Professional Documents

Culture Documents

E.4 Leg Support Calculation

Uploaded by

naimCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E.4 Leg Support Calculation

Uploaded by

naimCopyright:

Available Formats

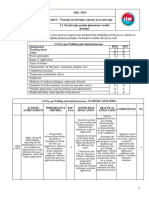

Doc No. : ART/DC/18-02 Client :Sbase Engineering Sdn. Bhd.

Rev No. : A Air Receiver Tank

Leg Support - Operating Condition

Design Data :

Total Weight of Vessel @ Operating W 2500 Kg

Horizontal Base Shear V 800 N

Y

Leg Information : Z

W

Material EN 10025 S275JR

Modulus of Elasticity E 180000 Mpa X e X

Material Yield Strength Fy 275 Mpa a

Number of Legs n 3

Z

Leg Initial degree 45 deg

W

Geomtery Information : Y

Moment of Elastic Modulus Centre of

Section Width, b Height, thick. t Area, A 4 3

Gravity (mm)

2 Inertia (mm ) (mm )

member (mm) h (mm) (mm) (mm )

Ix Iy Sx Sy x' y'

50x50x6 50.0 50.0 6.0 465.8 126000 126000 3550 3550 1.5 1.5

Moment of Elastic Modulus Radius of Centre of

Section

member

Inertia (mm4) (mm3) Gyration (mm) Gravity (mm)

Iw Iz Sw Sz rw rz w' z'

50x50x6 45344 206656 2245 97419 9.9 21.1 2.1 2.1

Shell Data :

D

Outer Diameter of Shell D 600 mm Fv

Thickness of Shell ts 12.7 mm

Fh C.G

Leg Support Data : f1 f1

Distance from base to C.G L 750.0 mm Fv

Overall Length of Leg Lt 500.0 mm

Effective Leg Length Le 350.0 mm Vn L

Outermost Leg Diameter d 604.2 mm Lt

Attachment Length C11 150 mm

Le

Eccentricity of leg e 25 mm

Effective Length Factor K 1.0

V

d

A. Available Load on the Leg Support

Fn Fn

Horizontal Force @ C.G of vessel Fh 800 N

Vertical Force @ C.G of vessel Fv 25000 N

Overturning Moment @ Base Mb = L*Fh = 600000 N-mm

Overturning Moment @ Btm T.L Mt = (L-Le)*Fh = 320000 N-mm

Max. eccentric Load f1 = -Fv/n-4Mt/nD = -9044 N

Bending Moment @ Each Leg Support M = f1*e+Vn*Le = 506111 N-mm

Max. Axial Load @ Furtherst Dia. Leg from C.L

Fn = FD + FL

= Fv/n + 4M/nd

= 9450.1 N

B.Allowable Load as per AISC 360-10 14th Ed.

B.1 Allowable Compressive Stress as per Ch. E

Does b/t > 0.45*sqrt(E/Fy)? No

Does the slenderness ratio Lc/r > 200? No

Therefore, the geometry is consider as a slender element

Effective Length Member Lc = K*Le = 350 mm

Elastic Buckling Stress Fe = E*(p/(Lc/rw))2 = 1421.4 Mpa

Doc No. : ART/DC/18-02 Client :Sbase Engineering Sdn. Bhd.

Rev No. : A Air Receiver Tank

Leg Support - Operating Condition

The crticial stress of the member

Does the ratio Lc/r > 4.71*sqrt(E/Fy)? No

The critical stress Fcr = (0.658^(Fy/Fe))Fy = 253.6 Mpa

Nominal Compressive Stress Pn = (Fcr*A)/1.67 = 70739 N

B.2 Allowable Flexural Stress as per Ch. F

Does b/t > 0.54*sqrt(E/Fy)? No

Does b/t > 0.91*sqrt(E/Fy)? No

Therefore, the section is consider as compact

B.2.1 Limit States due to Yielding

Elastic Yield Moment My = Fy*Sw = 617375 N-mm

Limit State due to Yielding Mn1 = 1.5*My = 926062.5 N-mm

B.2.3 Limit States due to Leg Local Buckling

2

Fcr = 0.71E/(b/t)

= 1840.3 Mpa

Mn2 = 0

= 0.0 N-mm

Nominal Flexural Strength Mn = min(Mn1,Mn2) = 926063 N-mm

Allowable Flexural Moment Mc = Mn/1.67 = 554528 N-mm

Therefore,The limit state of the member was due to Yielding

Note:

Since the calculation is refering bending

about the minor axis, the limit state of

yielding and leg local buckling is apply

C. Stress Ratio as per Ch. H

Does the ratio Pr/Pc < 0.2? Yes

Ratio = Fn/2Pn+(M/Mc)

= 0.98

Does the stress ratio, Ratio < 1? Yes

Therefore, the selected member for the leg support is sufficient

You might also like

- Lug SupportDocument2 pagesLug SupportSachin5586No ratings yet

- Base Ring Fillet Size CalculationDocument4 pagesBase Ring Fillet Size Calculationmiteshpatel191No ratings yet

- Flange Pad CalcsDocument4 pagesFlange Pad CalcstomNo ratings yet

- Saddle Stresses On Shell During Transportation: Equipment NoDocument5 pagesSaddle Stresses On Shell During Transportation: Equipment NoshazanNo ratings yet

- Skirt To Dish Joint PDFDocument64 pagesSkirt To Dish Joint PDFPrajwal ShettyNo ratings yet

- Support Leg DesignDocument4 pagesSupport Leg DesignDeepika0% (2)

- 3-Leg Calculation for Vertical Vessel SupportDocument21 pages3-Leg Calculation for Vertical Vessel SupportBahtiar Anak LaNangNo ratings yet

- Collar bolt sizing calculationDocument2 pagesCollar bolt sizing calculationMohammad Zahid50% (2)

- Saddle Road Transportation Analysis 1Document2 pagesSaddle Road Transportation Analysis 1vpjagannaathNo ratings yet

- Horizontal Vessel Stress AnalysisDocument12 pagesHorizontal Vessel Stress AnalysissridharNo ratings yet

- SADDLE SUPPORT DESIGNDocument6 pagesSADDLE SUPPORT DESIGNSISIR KR BARMAN0% (1)

- Documents - Tips - Pressure Vessel Design Calc Asme VIII Div 1Document35 pagesDocuments - Tips - Pressure Vessel Design Calc Asme VIII Div 1bainNo ratings yet

- Agitator FINITE ELEMENT METHODDocument5 pagesAgitator FINITE ELEMENT METHODRoopesh S AcharyaNo ratings yet

- PPE-STD-CAL-ME-006 Rectangular Tank Thickness CalculationDocument4 pagesPPE-STD-CAL-ME-006 Rectangular Tank Thickness CalculationNadya Askar100% (1)

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFDocument4 pagesBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiNo ratings yet

- PV Elite Webinar 001Document23 pagesPV Elite Webinar 001MEC_GuiNo ratings yet

- Small Vertical Pressure Vessel Leg Support Design - Boiler and Pressure Vessel Engineering - Eng-Tips PDFDocument6 pagesSmall Vertical Pressure Vessel Leg Support Design - Boiler and Pressure Vessel Engineering - Eng-Tips PDFhussamammarNo ratings yet

- Crossover Area Calc For Floating HeadDocument2 pagesCrossover Area Calc For Floating HeadRitesh VishambhariNo ratings yet

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Document32 pagesPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNo ratings yet

- H200141 - Calculation of Basering Rev 0 PDFDocument9 pagesH200141 - Calculation of Basering Rev 0 PDFSani Adipura WinataNo ratings yet

- Check 18Document6 pagesCheck 18Anonymous qBwHKusNo ratings yet

- Lifting Lug Design CalculationsDocument17 pagesLifting Lug Design CalculationsSiva baalan100% (1)

- Saddle AnalysisDocument17 pagesSaddle AnalysisAntonio Perez ZornozaNo ratings yet

- Roark's Circular PlateDocument2 pagesRoark's Circular PlatePaulo MoreiraNo ratings yet

- Tailing LugDocument3 pagesTailing LugSajad AbdulNo ratings yet

- Swing Bolt CalculationDocument2 pagesSwing Bolt CalculationNicolaSavili100% (2)

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- Leg CalculationDocument10 pagesLeg Calculationmashudi_fikriNo ratings yet

- How To Calculate Flat Plate Thickness of Flat Bottom Storage TankDocument3 pagesHow To Calculate Flat Plate Thickness of Flat Bottom Storage TankSiva baalanNo ratings yet

- 015 DH 1003 Rectangular TanksDocument12 pages015 DH 1003 Rectangular TanksAndrew PopeNo ratings yet

- Discipline document calculationDocument20 pagesDiscipline document calculationSivi NallamothuNo ratings yet

- Hinge Calculation FormulasDocument2 pagesHinge Calculation FormulasamaNo ratings yet

- 5.7 Asmeviii A-2 & Tema Split Backing RingDocument1 page5.7 Asmeviii A-2 & Tema Split Backing RingpastylNo ratings yet

- Compress EvaluateDocument23 pagesCompress EvaluateVishalDhiman100% (1)

- Skirt Support Analysis Per en 13445Document13 pagesSkirt Support Analysis Per en 13445karthik1amarNo ratings yet

- Sample Design Calculation - Vessel Supported On LugsDocument4 pagesSample Design Calculation - Vessel Supported On LugsAbhay Upadhyay0% (1)

- Support RingDocument13 pagesSupport RingvamsiNo ratings yet

- Etank Full ReportDocument108 pagesEtank Full ReportFaizal SattuNo ratings yet

- NozzleDocument11 pagesNozzleharyfadlyNo ratings yet

- Internal Pipe Distributor Design ProcedureDocument5 pagesInternal Pipe Distributor Design Proceduresenthil kumarNo ratings yet

- Saddle CalculationDocument10 pagesSaddle Calculationpharis_chrisNo ratings yet

- Pressure Vessel Lifting Lug CalculationDocument2 pagesPressure Vessel Lifting Lug Calculationtekstep750% (2)

- WRC Check List CriteriaDocument1 pageWRC Check List CriteriaAlvin Smith100% (1)

- Agitator Nozzle Load Data SheetDocument1 pageAgitator Nozzle Load Data SheetAnonymous MB5YbaLrBENo ratings yet

- Weir Plate or Baffle Plate CalculationDocument2 pagesWeir Plate or Baffle Plate CalculationamaNo ratings yet

- Pvelite OutputDocument44 pagesPvelite OutputRam MurtyNo ratings yet

- Body Flange DesignDocument3 pagesBody Flange DesignDeepikaNo ratings yet

- Longitudinal Bending Stress: M1 Allowable Limit RemarkDocument16 pagesLongitudinal Bending Stress: M1 Allowable Limit RemarkSandal JepitNo ratings yet

- BASE PLATE DESIGNDocument4 pagesBASE PLATE DESIGNvinujohnpanickerNo ratings yet

- BASE PLATE DESIGN CHECKDocument4 pagesBASE PLATE DESIGN CHECKAbhay ThakurNo ratings yet

- Base Plate Design BS CodeDocument3 pagesBase Plate Design BS CodeFodor ZoltanNo ratings yet

- Calculating steel profile strength and capacityDocument4 pagesCalculating steel profile strength and capacityosman_sultan100% (1)

- 27Document3 pages27Fazri CMENo ratings yet

- Spreader Beam: ASME BTH-1: InputsDocument17 pagesSpreader Beam: ASME BTH-1: InputsGokul AmarnathNo ratings yet

- Channel Design AISCDocument9 pagesChannel Design AISCRajveer SinghNo ratings yet

- Piezoelectric Force Washer: Special FeaturesDocument4 pagesPiezoelectric Force Washer: Special FeaturesEngineerNo ratings yet

- ERECTION S1-Combined-1Document56 pagesERECTION S1-Combined-1priya giriNo ratings yet

- Davit Arm Calculation-5mtDocument2 pagesDavit Arm Calculation-5mtPrabha Karan0% (1)

- Column Design PDFDocument4 pagesColumn Design PDFRaju SainiNo ratings yet

- Jack Support Beam (8 PG)Document8 pagesJack Support Beam (8 PG)dheeraj SureshNo ratings yet

- Template Alamat SuratDocument1 pageTemplate Alamat SuratnaimNo ratings yet

- Verificación Por Corte PDFDocument98 pagesVerificación Por Corte PDFTUAMIGOVANCITONo ratings yet

- External Pressure-Dish Head and Shell-Taiwan TankDocument1 pageExternal Pressure-Dish Head and Shell-Taiwan TanknaimNo ratings yet

- 9011S121 Sample PDFDocument5 pages9011S121 Sample PDFEngr Baha KhatibNo ratings yet

- WRC 107 Calculation-Circular Attachment On Cylinder (Without Repad)Document3 pagesWRC 107 Calculation-Circular Attachment On Cylinder (Without Repad)naim100% (1)

- HDHDHFHHFDocument6 pagesHDHDHFHHFFu AdNo ratings yet

- DOSH HydrotestDocument1 pageDOSH HydrotestnaimNo ratings yet

- Technical Catalogue: Pipes Tubes Fittings FlangesDocument121 pagesTechnical Catalogue: Pipes Tubes Fittings FlangesDANIELVENZUELAANo ratings yet

- Example Truss Problem PDFDocument2 pagesExample Truss Problem PDFnaimNo ratings yet

- ASME ListDocument1 pageASME ListnaimNo ratings yet

- Drawing1 ModelDocument1 pageDrawing1 ModelnaimNo ratings yet

- Example Truss Problem PDFDocument2 pagesExample Truss Problem PDFnaimNo ratings yet

- Book ReferenceDocument1 pageBook ReferencenaimNo ratings yet

- Pipe ListDocument1 pagePipe ListnaimNo ratings yet

- Shackle Verification DimensionDocument1 pageShackle Verification DimensionnaimNo ratings yet

- Base Ring AnalysisDocument9 pagesBase Ring Analysisasirul_meNo ratings yet

- SampleDocument26 pagesSamplenaimNo ratings yet

- Discussion - Design of W-Shapes For Combined Bending and TorsionDocument2 pagesDiscussion - Design of W-Shapes For Combined Bending and TorsionnaimNo ratings yet

- Clamps Poster English PDFDocument1 pageClamps Poster English PDFJati PangarsoNo ratings yet

- Test 4Document3 pagesTest 4naimNo ratings yet

- Test 2Document2 pagesTest 2naimNo ratings yet

- FEA Pressure VesselDocument48 pagesFEA Pressure VesselnaimNo ratings yet

- Tees Cut From Universal Beams To BS4 Part 1 - 1993Document4 pagesTees Cut From Universal Beams To BS4 Part 1 - 1993naim100% (1)

- Calculating Truss ForcesDocument29 pagesCalculating Truss Forcesrecep1No ratings yet

- Ovaling Deformations of Circular Tunnels Under Seismic Loading, An Update On Seismic Design and Analysis of Underground Structures PDFDocument7 pagesOvaling Deformations of Circular Tunnels Under Seismic Loading, An Update On Seismic Design and Analysis of Underground Structures PDFnaimNo ratings yet

- Design of Saddle Support For Horizontal Pressure Vessel PDFDocument5 pagesDesign of Saddle Support For Horizontal Pressure Vessel PDFnizam1372100% (3)

- PV Elite WebinarDocument24 pagesPV Elite WebinarAndrea Hank LattanzioNo ratings yet

- Hex Meshing CAEADocument31 pagesHex Meshing CAEAnaimNo ratings yet

- Beam Size SelectionDocument1 pageBeam Size SelectionnaimNo ratings yet

- Avionics Fiber Optical CablesDocument6 pagesAvionics Fiber Optical CablesT/ROX100% (1)

- Alcohol, Phenol and Ethers Digital Notes by Bharat PanchalDocument24 pagesAlcohol, Phenol and Ethers Digital Notes by Bharat Panchalzaid ansari86% (7)

- Smart Supercapacitors From Materials To DevicesDocument13 pagesSmart Supercapacitors From Materials To DevicesRavi SuryaNo ratings yet

- 2 - (Biochem) Oxidizing and ReducingDocument3 pages2 - (Biochem) Oxidizing and ReducingKaireen OzNo ratings yet

- M&MSDocument2 pagesM&MSASIST MechNo ratings yet

- Hydac Filter ElementsDocument30 pagesHydac Filter Elementsatorresh090675No ratings yet

- Chapter2 Di Pa TaposDocument13 pagesChapter2 Di Pa TaposDianne VillanuevaNo ratings yet

- Peri Tillbehör PDFDocument20 pagesPeri Tillbehör PDFAchmadRiduwanNo ratings yet

- Chem Depth Study - Mod 8Document6 pagesChem Depth Study - Mod 8Charlotte JaisonNo ratings yet

- 2019 - 1.2. Zavarivanje Gasnim Plamenom I Srodni PostupciDocument25 pages2019 - 1.2. Zavarivanje Gasnim Plamenom I Srodni PostupciticmaNo ratings yet

- Theory - of - Indicators OswalDocument3 pagesTheory - of - Indicators OswalHitansh KotadiyaNo ratings yet

- Sample Concept PapersDocument30 pagesSample Concept PapersEmily Dueñas SingbencoNo ratings yet

- Experiences in Designing and Operating The Latest 1,050-MW Coal-Fired BoilerDocument5 pagesExperiences in Designing and Operating The Latest 1,050-MW Coal-Fired BoilerswatkoolNo ratings yet

- Kinetic Particle TheoryDocument6 pagesKinetic Particle TheoryHassan AlviNo ratings yet

- MSE 440/540 Surface Processing LecturesDocument38 pagesMSE 440/540 Surface Processing LecturesrustyryanbradNo ratings yet

- Hook-Up Solutions Hanley Controls Compressed AirDocument16 pagesHook-Up Solutions Hanley Controls Compressed AirAriel HughesNo ratings yet

- Recent Advance Reactive Extrusion in PolymerDocument24 pagesRecent Advance Reactive Extrusion in Polymershanshicn8351No ratings yet

- CSA GasTrade-Ed7 Quiz U10-Ch3Document2 pagesCSA GasTrade-Ed7 Quiz U10-Ch3diegoNo ratings yet

- Ias 4 4 275 284 PDFDocument10 pagesIas 4 4 275 284 PDFHarjinder SinghNo ratings yet

- Interzinc 22 Application Guidelines UkDocument10 pagesInterzinc 22 Application Guidelines Ukapde06No ratings yet

- Construction Tech II Door TypesDocument105 pagesConstruction Tech II Door Typessydney augustNo ratings yet

- SSC Resistance of QT-900 and QT-1000 Coiled TubingDocument11 pagesSSC Resistance of QT-900 and QT-1000 Coiled TubingSeçkin ÖztelNo ratings yet

- P028 Industrial Lattice Frame BuildingDocument100 pagesP028 Industrial Lattice Frame BuildingAnilMohanK100% (12)

- Steel Manufacturing Pollution Impacts Da Hoi VillageDocument24 pagesSteel Manufacturing Pollution Impacts Da Hoi VillageThuận Nguyễn HữuNo ratings yet

- Load CalculationsDocument3 pagesLoad CalculationsWilkenn TuazonNo ratings yet

- Et 0000 0 000 04 750Document83 pagesEt 0000 0 000 04 750RenatoNo ratings yet

- Application Ultratrace Ree Icp-Qqq-5994-1785en Us AgilentDocument5 pagesApplication Ultratrace Ree Icp-Qqq-5994-1785en Us AgilentGuillermo Acosta OchoaNo ratings yet

- Environmental Impacts of Plastic RecyclingDocument2 pagesEnvironmental Impacts of Plastic RecyclingBernard BaluyotNo ratings yet

- Black PowderDocument48 pagesBlack PowderxiaotaoscribdNo ratings yet

- Zhou Yi 50Document155 pagesZhou Yi 50emiliofalsoNo ratings yet