Professional Documents

Culture Documents

Heat Exchanger Selec

Uploaded by

wassiliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heat Exchanger Selec

Uploaded by

wassiliCopyright:

Available Formats

lOMoARcPSD|2871284

Sample/practice exam June 2011-2015, questions

Process Heat Transfer (University College London)

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

Answer 4 question in total. Only the first four answers will be marked.

All answers carry a total of 25 marks each, distributed as shown 11

1. a) Derive an expression for the radiant heat transfer rate per unit area between two

large parallel planes of emissivity s1 and 6.2 which are at absolute temperature T1 and

T2 respectively. Show the equivalent circuit representation of this arrangement. [8]

b) Two such planes are situated 2.5 mm apart in air. One has an emissivity of 0.1

and is at a temperature of 350 K, and the other has an emissivity of 0.05 and is at a

temperature of 300 K. Assume that there is no convection in the very narrow space

between the planes. Take the Stefan-Boltzmann constant = 5.67 x 10-8 W m K4

and the thermal conductivity of air = 0.026 W ITI-1 K-1. Calculate:

i) The heat transfer by thermal radiation between the planes. [4]

ii) The total heat transfer by conduction and radiation between the two planes. [4]

c) Assuming that the following figures show cross-section of long elements,

determine all the view factors for the following geometries. Note that letters indicate

lengths. [9]

2

3

a

a 2 4

1 a

b

1

2. a) Describe with the aid of a sketch how the local heat transfer coefficient and

hydrodynamic boundary layer thickness varies along a plane surface as the flow

regime changes from laminar to turbulent. Assume the transition period between the

two regimes occurs instantly. [8]

b) Formulate an expression for the overall heat transfer coefficient for a plane

surface taking the local Nusselt number for laminar and turbulent flow to be:

hx'turbX

Nux,tur 0.0296Re 415 Pril3

lanzx

Nu, am ' 0.331Re2 /2 Pr1/3

k

Take the critical value of the Reynolds number to be 5x105. [11]

Question 1 continued

TURN OVER

CENG2006 1

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

c) Describe the physical significance of the Nusselt, Reynolds and Prandtl numbers.

For each, show the relevant equations. [6]

3. a) Derive the Heat Conduction Equation for a large thin plane wall from an energy

balance on the system. Assume constant thermal conductivity. [12]

b) Assuming constant thermal conductivity, show how the heat conduction equation

reduces for the case of: (i) steady state; (ii) transient heat transfer with no heat

generation, and (iii) steady state with no heat generation. [3]

c) Consider a large plane wall L = 0.2 m, thermal conductivity k= 1.2 W m' IC', and

surface area A = 15 m2. The two sides of the wall are maintained at constant

temperatures of T1 = 120 °C and T2 = 50 °C. Assume: Heat conduction is steady;

heat conduction is one-dimensional; thermal conductivity is constant; there is no heat

generation. Using an analytical approach, determine: [10]

i) an expression for variation of temperature within the wall and the value of

temperature at x = 0.1 m (half way through the wall).

(ii) the rate of heat conduction through the wall under steady conditions.

4. Water flows at 2 m s-1 through a 2.5 m length of a 25 mm diameter tube. The tube is

at 320 K and the water enters and leaves at 293 K and 295 K respectively. Taking the

density of water to be 1000 kg m-3 and the specific heat capacity to be

4.18 kJ kg-1 IC', find:

a) The heat load. [4]

b) The log mean temperature difference. [3]

c) The overall heat transfer coefficient. [4]

d) An estimate may be made of the inside heat transfer coefficient (h) from:

= 4280(0.00488T 1)0'8 d0.2

Where T , the mean temperature of water, is 294 K, u is the mean velocity of the

flow (m s') and d is the diameter of the tube (m). From this, calculate the internal

heat transfer coefficient and the thermal resistance of the scale (fouling layer)

between the tube and the water inside the tube. [6]

Question 4 continued

TURN OVER

CENG2006 2

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

c.

e) How would the outlet temperature change if the velocity was increased by 50%?

Assume a mean water temperature of 300 K. 181

5. a) Why is the maximum in the heat flux versus wall superheat curve in pool boiling

called the "burnout point"? [5]

b) Water in a tank is to be boiled at atmospheric pressure by a 5 m long, 1 cm

diameter nickel plated steel heating element equipped with electrical resistance wires

inside. If the temperature of the wire is 115 °C determine the heat flux at the nucleate

boiling regime. [5]

c) What is the rate of water evaporation? [5]

d) Determine the maximum heat flux that can be achieved at the nucleate boiling

regime and the temperature of the heater in that case. [10]

The following equations can be used for pool boiling heat transfer:

Heat flux during nucleate boiling:

g(pi, /2 )\3

q =11Lhfg

C -11 g PrL13

sj f

Critical heat flux:

q = 0.18hfgpG ( cYg(PL -; PG)

Pa

where:

(T,,,-Tsat) is the temperature difference between the wall and the saturated liquid,

Pri, is the liquid Prandtl number,

Cy- is a coefficient whose value depends on the fluid surface combination.

The rest of the symbols have their usual meaning.

You can use the following properties:

Liquid: pi, = 957.9 kg m-3, µz = 0.282x10-3 kg m-I s-1, cpr, = 4217 J kg -1 °C-1

Vapour: pG = 0.6 kg m-3

Also: lifg= 2257x103 J kg', a = 0.0589 N m1 and Cr 0.013

Take the acceleration due to gravity to beg = 9.8 m s-2

Question 5 continued

TURN OVER

CENG2006 3

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

6. a) Describe the four different modes of condensation. [7]

b) Atmospheric pressure saturated steam condenses on the outside of a horizontal

tube with wall temperature T= 60 °C and outer diameter D = 2 cm. Assume that the

condensate forms a laminar film and calculate the mass flow rate per unit length of

tube dripping from the bottom of the tube. [12]

You can use the following equation for the overall heat transfer coefficient 14,

[ ki,3py (pi, pG)ghfg

hL = 0.725

lit,(Ts Tiv)D

Where: pi. is the liquid viscosity, 11/2 is the latent heat of condensation, pi, and pG are

the liquid and gas densities respectively, kL is the liquid thermal conductivity, 7'

the saturation temperature and g is the acceleration of gravity.

Calculate also the film Reynolds number and check if the film laminar flow

assumption is correct. What would be the difference in the mass flowrate of the

condensate if the Reynolds number indicated that the flow in the film is turbulent? 161

You can use the following properties for the steam and the condensate:

Liquid: pi, = 958.4 kg m-3, [IL = 2.84x104 kg nil s-1, kL = 0.682 W m 1 K-1

Vapour: pG = 0.596 kg M-3

kg= 2257x103 J kg-1

Take the acceleration due to gravity to beg = 9.8 m S-2

END OF PAPER

CENG2006 4

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

. Answer 4 question in total. Only the first four answers will be marked.

All answers carry a total of 25 marks each, distributed as shown... []

1. A shell and tube heat exchanger is to be used to heat 150,000 kg hr-I of crude oil from

20 to.57°C. The crude oil will be heated by 129,000 kg hr-1 of non-corrosive liquid

product from the bottom of a distillation column. The initial temperature of the

distillation product is 146°C.

a) Determine the heat load on the exchanger and show that the final

temperature of the distillation product will be 107°C. [51

b) If you were designing a shell and tube heat exchanger for this purpose

which of the two fluids would you pass through the tubes? Why? [31

c) Details of an existing shell and tube heat exchanger are given below. The

plant manager wants to use this exchanger to heat the crude oil. Determine if

it is suitable for the purpose. [17]

In your calculations you can assume an overall fouling resistance, rf , of 1 x10-3 m2 K W-1

and a log mean temperature correction factor of 0.97.

Average fluid properties:

Crude oil Distillation

product

Heat capacity (J kg-I K-I) cp 1.99 x103 2.20 x103

Viscosity (Pa s) 2.9 x10-3 5.2 x10-3

ii

Density (kg m-3) p 825 867

Thermal conductivity (W m-1 K-I) k 0.137 0.119

Prandtl Number (-) Pr 42.1 96.1

Properties of the existing shell and tube exchanger:

Constructed from carbon steel (k = 45 W m-1 K-I).

1 shell pass, 2 tube passes.

Shell diameter 0.59 m.

324 tubes: 15mm inside diameter, 19 mm outside diameter, 5 m in total length

(including both tube passes).

The tubes are arranged with a 25.4 mm square pitch (pt) and the baffle spacing (/b)

is 0.25 m.

Question 1 continued

TURN OVER

CENG2006 1

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

Design equations:

The overall heat transfer coefficient, Uo, in a shell and tube exchanger can be

calculated using:

1 1 deln(del di) do

+ rf

Uo h, 21c, diht

The following correlations can be used to estimate the tube-side and shell-side heat

transfer coefficients:

r. 0.8

htdt

= 0.027 (ltilit) (Prt)113

hsde ( d e G 5)055 (pro113

= 0.36

k it )

where

1.27

de = (79 0.785do2)

d,

03t do)dslb

AS

Pt

As Cross flow area in shell (m2)

At Area for flow in tubes (m2)

de Shell-side-hydraulic-diameter(m)

di Tube inside diameter (m)

do Tube outside diameter (m)

cis Shell inside diameter (m)

G, Mass velocity of fluid in shells Ms/A, (kg s-I m-2)

Gt Mass velocity of fluid in tubes Mt/At (kg s-I m-2)

m2K-1)

hs Shell side heat transfer coefficient (W

ht Tube side heat transfer coefficient (W m-2K-1)

1b a Baffle spacing (m)

pt Tube pitch (m)

2. a) Derive the following s-NTU expression for co-flow heat exchanger operation. [121

UA (1+ Cminy i

1 exp [

Chin C./J

Max

(1 + CMinICMax)

Where e is the heat transfer effectiveness, NTU is the number if transfer units, U

is the overall heat transfer coefficient, A is the heat transfer area, C,nin and Can are

the minimum and maximum heat transfer rates, respectively.

Question 2 continued

TURN OVER

CENG2006 2

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

b) A process fluid (cp = 2200 J kg-I K-I) flowing at 130,000 kg hr-I with a

temperature of 146°C is used to preheat 150,000 kg hr-I of crude oil

(cp = 1990 J kg K-I) initially at 20°C. This is achieved using a 1-2 shell and tube

heat exchanger. When the exchanger is installed the design heat transfer

coefficients are Uckan = 410 W m-2 K-I and the surface area is A = 120 m2. Using

the 6-NTU method determine:

i) the heat exchanged when the heat exchanger is new (U= UClean) [9]

ii) the outlet temperatures when the exchanger is new [4]

Use the following 6-NTU equation for this heat exchanger configuration (where C

is the heat capacity ratio = Cmin/Cmax):

Q 2

E

VMax (1 + exp(NTUV1 + C2))

1 + C + \11 + C2

1 exp(NTUV1 + C2))

3. Consider a cylindrical furnace as shown in Figure 1. Emissivities: si = 0.8 and

62 = 0.4. The side surface closely approximates a blackbody.

2. T2= 500 K

3. T3 = 400 K 62 = 0.4

63 = blackbody

r0= H =1 m

/ Ti = 7u

= 0.8

Figure 1: Illustration of cylindrical furnace with temperature and emissivities of internal

surfaces shown.

a) With the aid of Figure 2, find all of the view factors for the internal surfaces

of the furnace. [71

Find the radiosity of each surface using the direct method. [13]

b)

c) Determine the net rate of radiation heat transfer at each surface during

operation. [5]

Question 3 continued

CENG2006 3

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

TURN OVER

Assumptions:

- Steady operating conditions

- Surfaces are opaque

- Convection heat transfer not considered

Consider furnace to be a 3 surface enclosure

1.0

0.8

fi

0.6

0.4

0.2

0

0.1 0.2 0.4 0.6 0.8 1 2 4 6

Lir;

Figure 2: View factors as a function of geometric dimensions for concentric parallel circular

surfaces.

4. A long, 6.5 cm diameter, solid cylinder is made of steel. It is initially at a uniform

temperature Ti= 150°C. It is suddenly exposed to a convective environment at T , = 50°C,

and the overall surface convective heat transfer coefficient is h= 285 W m-2 K-1.

a) Calculate the Biot number for the system. [6]

b) Calculate the temperature at the axis of the cylinder after 5 minutes of

exposure. [4]

c) Calculate the temperature at a radial distance of 2.5 cm after 5 minutes of

exposure. [4]

d) Determine the total energy transferred from the cylinder per meter length

during the first 5 minutes of cooling. [6]

e) For a vertical slab removed from a hot furnace and left to cool in air, draw

the temperature profiles within the slab as time progresses for a system with

Bi <<1, Bi = 1 and Bi >> 1. [5]

Question 4 continued

CENG2006 4

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

TURN OVER

Take the following values for steel: k= 16.3 W m ICI; a-- 4.44x10-6 m2 s-1;

p= 7817 kg rn.3; cp = 0.46 kJ kg-1 ICI.

Use the following transient heat transfer charts Figures (a), (b) and (c) to solve this

problem.

Question 4 continued

TURN OVER

CENG2006 5

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

'

"11.17

-.

2 14 16 18 20 22 24 26 28 30 40 5 60 0 80 90100 115 130

Centreline temperature as a ftl!nction of time for an infinite cylinder of radius, ro.

0

co

°

tr),t m

.-d cc d N0

f"--

0

000 Cf)

LO CY)

t.0

0-1

O

c; ddddc 8Fc'i

0000 Nq 8O 8q 8000

=4- cf)

0000 0.o

D

O

-1-11 '0

CNJ

"0 .0

0 h c\J

4-4 0 00

Lo.

0 0

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

0

ii

GI

00000 00

co Lc' Lc). 't". Cr) LV

CNI

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

0

....-ye L.. ..---.

4,

- as 0

:.111,11. ....

1

POs T 41i

0t-4

.4...,. .111.Y. ......s1 ke..4

...... r," . tt.,.....

47.

...VV..

0

Lc)

Id.

I

,

--ar

L .. .". 1... 4 ." - 1-4-71...II ..,

0N

4

-le - 4( .;,16 ...... .., las

: YIP.

.... #:-.. L.

4. :Mt 4;0 ...4111 Vf 41

, 1 a.a , 1 le -:,..

t 2

40.

L L'

t,. I _

-r 0

-

. ...,

..._ AA, 406.41.....Wr - Vsl

4it2, mi.?. 0.0*. Wk. ...4

Pe 4,..

.. ....-

.4

A. .1;

1..

.4o v.v..

4k. r,-. ... !---m. ...... aa.k

,44

...... -../ r-% 4.*

...1.1% /..* * . '',:.14.041 ,'......4...s. ....../ 4.0... ...2.

.....4.. It a* .4.... by c-.. . .41%.: ... 0

.r: ..** ... *" 't 1 t a,. *I. .o a aft, .i .*1 ... (1)

.... / 1

f***...*=.

a. S(**,*at...L co

r fl"::: .t ,- 1 14.1.,... ..... ;004.,T4 s...

4. tweg, 40.* :i 4'

e Kt: 1PV

/ as v.4^t- N

i 4

../.

, *At

s1,, v

."...2%. ..1,LV. Y..

2 :-,-.4--,,.1."-0,-., "..." W41.:.-......3

P,- -. or 4:3,..., 41616 ., ....4e11.46+ ...4014#4111,

.

%At-,

.; ta ..,

-... ). ag,,....

.,,,...:

,

"'N. .4

g

.5

at .44.

.. ....

. 1

4,45.4.

-1.,a,

4.4

Pat,

..1.17-,.-41.1.A.4 s..w

......, , . 4 ro III

4

14,41 3,,V.; V

.....m.,.... to, ...rop

61.,

! .?

,141/,:,:. ...';

t 0..i.. ...A re. ,,

..1

Ilf.V **..af 0 00

.. ii C .15

:ea L .ai.: ..* L. --I --' t

`

.**....ail, rA..., ... '-'4,.

i

*

N

.ta,:dr* . i.,.. ' 1-

---: - 07:,

CCS

. , A.t .-

r

,

lo -

.--Is' Ir. .01 ss.

'e! 1" ........01,

..... N ..

... Wt.. 0

- .....

.--4...,,!..

.. ... *

41 ;

0

...: - - . .

- 0 44

17 ci

:4 Q. ,

al C°. (1)

t; c\J od

CD.

0 0 o 0 0 0 0 r3

°i

^ _00

641. I 0

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

5. A saturated mixture of steam and water at 510 K is flowing through a horizontal pipe

with internal diameter 4 cm. The mixture has a qiiality of 0.3 and a mass flux of

3000 kg m-2 s-1. Calculate the frictional pressure drop in the pipe using:

a) the homogeneous model [8]

b) the following correlation suggested by Chisholm for separated flow [14]

C 1

OL2 = 1++

X X2

where PL2 and X2 are the Lockhart-Martinelli parameters and C = 20 for

turbulent-turbulent flow, C = 12 for laminar (liquid)-turbulent flow, C = 10 for

turbulent (liquid)-laminar flow, C = 5 for laminar-laminar flow.

The homogeneous viscosity can be calculated as follows:

1

I-1

= +

x

Itg

1

Ai

x

where:

x is the quality

pig and pti are the gas and liquid viscosities respectively.

You can assume that transition from laminar to turbulent flow for each phase occurs

when its Reynolds number based on superficial velocities is greater than 2000.

c) What are the main assumptions in the above models for homogeneous and

separated flow? 131

The following properties can be used:

Water density = 946 kg m-3, water viscosity = 2.39x10-4 Pa s

Steam density = 1.02 kg m-3, steam viscosity = 16.9x10-6 Pa s

f= 64/Re LAMINAR

f = 0.316/Re°25 TURBULENT

Describe the four different modes of condensation. [8]

6. a)

b) Atmospheric pressure saturated steam condenses on the outside of a horizontal

tube with wall temperature T1 = 60°C and outer diameter D = 2 cm. Assume that

the condensate forms a laminar film and calculate the mass flowrate per unit

length of tube dripping from the bottom of the tube. [12]

Question 6 continued

TURN OVER

CENG2006 9

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

You can use the following equation for the overall heat transfer coefficient hL

1/4

(Pc PG)glif 91

hL = 0.725 [kL3PL

[ PL(Ts Ti,)D i

Where: pi, is the liquid viscosity, hfg is the latent heat of condensation, pi, and pG are

the liquid and gas densities respectively, kL is the liquid thermal conductivity, Ts is the

saturation temperature and g is the acceleration of gravity.

Calculate also the film Reynolds number and check if the film laminar flow

assumption is correct. [51

You can use the following properties for the steam and the condensate:

Liquid: PL.= 958.4 kg m-3, it L= 2.84x10-4 kg m-1 s-1, kL= 0.682 W m-1 K-1

Vapour: pG = 0.596 kg m-3.

hf9 = 2.257x106J kg-1.

END OF PAPER

CENG2006 10

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

Answer 4 questions in total. Only the first four answers will be marked.

All answers carry a total of 25 marks each, distributed as shown. []

I. The walls of a house are 4 m high,S m wide and 0.3 m thick with a thermal

conductivity of k = 0.6 W m'l K· 1 • The temperature of the air inside the house is

20°C and outside it is -lOoC. There is a heat transfer coefficient of 10 W m· 2 K- 1

on the inside and 30 W m- 2 K' on the outside of the wall.

a) Sketch the temperature profile from the air inside to that outside the

house through the thickness of the wall. [6]

b) Calculate the heat flux and total heat flow through the wall. [12]

c) Calculate the inside and outside surface temperatures of the wall. [7]

Assume: one dimensional, steady-state conduction through the wall and

constant thermal properties.

2. A double-pipe, parallel-flow heat exchanger is to be used to cool oil (0.15 kg S·l

at 90°C), using sea water (0.3 kg S·l at 10°C). The area of the heat exchanger is

11.5 m2 and the overall heat transfer coefficient (ll) is 21.9 W m'2 K-'.

1 l l l

(cp,Oi/= 2131 J kg· K and cp,water= 4178 J kg· K' )

a) Calculate the NTU (number of transfer units) for the heat exchanger. [6]

b) Calculate the effectiveness of the heat exchanger. [7]

c) What is the heat duty? [5]

d) What are the exit temperatures for the oil and water from the heat

exchanger? [7]

Take:

1 - exp[-NTU{l + (Cmin/Cmax)}]

E=

1 + (Cmin/Cmax)

where Cmin is the smaller heat capacity ratio and Cmax is the larger heat

capacity ratio.

3. a) What is the criterion for lumped system analysis to be applied for transient

heat conduction? Provide the relevant equation. [3]

b) Based on an energy balance on a body of arbitrary shape, derive an

expression relating the lumped temperature of the body and time. [10]

Question 3 continued

TURNOVER

CENG2006

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

c) A metal sphere 5 cm in diameter (cp = 0.46 kJ kg,l °e l, k = 35 W m,l °e l ,

p = 7800 kg m,3) is cast in a furnace. It is removed at a temperature of

450°C and transferred to a lower temperature oven maintained at 100°C.

The convection heat transfer coefficient is 10 W m -2 °e l •

i) Show that the lumped system analysis can be applied in this case.

ii) Calculate the time required for the ball to attain a temperature of

I50 a C.

[12]

4. a) State what you understand by the term 'black-body' and 'grey body' when

applied to heat transfer. [6]

The spectral, hemispherical absorptivity of an opaque surface and the

spectral irradiation at a surface is shown in Figure 1.

1.0

.....

o......... ....,;iiiii!

0 0 2 4 6 8 10 12 14 16 o 2 4 6 8 10 12 14 16

},(Jlm) ),(Jlml

Figure 1: Spectral, hemispherical absorptivity of an opaque surface (left)

and the spectral irradiation (right) at the surface of the body.

b) Show how the spectral, hemispherical reflectivity will vary with

wavelength? [4]

c) What is the total, hemispherical absorptivity of the surface? [10]

d) If the surface is initially at 500 K and has a total hemispherical emissivity of

0.8, how will its temperature change upon exposure to the radiation? [5]

Assume: the surface is opaque, convection effects are negligible and the

back surface of the body is insulated.

Take the Stefan-Boltzmann constant (0) to be 5.67 x lO- 8 W m- 2 K-4.

TURNOVER

CENG2006 2

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

5. A saturated mixture of steam and water at 51 OK is flowing through a horizontal

smooth pipe with internal diameter 4 em. The mixture has a quality of 0.3 and

mass flux 01'3000 kg m- 2 S-I.

Calculate the frictional pressure drop in the pipe using:

a) the homogeneous model. [8]

b) the following correlation suggested by Chisholm for separated flow:

2 C 1

¢L = 1 +-+-

X X2

[14]

where: C = 20 for turbulent-turbulent flow

C = 12 for laminar (liquid) - turbulent (gas) flow

C = 10 for turbulent (liquid) - laminar (gas) flow

C = 5 for laminar-laminar flow

and ¢ L 2 and X 2 are the Lockhart-Martinelli parameters.

The homogeneous viscosity can be calculated as follows:

1 x 1- x

.-=-+--

11 119 III

where: x is the quality

119 and III are the gas and liquid viscosities respectively.

What are the main assumptions in the above models for homogeneous and

separated flow? [3]

The following properties can be used:

Water density = 818 kg m- 3 , water viscosity = 1.15x 10-4 Pa s

Steam density = 15.8 kg m- 3, steam viscosity = 16.9xI0-6 Pa s

6. Following Nusselt's procedure show that the average heat transfer coefficient,

hL' in film condensation over a vertical flat plate, with length L, for laminar flow

of the film, is given by:

3 1/4

hL = 0.943 [k L PL(PL - PC)Bhr9 ]

IlJTs - Tw)L

[15]

A plane vertical wall of temperature, Tw , 60°C faces a space filled with stagnant

saturated steam at atmospheric pressure. The height, L, of the wall is 2m.

Assume that the film is laminar and calculate the condensate mass flow rate per

unit width of the wall, at the bottom of the wall. [8]

Question 6 continued

TURN OVER

CENG2006 3

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

Is the assumption of laminar film flow correct? [2]

·

The following properties can be used:

Condensate:

density, PL= 972 kg m- 3,

.. 3 10-4 kg m-I S-I ,

VISCOSIty, ilL = x

thermal conductivity, k L = 0.67 W m-1K- 1.

Vapour:

3

density, Pc = 0.9 kg m- .

latent heat, hfg = 2.257xI0 6 J kg-I

Also:

Ts is the saturation temperature,

9 is the acceleration of gravity, 9 = 9.81 m S-2

END OF PAPER

CENG2006 4

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

Answer ALL FOUR questions.

All answers carry a total 0/25 marks each, distributed as shown. []

1. Consider an oil-to-oil double-pipe heat exchanger with the same type of oil each side

of the heat exchanger and whose flow atTangement is not known. The temperature

measurements indicate that the cold oil enters at 20°C and leaves at 55°C, while the

hot oil enters at 80°C and leaves at 45°C.

a) Is the flow CO-CUtTent or counter-current and why? [2]

b) What is the effectiveness of this heat exchanger? [15]

C) Name 4 types of heat exchanger fouling. [4]

d) Name 4 variables that affect fouling. [4]

TURNOVER

CENG2006

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

2. a) Determine the view factor for the following geometries:

i) a sphere within a box (find F 12 and F 2/ ) (Figure 1)

ii) a long triangular duct (find Fl!' F 12 , F21 and F 13 ) (Figure 2)

L /)

Figure 1. Sphere within a box

T .-\ 1

L A.').:..

.1 ..\3

Figure 2. Triangular duct

[101

b) A thin aluminium plate with an emissivity of 0.1 on both sides is placed between two

very large parallel plates that are maintained at a lmiform temperature of T1 = 800 K

and Tz = 500 K with emissivities of El = 0.2 and Ez = 0.7. Determine the net heat

transfer rate with and without the aluminium shield. Assume that the surfaces are

opaque, diffuse and grey.

Take the Stefan-Boltzmarm constant (J = 5.67 x 10'8 W m'2 K-4. [151

3. a) A steel ball 12 mm in diameter is initially held at 1150 K and then cooled to

400 K in air for which Too = 325 K and h = 20 W m,2 K'J.

Assuming the properties of the steel to be k = 40 W m -I K'l, P = 7800 kg m'3, and

Cp = 600 J kg' K'i,

i) Check if a lumped system can be used here [5]

ii) Estimate the time required for the cooling process. [12]

b) Consider a large slab that is initially hot and then cooled in air. Sketch how the

temperature gradient varies with time through the thickness of the slab at its

centre for a system with Bi »1 and Bi « 1 where Bi is the Biot number. [8]

TURNOVER

CENG2006 2

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

4. a) Describe the different regimes of pool boiling occurring when an electrically

heated horizontal wire (heat flux changes) is immersed in a pool of water at its

saturation temperature. How does the heat flux vary with the difference between

the wire temperature and the saturation temperature of water? [10J

b) Water is boiled at atmospheric pressure by a horizontal copper heating wire of

diameter D = 5 mm and emissivity E = 0.05, immersed in a pool of water. If the

temperature of the heating wire is 350 e C, determine the rate of heat transfer from

the wire to the water per unit length of the wire. [15]

You can assume that film boiling occurs together with radiation. The following

equations can be used for the heat transfer coefficients:

Heat transfer coefficient for film boiling:

3(

k c Pc PL - Pc)gh fg )1/4

h film = 0.62 ( D

fic

(T

w

- T

sat

)

Heat transfer coefficient for radiation:

CTE(Tw 4 - Tsat 4)

h rad =

Tw - Tsat

The overall heat transfer coefficient is given by:

3

h tat = hfilm + "4 h rad

Where:

k c = 0.00358 W m-I ec- I, is the vapour thermal conductivity

fie = 0 .75 x 10-5 Pa s, is the vapour viscosity

Pc = 0.444 kg m-], is the vapour density

PL = 957.9 kg m-], is the water density

h fg = 2257 x 103 J kg-I, is the latent heat

T w is the temperature of the heating wire

T sat is the saturation temperature of water

9 = 9.81 m S·2

CT = 5.68 x 10. 8 W m- 2 K-4 is the Stefan-Boltzmann constant

END OF PAPER

CENG2006 3

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

Answer ALL FOUR questions.

Each question carries a total of 25 marks, distributed as shown [ ]

1. A 10m long and 10 mm inner diameter pipe made of commercial steel is used to heat a

liquid in an industrial process. The liquid enters the pipe with an inlet temperature

T j = 25°C and a volumetric flow rate V = 0.8 m S-I. A uniform heat flux is maintained by

an electrical resistance heater wrapped around the outer surface of the pipe, so that the

fluid exits at 75°C.

Assuming fully developed flow and taking the following properties of the fluid:

Density Specific heat Viscosity Thermal conductivity Prandtl number

p Co fJ k Pr

1000 kgm- J 4000 J kg-I. K- I 0.002 kg m-ls' 0.48 W m·1K· 1 10

Determine:

(a) the required surface heat flux q produced by the heater (in W m- 2 ).

[7]

(b) the surface temperature at the exit Te using Nu = 0.023Reo. 8 PrO. 4 (in °C).

Herein Nu is Nusselt number, Re is Reynolds number and Pr is Prandtl number.

[12]

(c) the pressure loss through the pipe (in Pa) using the equation of

b.P 2fpV 2

L D

and Moody chart as shown in Figure Q.l. [6]

e, cm

I Turbulent

Drawn Tubing 0.00015

0.020 Transitional : Commercial Steel 0.0046

. I Asphah Cast Iron 0.012

Lamlnar I

I Galvanized Iron 0.Q15

0.Q15 I Cast Iron 0.026

I Wood Slave 0.0185-0.090

S: I

Concrete 0.03-0.3

:::J 0.010 Rivetted Steel 0.090·0.90 0.01

0.009

Q. 0.008

<:l 0.004

II 0.007

.....

0.006

C5

ti

rf. 0.005 f- 0.0791 / ,

c

ono

'i::

0.004

f= 16JRe

- (Re) 0.25 "

, ,

0.0004

u.. (Circular Pipe Only) 0.0001

0.003

0.00005

0.002

1(]l 2 3 4568, 0 4 105 106

Re =umd;/v

Figure Q.1. Moody chart TURNOVER

CENG2006

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

2. (a) How does co-current fluid flow differ from counter-current fluid flow?

[5]

Illustrate the temperature change in both cases (expressed by schemes)

[7]

(b) A double pipe counter flow heat exchanger is to be used to cool ethylene glycol

(specific heat cp = 2560 J kg- l °e l ) flowing at a rate of 3.5 kg S·I from 80°C to 40 °C

in the inner pipe using water (cp = 4180J kg-IC· I ) that enters at 20°C and leaves at

55 °C in the outer pipe. The overall heat transfer coefficient based on the inner

surface area of the tube is 250 W m-2 K- l .

Determine:

(i) the rate of heat transfer Q (in kW). [7]

(ii) the mass flow rate of water (in kg s-I). [6]

CONTINUED

CENG2006 2

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

3. A furnace is shaped like a long duct with a cross section shaped as an equilateral triangle

as shown in Figure Q.3. The width of the base is 1 m. The surfaces may be approximated

as grey bodies and have an emissivity Cj of 0.75. The base is heated externally and

maintained at 1200 K, while the two sides are maintained at 750 K.

(a) Derive the electrical circuit equivalent to the radiative heat transfer process.

[5]

(b) Determine the view factors for this geometry.

[5]

l

(c) Determine the rate of heat transfer per unit length (in kW m- ) that is supplied to

the base surface in order to maintain these operating conditions. The surface

resistance Ri is given by

and the space resistance Rij by

where Ai is area of surface i, Ci is emissivity of surface i and Fi} is the view factor from

surface i to surface j. The Stefan-Boltzmann constant is ( j = 5.67 . 10-8 W m-2 K"4. Neglect

end-effects and assume radiation to be the only relevant heat transfer mechanism.

[15]

Figure Q.3. Cross section of the furnace

TURNOVER

CENG2006 3

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

4. (a) Define the Lockhart-Martinelli parameter X [3]

Water is vaporised in a forced convection boiler that operates at 9.3 bar pressure and

450 K temperature. The water enters the tubes with a mass flux of 2000 kg sol m-2 • The

tubes of the boiler are smooth with internal diameter 20 mm and wall temperature 480 K

(saturation pressure = 17.9 bar). At a point where 5% of the liquid mass has vaporised,

calculate:

(b) the convective part of the heat transfer coefficient [12]

(c) the flow boiling part of the heat transfer coefficient [8]

(d) the local heat transfer coefficient [2]

You can use the following equation for the heat transfer coefficient by convection, hc , in

the gas-liquid mixture:

hc = 0023

. kDL Re TP 0.8prL 0.4

and the following equation for the heat transfer coefficient by pool boiling, h PB :

k 0.79 0.45 0.49 )

_ L CpL PL 0.24 0.75

h PB - 0.00122 ( 024 (Tw - TSAT ) (Pw - P SAT )

(j0.5fl 0.29 h . P 0.24

L fg C

where

ReTP is the two phase Reynolds number,

PrL is the liquid Prandtl number

Tw and TSAT are the wall and the liquid saturation temperatures respectively, and

Pw and PSATare the saturation pressures corresponding to the wall and the liquid

temperatures

P is density

fl is viscosity

k is thermal conductivity

cp is heat capacity

(j is the liquid surface tension

hf9 is the latent heat of vaporisation

and the subscripts Land G refer to the liquid and gas phases respectively.

Fluid properties

Liquid at 450 K: PL = 890 kg m-3, flL = 1.51 . 10-4 kg m'l S-l, k L = 0.679 W m- I K- I, CpL = 4390 J kg- l K- I

Vapour at 450 K: Pc = 4.8 kg m- 3, flc = 14.9 x 10-6 kg m- I S-I

hfg = 20.2,10 5 J kg-I, (j = 42.9' 10-3 N m- I

CONTINUED

CENG2006 4

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

lOMoARcPSD|2871284

You can also use the graphs below:

100

.....

V

V

./

/

u :,,1'

)/

U. 10

./

./

/

,;'

/

........1'

..... 1--'

V "

1

0.1

---- 10 100

1/X

Figure Q4.1: Graph of Fe parameter against l/X

0.9

""" '"

0.8

0.7

0.6

"'-

(,J

(J) 0.5

0.4

"" ........

.........

0.3

0.2

0.1

'" ----- r-

o

1.E+04 1.E+05 1.E+06

ReTP

Figure Q4.2: Graph of Se parameter against the two-phase Reynolds number

END OF PAPER

CENG2006 5

Distributing prohibited | Downloaded by was ki (wassiliftw@gmail.com)

You might also like

- Heat Transfer (HT) QueDocument6 pagesHeat Transfer (HT) QueAshutosh KushwanshiNo ratings yet

- JNTU Hyderabad Heat Transfer Exam QuestionsDocument2 pagesJNTU Hyderabad Heat Transfer Exam QuestionsAsheesh Kumar100% (1)

- Heat Transfer Operation Winter 2019 Question PaperDocument4 pagesHeat Transfer Operation Winter 2019 Question PaperMitesh ThakurNo ratings yet

- Exam Jan 2007Document5 pagesExam Jan 2007Sam RutherfordNo ratings yet

- WWW - Manaresults.Co - In: (Common To ME, AME, MSNT)Document2 pagesWWW - Manaresults.Co - In: (Common To ME, AME, MSNT)Asheesh KumarNo ratings yet

- (Sem. Iv) Theory Examination 2013-14: PAPER ID: 151406Document2 pages(Sem. Iv) Theory Examination 2013-14: PAPER ID: 151406Sarvesh KumarNo ratings yet

- MidSem 2016Document2 pagesMidSem 2016avi0341No ratings yet

- 4363 112 Heat TransferDocument6 pages4363 112 Heat Transferyogesh_b_kNo ratings yet

- Fluid Mechanics and Heat Transfer April May 2008 Question PaperDocument8 pagesFluid Mechanics and Heat Transfer April May 2008 Question PaperelimelekNo ratings yet

- 07a40801 Process Heat TransferDocument8 pages07a40801 Process Heat TransferSRINIVASA RAO GANTANo ratings yet

- CH8591 - Heat TransferDocument5 pagesCH8591 - Heat TransferS9048 SUDHARSAN ANo ratings yet

- Question Paper Code:: Reg. No.Document3 pagesQuestion Paper Code:: Reg. No.jgkgopiNo ratings yet

- 09 - Chapter 1Document2 pages09 - Chapter 1Mohammed SohailNo ratings yet

- HTDocument2 pagesHTPrashant27992No ratings yet

- 2222Document3 pages2222ArunNo ratings yet

- 2222Document3 pages2222ArunNo ratings yet

- Rr310803 Heat TransferDocument8 pagesRr310803 Heat TransferSaravanan MathiNo ratings yet

- Donnee Exo SupplDocument5 pagesDonnee Exo SupplMohamud LhafNo ratings yet

- KCT 2010-2011 HTDocument4 pagesKCT 2010-2011 HTask4krishnanNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityPARMAR MAHENDRANo ratings yet

- Heat Transfer Document AnalysisDocument8 pagesHeat Transfer Document Analysisbhaskar5377No ratings yet

- JNTU Old Question Papers 2007Document8 pagesJNTU Old Question Papers 2007Srinivasa Rao G100% (3)

- 2015 Heat TransferDocument4 pages2015 Heat TransferJitendra Kumar BiswasNo ratings yet

- Summer-2013 HMTDocument3 pagesSummer-2013 HMTPandyaNo ratings yet

- T 211Document7 pagesT 211gvsmsuryaNo ratings yet

- Code No: 45081Document8 pagesCode No: 45081SRINIVASA RAO GANTANo ratings yet

- Mse-2 HT QPDocument2 pagesMse-2 HT QPNAZEERUDDIN MOHAMMEDNo ratings yet

- Rr310803 Heat TransferDocument8 pagesRr310803 Heat TransferSrinivasa Rao GNo ratings yet

- NR 310803 Heat TransferDocument8 pagesNR 310803 Heat TransferSrinivasa Rao GNo ratings yet

- Tutorial Heat & Mass 431 No4Document2 pagesTutorial Heat & Mass 431 No4Moll22No ratings yet

- BKF2423 Heat Transfer Sem 2 1718Document5 pagesBKF2423 Heat Transfer Sem 2 1718Tony AngNo ratings yet

- Heat and Mass Transfer Exam Questions on Conduction, Convection, RadiationDocument2 pagesHeat and Mass Transfer Exam Questions on Conduction, Convection, RadiationPandyaNo ratings yet

- Heat Transfer Exam QuestionsDocument9 pagesHeat Transfer Exam QuestionsWen Ming LauNo ratings yet

- T.Y.B.tech Mech Sem VDocument24 pagesT.Y.B.tech Mech Sem VChirag JainNo ratings yet

- Heat & Mass Transfer Model ExamDocument6 pagesHeat & Mass Transfer Model ExamjayanthikrishnanNo ratings yet

- T.E. (Mechanical) (Semester - I) Examination, 2011 Heat Transfer (2008 Pattern) (New)Document4 pagesT.E. (Mechanical) (Semester - I) Examination, 2011 Heat Transfer (2008 Pattern) (New)saurabhNo ratings yet

- Ay1011sem1 Me3122eDocument3 pagesAy1011sem1 Me3122eCammy MiunoNo ratings yet

- Phys 161Document5 pagesPhys 161Collins BichiyNo ratings yet

- Scheme - I Sample Question PaperDocument5 pagesScheme - I Sample Question PaperSai divakarNo ratings yet

- B.Tech. Degree Examination: Instructions: Each Module Carries 12 MarksDocument3 pagesB.Tech. Degree Examination: Instructions: Each Module Carries 12 MarksKalidindi sai tharunNo ratings yet

- Tutorial SheetDocument5 pagesTutorial Sheetpradeep.kumarNo ratings yet

- r05320306 Heat TransferDocument8 pagesr05320306 Heat TransferSrinivasa Rao GNo ratings yet

- Special Question BankDocument8 pagesSpecial Question BankAKHIL HARINo ratings yet

- 9A23501 Heat Transfer in BioprocessesDocument4 pages9A23501 Heat Transfer in BioprocessessivabharathamurthyNo ratings yet

- Gujarat Technological University: InstructionsDocument2 pagesGujarat Technological University: InstructionsPandyaNo ratings yet

- Transport Phenomena: B.Tech. (Chemical Engineering) Seventh Semester (C.B.S.)Document4 pagesTransport Phenomena: B.Tech. (Chemical Engineering) Seventh Semester (C.B.S.)artiNo ratings yet

- Cycle Test 1 Set1Document6 pagesCycle Test 1 Set1logeshboy007No ratings yet

- HEAT TRANSFER 2011 JNTUH Question PaperDocument8 pagesHEAT TRANSFER 2011 JNTUH Question PaperAnil Frivolous AbstemiousNo ratings yet

- Question Paper Code:: Reg. No.Document4 pagesQuestion Paper Code:: Reg. No.kannanNo ratings yet

- 171212-170102-Theory of Heat TransferDocument2 pages171212-170102-Theory of Heat TransferKelvin SudaniNo ratings yet

- First Semester M.Tech Degree Examination, June 2009 (2008 Scheme) Propulsion Engineering MTC 1002: Advanced Heat and Mass TransferDocument2 pagesFirst Semester M.Tech Degree Examination, June 2009 (2008 Scheme) Propulsion Engineering MTC 1002: Advanced Heat and Mass TransferKhadeeja NicyNo ratings yet

- 07a40302 Fluid Mechanics & Heat TransferDocument8 pages07a40302 Fluid Mechanics & Heat TransferSRINIVASA RAO GANTANo ratings yet

- Nov2020 Odl Test Mec551 Set BDocument5 pagesNov2020 Odl Test Mec551 Set BMUHAMMAD IKMAL MOHD ZAMRINo ratings yet

- A Modern Course in Statistical PhysicsFrom EverandA Modern Course in Statistical PhysicsRating: 3.5 out of 5 stars3.5/5 (2)

- Heat Transfer in Polymer Composite Materials: Forming ProcessesFrom EverandHeat Transfer in Polymer Composite Materials: Forming ProcessesNicolas BoyardNo ratings yet

- Geothermal Energy: Sustainable Heating and Cooling Using the GroundFrom EverandGeothermal Energy: Sustainable Heating and Cooling Using the GroundNo ratings yet

- Ice Hockey Equipment Checklist PDFDocument23 pagesIce Hockey Equipment Checklist PDFwassiliNo ratings yet

- Production of Formaldehyde From Methanol PDFDocument200 pagesProduction of Formaldehyde From Methanol PDFwassiliNo ratings yet

- Karimietal 1dec 2015Document9 pagesKarimietal 1dec 2015wassiliNo ratings yet

- Heat Exchangers: Theory and Selection: Thermal FundamentalsDocument6 pagesHeat Exchangers: Theory and Selection: Thermal FundamentalsMarie GalvãoNo ratings yet

- Selection of Internals For Distillation ColumnsDocument29 pagesSelection of Internals For Distillation ColumnsAliya JamesNo ratings yet

- WDM technology multiplies fiber capacity using laser wavelengthsDocument8 pagesWDM technology multiplies fiber capacity using laser wavelengthsAnkit SharmaNo ratings yet

- Somos PerFORM Datasheet CompleteDocument4 pagesSomos PerFORM Datasheet CompleteAdriano AraujoNo ratings yet

- BR HighFlowDocument4 pagesBR HighFlowRocky SarmientoNo ratings yet

- Tire Terminology Explained: 40+ Key TermsDocument6 pagesTire Terminology Explained: 40+ Key Termsgovindarun5No ratings yet

- Checklist Pekerjaan Spun PileDocument1 pageChecklist Pekerjaan Spun PileBudhi Kurniawan100% (1)

- Foxboro CFT50 Digital Coriolis Mass Flow TransmitterDocument4 pagesFoxboro CFT50 Digital Coriolis Mass Flow TransmitterPhaniNo ratings yet

- Assignment # 2 ME - 615 Last Date of Submission: 01-03-2013 Rotor Dynamics Marks: 20Document1 pageAssignment # 2 ME - 615 Last Date of Submission: 01-03-2013 Rotor Dynamics Marks: 20Nishant PatilNo ratings yet

- NASA Understanding Earth - Whats Up With PrecipitationDocument16 pagesNASA Understanding Earth - Whats Up With PrecipitationSB CarmzNo ratings yet

- Lesson Plan Che463Document3 pagesLesson Plan Che463Rafiqah RahimNo ratings yet

- Aluminium Pipe FittingsDocument12 pagesAluminium Pipe Fittingsrahult19No ratings yet

- Martin&Randolph IACMAG 01Document13 pagesMartin&Randolph IACMAG 01julianaruiz06No ratings yet

- Using Phase Change Material in Heat Sinks To Cool Electronics Devices With Intermittent UsageDocument19 pagesUsing Phase Change Material in Heat Sinks To Cool Electronics Devices With Intermittent UsagekaushikNo ratings yet

- Gas Laws: Pressure, Volume, and Hot Air: A Chemistry Lesson For 10 Grade Students Created by Warren MerkelDocument30 pagesGas Laws: Pressure, Volume, and Hot Air: A Chemistry Lesson For 10 Grade Students Created by Warren MerkelDheeDazPequina100% (1)

- Validation of ENVI-met PMV Values by In-Situ Measuremen TsDocument6 pagesValidation of ENVI-met PMV Values by In-Situ Measuremen TsHendra CesmamulyaNo ratings yet

- ChemDocument29 pagesChemPearl LingbawanNo ratings yet

- Seismic Load STG BuildingDocument6 pagesSeismic Load STG BuildingWahyu MunajatNo ratings yet

- Stainless WDocument8 pagesStainless WsunsirNo ratings yet

- BS 1474-1987Document31 pagesBS 1474-1987raftipdo0aNo ratings yet

- M11 Bor Pile Load Lateral 15257 0Document28 pagesM11 Bor Pile Load Lateral 15257 0Yusril RamadhanNo ratings yet

- Reference Phthalic AcidDocument2 pagesReference Phthalic AcidBeningNo ratings yet

- Interview Questions (TD)Document9 pagesInterview Questions (TD)anil gautamNo ratings yet

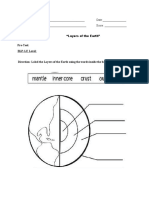

- Worksheets LS2 Layers of The EarthDocument7 pagesWorksheets LS2 Layers of The EarthAngeline Panaligan Ansela100% (1)

- Experimental and Numerical Investigation of Lower Limb Prosthetic Foot Made From Composite Polymer Blends1Document12 pagesExperimental and Numerical Investigation of Lower Limb Prosthetic Foot Made From Composite Polymer Blends1Jawad K. OleiwiNo ratings yet

- ASCE-AIr Cooled CondensersDocument9 pagesASCE-AIr Cooled CondensersYanan CamarazaNo ratings yet

- Wind Asce7 16Document7 pagesWind Asce7 16MIHDI PALAPUZNo ratings yet

- Damped Free VibrationDocument9 pagesDamped Free VibrationAdeoti OladapoNo ratings yet

- Choi 2012Document5 pagesChoi 2012tuanhoa123No ratings yet

- 185hr DatasheetDocument3 pages185hr DatasheetAsh VigilNo ratings yet

- Sky Air Seasonal Classic Conductos Baja Silueta Serie DDocument1 pageSky Air Seasonal Classic Conductos Baja Silueta Serie DmiroNo ratings yet

- CBSE Class 11 Physics Sample Paper 01 SolvedDocument29 pagesCBSE Class 11 Physics Sample Paper 01 SolvedLalbahadur RaiNo ratings yet