Professional Documents

Culture Documents

HandbookTable of Contents

Uploaded by

Anonymous zwSP5gv0 ratings0% found this document useful (0 votes)

48 views6 pagesBook

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBook

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

48 views6 pagesHandbookTable of Contents

Uploaded by

Anonymous zwSP5gvBook

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

Contents

Preface to the First Edition xiv

Preface to the Third Edition xvii

Acknowledgements xix

Chapter 1. Dimensions, Units, and Conversion Factors 1

1.1 The SI System of Units 1

1.1.1 Derived Units 2

1.1.2 Units Outside the SI 3

1.1.3 Comments on Some Quantities and Their Units 4

1.2 The American Engineering System (AES) of Units 4

1.3 Conversion of Units 6

1.3.1 Conversion Factor Tables 6

1.3.2 The Dimension Table 7

1.3.3 Conversion Equations — Temperature and Pressure 8

1.4 Unit Conversions Using the U-Converter Program 11

1.5 Amount of Substance — the Mole Unit 11

1.6 Density and Concentration 13

1.6.1 Density 13

1.6.2 Composition and Concentration 16

1.6.3 Composition of Gases 18

1.7 Electrical Units 20

1.8 Calculation Guidelines 21

1.9 Summary 22

References and Further Reading 23

Exercises 23

Chapter 2. Thermophysical and Related Properties of Materials 26

2.1 State of a System and Properties of a Substance 26

2.2 The Gibbs Phase Rule 27

2.2.1 Consequences of the Phase Rule for Non-Reactive and Reactive Systems 27

2.2.2 Application of the Phase Rule to One-Phase Non-Reactive Systems 28

2.2.3 Application of the Phase Rule to Multi-Phase Non-Reactive Systems 28

2.2.4 Application of the Phase Rule to Reactive Systems 29

2.3 The Gas Phase 30

2.3.1 The Ideal Gas Law 30

2.3.2 Non-Ideal Gas Behavior 32

2.4 Condensed Phases 34

2.5 Vapor-Liquid Equilibrium (VLE) 35

2.5.1 Mixtures of Condensable and Non-Condensable Gases 38

2.5.2 Software for Making Dew Point and Humidity Calculations 39

2.6 Effect of Pressure on Phase Transformation Temperatures 42

2.7 Steam and Air Property Calculators 44

2.8 Properties of Solutions 44

2.8.1 Ideal Solutions — Raoult’s Law 44

2.8.2 Non-Ideal Solutions — Activity Coefficients 46

2.8.3 Solutions of Gases in Condensed Phases 47

2.8.4 The Solubility Limit 48

2.8.5 The Solubility of Ionic Species in Water; the Solubility Product 49

2.9 Summary 50

References and Further Reading 51

Exercises 52

Chapter 3. Statistical Concepts Applied to Measurement and Sampling 54

3.1 Basic Statistical Concepts and Descriptive Tools 55

3.1.1 Histograms and Frequency Distributions 56

3.1.2 Mean, Standard Deviation, and Variance 59

3.1.3 Median, Percentile and Quantile 60

3.2 Distributions of Random Variables 62

3.2.1 The Uniform Distribution 62

3.2.2 The Normal Distribution 70

3.3 Basic Applications of Inferential Statistics to Measurement 75

3.3.1 Sampling Distributions of the Mean and the Central Limit Theorem 78

3.3.2 Confidence Intervals 82

3.3.3 Treatment of Errors 86

3.3.4 Error Propagation 92

3.4 Curve Fitting 95

3.4.1 Simple Linear Regression and Excel’s Trendline Tool 96

3.4.2 Using Solver to Develop Single-Variable Regression Models 101

3.4.3 Multiple Linear and Non-linear Regression 102

3.4.4 Using Solver and Excel’s SSD Tool to Find Equation Coefficients 105

3.4.5 Choosing Among Models 106

3.4.6 Polynomial vs. Rational Function Models 116

3.4.7 Outliers 117

3.4.8 Warnings 119

3.5 Experimental Design 119

3.5.1 Factorial Design 120

3.5.2 Fractional Factorial Design 130

3.6 Summary 137

References and Further Reading 137

Exercises 138

Chapter 4. Fundamentals of Material Balances with Applications to Non-Reacting Systems 144

4.1 System Characteristics 144

4.2 Process Classifications 145

4.3 Flowsheets 146

4.4 The General Balance Equation 150

4.5 Material Balances on Simple Non-Reactive Systems 151

4.6 Strategy for Making Material Balance Calculations 154

4.6.1 Guidelines for Setting up a Materials Balance 155

4.6.2 Guidelines for Resolving a Set of Equations 156

4.6.3 Objectives of a Material Balance 157

4.7 Degree-of-Freedom Analysis 158

4.7.1 DOF Concepts 159

4.7.2 DOF Calculation Strategy for a Single Non-Reactive Device 160

4.7.3 A Washing Process Having Zero Degrees of Freedom 162

4.7.4 A Washing Process Having a DOF = +1 168

4.7.5 A Leaching Process Having a DOF = –1 171

4.8 Using Excel-based Calculational Tools to Solve Equations 174

4.8.1 Goal Seek and Solver as Calculational Aids 174

4.8.2 Software for Conversion of Stream Units: MMV-C 178

4.9 Balances on Systems with Multiple Devices 179

4.10 Extension of Excel’s Calculational Tools for Repetitive Solving 194

4.10.1 SuperGS 194

4.10.2 SuperSolver 196

4.11 Special Multiple-Device Configurations I — Recycle and Bypass 197

4.12 Special Multiple-Device Configurations II — Counter-Current Flow 205

4.13 Using FlowBal for Material Balance Calculations 216

4.13.1 FlowBal Example #1: Mixer/Splitter 217

4.13.2 FlowBal Example #2: Evaporation/Condensation Process 219

4.13.3 FlowBal Example #3: Systems with Multi-Phase Streams 221

4.14 Continuous-Mixing Devices 223

4.14.1 Steady-State Processes 223

4.14.2 Unsteady-State Systems 226

4.14.3 Inert Gas Flushing 229

4.15 Graphical Representation of Material Balances 232

4.16 Measures of Performance 232

4.17 Controllers 234

4.18 Summary 239

References and Further Reading 240

Exercises 241

Chapter 5. Stoichiometry and the Chemical Equation 248

5.1 Atomic and Molecular Mass 248

5.2 Composition of Compounds and the Gravimetric Factor 249

5.3 Writing and Balancing Chemical Equations 251

5.3.1 Chemical Reaction Concepts 252

5.3.2 Writing and Balancing Chemical Reactions for Simple Processes 253

5.4 Calculations Involving Excess and Limiting Reactants 256

5.5 Progress of a Reaction 258

5.5.1 Extent of Species Reaction and Rate of Reaction Terminology 258

5.5.2 Chemical Reaction Kinetics 259

5.5.3 Reaction Progress and Keq 263

5.5.4 Keq Values from FREED 264

5.5.5 Guidelines for Using Keq to Determine Maximum Reaction Extent 265

5.5.6 Application of Equilibrium Limitations for Gas-Condensed Phase Reactions 266

5.5.7 Application of Equilibrium Limitations to Gas-Phase Reactions 268

5.6 Practical Indicators of the Progress of Reactions and Processes 269

5.7 Parallel, Sequential and Mixed Reactions 273

5.8 Independence of Chemical Reactions 274

5.9 Practical Examples of Reaction Writing and Stoichiometry 274

5.9.1 Calculations in Gas-Condensed Phase Processes 275

5.9.2 Calculations in Gas-Phase Processes 277

5.10 Use of Chemical Reactions in FlowBal 279

5.10.1 FlowBal’s Extent of Reaction Tool 280

5.10.2 FlowBal’s Insert Equation Tool 282

5.11 Balancing Aqueous (Ionic) Reactions 283

5.12 Summary 286

References and Further Reading 288

Exercises 288

Chapter 6. Reactive Material Balances 294

6.1 The General Material Balance Procedure for a Reactive System 294

6.1.1 Independent Chemical Reactions, Independent Species, and Independent Elements 295

6.1.2 Molecular Species Material Balance Method 296

6.1.3 Atomic Species Method 300

6.1.4 Atomic and Molecular Species Balance Examples 302

6.2 The Use of Excel-based Computational Tools in Reactive System Balances 306

6.2.1 Application of SuperSolver 306

6.2.2 Reactive System Material Balances Using FlowBal 309

6.3 Combustion Material Balances 321

6.3.1 Material Balance for the Combustion of a Gaseous Fuel 322

6.3.2 Combustion of Liquid Fuels 327

6.3.3 Combustion of Solid Fuels 327

6.3.4 Use of Feed-Forward and Stack Gas Analysis for Combustion Control 329

6.3.5 Use of FlowBal for Combustion Calculations 333

6.3.6 Trace Combustion Products 335

6.4 The Production of a Reducing Gas 340

6.5 Gas-Solid Oxidation-Reduction Processes 345

6.5.1 Oxidation-Reduction During Calcination 345

6.5.2 The Reduction of Iron Ore Concentrate 348

6.5.3 The Chemistry of Fluidized Bed Reduction of Iron Ore by Hydrogen 349

6.5.4 Excel Simulation of the Fluidized Bed Reduction of Hematite 351

6.5.5 FlowBal Simulation of the Fluidized Bed Reduction of Hematite 355

6.5.6 Shaft Furnace Reduction of Iron Ore Concentrate 359

6.5.7 The Roasting of a Sulfide Concentrate 366

6.6 The Production of Gases with Controlled Oxygen and Carbon Potential 370

6.7 Processes Controlled by Chemical Reaction Kinetics 371

6.8 The Reconciliation of an Existing Materials Balance 372

6.9 The Use of Distribution Coefficients in Material Balance Calculations 377

6.9.1 Use of Tabulated Distribution Coefficients 377

6.9.2 Thermodynamic Databases as a Source of Distribution Coefficient Data 381

6.10 Time-Varying Processes 384

6.11 Systems Containing Aqueous Electrolytes 389

6.11.1 The Stability of Ions 390

6.11.2 Aqueous Processes 392

6.11.3 The Solubility of Ionizable Gases in Water 398

6.12 Summary 402

References and Further Reading 404

Exercises 405

Chapter 7. Energy and the First Law of Thermodynamics 410

7.1 Principles and Definitions 410

7.2 General Statement of the First Law of Thermodynamics 413

7.3 First Law for an Open System 415

7.4 Enthalpy, Heat Capacity, and Heat Content 416

7.5 Enthalpy Change of Phase Transformations 418

7.6 Enthalpy Change of Chemical Reactions 420

7.7 Thermodynamic Databases for Pure Substances 421

7.8 Effect of Temperature on Heat of Reaction 426

7.8.1 Application of Kirchhoff’s Equation to Chemical Reactions 426

7.8.2 Heat of Transformation for Non-Standard and Non-Physical States 428

7.9 The Properties of Steam and Compressed Air 431

7.9.1 Properties of Steam 431

7.9.2 Properties of Compressed Air 432

7.9.3 Temperature Change for Free Expansion of a Gas 433

7.9.4 Cooling by Steam Venting 435

7.9.5 Enthalpy of Psychrometry 436

7.10 The Use of FREED in Making Heat Balances 437

7.11 Heat of Solution 441

7.11.1 Formation of Non-ideal Metallic Solutions 441

7.11.2 Polymeric Solutions 442

7.11.3 Aqueous Solutions 444

7.12 Summary 445

References and Further Reading 446

Exercises 447

Chapter 8. Enthalpy Balances in Non-Reactive Systems 450

8.1 Combined Material and Heat (System) Balances 450

8.2 Heat Balances for Adiabatic Processes 458

8.3 Psychrometric Calculations 462

8.4 Energy Efficiency 468

8.5 Recovery and Recycling of Heat 469

8.5.1 Heat Exchange Between Fluids 469

8.5.2 Heat Exchange between Solids and Fluids 474

8.5.3 Application of Heat Recovery Techniques to Aluminum Melting 474

8.5.4 Heat Exchange Accompanied by Material Transfer 478

8.6 Multiple-Device System Balances 483

8.7 Use of FlowBal for System Balances 488

8.8 Heat Balances Involving Solution Phases 494

8.9 Enthalpy Change During Dissolution of an Electrolyte 496

8.10 Graphical Representation of a Heat Balance 499

8.11 Summary 500

References and Further Reading 501

Exercises 5020

Chapter 9. System Balances on Reactive Processes 505

9.1 Thermal Constraints on a Material Balance 505

9.1.1 Uncoupled System Balances 506

9.1.2 Strategy for Coupled System Balance 508

9.2 Combustion of Fuels 511

9.2.1 Heat of Combustion Calculations 512

9.2.2 Use of Wobbe Index for Combustion Burner Control 514

9.2.3 Combustion of Fuels of Uncertain Molecular Composition 516

9.3 Adiabatic Processes 517

9.3.1 System Balances Involving Combustion Reactions 518

9.3.2 ART for Condensed-Phase Reaction Processes 531

9.4 System Balances Using FlowBal 533

9.5 Quality of Heat and Thermal Efficiency 542

9.6 System Balances with Heat Exchangers 548

9.7 Aqueous Processes 565

9.8 Electrolytic Processes 571

9.8.1 Energy Requirement for Electrorefining 571

9.8.2 Energy Requirement for Electrowinning 572

9.9 Summary 573

References and Further Reading 574

Exercises 574

Chapter 10. Case Studies 577

10.1 Material Balance for an H-Iron Reduction Process with Gas Tempering and Recycle 577

10.2 Mass and Heat Balance Simulation for the Use of DRI in EAF Steelmaking 581

10.3 Natural Gas Combustion Control and the Wobbe Index 588

10.3.1 The Stoichiometry of NG Combustion with Excess Air 588

10.3.2 The Wobbe Index as a Natural Gas Combustion Control Parameter 591

10.4 Reduction of Hematite to Magnetite 592

10.4.1 Preliminary Calculations — Single Reactor 593

10.4.2 Simulation of Hematite Reduction by a Multi-Stage Process 595

10.5 Conversion of Quartz to Cristobalite in a Fluidized Bed 598

10.5.1 Process Characteristics 598

10.5.2 Device Sizing and Heat Loss Calculation 598

10.5.3 Material and Heat Balance Calculations 599

Exercise 600

Appendix. Computational Tools for Making Material and Heat Balance Calculations 601

A.1 U-Converter 601

A.2 Thermophysical Properties of Steam and Air 602

A.3 Stream Units Conversion Calculator (MMV-C) 602

A.4 Extension of Excel Tools for Repeat Calculation 603

A.5 Thermodynamic Database Programs 604

A.6 Flowsheet Simulation and System Balancing 604

You might also like

- Stoichiometry and Process Calculations (T.L) PDFDocument600 pagesStoichiometry and Process Calculations (T.L) PDFDanielSilvadaFonseca80% (10)

- Stoichiometry and Process CalculationsDocument535 pagesStoichiometry and Process CalculationsAndrés Ceverisae76% (38)

- Stoichiometry and Process Calculations (2017) PDFDocument613 pagesStoichiometry and Process Calculations (2017) PDFMarcelo Antonucci Cos100% (4)

- Chemical and Engineering ThermodynamicsDocument5 pagesChemical and Engineering Thermodynamicscristian gonzalezNo ratings yet

- Front Matter PDFDocument8 pagesFront Matter PDFYosephine TanNo ratings yet

- Bioprocess Engineering Principles: Second EditionDocument6 pagesBioprocess Engineering Principles: Second Editionvodounnou0% (1)

- Thermodynamics Article SummaryDocument6 pagesThermodynamics Article SummaryucaasNo ratings yet

- 2Document7 pages2salim salimNo ratings yet

- Chemical Engineering FundamentalsDocument3 pagesChemical Engineering FundamentalsJaleed AhmedNo ratings yet

- Chemical, Biochemical, and Engineering Thermodynamics: Stanley I. SandlerDocument5 pagesChemical, Biochemical, and Engineering Thermodynamics: Stanley I. SandlerAriadne ChuaNo ratings yet

- Chemical ThermodynamicsDocument6 pagesChemical Thermodynamicspenelopezeus39No ratings yet

- Transport Processes and Separation Process Principles: University OfminnesotaDocument8 pagesTransport Processes and Separation Process Principles: University Ofminnesotaİdil KorkmazNo ratings yet

- Fundamentals of Engineering ThermodynamicsDocument7 pagesFundamentals of Engineering ThermodynamicsMuhammad Muneer uddinNo ratings yet

- Stoichiometry: and ProcessDocument613 pagesStoichiometry: and ProcessPRATIKNo ratings yet

- Instrumental Methods Table of ContentsDocument11 pagesInstrumental Methods Table of ContentsmanjushreeNo ratings yet

- Computational Fluid Dynamics Vol.I - HoffmannDocument500 pagesComputational Fluid Dynamics Vol.I - HoffmannMahesh J Rao50% (2)

- Solution Manual For Introduction To Engineering Analysis 4 e 4th Edition Kirk D HagenDocument7 pagesSolution Manual For Introduction To Engineering Analysis 4 e 4th Edition Kirk D HagenCecelia Sams100% (34)

- Elements of Chemical Reaction Engineering Prentice Hall International Series in The Physical and Chemical Engineering Sciences Ebook PDF VersionDocument62 pagesElements of Chemical Reaction Engineering Prentice Hall International Series in The Physical and Chemical Engineering Sciences Ebook PDF Versionadolfo.milliken178100% (43)

- Mathematics Manual For Water and Wastewater Treatment Plant OperatorsDocument328 pagesMathematics Manual For Water and Wastewater Treatment Plant OperatorsDavid Hernandez GonzalezNo ratings yet

- 3110614421Document558 pages3110614421ostomaconsultingNo ratings yet

- Ann Saterbak, Ka-Yiu San, Larry v. McIntire - Bioengineering Fundamentals (2nd Edition)Document622 pagesAnn Saterbak, Ka-Yiu San, Larry v. McIntire - Bioengineering Fundamentals (2nd Edition)Abdi TeferiNo ratings yet

- Heat and Mass Transfer PropertiesDocument63 pagesHeat and Mass Transfer Propertieskaushita banerjeeNo ratings yet

- Ebook PDF Wastewater Treatment Process Modeling Second Edition 2nd Edition PDFDocument41 pagesEbook PDF Wastewater Treatment Process Modeling Second Edition 2nd Edition PDFjames.price548100% (33)

- Riccardo Tesser, Vincenzo Russo - Advanced Reactor Modeling With MATLAB - Case Studies With Solved Examples-De Gruyter STEM (2020)Document300 pagesRiccardo Tesser, Vincenzo Russo - Advanced Reactor Modeling With MATLAB - Case Studies With Solved Examples-De Gruyter STEM (2020)Leonardo Almeida de CamposNo ratings yet

- Chemical Process Eq1Jipment Design: Richard Turton - Joseph ShaeiwitzDocument26 pagesChemical Process Eq1Jipment Design: Richard Turton - Joseph Shaeiwitzshubham prakashNo ratings yet

- Water Resources Systems Planning Ano Management: S.K. JainDocument15 pagesWater Resources Systems Planning Ano Management: S.K. JainsaiusedshivshaktiNo ratings yet

- Statistical Digital Signal Processing and ModelingDocument622 pagesStatistical Digital Signal Processing and ModelingAmit Patel100% (4)

- Mass Transfer Principles and Operations de SinhaDocument728 pagesMass Transfer Principles and Operations de Sinhahann_dle88% (32)

- Mechatronic Systems: FundamentalsDocument10 pagesMechatronic Systems: FundamentalsNguyen Van ToanNo ratings yet

- 6 de NDocument14 pages6 de NGeorge Morales TorresNo ratings yet

- Analysis and Control of Production Systems: Soci Igebiete: ....Document6 pagesAnalysis and Control of Production Systems: Soci Igebiete: ....Huricane TriangleNo ratings yet

- Mathematical Modelling and Simulation of Physical SystemsDocument375 pagesMathematical Modelling and Simulation of Physical Systems87482127100% (1)

- Logic and Discrete Mathematics A Computer Science - 1Document11 pagesLogic and Discrete Mathematics A Computer Science - 1DeadPool PoolNo ratings yet

- Braun1988 PDFDocument434 pagesBraun1988 PDFDavid PérezNo ratings yet

- Biocatalysts and Enzyme TechnologyDocument9 pagesBiocatalysts and Enzyme TechnologyMichelle Santillán0% (1)

- Elementary Principles of Chemical Processes, 4th Edition (PDFDrive) - 15-17Document3 pagesElementary Principles of Chemical Processes, 4th Edition (PDFDrive) - 15-17Lê Quỳnh0% (1)

- A Textbook Of: Hemical Ngineering HermodynamicsDocument11 pagesA Textbook Of: Hemical Ngineering HermodynamicsAiswarya RaviNo ratings yet

- Introduction to Applied Statistical Signal Analysis: Guide to Biomedical and Electrical Engineering ApplicationsFrom EverandIntroduction to Applied Statistical Signal Analysis: Guide to Biomedical and Electrical Engineering ApplicationsNo ratings yet

- Numerical Solution of Ordinary Differential EquationsFrom EverandNumerical Solution of Ordinary Differential EquationsRating: 5 out of 5 stars5/5 (1)

- Stability and Control of Aircraft Systems: Introduction to Classical Feedback ControlFrom EverandStability and Control of Aircraft Systems: Introduction to Classical Feedback ControlNo ratings yet

- Reactive Distillation: Status and Future DirectionsFrom EverandReactive Distillation: Status and Future DirectionsKai SundmacherRating: 1 out of 5 stars1/5 (1)

- The Thermoeconomics of Energy ConversionsFrom EverandThe Thermoeconomics of Energy ConversionsRating: 5 out of 5 stars5/5 (2)

- Preparative Chromatography for Separation of ProteinsFrom EverandPreparative Chromatography for Separation of ProteinsArne StabyNo ratings yet

- Fixed-Bed Reactor Design and Diagnostics: Gas-Phase ReactionsFrom EverandFixed-Bed Reactor Design and Diagnostics: Gas-Phase ReactionsRating: 4 out of 5 stars4/5 (5)

- Boiling: Research and AdvancesFrom EverandBoiling: Research and AdvancesYasuo KoizumiNo ratings yet

- Modeling Embedded Systems and SoC's: Concurrency and Time in Models of ComputationFrom EverandModeling Embedded Systems and SoC's: Concurrency and Time in Models of ComputationNo ratings yet

- Theory of Simple Liquids: with Applications to Soft MatterFrom EverandTheory of Simple Liquids: with Applications to Soft MatterNo ratings yet

- Computational Flow Modeling for Chemical Reactor EngineeringFrom EverandComputational Flow Modeling for Chemical Reactor EngineeringRating: 3 out of 5 stars3/5 (3)

- Evaluation FormDocument1 pageEvaluation FormAnonymous zwSP5gvNo ratings yet

- Mess Bill Jan+FebDocument1 pageMess Bill Jan+FebAnonymous zwSP5gvNo ratings yet

- SuppliersDocument1 pageSuppliersAnonymous zwSP5gvNo ratings yet

- Evaluation FormDocument1 pageEvaluation FormAnonymous zwSP5gvNo ratings yet

- Mess Bill Jan+FebDocument1 pageMess Bill Jan+FebAnonymous zwSP5gvNo ratings yet

- ZhuozhouDocument1 pageZhuozhouAnonymous zwSP5gvNo ratings yet

- Water Gas Shift Reaction Kinetics and Reactor Modeling For Fuel Cell Grade Hydrogen PDFDocument8 pagesWater Gas Shift Reaction Kinetics and Reactor Modeling For Fuel Cell Grade Hydrogen PDFKmilo BolañosNo ratings yet

- HAZIDDocument2 pagesHAZIDAnonymous zwSP5gvNo ratings yet

- Tubular ReactorDocument2 pagesTubular ReactorAnonymous zwSP5gvNo ratings yet

- Diesel Fuel ASTM LimitsDocument1 pageDiesel Fuel ASTM LimitsAnonymous zwSP5gvNo ratings yet

- Mess Bill Jan+Feb PDFDocument1 pageMess Bill Jan+Feb PDFAnonymous zwSP5gvNo ratings yet

- Simulation of Aqua Ammonia Refrigeration System Using The Cape Open To Cape Open Coco Simulator PDFDocument4 pagesSimulation of Aqua Ammonia Refrigeration System Using The Cape Open To Cape Open Coco Simulator PDFAnonymous zwSP5gvNo ratings yet

- Graduate Assessment Test (GAT 2018-III) GAT General: (Result)Document1 pageGraduate Assessment Test (GAT 2018-III) GAT General: (Result)Anonymous zwSP5gvNo ratings yet

- Robur Abso en 02 2019Document35 pagesRobur Abso en 02 2019Anonymous zwSP5gvNo ratings yet

- Diesel Fuel ASTM LimitsDocument1 pageDiesel Fuel ASTM LimitsAnonymous zwSP5gvNo ratings yet

- Blast Furnace Heat and Material Balance Using MS-Excel-SolverDocument11 pagesBlast Furnace Heat and Material Balance Using MS-Excel-SolverAnonymous zwSP5gvNo ratings yet

- Fish FoodDocument6 pagesFish FoodAnonymous zwSP5gvNo ratings yet

- HAZIDDocument2 pagesHAZIDAnonymous zwSP5gvNo ratings yet

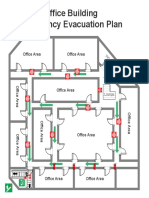

- Emergency Evacuation PlanDocument1 pageEmergency Evacuation PlanAnonymous zwSP5gvNo ratings yet

- Hazard Identification Study SS RISK4 160410 1Document2 pagesHazard Identification Study SS RISK4 160410 1Anonymous zwSP5gvNo ratings yet

- StandardsDocument9 pagesStandardsmanoj983@gmail.comNo ratings yet

- Nust CV FormDocument8 pagesNust CV FormAnonymous zwSP5gvNo ratings yet

- Siphon - Sizing 6 PDocument6 pagesSiphon - Sizing 6 PJaber Osmani100% (1)

- Neutron PoisonsDocument27 pagesNeutron PoisonsAnonymous zwSP5gvNo ratings yet

- Construction Completion Report Form For Submittal Exception ProcessDocument3 pagesConstruction Completion Report Form For Submittal Exception ProcessAnonymous zwSP5gvNo ratings yet

- ..:: Proposals For ELMO RIETSCHLE PUMPS::.Document5 pages..:: Proposals For ELMO RIETSCHLE PUMPS::.Anonymous zwSP5gvNo ratings yet

- Construction Completion Report FormDocument2 pagesConstruction Completion Report FormAnonymous zwSP5gvNo ratings yet

- UK Conductive Heater RangeDocument4 pagesUK Conductive Heater RangeAnonymous zwSP5gvNo ratings yet

- Construction Completion Report FormDocument1 pageConstruction Completion Report FormG-SamNo ratings yet

- History of washing machines evolutionDocument47 pagesHistory of washing machines evolutionKeyur PatelNo ratings yet

- Corner Design For All Users - Alta - Sept 2020Document48 pagesCorner Design For All Users - Alta - Sept 2020Wayne MartinNo ratings yet

- ENGLISH TEST: A GUIDE TO STRUCTURE, VOCABULARY, AND COMPREHENSIONDocument20 pagesENGLISH TEST: A GUIDE TO STRUCTURE, VOCABULARY, AND COMPREHENSIONRhephee Rhephee RepheeNo ratings yet

- Pygmy Deposit System Through Android CloudDocument4 pagesPygmy Deposit System Through Android CloudInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Bhagavad Gita Chapter 7 and 9 by Sri Sri RavishankarDocument61 pagesBhagavad Gita Chapter 7 and 9 by Sri Sri Ravishankarprashantmanral100% (2)

- Furuno Gp170 GpsDocument4 pagesFuruno Gp170 GpsvedranNo ratings yet

- Tamilnadu State Council For Science and Technology: Dr. V. AmbikapathyDocument4 pagesTamilnadu State Council For Science and Technology: Dr. V. AmbikapathySughasiny KannaNo ratings yet

- Longitude Festival 2022 Friday Lineup, Stage TimDocument2 pagesLongitude Festival 2022 Friday Lineup, Stage Timhuy3No ratings yet

- Republic of ArmeniaDocument57 pagesRepublic of ArmeniaShreya GuptaNo ratings yet

- PR 2 Module 2Document18 pagesPR 2 Module 2Earl Laurence PlatinoNo ratings yet

- Still RX60-16,18,20 Parts CatalogueDocument678 pagesStill RX60-16,18,20 Parts CatalogueПетр100% (1)

- Ielts Academic Reading Practice Test 9 3aed21036aDocument3 pagesIelts Academic Reading Practice Test 9 3aed21036aJohnNo ratings yet

- Tech Manual Index PDFDocument36 pagesTech Manual Index PDFMartín Ignacio del CampoNo ratings yet

- 2006 - Kamal and Mohamad Combustion in Porous MediaDocument22 pages2006 - Kamal and Mohamad Combustion in Porous Mediavivek joshiNo ratings yet

- UntitledDocument1 pageUntitledPedro MiguelNo ratings yet

- KawasanDocument2 pagesKawasanSel TopiaNo ratings yet

- Stone Houses of Jefferson CountyDocument240 pagesStone Houses of Jefferson CountyAs PireNo ratings yet

- DAGR BrochureDocument2 pagesDAGR BrochureNasir Khan BhittaniNo ratings yet

- Mototaro Eguchi - Electret PDFDocument2 pagesMototaro Eguchi - Electret PDFLeonardo MartoneNo ratings yet

- WPS RB GM 01Document12 pagesWPS RB GM 01hetpinNo ratings yet

- Rtaa Iom 1Document90 pagesRtaa Iom 1ahmed gamalNo ratings yet

- An Efficient Conversion of Alcohols To Alkyl Bromides Using Pyridinium Based Ionic Liquids: A Green Alternative To Appel ReactionDocument5 pagesAn Efficient Conversion of Alcohols To Alkyl Bromides Using Pyridinium Based Ionic Liquids: A Green Alternative To Appel ReactionananNo ratings yet

- 1994 Prowler NewDocument66 pages1994 Prowler Newrs657100% (5)

- Notebook PC: E-Manual For ChromebookDocument90 pagesNotebook PC: E-Manual For ChromebookballNo ratings yet

- ASTM Designation: E1166 00 (Reapproved 2009)Document2 pagesASTM Designation: E1166 00 (Reapproved 2009)Lupita RamirezNo ratings yet

- Post Hoc Test in ANOVADocument17 pagesPost Hoc Test in ANOVAJelly Jean PayeNo ratings yet

- Eo 192Document20 pagesEo 192Xryn MortelNo ratings yet

- Rectangular Tank 4 July 2015Document27 pagesRectangular Tank 4 July 2015Asep DarojatNo ratings yet

- HPLC Technical Tips PosterDocument1 pageHPLC Technical Tips PostermokhtarsimonNo ratings yet

- Baterías AlphaDocument2 pagesBaterías Alphadisanty94No ratings yet