TIE44 Processing of ZerodurDocument11 pagesTIE44 Processing of Zerodur侯涛No ratings yet

- Xometry Sheet Metal Design Guide 2020Document22 pagesXometry Sheet Metal Design Guide 2020itsme5616No ratings yet

- Honda StandardDocument4 pagesHonda StandardBjorn Fejer67% (6)

- V Forge ThixocastingDocument1 pageV Forge ThixocastinggiakovidNo ratings yet

- Specs - ABSDocument3 pagesSpecs - ABSBurak KececiNo ratings yet

- Parts Produced by Planning, Shaping and Slotting: Process DescriptionDocument7 pagesParts Produced by Planning, Shaping and Slotting: Process DescriptionsansagithNo ratings yet

- hyperMILL 2D 3DDocument602 pageshyperMILL 2D 3DX800XL100% (1)

- HyperMILL CuDocument106 pagesHyperMILL CuX800XL100% (1)

- Defect DefinitionsDocument2 pagesDefect DefinitionsVarro NinaNo ratings yet

- Metals: Mechanical and Microstructural Features of Plasma Cut Edges in A 15 MM Thick S460M Steel PlateDocument13 pagesMetals: Mechanical and Microstructural Features of Plasma Cut Edges in A 15 MM Thick S460M Steel PlateX800XLNo ratings yet

- SSAB Cutting of Hardox and Strenx V2 2016Document8 pagesSSAB Cutting of Hardox and Strenx V2 2016Jorge Mario Vargas AcostaNo ratings yet

- hyperMILL 5XDocument148 pageshyperMILL 5XX800XL100% (2)

- Aws A2.4-2020Document166 pagesAws A2.4-2020X800XLNo ratings yet

- PropertiesofsomeMetalsandAlloys 297Document88 pagesPropertiesofsomeMetalsandAlloys 297xaaabbb_550464353No ratings yet

- MILLER DrillingDocument318 pagesMILLER DrillingX800XLNo ratings yet

- Aberlink 3D Mk4 User Manual (Iss 26-3)Document140 pagesAberlink 3D Mk4 User Manual (Iss 26-3)X800XL100% (1)

- PCC 8064 SM Alloy Handbook v04 PDFDocument23 pagesPCC 8064 SM Alloy Handbook v04 PDFAVINASH CHAVANNo ratings yet

- CATALOGUE Carbide Drill RealmerDocument14 pagesCATALOGUE Carbide Drill RealmerX800XLNo ratings yet

- Milling Tools and Inserts 2004 PDFDocument122 pagesMilling Tools and Inserts 2004 PDFPalade LucianNo ratings yet

- ATA Heet: LSS Chipper KnifeDocument2 pagesATA Heet: LSS Chipper KnifeX800XL100% (1)

- 10 - 06 - 29 Technical Product Overview - PPT - Production - MtuDocument63 pages10 - 06 - 29 Technical Product Overview - PPT - Production - MtuX800XLNo ratings yet

- Crucible: Data SheetDocument2 pagesCrucible: Data SheetX800XLNo ratings yet

- Vac Arc PDFDocument2 pagesVac Arc PDFX800XLNo ratings yet

- ATA Heet: LSS D2Document2 pagesATA Heet: LSS D2X800XLNo ratings yet

- 41 Rolling Contact BearingsDocument11 pages41 Rolling Contact BearingsPRASAD326100% (3)

- Rev o Lu Tion: Medium Chrome Tool SteelDocument6 pagesRev o Lu Tion: Medium Chrome Tool SteelX800XLNo ratings yet

- Dayton Tech-Balancing-Wear Strength ToughnessDocument4 pagesDayton Tech-Balancing-Wear Strength Toughnesswulfgang66No ratings yet

- Lecture 4.4: Transfer Molding and Compression Molding Transfer MoldingDocument5 pagesLecture 4.4: Transfer Molding and Compression Molding Transfer Moldingapi-256504985No ratings yet

- Crucible: Data SheetDocument2 pagesCrucible: Data SheetX800XLNo ratings yet

- Bearing-Study Material Mechanical Engg-1Document14 pagesBearing-Study Material Mechanical Engg-1anishiitdNo ratings yet

- 3.1 Components ActuatorDocument10 pages3.1 Components ActuatorAyman EsaNo ratings yet

- Basic Hydraulic: Hands-On TrainingDocument16 pagesBasic Hydraulic: Hands-On TrainingX800XLNo ratings yet

- Hands-On Training: Power of ColorsDocument18 pagesHands-On Training: Power of ColorsAyman EsaNo ratings yet

- DesignDocument189 pagesDesignumashankaresNo ratings yet

- Basic Hydraulic: Hands-On TrainingDocument25 pagesBasic Hydraulic: Hands-On TrainingX800XL100% (1)

- Fundamantals of HydraulicDocument17 pagesFundamantals of HydraulicmnowaqNo ratings yet

- Section 19: Plumbing Work 02: Water Distribution: 2.6.2 Drain TapsDocument3 pagesSection 19: Plumbing Work 02: Water Distribution: 2.6.2 Drain TapsAfnanMuhammadNo ratings yet

- Pricelist-Tubes & ValvesDocument39 pagesPricelist-Tubes & ValvesHKRajesh100% (1)

- CCANZ - Cracking (IB 73) PDFDocument8 pagesCCANZ - Cracking (IB 73) PDF4493464No ratings yet

- CoreBOO Brochure April 2023Document7 pagesCoreBOO Brochure April 2023Lavkesh KumarNo ratings yet

- HILTI Direct Fastening Technical Guide - Ed 18Document212 pagesHILTI Direct Fastening Technical Guide - Ed 18rodriguez.gaytanNo ratings yet

- Fork Head DIN 71752 Fork Joints GN 751Document2 pagesFork Head DIN 71752 Fork Joints GN 751Anonymous HPlNDhM6ejNo ratings yet

- Updated SP-511Document7 pagesUpdated SP-511Feroz GullNo ratings yet

- BS 882 - 1992 - Aggregates From Natural Sources For ConcreteDocument12 pagesBS 882 - 1992 - Aggregates From Natural Sources For Concretegokhan.soylu3520No ratings yet

- On U Boot Beton TechnologyDocument16 pagesOn U Boot Beton TechnologyJHLIKNo ratings yet

- TLE Activity Sheet Carpentry 4th QuarterDocument13 pagesTLE Activity Sheet Carpentry 4th QuarterJymaer Geromo100% (2)

- Heat TintDocument4 pagesHeat Tintvratsista agoritsaNo ratings yet

- Dupa Cost Estimate-MrfDocument23 pagesDupa Cost Estimate-MrfJonathanNo ratings yet

- Anaconda, Fatflot & Sludgeway Toro Wastewater EquipmentDocument16 pagesAnaconda, Fatflot & Sludgeway Toro Wastewater EquipmentDavidQueridoNo ratings yet

- MK1-2100AB001 - R0 - MTO Installation Material Area 2100Document12 pagesMK1-2100AB001 - R0 - MTO Installation Material Area 2100Farshad MahmoudiNo ratings yet

- Welder Training in SMAW, GTAW & GMAW Welding Engineering & NDT Consultancy Welding Engineering Related TrainingDocument4 pagesWelder Training in SMAW, GTAW & GMAW Welding Engineering & NDT Consultancy Welding Engineering Related TrainingKavin PrakashNo ratings yet

- Chapter-1 Door and WindowsDocument66 pagesChapter-1 Door and WindowsDawit TesfayNo ratings yet

- Lista Preturi Pardoseli 1iulie2020Document42 pagesLista Preturi Pardoseli 1iulie2020elyeliza2000No ratings yet

- BC With PlasticDocument3 pagesBC With PlasticKiran AEE BvrmNo ratings yet

- Fence ESTIMATE SampleDocument1 pageFence ESTIMATE SampleEvans Corp75% (4)

- Training - Cga ApplicationDocument34 pagesTraining - Cga ApplicationSubhan MuhammadNo ratings yet

- Reinforced Concrete Design Solution Manual 7th Edition PDFDocument5 pagesReinforced Concrete Design Solution Manual 7th Edition PDFEdmond Orena BautistaNo ratings yet

- Curtain Wall - Case StudyDocument1 pageCurtain Wall - Case StudyYou LoserNo ratings yet

- MGN628 - Part - 6 - GRP - Construction - R07.20 - PAG 29Document40 pagesMGN628 - Part - 6 - GRP - Construction - R07.20 - PAG 29Steven Salazar ArangoNo ratings yet

- Epoline Epoxy Tank Lining PDFDocument2 pagesEpoline Epoxy Tank Lining PDFYendyx NamuagNo ratings yet

- Sika Hydrotite CJ-Type 2012-01-1Document5 pagesSika Hydrotite CJ-Type 2012-01-1pandavision76No ratings yet

- Industrial Visit.: Mechanical EngineeringDocument9 pagesIndustrial Visit.: Mechanical EngineeringShivraj KolambekarNo ratings yet

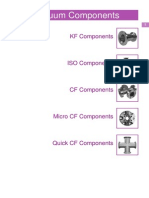

- 01 Vacuum ComponentsDocument84 pages01 Vacuum ComponentsNick LaveryNo ratings yet

- WTA Bellow Sealed Valve MaintenanceDocument1 pageWTA Bellow Sealed Valve MaintenanceicingrockNo ratings yet

- D10414410a Fmea CastingDocument7 pagesD10414410a Fmea CastingSuraj RawatNo ratings yet

- MP 0024Document4 pagesMP 0024Loren Viejay100% (1)