Professional Documents

Culture Documents

Hall Effect

Uploaded by

Qaisara Ewa SyafawatiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hall Effect

Uploaded by

Qaisara Ewa SyafawatiCopyright:

Available Formats

AUTOMOTIVE MAINTENANCE TECHNOLOGY

SUBJECT : AUTOTRONIC 2

TITLE: TRANSISTORISED IGNITION WITH HALL GENERATOR TI-H

Transistorized ignition with Hall generator TI-H

In addition to the breaker-triggered transistorized ignition system (TI-B), there

are two other versions of transistorized ignition with Hall triggering system (TI-

H).

On one version, the dwell angle is determined by the shape of the rotor in the

ignition distributor.

The other version contains a control unit incorporating hybrid circuitry and

which automatically regulates the dwell angle.

An additional current limiter with a highly efficient ignition coil makes this

version a particularly high-performance ignition system.

Hall Effect

If electrons move in a conductor to which the lines of force of a magnetic field

are applied, the electrons are deflected perpendicularly to the current

direction and perpendicularly to the direction of the magnetic field, an excess

of electrons occurs at A1 and a deficiency of electrons occurs at A2 i.e.

The hall voltage occurs across A1 and A2. This so-called Hall Effect is

particularly prominent in the case of semiconductors.

Semester : Date :

Duration : 5 Page :Page 1 / 7

AUTOMOTIVE MAINTENANCE TECHNOLOGY

SUBJECT : AUTOTRONIC 2

TITLE: TRANSISTORISED IGNITION WITH HALL GENERATOR TI-H

Hall generator

When the ignition-distributor shaft turns, the vanes of the rotor move through

the air gap of the magnetic barrier without touching it.

When the air gap is unobstructed the incorporated IC and the Hall layer are

subjected to the magnetic field.

At the Hall layer, the magnetic flux density B is high and the Hall voltage UH

is maximum.

The Hall IC is activated. As soon as one of the rotor vanes enters the air gap,

most of the magnetic flux runs through the vane area and is thus largely

prevented from reaching the Hall layer.

The flux density at the Hall layer is reduced to a virtually negligible level,

resulting from the leakage field. Voltage UH is at minimum. The Hall

generator is accommodated in the ignition distributor.

The magnetic barrier is mounted on the movable carrying plate.

The Hall IC is located on a ceramic substrate and is potted in plastic together

with one of the conductive elements in order to protect it against moisture, dirt

and mechanical damage.

The conductive elements and trigger wheel are of a soft magnetic material.

The trigger wheel and distributor rotor comprise one component on the retrofit

version.

The number of vanes is equal to the number of cylinders.

The width b of the individual vanes can determine the maximum dwell angle

of the ignition system, dependent upon the ignition trigger box.

The dwell angle consequently remains constant throughout the entire service

life of the Hall generator; thus, there is no need to set it.

The mode of operation and design of the Hall generator permit the ignition

system to be set with the engine switched off providing peak-coil-current cut-

off is incorporated.

If the technical prerequisites are fulfilled, and the installation instructions are

observed precisely, it is an easy matter to convert from conventional ignition

to breaker less ignition.

Bosch service stations will be able to provide you with further information.

Semester : Date :

Duration : 5 Page :Page 2 / 7

AUTOMOTIVE MAINTENANCE TECHNOLOGY

SUBJECT : AUTOTRONIC 2

TITLE: TRANSISTORISED IGNITION WITH HALL GENERATOR TI-H

Current regulation and dwell-angle closed-loop control

High-performance ignition systems operate with ignition coils which charge

very rapidly.

For this purpose, the ohmic resistance of the primary winding is reduced to

less than 1 ohm.

The information content of the signal of a Hall vane switch in the ignition

distributor corresponds to the signal of an ignition contact breaker.

In one case, the dwell angle is determined by the distributor cam and, in the

other the pulse duty factor is determined by the rotor vane.

A rapidly chargeable ignition coil cannot operate with a fixed dwell angle.

Semester : Date :

Duration : 5 Page :Page 3 / 7

AUTOMOTIVE MAINTENANCE TECHNOLOGY

SUBJECT : AUTOTRONIC 2

TITLE: TRANSISTORISED IGNITION WITH HALL GENERATOR TI-H

This is why two measures must be taken to protect the ignition coil: a primary-

current regulation system and a dwell-angle closed-loop control system.

Current-regulation function

The primary-current regulation system serves to limit the current through the

ignition coil and, thus, to limit the build-up of energy to a specific amount.

A certain lead time is required in order to cope with the dynamic conditions

applicable when the engine accelerates.

This means that the ignition coil should reach its nominal value before the

ignition point.

During this current regulation phase, the ignition transistor operates in its

active range.

More voltage than in the pure switch mode drops across the transistor.

This means a high power loss which may lie between 20 and 30 W.

Semester : Date :

Duration : 5 Page :Page 4 / 7

AUTOMOTIVE MAINTENANCE TECHNOLOGY

SUBJECT : AUTOTRONIC 2

TITLE: TRANSISTORISED IGNITION WITH HALL GENERATOR TI-H

In order to minimize this, and in order to set the appropriate dwell angle, a

dwell-angle closed-loop control system is required (which is actually a dwell

period closed loop control system since the coil is charged as a function of

time).

Function of the dwell-angle closed- loop control system

Since control processes in analog systems are carried out simply by shifting

voltage threshold values, the square wave signal of the Hall generator is first

converted to a ramp signal by charging and discharging capacitors.

The pulse duty factor of the Hall generator is 30:70 between two ignition

points.

The ignition point determined by adjustment of the ignition distributor lies at

the end of the vane width corresponding to 70 %.

The closed loop control system is set such that the current control time t1

corresponds precisely to the required dynamic lead.

A voltage is formed on the basis of value t1 and is compared with the trailing

ramp of the ramp voltage.

The primary current is switched on at the intersection point "ON" and the

dwell angle starts.

In this way, the switch-on point of the dwell angle can be varied as required

by shifting the intersection point on the ramp voltage and by varying the

voltage derived from the current control time.

This means that the correct dwell angle is always formed for every operating

range.

Since current regulation and dwell angle closed-loop control are de- pendent

directly upon current and time, this eliminates the effects of varying battery

voltage and temperature effects or other ignition-coil tolerances.

This renders these ignition systems particularly suitable for cold starting.

Since primary current can flow owing to the wave form of the Hall signal with

the engine switched off and with the ignition-starting switch switched on, the

control units can be equipped with an auxiliary circuit which switches off this

"peak-coil current" after a certain period.

Semester : Date :

Duration : 5 Page :Page 5 / 7

AUTOMOTIVE MAINTENANCE TECHNOLOGY

SUBJECT : AUTOTRONIC 2

TITLE: TRANSISTORISED IGNITION WITH HALL GENERATOR TI-H

Control unit (ECU)

Semester : Date :

Duration : 5 Page :Page 6 / 7

AUTOMOTIVE MAINTENANCE TECHNOLOGY

SUBJECT : AUTOTRONIC 2

TITLE: TRANSISTORISED IGNITION WITH HALL GENERATOR TI-H

Transistorized ignition systems with current regulation and dwell angle closed

loop control, virtually all comprise hybrid circuits.

This makes it possible to combine the compact and lightweight control units

for instance with the ignition coil, to form one assembly.

Owing to the power loss which occurs in the ignition coil and in the

transistorized ignition control unit, adequate cooling and good thermal contact

with the bodywork are required.

Semester : Date :

Duration : 5 Page :Page 7 / 7

You might also like

- Computers and Sensors GuideDocument30 pagesComputers and Sensors GuidePablo Ernesto Vigneaux Wilton0% (1)

- 2011 Ford F-650 and F-750 Super Duty TrucksDocument10 pages2011 Ford F-650 and F-750 Super Duty TrucksBartow Ford Company100% (1)

- Electrical Test EquipmentsDocument17 pagesElectrical Test Equipmentsengrroy100% (1)

- 2022 Auto Wiring DLC TestDocument4 pages2022 Auto Wiring DLC TestmilevyoNo ratings yet

- Autotronics Training Lab Ver 4 9Document36 pagesAutotronics Training Lab Ver 4 9Fernando Carlos100% (1)

- Teach Theory and Diagnosis of Multiple CAN Systems Using DLCDocument16 pagesTeach Theory and Diagnosis of Multiple CAN Systems Using DLCJaffer HussainNo ratings yet

- Introduction - : Electronic Parking Brake Systems (EPB)Document6 pagesIntroduction - : Electronic Parking Brake Systems (EPB)Hesham SalehNo ratings yet

- Chapter 1 Det1013Document35 pagesChapter 1 Det1013siti zuraini100% (1)

- Can Test BoxDocument3 pagesCan Test Boxjulio261No ratings yet

- Starting SystemDocument19 pagesStarting SystemJonathan Javier Ceballos Bonilla100% (1)

- Catalog Caterpillar Electronics Products Control Modules Displays Monitors Electrical Components CommunicationsDocument35 pagesCatalog Caterpillar Electronics Products Control Modules Displays Monitors Electrical Components Communicationsleaw81No ratings yet

- CAN Bus Serial Protocol DecodingDocument5 pagesCAN Bus Serial Protocol Decodingfillafolio100% (2)

- SE EFI Installation ManualDocument85 pagesSE EFI Installation ManualTiến Minh100% (1)

- Injection and Ignition SystemsDocument18 pagesInjection and Ignition Systems4gen_7No ratings yet

- Tech Tool Adapters and Cables V1.15Document17 pagesTech Tool Adapters and Cables V1.15edelsagua70100% (1)

- Haltech Platinum Sprint 500 ManualDocument19 pagesHaltech Platinum Sprint 500 ManualDaniel Kurniawan67% (3)

- Automotive Engine ElectronicsDocument5 pagesAutomotive Engine Electronicsmachine tunisieNo ratings yet

- Requirements and Types of Starting SystemsDocument34 pagesRequirements and Types of Starting SystemsChandan135100% (1)

- Introduction To Vehicle Electronic Systems and Fault DiagnosisDocument20 pagesIntroduction To Vehicle Electronic Systems and Fault Diagnosisyogita patil100% (1)

- Curso Scaner NextechDocument56 pagesCurso Scaner NextechJuan Manuel VasquezNo ratings yet

- Components of The Ignition SystemDocument5 pagesComponents of The Ignition SystemJaston MwicheNo ratings yet

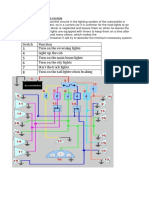

- Automotive Lighting SystemDocument4 pagesAutomotive Lighting SystemWilson Acosta Liñan100% (1)

- Standards and Codes: What Is A Standard?Document78 pagesStandards and Codes: What Is A Standard?Sachin kumar MaileNo ratings yet

- Automotive Science and Mathematics AnswersDocument14 pagesAutomotive Science and Mathematics AnswersBig FloresNo ratings yet

- Ignition SystemDocument51 pagesIgnition SystemEyob TeklemariamNo ratings yet

- HP Injection Valve HDEV 52 Datasheet 51 en 2776067211pdfDocument4 pagesHP Injection Valve HDEV 52 Datasheet 51 en 2776067211pdfPaula JurcăuNo ratings yet

- Ignition System BasicsDocument27 pagesIgnition System BasicsRajesh KumarNo ratings yet

- Bosch Motronic FailuresDocument1 pageBosch Motronic FailuresQaisara Ewa SyafawatiNo ratings yet

- Bosch Motronic FailuresDocument1 pageBosch Motronic FailuresQaisara Ewa SyafawatiNo ratings yet

- Bosch Motronic FailuresDocument1 pageBosch Motronic FailuresQaisara Ewa SyafawatiNo ratings yet

- ECU MS 4 Sport: Bosch Motorsport ManualDocument23 pagesECU MS 4 Sport: Bosch Motorsport ManualmohsihummerNo ratings yet

- Hybrid02 SYS OPERATION-dikonversiDocument22 pagesHybrid02 SYS OPERATION-dikonversiJajankAbdullohNo ratings yet

- Unit 4-AEEDocument92 pagesUnit 4-AEEMrs G Hemalatha PSG-PTCNo ratings yet

- Gasoline Direct InjectionDocument21 pagesGasoline Direct InjectionhoangNo ratings yet

- Electronic Sensors in Off-Road VehiclesDocument8 pagesElectronic Sensors in Off-Road VehiclesKrunal Gandhi100% (1)

- Astm E426-98 R03 E03 Et PDFDocument4 pagesAstm E426-98 R03 E03 Et PDFJORGE ARTURO TORIBIO HUERTA100% (1)

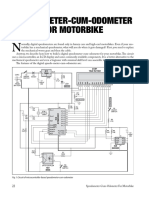

- Speedometer-Cum-odometer For MotorbikeDocument6 pagesSpeedometer-Cum-odometer For MotorbikeAnonymous 8pCXXs100% (2)

- Electric Vehicle Starting MotorsDocument29 pagesElectric Vehicle Starting MotorsRuth Mwenda100% (1)

- Toyota Vehicle Security System (TVSS) Owners Manual: VIOS - DEC - 2020 - 001Document12 pagesToyota Vehicle Security System (TVSS) Owners Manual: VIOS - DEC - 2020 - 001Pafuncio AlecrimNo ratings yet

- Student Workbook2Document52 pagesStudent Workbook2papipapiiNo ratings yet

- Anti-Lock Braking SystemDocument11 pagesAnti-Lock Braking SystemArjunAgharaNo ratings yet

- Mechatronics - Multiple Choice QuestionsDocument5 pagesMechatronics - Multiple Choice QuestionsDHAYANEETHI SNo ratings yet

- Automobile Engines PDFDocument3 pagesAutomobile Engines PDFPrashant GautamNo ratings yet

- Automotive Electrical SystemDocument6 pagesAutomotive Electrical SystemLuke Scofield100% (1)

- Electrical Systems in Automotive TechnologyDocument9 pagesElectrical Systems in Automotive TechnologyMilind ChitaleNo ratings yet

- Daewoo Matiz 2000-2013 Wheel AlignmentDocument6 pagesDaewoo Matiz 2000-2013 Wheel AlignmentOMARNo ratings yet

- Sensors System, Advanced Fuel Injection System, Computer Control SystemDocument34 pagesSensors System, Advanced Fuel Injection System, Computer Control SystemAdil RandhawaNo ratings yet

- Ignition System Components and Operation ChapterDocument41 pagesIgnition System Components and Operation Chaptersweetu_adit_eeNo ratings yet

- Chapter 1 - Introduction To Automotive Electrical and Electronic SystemDocument26 pagesChapter 1 - Introduction To Automotive Electrical and Electronic SystemThao HuynhNo ratings yet

- Automatic Transmission System SeminarDocument14 pagesAutomatic Transmission System SeminarAnonymous 2YgIckU0No ratings yet

- Sanden LTD - Automobile Air-Conditioning - Mechanical Engg. (ME) Summer Training Project ReportDocument29 pagesSanden LTD - Automobile Air-Conditioning - Mechanical Engg. (ME) Summer Training Project ReportRITESH ROHILLANo ratings yet

- Fuel System of Conventional EFI-dieselDocument27 pagesFuel System of Conventional EFI-dieselnahomNo ratings yet

- Advanced Braking Systems: From Concepts to Cutting Edge TechnologiesDocument24 pagesAdvanced Braking Systems: From Concepts to Cutting Edge TechnologiesMuhammed ImamovićNo ratings yet

- MPFI System ExplainedDocument15 pagesMPFI System Explainedಶಿವರಾಜ್ ಎನ್No ratings yet

- PLC Chapter 2 Input-Out DevicesDocument21 pagesPLC Chapter 2 Input-Out DevicesANIK Kumar SannasiNo ratings yet

- 4 EngineDocument14 pages4 EngineSoeAyeNo ratings yet

- DIGITAL SPEEDOMETER - Measures Speed in Kmph Using Infrared LED & PhototransistorDocument2 pagesDIGITAL SPEEDOMETER - Measures Speed in Kmph Using Infrared LED & PhototransistorSrikanth ReddyNo ratings yet

- j1708 IntroductionDocument5 pagesj1708 Introductionjrsimma100% (1)

- ELECTRONIC DIESEL CONTROL (EDC) SYSTEMDocument9 pagesELECTRONIC DIESEL CONTROL (EDC) SYSTEMSUNIL TNo ratings yet

- Multi Port Fuel Injection SystemDocument4 pagesMulti Port Fuel Injection SystemVarsha SreekumarNo ratings yet

- Anti-Lock Braking System (ABS) & Electronic Brake-Force Distribution (EBD or EBFD) SystemDocument15 pagesAnti-Lock Braking System (ABS) & Electronic Brake-Force Distribution (EBD or EBFD) SystemAkshit GoyalNo ratings yet

- 556U Immobolizer InterfaceDocument9 pages556U Immobolizer InterfaceLuis Perez100% (1)

- Basic of MPX (Multiplex Communication) 1. GeneralDocument7 pagesBasic of MPX (Multiplex Communication) 1. Generaldima65No ratings yet

- VR BookDocument186 pagesVR Bookanon_320955915No ratings yet

- 1.automotive Electrical LabDocument16 pages1.automotive Electrical LabSathya NarayananNo ratings yet

- Different Types of VVT VTECDocument12 pagesDifferent Types of VVT VTECshahrizalNo ratings yet

- Hall EffectDocument3 pagesHall EffectQaisara Ewa SyafawatiNo ratings yet

- 1.1 TI-B Ignition SystemDocument6 pages1.1 TI-B Ignition SystemQaisara Ewa SyafawatiNo ratings yet

- Induction MotorDocument6 pagesInduction MotorHamdani RizkiNo ratings yet

- Autotronic 2 Multiplexing Session at Malaysia France InstituteDocument12 pagesAutotronic 2 Multiplexing Session at Malaysia France InstituteQaisara Ewa SyafawatiNo ratings yet

- Mo TronicDocument5 pagesMo TronicQaisara Ewa SyafawatiNo ratings yet

- Hall EffectDocument3 pagesHall EffectQaisara Ewa SyafawatiNo ratings yet

- 1.1 TI-B Ignition SystemDocument6 pages1.1 TI-B Ignition SystemQaisara Ewa SyafawatiNo ratings yet

- Hall EffectDocument3 pagesHall EffectQaisara Ewa SyafawatiNo ratings yet

- Ignition System FundamentalDocument27 pagesIgnition System FundamentalEmad SatariNo ratings yet

- Types of SensorsDocument1 pageTypes of SensorsQaisara Ewa SyafawatiNo ratings yet

- Allegro Selection GuideDocument16 pagesAllegro Selection GuidelalociscoNo ratings yet

- Magnetic Fields Tutorial 7: Magnetic Forces and FieldsDocument2 pagesMagnetic Fields Tutorial 7: Magnetic Forces and FieldsLihle LuhadiNo ratings yet

- Measurement of High Voltages and High CurrentsDocument3 pagesMeasurement of High Voltages and High CurrentspriyadarshniNo ratings yet

- 22 Series BLDC Motor: Wire DiagramDocument13 pages22 Series BLDC Motor: Wire DiagramСергей СалтыковNo ratings yet

- Measure Linear Displacement with Potentiometers & LVDT SensorsDocument16 pagesMeasure Linear Displacement with Potentiometers & LVDT SensorsCristian GodeanuNo ratings yet

- Laboratory 2 Hall-Effect Sensors: ME 104 Sensors and Actuators Fall 2003Document13 pagesLaboratory 2 Hall-Effect Sensors: ME 104 Sensors and Actuators Fall 2003Jalaj JainNo ratings yet

- Lattice Vibrations and Free Electron TheoryDocument43 pagesLattice Vibrations and Free Electron TheoryᎽᎪsh ᏒᎪj sᎥᏁᎶhNo ratings yet

- SS5080 Sensor Hall SeriesDocument4 pagesSS5080 Sensor Hall SeriesAnonymous ePW4IGwRWNo ratings yet

- Av02 2420enDocument22 pagesAv02 2420enaani13No ratings yet

- Universal Current SensorDocument24 pagesUniversal Current SensorZakir Uddin Ahmad57% (7)

- Lecture 11 Conduction in Metals and Hall EffectDocument19 pagesLecture 11 Conduction in Metals and Hall EffectGauri Deshmukh KaranjgaokarNo ratings yet

- What Are The Types of Pneumatic Actuators AvailableDocument11 pagesWhat Are The Types of Pneumatic Actuators AvailableKalum ChandraNo ratings yet

- 35257lecture 6 - 1-15Document15 pages35257lecture 6 - 1-15Bane San MiguelNo ratings yet

- Automate Slot Cars With An Arduino - Arduino Project HubDocument22 pagesAutomate Slot Cars With An Arduino - Arduino Project HubPhops FrealNo ratings yet

- Ali - Tachometers An OverviewDocument22 pagesAli - Tachometers An Overviewsunil1237No ratings yet

- Hall EffectDocument8 pagesHall EffectMohamed NajimNo ratings yet

- Data SheetDocument13 pagesData SheetJuanito Naxito Jebus ArjonaNo ratings yet

- Lab Skill Workbook - Applied Physics - Seph0009 07-12-2023Document87 pagesLab Skill Workbook - Applied Physics - Seph0009 07-12-2023rahulsaitalasilaNo ratings yet

- Hebi Teardown PresentationDocument22 pagesHebi Teardown PresentationPrashant Kumar100% (1)

- AN296065 Allegro Hall Effect Sensor ICs PDFDocument5 pagesAN296065 Allegro Hall Effect Sensor ICs PDFPhong DoNo ratings yet

- 3D Hall-Effect Position Sensor Offers Stray-Field CompensationDocument4 pages3D Hall-Effect Position Sensor Offers Stray-Field CompensationCarlos H. CarneiroNo ratings yet

- Lab 1 ReportDocument11 pagesLab 1 ReportangelosoutiNo ratings yet

- Ss40F, Ss40Af: Bipolar Hall-Effect Digital Position Sensor IcsDocument6 pagesSs40F, Ss40Af: Bipolar Hall-Effect Digital Position Sensor IcsNaur AvilaNo ratings yet

- Amploc: 50 Ampere RatingDocument1 pageAmploc: 50 Ampere RatingRezaadityamuhaNo ratings yet