Professional Documents

Culture Documents

Hazard Identification Study SS RISK4 160410 1

Uploaded by

Anonymous zwSP5gvCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hazard Identification Study SS RISK4 160410 1

Uploaded by

Anonymous zwSP5gvCopyright:

Available Formats

HAZARD IDENTIFICATION STUDY

(HAZID)

A Powerful Tool for Identifying Major Hazards and Risk Issues

BUSINESS CHALLENGE

Most government licensing authorities require operating companies to carry out Health, Safety

and Environmental (HSE) hazard identification (HAZID) studies during the design of facilities, as

well as prior to construction and during operation. Company corporate requirements also cover

Hazid studies.

Hazard studies carried out late in the design phase, such as Hazard and Operability Studies

(HAZOP), often identify safety and environmental issues that can cause project delays or costly

design changes. Therefore, many clients require a Hazid study during early design so that hazards

can be avoided or reduced.

SOLUTION

What is HAZID?

A HAZID study is a tool for hazard identification used early in a project as soon as process flow

diagrams, draft heat & mass balances, and plot layouts are available. Sources of external hazard,

such as existing site infrastructure, weather, and geotechnical data, are also required. The method

is a design-enabling tool, acting to help organise the HSE deliverables in a project. The structured

brainstorming technique typically involves the designer and client personnel engineering

disciplines, project management, commissioning and operations. The major findings and hazard

risk ratings help to deliver HSE compliance, and form part of the project Risk Register required by

many licensing authorities and company in-house standards.

What are the key benefits?

A well-organised HAZID study activity will deliver a

clear identification of hazards and safeguards at an

RELATED SERVICES

early stage in the design of a facility. Team output helps

to ensure that: • Concept Safety Assessment

• Process Hazard Analysis

• Potential deviations from intended design function • Hazard & Operability (HAZOP) Study

are identified and corrected;

• Layers of Protection Analysis (LOPA)

• HSE hazards are revealed at an early stage in

• Safety Integrity Level (SIL) Study

the project, before significant costs have been

• RAM and Reliability studies

incurred;

• HSE Management Systems

• Hazards are recorded and actioned so that they can

be avoided, mitigated or highlighted for further risk • Safety Cases

reduction measures during detailed design; • SIMOPS Study

• Action responses are auditable by Management • Fire and explosion assessment

and Legislative Inspectorates; • Non-flammable Hazards Analysis

• Design or Construction delays and budget over- • Emergency Response Plans

runs are avoided; • Design Optimisation and

• Fewer hazards remain unknown at commissioning Decision Support

& operation of plant.

WHY CHOOSE BUREAU VERITAS?

Recognition Founded in 1828, Bureau Veritas is a world leader specialising in conformity assessment

services related to Quality, Health, Safety & Environment (QHSE).

Certified to ISO 9001 for all of its activities globally, Bureau Veritas is well known for its ability to adapt

to changing client environments and situations, and for its commitment to providing leading solutions

through quality service.

Knowledge & Expertise Through expert local teams and technical knowledge, Bureau Veritas are able

to deliver packaged and targeted solutions and information, to support our clients’ unique business

requirements.

Network With a network of 900 locations, and over 39,000 employees in more than 140 countries,

Bureau Veritas provides solutions to over 370,000 clients throughout the world across a diverse range of

industries.

OUR APPROACH

Bureau Veritas believes that hazard study is an integral part

of the feasibility study and design of hazardous facilities. CLIENT REFERENCES

Bureau Veritas supplies all of the administrative Bureau Veritas has delivered HAZID studies

arrangements for hazard studies, including the meeting’s to major operators in all regions of the world.

Chairman and Secretary, the computer software support and Our HAZID studies are tailored to meet the

offsite meeting venues, if appropriate. precise needs of each client situation – from

LNG storage in UK to high H2 S gas plant in

Our Hazard Register tool simplifies both the identification of

China, and from deep water operations of

hazards and compilation of a Hazards Register.

Brazil to refinery turnaround in the USA.

The company provides consistent reporting formats and

For example, during turnaround we

action response auditing to ensure that issues have been

provide an approach to risk management

addressed to meet the project schedule.

through a HAZID process which accounts

for interactions between different

FAQ – FREQUENTLY ASKED contractor groups. This approach provides

a comprehensive picture of the risks during

QUESTIONS turnaround.

How long does a HAZID take? The top-down nature of the HAZID process

For the installation of an oil & gas unit on an existing site, means that it is likely to identify the fullest

typically 2 to 5 days. range of hazards to which personnel may be

exposed.

Can you advise what types of hazard study are required for Appropriate management measures are

a project in our location? then developed and the effectiveness of the

Yes, we can advise on legislative requirements and good implementation is monitored.

practice compliance.

CONTACT FOR MORE INFORMATION

SS_RISK4_160410_1

For details about this service, please contact

Risk Management Services Aus & NZ Please Visit: www.bureauveritas.com.au

Phone Australia: Email: bvaus@au.bureauveritas.com

Melb HQ: + 61 (0) 3 9922 0700

Perth: + 61 (0) 8 9481 0100

Phone New Zealand: + 64 (09) 526 4546

You might also like

- Hazard Identification Study RISK 1210Document2 pagesHazard Identification Study RISK 1210Muhammad AbidNo ratings yet

- HAZIDDocument2 pagesHAZIDDan AngheleaNo ratings yet

- Irc Hazid SSDocument2 pagesIrc Hazid SSSayed RedaNo ratings yet

- HAZID Study BenefitsDocument2 pagesHAZID Study Benefitsrizanda93No ratings yet

- HAZIDDocument2 pagesHAZIDAnonymous zwSP5gvNo ratings yet

- H011228 PDFDocument2 pagesH011228 PDFchandu666creatorNo ratings yet

- H011228 PDFDocument2 pagesH011228 PDFAndres Fernando Cano UrreaNo ratings yet

- Google Cloud PlatforDocument6 pagesGoogle Cloud PlatforjohnNo ratings yet

- Method Statement For Construction - Designing Buildings Wiki PDFDocument5 pagesMethod Statement For Construction - Designing Buildings Wiki PDFKareemAdelNo ratings yet

- Through Digital Transformation.: Leveraging The Value of Integrated Safety Solutions From A Trusted PartnerDocument13 pagesThrough Digital Transformation.: Leveraging The Value of Integrated Safety Solutions From A Trusted PartnerKhaled RamzyNo ratings yet

- Risk Based Process Safety DesignDocument13 pagesRisk Based Process Safety DesignVan SotNo ratings yet

- Your Partner For Safer Tomorrow: Ement Servic EsDocument11 pagesYour Partner For Safer Tomorrow: Ement Servic Esquaiser_nikoNo ratings yet

- CV HarisDocument3 pagesCV HarisSyed HarisNo ratings yet

- My ResumeDocument4 pagesMy Resumeengrsaidnawab2020No ratings yet

- SE Slides9Document16 pagesSE Slides9tayyabson06No ratings yet

- Front-End Engineering and Design (FEED)Document7 pagesFront-End Engineering and Design (FEED)hussnainreflectNo ratings yet

- Cobalt ROI of Modern Pentest Report 2021Document23 pagesCobalt ROI of Modern Pentest Report 2021maashNo ratings yet

- Chola MS Risk - Corporate ProfileDocument40 pagesChola MS Risk - Corporate ProfilejitheshsvNo ratings yet

- A New Concept To Evaluate Risk in Preliminary Design StageDocument6 pagesA New Concept To Evaluate Risk in Preliminary Design StageEmad ElgebesyNo ratings yet

- Hazard Assessment Safety Action Plan (Hasap)Document25 pagesHazard Assessment Safety Action Plan (Hasap)Mohamed HadjkacemNo ratings yet

- Application Container Audit ProgramDocument7 pagesApplication Container Audit ProgramSushil AndreNo ratings yet

- GRC ConsultantimtDocument7 pagesGRC ConsultantimtazzuNo ratings yet

- PoojaVerma (15 0)Document2 pagesPoojaVerma (15 0)Rohit SrivastavaNo ratings yet

- Dow Corning: Sap® Ehs Management For Sustainability and ComplianceDocument4 pagesDow Corning: Sap® Ehs Management For Sustainability and ComplianceSreekanth PCNo ratings yet

- Rig Inspections: Lloyd's Register Energy - DrillingDocument2 pagesRig Inspections: Lloyd's Register Energy - DrillingShraddhanand MoreNo ratings yet

- Introduction To Functional Safety Assessments of Safety Controls, Alarms, and Interlocks: How Efficient Are Your Functional Safety Projects?Document7 pagesIntroduction To Functional Safety Assessments of Safety Controls, Alarms, and Interlocks: How Efficient Are Your Functional Safety Projects?ERICK MARTINEZ AGUIRRE100% (1)

- R. Dinesh Kumar's Curriculum VitaeDocument6 pagesR. Dinesh Kumar's Curriculum VitaeBasker BaluNo ratings yet

- SAFETY IN DESIGN: KEY PRINCIPLES AND BENEFITSDocument14 pagesSAFETY IN DESIGN: KEY PRINCIPLES AND BENEFITSJay JayNo ratings yet

- Sajid Tanwar: HSE OfficerDocument4 pagesSajid Tanwar: HSE OfficerShahid BhattiNo ratings yet

- Rejeeb Ibrahim: Sr. HSE AdvisorDocument3 pagesRejeeb Ibrahim: Sr. HSE Advisorlcw57860No ratings yet

- Risk Analysis in SPMDocument13 pagesRisk Analysis in SPMJawad AhmadNo ratings yet

- Integrity v6Document16 pagesIntegrity v6khanz88_rulz1039No ratings yet

- CGRA HSE Capabilities 7.30Document7 pagesCGRA HSE Capabilities 7.30Fabio ThomazNo ratings yet

- Tuv Sud Risk Based Inspection and MaintenanceDocument2 pagesTuv Sud Risk Based Inspection and Maintenancemrizalygani99No ratings yet

- ResumeAsimMohinuddin PDFDocument6 pagesResumeAsimMohinuddin PDFJenniferNo ratings yet

- Anonymised Web Application Penetration Testing ReportDocument43 pagesAnonymised Web Application Penetration Testing Reportvlatko.lazarevskiNo ratings yet

- Multinational Bank Based in The Netherlands: Customer Case StudyDocument2 pagesMultinational Bank Based in The Netherlands: Customer Case StudykhalibandiNo ratings yet

- Professional Summary and Project ExperienceDocument2 pagesProfessional Summary and Project ExperienceGaurav kumarNo ratings yet

- Resume PDFDocument2 pagesResume PDFGaurav kumarNo ratings yet

- IT Auditor Imteyaz21Document6 pagesIT Auditor Imteyaz21Imteyaz AhmadNo ratings yet

- ResumeDocument2 pagesResumeGaurav kumarNo ratings yet

- Hazard Identification HAZID Guidance For Fertilizer Industry Document GuidanceDocument9 pagesHazard Identification HAZID Guidance For Fertilizer Industry Document GuidanceAbdul AwanNo ratings yet

- To Achieve Your Inspection, Reliability & Safety GoalsDocument19 pagesTo Achieve Your Inspection, Reliability & Safety GoalsPravin GowardunNo ratings yet

- 22 05.02.2021 Epsc Webinar DekraDocument32 pages22 05.02.2021 Epsc Webinar DekraShahzadNo ratings yet

- Abrahamnana Oseimainoo PDFDocument13 pagesAbrahamnana Oseimainoo PDFtech4ceconsultingNo ratings yet

- Audit Oversight For Onboarding Vendors Res Eng 0220Document16 pagesAudit Oversight For Onboarding Vendors Res Eng 0220Quynh Quynh0% (1)

- Maximo HSEDocument40 pagesMaximo HSEEngr.Arslan AbbasNo ratings yet

- LifeTech-Engineering-Services - Asset Integrity ManagementDocument14 pagesLifeTech-Engineering-Services - Asset Integrity Managementyogolain100% (1)

- DEKRA Process Safety Experts for Risk Management and Safety ComplianceDocument8 pagesDEKRA Process Safety Experts for Risk Management and Safety ComplianceNishir Shah100% (1)

- HAZOP HAZID Haliburton PDFDocument2 pagesHAZOP HAZID Haliburton PDFamirNo ratings yet

- Tuv Sud Hazop ProcedureDocument2 pagesTuv Sud Hazop ProcedurejohnloopsNo ratings yet

- Project Risk Analysis and ManagementDocument11 pagesProject Risk Analysis and ManagementaggibudimanNo ratings yet

- Chapter Five: Project Implementation, Monitoring and EvaluationDocument84 pagesChapter Five: Project Implementation, Monitoring and EvaluationNeway AlemNo ratings yet

- Senior Manager, CCR ReportingDocument5 pagesSenior Manager, CCR ReportingAkhilNo ratings yet

- Quest For Managing Cyberthreats in Healthcare PDFDocument4 pagesQuest For Managing Cyberthreats in Healthcare PDFSpit FireNo ratings yet

- Design For RelaibilityDocument10 pagesDesign For RelaibilityAnonymous s45kZauNsNo ratings yet

- Risk Management For Product DevelopmentDocument6 pagesRisk Management For Product DevelopmentgarvmonuNo ratings yet

- Managing Resistance To ChangeDocument4 pagesManaging Resistance To ChangeMatthew MohanNo ratings yet

- Mess Bill Jan+Feb PDFDocument1 pageMess Bill Jan+Feb PDFAnonymous zwSP5gvNo ratings yet

- Evaluation FormDocument1 pageEvaluation FormAnonymous zwSP5gvNo ratings yet

- Evaluation FormDocument1 pageEvaluation FormAnonymous zwSP5gvNo ratings yet

- SuppliersDocument1 pageSuppliersAnonymous zwSP5gvNo ratings yet

- Tubular ReactorDocument2 pagesTubular ReactorAnonymous zwSP5gvNo ratings yet

- HAZIDDocument2 pagesHAZIDAnonymous zwSP5gvNo ratings yet

- Mess Bill Jan+FebDocument1 pageMess Bill Jan+FebAnonymous zwSP5gvNo ratings yet

- Water Gas Shift Reaction Kinetics and Reactor Modeling For Fuel Cell Grade Hydrogen PDFDocument8 pagesWater Gas Shift Reaction Kinetics and Reactor Modeling For Fuel Cell Grade Hydrogen PDFKmilo BolañosNo ratings yet

- Mess Bill Jan+FebDocument1 pageMess Bill Jan+FebAnonymous zwSP5gvNo ratings yet

- Simulation of Aqua Ammonia Refrigeration System Using The Cape Open To Cape Open Coco Simulator PDFDocument4 pagesSimulation of Aqua Ammonia Refrigeration System Using The Cape Open To Cape Open Coco Simulator PDFAnonymous zwSP5gvNo ratings yet

- ZhuozhouDocument1 pageZhuozhouAnonymous zwSP5gvNo ratings yet

- Fish FoodDocument6 pagesFish FoodAnonymous zwSP5gvNo ratings yet

- Robur Abso en 02 2019Document35 pagesRobur Abso en 02 2019Anonymous zwSP5gvNo ratings yet

- Diesel Fuel ASTM LimitsDocument1 pageDiesel Fuel ASTM LimitsAnonymous zwSP5gvNo ratings yet

- Diesel Fuel ASTM LimitsDocument1 pageDiesel Fuel ASTM LimitsAnonymous zwSP5gvNo ratings yet

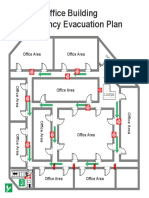

- Emergency Evacuation PlanDocument1 pageEmergency Evacuation PlanAnonymous zwSP5gvNo ratings yet

- Siphon - Sizing 6 PDocument6 pagesSiphon - Sizing 6 PJaber Osmani100% (1)

- Blast Furnace Heat and Material Balance Using MS-Excel-SolverDocument11 pagesBlast Furnace Heat and Material Balance Using MS-Excel-SolverAnonymous zwSP5gvNo ratings yet

- StandardsDocument9 pagesStandardsmanoj983@gmail.comNo ratings yet

- Graduate Assessment Test (GAT 2018-III) GAT General: (Result)Document1 pageGraduate Assessment Test (GAT 2018-III) GAT General: (Result)Anonymous zwSP5gvNo ratings yet

- HandbookTable of ContentsDocument6 pagesHandbookTable of ContentsAnonymous zwSP5gvNo ratings yet

- Neutron PoisonsDocument27 pagesNeutron PoisonsAnonymous zwSP5gvNo ratings yet

- Nust CV FormDocument8 pagesNust CV FormAnonymous zwSP5gvNo ratings yet

- UK Conductive Heater RangeDocument4 pagesUK Conductive Heater RangeAnonymous zwSP5gvNo ratings yet

- Construction Completion Report Form For Submittal Exception ProcessDocument3 pagesConstruction Completion Report Form For Submittal Exception ProcessAnonymous zwSP5gvNo ratings yet

- ..:: Proposals For ELMO RIETSCHLE PUMPS::.Document5 pages..:: Proposals For ELMO RIETSCHLE PUMPS::.Anonymous zwSP5gvNo ratings yet

- Construction Completion Report FormDocument2 pagesConstruction Completion Report FormAnonymous zwSP5gvNo ratings yet

- Construction Completion Report FormDocument1 pageConstruction Completion Report FormG-SamNo ratings yet

- Purpose: Premier Plastic Production Company Sop For Emergency Response Plan & PreparednessDocument19 pagesPurpose: Premier Plastic Production Company Sop For Emergency Response Plan & Preparednessimranul haqNo ratings yet

- Cygnus Industries Inc.Document19 pagesCygnus Industries Inc.sharielles /No ratings yet

- White Card - Training ManualDocument67 pagesWhite Card - Training ManualJeka Beta100% (1)

- HR Risk ManagementDocument18 pagesHR Risk ManagementomsharatNo ratings yet

- Janis Yue X140 Final PaperDocument6 pagesJanis Yue X140 Final PaperJanis YNo ratings yet

- Goldman's ABACUS Sales DocumentDocument66 pagesGoldman's ABACUS Sales DocumentFOXBusiness.com100% (2)

- System Safety Engineering An Overview For Engineers and ManagersDocument42 pagesSystem Safety Engineering An Overview For Engineers and Managersmadonnite3781No ratings yet

- Religare Securities LTD: A Project ReportDocument54 pagesReligare Securities LTD: A Project ReportRajesh KumarNo ratings yet

- Maharlika Investment Fund BillDocument25 pagesMaharlika Investment Fund BillPark JongseongNo ratings yet

- Portfolio Management at India InfolineDocument92 pagesPortfolio Management at India InfolineVasavi DaramNo ratings yet

- SCIArcMagazineNo 3Document38 pagesSCIArcMagazineNo 3Wilson ChangNo ratings yet

- 3 International Trade & BusinessDocument51 pages3 International Trade & BusinessRitunjay KumarNo ratings yet

- UMP Assingement (PRINCIPLES OF SAFETY ENGINEERING)Document15 pagesUMP Assingement (PRINCIPLES OF SAFETY ENGINEERING)Yogendran SundrasaigramNo ratings yet

- Norton Pressure Sore Risk Assessment ScaleDocument1 pageNorton Pressure Sore Risk Assessment ScaleZee ZangNo ratings yet

- Sensores PDFDocument202 pagesSensores PDFJorge HerreraNo ratings yet

- Acturarial Mathematics - BowersDocument780 pagesActurarial Mathematics - BowersEstefanía Luna Flores100% (1)

- Practice Management Guidelines 3rd Edition Pgguidance 2010Document66 pagesPractice Management Guidelines 3rd Edition Pgguidance 2010Hicham FaresNo ratings yet

- Risk Management Tools PDFDocument27 pagesRisk Management Tools PDFGeorge John AmegashieNo ratings yet

- Working Via SD Worx Staffings Solutions Vs 19.9.enDocument31 pagesWorking Via SD Worx Staffings Solutions Vs 19.9.enpnnn8q9qd2No ratings yet

- The Hazards and Risks of HydrogenDocument7 pagesThe Hazards and Risks of Hydrogenjorge bustosNo ratings yet

- Corp Governance Quiz 1Document12 pagesCorp Governance Quiz 1杰米No ratings yet

- Module-3 - The Project Management ProcessDocument93 pagesModule-3 - The Project Management ProcessJoseph Berlin JuanzonNo ratings yet

- PMIA FT Off Campus TasksDocument3 pagesPMIA FT Off Campus TasksSyed Oliur Rahman HimelNo ratings yet

- Planning The Audit Linking Audit Procedures To Risk RequirementDocument8 pagesPlanning The Audit Linking Audit Procedures To Risk Requirementyea okayNo ratings yet

- Submitted By: Project Submitted in Partial Fulfillment For The Award of Degree ofDocument9 pagesSubmitted By: Project Submitted in Partial Fulfillment For The Award of Degree ofMOHAMMED KHAYYUMNo ratings yet

- Third Party Risk July2023Document24 pagesThird Party Risk July2023hakkan meierNo ratings yet

- Risk Based Internal AuditDocument7 pagesRisk Based Internal AuditKit Millora100% (1)

- Powerpoint - Duty To Accommodate PresentationDocument27 pagesPowerpoint - Duty To Accommodate PresentationashNo ratings yet

- Illustrative Audit Case: Keystone Computers & Networks, IncDocument6 pagesIllustrative Audit Case: Keystone Computers & Networks, Incvaratvai0% (3)

- Project On Credit Management 222Document82 pagesProject On Credit Management 222Karthik Kartu J71% (7)