Professional Documents

Culture Documents

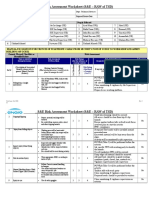

Safe Work Method Statement (SWMS) : Hot Work (Welding, Cutting, Grinding, Gas Cutting, in FGD-Unit#1&2)

Uploaded by

tamoor sarwarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safe Work Method Statement (SWMS) : Hot Work (Welding, Cutting, Grinding, Gas Cutting, in FGD-Unit#1&2)

Uploaded by

tamoor sarwarCopyright:

Available Formats

Contractor Company

Safe Work Method Statement (SWMS) Logo to be fixed here

ORGANISATION DETAILS

Contractor: SEPCO III Contact

Address:

Project Manager or MR.XU Contact Number 059-4279115

Supervisor: & Email:

Person completing the SWMS: TAMOOR SARWAR Contact Number 059-6478152

& Email:

Position: HSE SUPV (LEAD) Reviewed By:

(Technical / Senior Person)

Date Prepared: 28/7/2018 Review Date: 29/07/2018

PROJECT DETAILS

What is the Scope of the work? Hot Work (Welding, Cutting, Grinding, Gas Cutting, in FGD-Unit#1&2)

Who else was consulted / ROMCO HSE Dep & ROMCO Mechanical Dept.

involved in preparing this SEPCOIII (HSE & Site Engineer)

SWMS? (Internal or external Senior

Person)

What high risk work activities Welding, Cutting, Grinding, Gas Cutting, Confined Space

are covered by this SWMS?

References: Legislation,

Codes of Practice, and SOPs.

Other equipment involved in Welding Machines, Gas cylinders(Oxygen,Acetyline)

the scope of work:

RC/HSE/SP-008/FM-013 Rev.00 Rev. Date 28 Aug 2017 Page 1 of 6

Contractor Company

Safe Work Method Statement (SWMS) Logo to be fixed here

What high risk license classes Trained Employees, Competent Supervisor

will be required to do the Entry Attendant

work? e.g. 3rd Party

Certification, training

certificates etc.

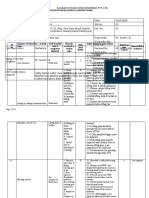

RISK MANAGEMENT

Identify each task in Specify the What are the risks to health and Describe your control measures, list as many as Who is responsible

order hazards you have safety? possible for implementing and

identified monitoring controls?

Preparation of Accident Due Personnel injury, Tool box talk, obtain Night work SEPCOIII

night Work to Poor permit close monitoring by

Electric shock SUPV

Illumination, supervisor as well as HSE

Burn. representative, Proper PPE, the

whole work place and all access

Emergencies and egress are well illuminated in

during the night time. barricade to exposed

night work. areas. high Visibility Vest to be wear

in night hours. effective

communication and coordination

Electrocution among supervisor and workers.

from cables Don’t let anybody to work alone

for lighting. during the dark hours (Buddy

system to be followed). Workers to

be trained and communicated about

the emergency response at site.

Workers should know Plant

Emergency Number. Supervisor

must be aware and monitor no of

workers at night. Contact number of

the supervisor shall be distributed

to all workers at night shift. Cables

for the lights shall be elevated or

RC/HSE/SP-008/FM-013 Rev.00 Rev. Date 28 Aug 2017 Page 2 of 6

Contractor Company

Safe Work Method Statement (SWMS) Logo to be fixed here

buried. Do not route the cables

through the wet areas. Access and

egress shall be clear from

obstructions. make sure the ELCB

is installed in electrical panel. Only

110 power tools are allowed inside

the confined space. arrange

additional emergency lights in case

of electricity got tripped.

Using power Electrical Noise, Dust, Bodily Wear appropriate Personal SEPCOIII

tools Hazard injury, Eye injury Protective Equipment. Never wear SUPV

loose cloths while using power

tools. Ensure all tools are

appropriately guarded and electrical

appliances are protected. Ensure all

extension leads are in a safe

condition with plugs and

connections. Use tools in a manner

that will not cause jamming or

seizing. Safety goggles (or

protective glasses) should always

be worn when using power tools.

Wear ear protection when using

tools. use only double insulated

power tools.

Welding, Fire, Electric Burn, various personnel Follow the PTW rules. conduct SEPCOIII

Cutting, shock injuries, property Toolbox Talk, Wear suitable SUPV

Grinding damage PPE’S according to activity.

Presence of a Fire watch, enough

fire blanket to cover the hot work

area. During welding/cutting

operations, proper welding gloves

RC/HSE/SP-008/FM-013 Rev.00 Rev. Date 28 Aug 2017 Page 3 of 6

Contractor Company

Safe Work Method Statement (SWMS) Logo to be fixed here

and a full-face, UV-ray protective

shield shall be worn to prevent

injuries to the operator. All

electrical cords shall be inspected

and in good working condition

prior to use. . All tools shall be

inspected prior to use and found

to be in good working order prior

to use. Welding/cutting operations

shall be performed by trained,

certified workers. Never leave

cylinders without cap.

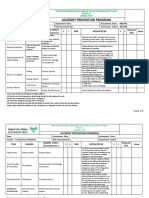

Manual Material Slip Personnel injury Work area to be well illuminated. SEPCOIII

Handling Share the loads properly between

Trip & Fall Foot injury SUPV

workers. Use Proper tools. Close

Finger puncture supervision & Coordination. All

Cuts access and egress shall be clear

from any obstructions. Use proper

PPE’S (Leather or suitable

Gloves) wile lifting manually.

confined space Oxygen Various personnel Obtain PTW before starting job in SEPCOIII

deficiency, injuries, dizziness confined space. Make sure gas SUPV

presence of test is conducted. Access and

Headache

toxic gases. egress must be clear from any

Hazardous Nausea type of obstruction. Provide

atmosphere, proper lightning as well as

Slip, Trip and ventilation (if its required). hole

fall hazards. watch must be at the confined

Dropped space entrance along with log

objects, poor sheet. All employee’s must write

lightning their name at attendance sheet.

Only trained and authorized

workers can perform work into the

RC/HSE/SP-008/FM-013 Rev.00 Rev. Date 28 Aug 2017 Page 4 of 6

Contractor Company

Safe Work Method Statement (SWMS) Logo to be fixed here

confined space. All welding

machines will be kept outside the

confined space. Use proper ladder

safety (3 points of contact),

harness properly worn.

Work at Height Falls, falling Fractures Use only green tagged scaffold SEPCOIII

objects maintain three 3-point contact

Head injuries SUPV

while ascending descending on

the Ladder. No work to be

undertaken in adverse weather

conditions (wind, rain). make sure

100% tie off harness while

working at the scaffold platform.

Put material and tools in basket or

away from the edge of scaffolding

platform to avoid falling objects.

Clear access from all obstacle and

arrange material to avoid tripping

hazard. Maintaining proper

housekeeping before start of work

and after end of shift.

RC/HSE/SP-008/FM-013 Rev.00 Rev. Date 28 Aug 2017 Page 5 of 6

Contractor Company

Safe Work Method Statement (SWMS) Logo to be fixed here

This SWMS has been developed in consultation and has been read, understood, and signed by all workers undertaking the scope of works.

Name: Job Title / Designation Signature & Date:

Reviewed & Approved by NOMAC HSE: Revision Number:

(Name & Signature) Date:

(This section will be filled by ROMCO HSE)

RC/HSE/SP-008/FM-013 Rev.00 Rev. Date 28 Aug 2017 Page 6 of 6

You might also like

- JSA-Scaffolding Erection & Dismantling Works RV-00Document2 pagesJSA-Scaffolding Erection & Dismantling Works RV-00abou bakarNo ratings yet

- Risk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in OmbDocument9 pagesRisk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in Ombnsadnan100% (1)

- JSA Installation-Fire-Alarm-SystemDocument12 pagesJSA Installation-Fire-Alarm-Systemuz9143895No ratings yet

- Risk Assessment For Refurbishment of Civil Assets in Pump Station Rev 00Document12 pagesRisk Assessment For Refurbishment of Civil Assets in Pump Station Rev 00Sachwin SachuNo ratings yet

- Lifting and Removing Using The Forklift or Telescopic Loader in SiteDocument3 pagesLifting and Removing Using The Forklift or Telescopic Loader in SiteAMINNo ratings yet

- Rmdjv-pj74-Hiradc-subc 03 (Hoisting & Rigging)Document1 pageRmdjv-pj74-Hiradc-subc 03 (Hoisting & Rigging)myn maliQueNo ratings yet

- Abrasive Wheels Risk AssessmentDocument4 pagesAbrasive Wheels Risk AssessmentAhmed El-sherpiniNo ratings yet

- Job Hazard Analysis: Format For JHA WorksheetDocument3 pagesJob Hazard Analysis: Format For JHA WorksheetWaseem AhmadNo ratings yet

- 13.2.11 RA SWP For Installation of Instruments and Instrument Tubing at DCLDocument17 pages13.2.11 RA SWP For Installation of Instruments and Instrument Tubing at DCLkeertiraj09100% (1)

- Ra of Manual Excavation For Trench of Telephone CableDocument5 pagesRa of Manual Excavation For Trench of Telephone CableRaza Muhammad SoomroNo ratings yet

- Risk Assessment Carpentry Works For Dismantling Wooden BoxesDocument10 pagesRisk Assessment Carpentry Works For Dismantling Wooden BoxesSinaNo ratings yet

- RA Underground Fire Pipe Installation Work R02Document15 pagesRA Underground Fire Pipe Installation Work R02vinayNo ratings yet

- Excavation & Backfilling Risk AssessmentDocument6 pagesExcavation & Backfilling Risk AssessmentAbdul Rasheed Mangrio100% (1)

- Activity Hazard Analysis (AHA) : Risk Assessment Code (RAC) Matrix Severity ProbabilityDocument2 pagesActivity Hazard Analysis (AHA) : Risk Assessment Code (RAC) Matrix Severity ProbabilityYug DobariyaNo ratings yet

- RA Pump TemoraryDocument12 pagesRA Pump TemoraryCarlos ImmanuelNo ratings yet

- HSE Risk Assessment For Hot Work ActivityDocument8 pagesHSE Risk Assessment For Hot Work ActivityDarseen RNo ratings yet

- 31.0.10 LLA - Manual HandlingDocument4 pages31.0.10 LLA - Manual HandlingGerritNo ratings yet

- Risk Assessment: Chilled Water Line Chemical Flushing and Passivation DubaiDocument4 pagesRisk Assessment: Chilled Water Line Chemical Flushing and Passivation DubaiSamboy Dionisio0% (1)

- Deep Excavation Risk AssessmentDocument12 pagesDeep Excavation Risk Assessmentdonfrancis639No ratings yet

- Building Materials Risk AssessmentDocument3 pagesBuilding Materials Risk AssessmentAhmed El-sherpiniNo ratings yet

- JSA For WIndow Opening and Finishing WorkDocument17 pagesJSA For WIndow Opening and Finishing WorkShekh BabulNo ratings yet

- JSA-054 Crossing WorksDocument6 pagesJSA-054 Crossing WorksMajdiSahnounNo ratings yet

- Using Hand Drill (WS)Document2 pagesUsing Hand Drill (WS)John KalvinNo ratings yet

- Risk Assessment of Cable Tray InstallationDocument10 pagesRisk Assessment of Cable Tray Installationfayaz fayazhotmail.comNo ratings yet

- 1 - Construction Mobilization THA-AHADocument5 pages1 - Construction Mobilization THA-AHAJojolas0% (1)

- Risk Assessment For Excavation Works Prior To Installation of Signage Gantry at Road A3Document6 pagesRisk Assessment For Excavation Works Prior To Installation of Signage Gantry at Road A3Muideen OyedeleNo ratings yet

- JSA Formet New Blasting & PaintingDocument5 pagesJSA Formet New Blasting & Paintingsakthi venkatNo ratings yet

- SS JSP - 009 Ground Preparation For Lean Concrete (Foundation Works)Document5 pagesSS JSP - 009 Ground Preparation For Lean Concrete (Foundation Works)Farhat SetharNo ratings yet

- 2.8c Risk Assessment Rev.02 - BlankDocument3 pages2.8c Risk Assessment Rev.02 - BlankShafie ZubierNo ratings yet

- Methodstatement and RiskAssessmentDocument13 pagesMethodstatement and RiskAssessmentAnonymous ExWAN2xjFJ100% (1)

- Risk Assesment Project VimalDocument7 pagesRisk Assesment Project VimalHASHIM TKNo ratings yet

- Job Safety Analysis (JSA) : Electronics (Cleaning + Servicing)Document2 pagesJob Safety Analysis (JSA) : Electronics (Cleaning + Servicing)Nishad MuhammedNo ratings yet

- Hazard Identification Risk Assessment Risk Control (HIRARC) - Submain Cable Ladder/tray InstallationDocument2 pagesHazard Identification Risk Assessment Risk Control (HIRARC) - Submain Cable Ladder/tray InstallationYasHie PwincsZaNo ratings yet

- Site Risk Register: Site Name: Rosebery ExDocument4 pagesSite Risk Register: Site Name: Rosebery ExvatasaNo ratings yet

- 7-609 Back Filling HiraDocument1 page7-609 Back Filling Hirar2mgt28ssvNo ratings yet

- Larsen & Toubro Limited Buildings and Factories Independent CompanyDocument5 pagesLarsen & Toubro Limited Buildings and Factories Independent CompanyabbasNo ratings yet

- Templates Package 1 ContentDocument1 pageTemplates Package 1 ContentM IqbalNo ratings yet

- Electrical Panel InstallationDocument2 pagesElectrical Panel InstallationKrishna PatilNo ratings yet

- Risk Assessment For FlushingDocument9 pagesRisk Assessment For FlushingABDUL BASITHNo ratings yet

- Task Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)Document3 pagesTask Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)andreNo ratings yet

- CRA - Structural Steel Staircase Fabrication Works at Leighton Plant YardDocument4 pagesCRA - Structural Steel Staircase Fabrication Works at Leighton Plant YardRiyas Mangodan100% (1)

- Hazard Identification & Risk Assessment (Hira) /jsa: Hira & Jsa For Tri Butyl Phosphate (TBP) PlantDocument6 pagesHazard Identification & Risk Assessment (Hira) /jsa: Hira & Jsa For Tri Butyl Phosphate (TBP) PlantShariq KhanNo ratings yet

- Stars - BoH Nomination FormDocument1 pageStars - BoH Nomination FormRafael-Cheryl Tupas-LimboNo ratings yet

- 20-RAS-Transformer InstallationDocument2 pages20-RAS-Transformer InstallationWalid MarhabaNo ratings yet

- Excavaten Work PermitDocument1 pageExcavaten Work Permitasem sawalmehNo ratings yet

- Form No. Hazard Identification & Risk AssessmentDocument3 pagesForm No. Hazard Identification & Risk AssessmentChandra Shekar EmaniNo ratings yet

- Al-Nafay Engeenering Solution Co. BSPM Kasur: Description: Risk Assessment of General Maintenance Work On Bio MassDocument11 pagesAl-Nafay Engeenering Solution Co. BSPM Kasur: Description: Risk Assessment of General Maintenance Work On Bio MassMuhammad Muneeb Naeem NaeemNo ratings yet

- Risk Assessment - Hand ToolsDocument2 pagesRisk Assessment - Hand ToolsRoy Chandra Sekar JeyapaulNo ratings yet

- Risk Assessment LoaderDocument3 pagesRisk Assessment Loadermohamed ghalyNo ratings yet

- 004-JSA Manual WeldingDocument6 pages004-JSA Manual WeldingMoaatazz NouisriNo ratings yet

- Elephant Project - Sayakha GujaratDocument8 pagesElephant Project - Sayakha Gujaratalla malikNo ratings yet

- 17.scafold Inspection UNISCO (PF) - 17Document2 pages17.scafold Inspection UNISCO (PF) - 17Benasher IbrahimNo ratings yet

- Risk Assessment For Ms Installation of Precast BoundrywallDocument11 pagesRisk Assessment For Ms Installation of Precast BoundrywallSajid ShahNo ratings yet

- Personal Protective Equipment Hazard AssessmentDocument5 pagesPersonal Protective Equipment Hazard AssessmentKrsnaPentayah100% (1)

- Risk Assessment - Rebar Shifting Using BHDocument4 pagesRisk Assessment - Rebar Shifting Using BHLeoniv Arviz LiboroNo ratings yet

- CSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Document12 pagesCSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Dan SarmientoNo ratings yet

- RA For Installation of Earthing & Bonding SystemDocument10 pagesRA For Installation of Earthing & Bonding SystemProjects INTSNo ratings yet

- Paint WorkDocument1 pagePaint WorkNarender BhardwajNo ratings yet

- P-985-SH-AHA-003. AHA For Outage Lock Our Tag OutDocument3 pagesP-985-SH-AHA-003. AHA For Outage Lock Our Tag OutPatrick Bibila NdansiNo ratings yet

- GGH Basket RemovelDocument9 pagesGGH Basket Removeltamoor sarwarNo ratings yet

- Ambulance Driver Specific OrientationDocument1 pageAmbulance Driver Specific Orientationtamoor sarwarNo ratings yet

- Ambulance Driver Competency AssessmentDocument1 pageAmbulance Driver Competency Assessmenttamoor sarwarNo ratings yet

- PR-CSF-CSS-P-035 PpeDocument17 pagesPR-CSF-CSS-P-035 Ppetamoor sarwarNo ratings yet

- GGH Basket RemovelDocument9 pagesGGH Basket Removeltamoor sarwarNo ratings yet

- How To Stabilize Equine Fractures in The Field Palmer AAEP 2012Document7 pagesHow To Stabilize Equine Fractures in The Field Palmer AAEP 2012Turok StaffNo ratings yet

- Chemical Burns Revisited: What Is The Most Appropriate Method of Decontamination?Document3 pagesChemical Burns Revisited: What Is The Most Appropriate Method of Decontamination?AdharaaNo ratings yet

- Basic First Aid ExamDocument2 pagesBasic First Aid ExamEMS Region2No ratings yet

- Sports Injury StatisticsDocument2 pagesSports Injury StatisticsJeffrey EscauriagaNo ratings yet

- HR2N2 TR106 ExamDocument3 pagesHR2N2 TR106 ExamMelissa Formento LustadoNo ratings yet

- Good Housekeeping Is The Foundation of S SafeDocument7 pagesGood Housekeeping Is The Foundation of S Saferahmani sakinaNo ratings yet

- Risk Assessment For Cable TrayDocument11 pagesRisk Assessment For Cable Traynellaika puspa dewiNo ratings yet

- Introduction To TCCC ASM Didactic PresentationDocument36 pagesIntroduction To TCCC ASM Didactic PresentationPaulo De Fão SousaNo ratings yet

- JSA FOR MaxseamDocument20 pagesJSA FOR Maxseamwahyu nugrohoNo ratings yet

- Anterior Cruciate Ligament Tear DefinitionDocument8 pagesAnterior Cruciate Ligament Tear DefinitionEunice IquinaNo ratings yet

- Assignment 6 - Putri Arifa Nur'Aini - 464211052Document3 pagesAssignment 6 - Putri Arifa Nur'Aini - 464211052Putri Arifa N.No ratings yet

- The Epidemiology of Open Long Bone FracturesDocument6 pagesThe Epidemiology of Open Long Bone FracturesLuigi Paolo Zapata DelgadoNo ratings yet

- Safty & SecurityDocument16 pagesSafty & SecurityAbul Hasan Shuvo100% (1)

- Tips For Office SafetyDocument1 pageTips For Office Safetyhunain zafarNo ratings yet

- Emergency Dispatch ProtocolDocument17 pagesEmergency Dispatch Protocolmeljamerlan100% (2)

- Return Demonstration: Medical Emergencies Common Medical EmergenciesDocument7 pagesReturn Demonstration: Medical Emergencies Common Medical EmergenciesMarc Angelo DareNo ratings yet

- Resource Unit. AdwcwdDocument6 pagesResource Unit. AdwcwdGreg Martin OrbegosoNo ratings yet

- Laporan Tutorial 2 Pertemuan 1Document7 pagesLaporan Tutorial 2 Pertemuan 1Fitri ArianiNo ratings yet

- TCAR ManualDocument193 pagesTCAR ManualJoe Reed (Game Master)No ratings yet

- What I Have Learned: Suffering A Double Stress FractureDocument5 pagesWhat I Have Learned: Suffering A Double Stress FractureAshley11 DeCastroNo ratings yet

- JSA E&I 10.electrical Instrument Panels RemovalDocument3 pagesJSA E&I 10.electrical Instrument Panels RemovalAmyNo ratings yet

- PEH 2 WK 7Document9 pagesPEH 2 WK 7memeNo ratings yet

- Executive HSE Dashboard - May 2023Document1 pageExecutive HSE Dashboard - May 2023Luqman ZamanNo ratings yet

- Locked PlateDocument2 pagesLocked PlatemesolyNo ratings yet

- Battered Child Syndrome (BCS) : Physical SignsDocument4 pagesBattered Child Syndrome (BCS) : Physical SignssabinNo ratings yet

- 47 Cable Glanding and TerminationDocument3 pages47 Cable Glanding and TerminationvasudevanmNo ratings yet

- Skills You Need To Learn First Aid Survival Skills Checklist 1 1Document3 pagesSkills You Need To Learn First Aid Survival Skills Checklist 1 1Agustin PeraltaNo ratings yet

- First Aid ROLDocument20 pagesFirst Aid ROLAnitha NoronhaNo ratings yet

- Supervisors Review Rating Sheet For Safety Performance (Circle Appropriate Evaluation Points For Performance)Document1 pageSupervisors Review Rating Sheet For Safety Performance (Circle Appropriate Evaluation Points For Performance)Ronak MotaNo ratings yet

- Jurnal CTDs KuntodiDocument22 pagesJurnal CTDs KuntodiHanunNo ratings yet