Professional Documents

Culture Documents

Physical Inventory

Uploaded by

pprasad_g9358Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Physical Inventory

Uploaded by

pprasad_g9358Copyright:

Available Formats

Inventory Sampling o Randomly selected stocks of the company are physically counted on the

balance sheet key date. o If found not much variance between the counted stock and the book

book stock, it is presumed that the book inventory balances for the other stocks are correct.

Physical Inventory Process Cycle Flow 1. Creation of physical inventory document - Physical

inventory document(s) is created individually or using the batch program, click for more

information - The transaction codes for creation physical inventory are as follow Individual

Inventory documetion creation MI01 - Individual physical inventory creation MIS1 - Inventory

Sampling document creation MICN - Cycle count inventory document creation Collective

Inventory document creation MI31 - Own stock without spcial stock MIK1 - Vendor consignment

MIQ1 - Project stock MIM1 - Returnable Transporation material MIW1 - Customer Consignment

stock MIV1 - Returnable material with customer MIO1 - Material provided to Vendor

(Subcontracting material) 2. Print physical inventory document - Physical Inventory document can

be printed based on the physical inventory document status and or item status - Transaction code

MI21 is used to print the inventory document where print default value can be populated 3. Count

the physical stock - Based on the inventory doucmen printout, the warehouse person will check

the stock of material physically and note that on print out. This is completely physical process. 4.

Enter count in system - On completion of physical count, the count result is needs to be entered

in the system. This can be with reference (using Tcode MI04) or without reference (using Tcode

MI04) to the physical inventory document. - If count quantity for that material is ZERO then select

ZC (zero count) column instead of putting 0 in qty field. If 0 is used for zero count then systm will

consider that as "not counted" 5. Analyze difference - Once count is posted in the sytem,

difference analysis can be carried out using trasnaction MI20 - The output gives information

based on the input criteria i.e. physical inventory document, plant, material etc. - The output gives

information about the book quantity, Counted quantity, difference in quantity and value. - From

this output list, you can carry out further process ie initiate recount, change count quantity, post

difference 6. Initiate recount and follow the steps 3,4,5 - If found unacceptable difference, recount

is initiated using directly from difference analysis list (transaction code MI20) or using transaction

code MI11. - New inventory document will be created for selected items or for entire document -

The original document items will be deactivated once recount is initiated so original document will

not be available for further process. - On initiating recount, you need to process same as for new

count document. 7. Post the difference - Several options are available for posting difference -

Post difference after count is posted using transaction code MI07 - Posting the count and

inventory differences using transaction code MI08, here you have created physical inventory but

not counted so with this you can count and post difference in sinle step. - Entering the count

without a document reference using trasnaction code MI10, with this you can create inventory

document, enter the count and post difference in single step. some more points for posting

difference - Posting period must be open to post inventory difference. - The fiscal year is set by

specifying a planned count date when creating a physical inventory document. - Tolerence to

crear difference per user group can be set in customization. - The system will generate material

document for the difference qty and post the value to appropriate account (for valuated stock) -

The movement type in material document will be 701 or 702 based on gain or loss of material

You might also like

- Invest in Your Career by Managing Your Online Brand: Malin Lidén, VP Community, Sap SeDocument19 pagesInvest in Your Career by Managing Your Online Brand: Malin Lidén, VP Community, Sap Sepprasad_g9358No ratings yet

- SAP SD Configuration GuideDocument25 pagesSAP SD Configuration GuideSreeja ManojNo ratings yet

- Data Migration to S/4 HANA GuideDocument6 pagesData Migration to S/4 HANA GuideSeang Hok YievNo ratings yet

- E01 Coal Fired Power GS AD GCT PDFDocument6 pagesE01 Coal Fired Power GS AD GCT PDFpprasad_g9358No ratings yet

- Coal Fired Thermal Power PlantsDocument14 pagesCoal Fired Thermal Power Plantspprasad_g9358No ratings yet

- Project Management Tools and Techniques in High-Technology SmesDocument21 pagesProject Management Tools and Techniques in High-Technology Smespprasad_g9358No ratings yet

- SAP - Solution Template For Electricity IndustryDocument4 pagesSAP - Solution Template For Electricity IndustryPrasanta SanyalNo ratings yet

- TPPDocument36 pagesTPPpprasad_g9358No ratings yet

- E01 Coal Fired Power GS AD GCT PDFDocument6 pagesE01 Coal Fired Power GS AD GCT PDFpprasad_g9358No ratings yet

- Relevance of Critical Success Factors - OPGCDocument14 pagesRelevance of Critical Success Factors - OPGCpprasad_g9358No ratings yet

- Ash Handling SystemDocument16 pagesAsh Handling SystemGirish HegdeNo ratings yet

- Fuel ManagementDocument27 pagesFuel Managementpprasad_g9358100% (1)

- Strategy for Running a Change Management OrganisationDocument39 pagesStrategy for Running a Change Management OrganisationypraviNo ratings yet

- Eight Key Factors To Ensuring Project Success PDFDocument4 pagesEight Key Factors To Ensuring Project Success PDFpprasad_g9358No ratings yet

- Solutions SAP ERP FactsheetDocument3 pagesSolutions SAP ERP Factsheetpprasad_g9358No ratings yet

- Processing Credit Memo Requests - Workflow1Document2 pagesProcessing Credit Memo Requests - Workflow1pprasad_g9358No ratings yet

- New Coal Fired Cost and Performance Estimates (2009, Sargeant & Lundy)Document82 pagesNew Coal Fired Cost and Performance Estimates (2009, Sargeant & Lundy)scribdjemNo ratings yet

- Isaac Coker PresentationDocument34 pagesIsaac Coker Presentationpprasad_g9358No ratings yet

- Function ModuleDocument2 pagesFunction Modulepprasad_g9358No ratings yet

- Eight Key Factors To Ensuring Project Success PDFDocument4 pagesEight Key Factors To Ensuring Project Success PDFpprasad_g9358No ratings yet

- Solutions SAP ERP FactsheetDocument3 pagesSolutions SAP ERP Factsheetpprasad_g9358No ratings yet

- Sap Oil & GasDocument2 pagesSap Oil & Gaspprasad_g9358100% (1)

- Sap MM Quick GuideDocument146 pagesSap MM Quick GuideEkjyot100% (4)

- KPMG GST TipsDocument1 pageKPMG GST Tipspprasad_g9358No ratings yet

- GST Training Highlights Key ImpactsDocument9 pagesGST Training Highlights Key Impactspprasad_g9358No ratings yet

- MTO MTS Process Food IndustryDocument23 pagesMTO MTS Process Food Industrypprasad_g9358No ratings yet

- GST-Phase-1 TrainingCourse 2015 PDFDocument2 pagesGST-Phase-1 TrainingCourse 2015 PDFsrinivasNo ratings yet

- Document Types SAP MMDocument10 pagesDocument Types SAP MMpprasad_g9358100% (1)

- Processing Credit Memo Requests - Workflow1Document2 pagesProcessing Credit Memo Requests - Workflow1pprasad_g9358No ratings yet

- Document Types SAP MMDocument10 pagesDocument Types SAP MMpprasad_g9358100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Cable Instrumentos KerpenDocument56 pagesCable Instrumentos KerpenAlexander Ariza NadjarNo ratings yet

- 123 Winner's Road New Employee Town, PA 12345Document3 pages123 Winner's Road New Employee Town, PA 12345Rachel CarongoyNo ratings yet

- Breakdown & Corrective Maintenance SapDocument18 pagesBreakdown & Corrective Maintenance SapShashanka KshetrapalasharmaNo ratings yet

- UHU Papercraft Dm2 StuartDocument3 pagesUHU Papercraft Dm2 StuartTeckhun LuckNo ratings yet

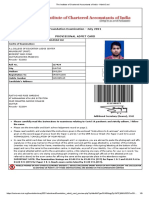

- Foundation Examination - July 2021 Provisional Admit CardDocument9 pagesFoundation Examination - July 2021 Provisional Admit CardVivekNo ratings yet

- Reusable Plastic Pallet Case StudyDocument2 pagesReusable Plastic Pallet Case StudyJuanita Hayes100% (1)

- Confessions of A Direct Mail Guy PDFDocument331 pagesConfessions of A Direct Mail Guy PDFMichael F Sineni50% (2)

- Human-Centered Design Class Prototyping ProcessDocument15 pagesHuman-Centered Design Class Prototyping Processdreamer4077No ratings yet

- Alphabroder - Carton Specification-Version 7.0. 2019Document2 pagesAlphabroder - Carton Specification-Version 7.0. 2019DebashishDolonNo ratings yet

- Card Board Boxes: Apitco Project ProfilesDocument3 pagesCard Board Boxes: Apitco Project ProfilesDurga PrasadNo ratings yet

- How to write a business letterDocument5 pagesHow to write a business letterNatalia PiragautaNo ratings yet

- All PagesDocument41 pagesAll PagesArjun ShuklaNo ratings yet

- Francisco vs. Chemical Bulk Carriers, Inc., G.R. No. 193577, September 9, 2011Document2 pagesFrancisco vs. Chemical Bulk Carriers, Inc., G.R. No. 193577, September 9, 2011Johnny100% (1)

- Global agents wanted for digital printing equipment manufacturerDocument6 pagesGlobal agents wanted for digital printing equipment manufacturerGiri Kanyakumari100% (1)

- Business Permit Application SummaryDocument4 pagesBusiness Permit Application SummaryMathenie DavidNo ratings yet

- Strategy & Booklist for RBI Grade B ExamDocument3 pagesStrategy & Booklist for RBI Grade B Examkiransurya2No ratings yet

- Auditing Cash Equivalents ProblemsDocument1 pageAuditing Cash Equivalents ProblemsJorz Pantaleta50% (8)

- Bauma 2016 ExhibitorsDocument3 pagesBauma 2016 Exhibitorsfredaster21No ratings yet

- 3D Printing For DummiesDocument2 pages3D Printing For DummiesSukrit ChatterjeeNo ratings yet

- AMD Sample Aptitude Placement Paper Level1Document7 pagesAMD Sample Aptitude Placement Paper Level1placementpapersample100% (1)

- Rift Valley University Excel for Accounting and FinanceDocument12 pagesRift Valley University Excel for Accounting and Financeabdella100% (1)

- FIRST QUIZ Q1 NEW NORMAL AutosavedDocument16 pagesFIRST QUIZ Q1 NEW NORMAL AutosavedClarissa Dela CruzNo ratings yet

- Barcode Sticker Hire Purchase Scheme InstructionsDocument2 pagesBarcode Sticker Hire Purchase Scheme InstructionsAkhtar RajaNo ratings yet

- Shree Hari Printers Job Records and AccountsDocument6 pagesShree Hari Printers Job Records and AccountsVidhita AgrawalNo ratings yet

- Incidents in The Life of An InstrumentDocument3 pagesIncidents in The Life of An InstrumentMona Liza100% (1)

- Nowata CapabilitiesDocument4 pagesNowata CapabilitiesKetan KarandikarNo ratings yet

- W&P Paper Manufacturing and Ideas For An Overall Sustainable ProcessDocument55 pagesW&P Paper Manufacturing and Ideas For An Overall Sustainable ProcessDinesh ChahalNo ratings yet

- Sop ReceivingDocument6 pagesSop ReceivingpoetoetNo ratings yet

- Kinds of MoneyDocument24 pagesKinds of MoneyIntet Nuestro100% (1)