Professional Documents

Culture Documents

488075

Uploaded by

SerryAlbercaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

488075

Uploaded by

SerryAlbercaCopyright:

Available Formats

488075

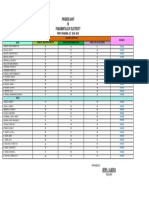

Motor Wiring Diagram

12 Lead, Dual Voltage, Wye Start - Delta Run or Part Winding Start

Per NEMA MG1 1998-1.76, "A Wye Start, Delta Run motor is one arranged for starting by

connecting to the supply with the primary winding initially connected in wye, then reconnected in

delta for running condition." This is accomplished by a special Wye-Delta starter configuration

using six leads from the motor and is intended to limit the inrush current required to start the

motor.

Motors designed by US Motors for Wye start, Delta Run may also be used for across the line

starting using only the Delta connection. Damage will occur if the motor is operated with load for

more than 30 seconds on the Wye without transition to Delta.

Per NEMA MG1 1998-1.75, "A Part-Winding Start motor is one which certain specially designed

circuits of each phase of the primary winding are initially connected to the supply line. The

remaining circuit or circuits of each phase are connected to the supply in parallel with initially

connected circuits, at a predetermined point in the starting operation." This is intended to limit the

inrush current required to start the motor. NEMA MG1 1998-14.38 states that the motor may not

accelerate to full speed in part-winding and may be noisier than when on full winding.

Motors designed by US Motors for Part-Winding Start may also be used for across the

line starting using only the full winding connection. Damage will occur if the motor is

operated with load for more than 2 seconds on part-winding without transition to full

winding.

To reverse direction of rotation, interchange leads L1 & L2.

Each lead may have one or more cables comprising that lead. In such case, each cable will be

marked with the appropriate lead number.

Connection Plate: 488075 Revised: 09/08/11

Connection Decal: ------ .

NIDEC MOTOR CORPORATION

ST. LOUIS, MISSOURI

488075

SPECIAL INFORMATION REGARDING PART WINDING STARTING

This motor is not designed to fully accelerate when started with the part winding

start connection shown on the motor connection diagram. In order to avoid

damaging the motor when it is started with the part winding start connection, set

timers so that the motor starter switches the motor connection from start to run

within two seconds from the time that the motor is initially energized. The motor

is not expected to fully accelerate before the motor connection is switched to run,

but the momentary operation on the start connection should allow time for

automatic voltage regulators on the power system to compensate for voltage dip

resulting from the high current draw of the motor during acceleration. Thus,

voltage dip in the power system will be minimized through proper use of the part

winding start connection. Once the motor has been switched over to the run

connection, it will finish accelerating up to full speed.

During the time that the motor is operated on the part winding start connection, it is

expected that the motor may be noisier than when operated on the run connection

and it is also expected that the line amp unbalance between phases may be

approximately 100% to 150%. This is due to the adverse effect of harmonics that

result from the unbalanced magnetic circuit on the part winding start connection.

For further information regarding characteristics of polyphase induction motors

when operated on a part winding start connection, refer to NEMA Publication MG

1-1998 Part 14.38.

Connection Plate: 488075 Revised: 09/08/11

Connection Decal: ------

NIDEC MOTOR CORPORATION

ST. LOUIS, MISSOURI

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Cooking - Sauces and Marinade RecipesDocument96 pagesCooking - Sauces and Marinade Recipesagape_1st7100% (3)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Buck 1948Document9 pagesBuck 1948Carlos Mora100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Gastronomia 10 Competition GuideDocument21 pagesGastronomia 10 Competition Guidefpvillanueva100% (1)

- Wheel Horse by YearDocument14 pagesWheel Horse by YearNeil SmallwoodNo ratings yet

- Tank Cleaning ConsiderationsDocument1 pageTank Cleaning ConsiderationsAdele PollardNo ratings yet

- Introduction To The Philosophy of The Human PersonDocument17 pagesIntroduction To The Philosophy of The Human Personrovie andes100% (1)

- Boge Screw UsaDocument40 pagesBoge Screw UsaAir Repair, LLC100% (1)

- General Indications: AnticoagulantsDocument15 pagesGeneral Indications: AnticoagulantswahidNo ratings yet

- Respiratory Medicine 1 50Document33 pagesRespiratory Medicine 1 50Ahmed Kh. Abu WardaNo ratings yet

- Burns SeminarDocument66 pagesBurns SeminarPratibha Thakur100% (1)

- FLSPfister IB05000 I GBTRWSD0216 MailDocument26 pagesFLSPfister IB05000 I GBTRWSD0216 MailLuis Angel BusturiaNo ratings yet

- All Over The WorldDocument5 pagesAll Over The WorldSerryAlbercaNo ratings yet

- Activity 1. FORUM & WEBINAR Objective: This Activity Will Allow The Students To Experience Some Communication Tools That Are UsefulDocument5 pagesActivity 1. FORUM & WEBINAR Objective: This Activity Will Allow The Students To Experience Some Communication Tools That Are UsefulSerryAlbercaNo ratings yet

- Job Application LetterDocument1 pageJob Application LetterSerryAlbercaNo ratings yet

- 1narrative 1 3rd Grading CulmanitionDocument1 page1narrative 1 3rd Grading CulmanitionSerryAlbercaNo ratings yet

- Educ Tech 2 Chapter 8Document2 pagesEduc Tech 2 Chapter 8SerryAlbercaNo ratings yet

- Analysis Chart IN Fundamentals of Electricity: FIRST GRADING PERIOD, S.Y. 2018-2019Document1 pageAnalysis Chart IN Fundamentals of Electricity: FIRST GRADING PERIOD, S.Y. 2018-2019SerryAlbercaNo ratings yet

- Gaisano Capital Surigao merchandiser evaluation letterDocument1 pageGaisano Capital Surigao merchandiser evaluation letterSerryAlbercaNo ratings yet

- Case ProblemDocument1 pageCase ProblemSerryAlbercaNo ratings yet

- What Is Plan ?Document2 pagesWhat Is Plan ?SerryAlbercaNo ratings yet

- Alberca, PROGRESS CHARTDocument1 pageAlberca, PROGRESS CHARTSerryAlbercaNo ratings yet

- A Synchronous Motor From A Hammond OrganDocument1 pageA Synchronous Motor From A Hammond OrganSerryAlbercaNo ratings yet

- Words With Multiple MeaningDocument2 pagesWords With Multiple MeaningSerryAlbercaNo ratings yet

- Aerial PlantsDocument1 pageAerial PlantsSerryAlbercaNo ratings yet

- 9 1 18Document1 page9 1 18SerryAlbercaNo ratings yet

- Iser 2012 SolarDocument7 pagesIser 2012 SolarSerryAlbercaNo ratings yet

- 488075Document2 pages488075SerryAlbercaNo ratings yet

- Educ Tech 2 Chapter 9Document3 pagesEduc Tech 2 Chapter 9SerryAlberca0% (1)

- Architecture: Successful Track Record in The Designing in Our BuildingDocument1 pageArchitecture: Successful Track Record in The Designing in Our BuildingSerryAlbercaNo ratings yet

- A Biological Definition of Self PDFDocument5 pagesA Biological Definition of Self PDFSerryAlbercaNo ratings yet

- Educ Tech 2 Chapter 6Document6 pagesEduc Tech 2 Chapter 6SerryAlbercaNo ratings yet

- Activity 1. FORUM & WEBINAR Objective: This Activity Will Allow The Students To Experience Some Communication Tools That Are UsefulDocument5 pagesActivity 1. FORUM & WEBINAR Objective: This Activity Will Allow The Students To Experience Some Communication Tools That Are UsefulSerryAlbercaNo ratings yet

- Computer Science Graduate Seeks JobDocument1 pageComputer Science Graduate Seeks JobSerryAlbercaNo ratings yet

- Educ Tech 2 Chapter 12Document2 pagesEduc Tech 2 Chapter 12SerryAlbercaNo ratings yet

- 488075Document2 pages488075SerryAlbercaNo ratings yet

- Solar Mobile Control Car1Document12 pagesSolar Mobile Control Car1SerryAlbercaNo ratings yet

- Detailed Lesson Plan in T L EDocument7 pagesDetailed Lesson Plan in T L ESerryAlbercaNo ratings yet

- Name:Jayford Longos Date:Sept 26,2018 Year & Section:11 Galileo Galilei ScoreDocument1 pageName:Jayford Longos Date:Sept 26,2018 Year & Section:11 Galileo Galilei ScoreSerryAlbercaNo ratings yet

- COYNODocument2 pagesCOYNOSerryAlbercaNo ratings yet

- How a linear voltage regulator maintains a steady output voltageDocument3 pagesHow a linear voltage regulator maintains a steady output voltageSerryAlbercaNo ratings yet

- Entrenamiento de Fuerza y Salud Pediátrica Ingles PDFDocument9 pagesEntrenamiento de Fuerza y Salud Pediátrica Ingles PDFGiiovanny PardoNo ratings yet

- Medray Letterhead TemplateDocument5 pagesMedray Letterhead TemplateSteve NjugiNo ratings yet

- Procedure Title - Vickers Hardness Testing With The Mitutoyo MVK-H1 Microhardness TesterDocument12 pagesProcedure Title - Vickers Hardness Testing With The Mitutoyo MVK-H1 Microhardness TesterVitor100% (1)

- CSHP Template For Small Construction Projects Residential Project/S (2 Storey and Below) or Minor Repair WorksDocument5 pagesCSHP Template For Small Construction Projects Residential Project/S (2 Storey and Below) or Minor Repair WorksZeny BocadNo ratings yet

- HVDCProjectsListingMarch2012 ExistingDocument2 pagesHVDCProjectsListingMarch2012 ExistingHARLEY SANDERSNo ratings yet

- Outcome of Pelvic Fractures Identi Fied in 75 Horses in A Referral Centre: A Retrospective StudyDocument8 pagesOutcome of Pelvic Fractures Identi Fied in 75 Horses in A Referral Centre: A Retrospective StudyMaria Paz MorenoNo ratings yet

- Plateau Pressure Ventilation MeasurementDocument1 pagePlateau Pressure Ventilation MeasurementImtiaz AliNo ratings yet

- Carbon Steel Alloys Steel, Pipe Dimension With Weight Test Pressures According To ANSI B36, 10 For ASTM A53/A 106/API 5L/A335/ SpecificationDocument6 pagesCarbon Steel Alloys Steel, Pipe Dimension With Weight Test Pressures According To ANSI B36, 10 For ASTM A53/A 106/API 5L/A335/ SpecificationsanjibkrjanaNo ratings yet

- RC14001® & RCMS®: Your Guide To Implementing A Responsible Care® Management SystemDocument4 pagesRC14001® & RCMS®: Your Guide To Implementing A Responsible Care® Management SystemMohammed MehranNo ratings yet

- Dermato Venerology ScienceDocument11 pagesDermato Venerology ScienceAQis AQishNo ratings yet

- Análisis de Estabilidad de TaludesDocument4 pagesAnálisis de Estabilidad de TaludesJosue Acosta EspinozaNo ratings yet

- Homes & Diamonds of Liz TaylorDocument42 pagesHomes & Diamonds of Liz TaylorFridayFunStuffNo ratings yet

- Study To Assess The Effectiveness of Planned Teaching Programme Regarding Knowledge of Traffic Rules Among Higher Secondary Students 15 18 Years in Selected Schools of DehradunDocument14 pagesStudy To Assess The Effectiveness of Planned Teaching Programme Regarding Knowledge of Traffic Rules Among Higher Secondary Students 15 18 Years in Selected Schools of DehradunEditor IJTSRDNo ratings yet

- Calculation of shell and dish thicknessDocument2 pagesCalculation of shell and dish thicknessThiru AnanthNo ratings yet

- Anthropometric Measurements Options For Identifying Low Birth Weight Newborns in Kumasi, GhanaDocument9 pagesAnthropometric Measurements Options For Identifying Low Birth Weight Newborns in Kumasi, GhanaDani KusumaNo ratings yet

- 2021 Rival IQ Social Media Benchmark ReportDocument132 pages2021 Rival IQ Social Media Benchmark ReportVu Thu TrangNo ratings yet

- 2 - Electrical Energy Audit PDFDocument10 pages2 - Electrical Energy Audit PDFPrachi BhaveNo ratings yet

- Airtel's Africa Growth: Surviving CompetitionDocument9 pagesAirtel's Africa Growth: Surviving CompetitionSagar RiazNo ratings yet

- R02.4 Standard III (A) - AnswersDocument11 pagesR02.4 Standard III (A) - AnswersShashwat DesaiNo ratings yet