Professional Documents

Culture Documents

1.4301 Austenite Stainless Steel

Uploaded by

SM Waqas ImamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.4301 Austenite Stainless Steel

Uploaded by

SM Waqas ImamCopyright:

Available Formats

1.

4301 Austenite Stainless Steel

What is 1.4301?

Grade 1.4301 is the German equivalent grade of 304 type stainless steel. It is an austenite

grade that is able to be deep drawn. Therefore it is widely used in drawing application such

as sinks or pans. It is the most commonly stainless steel, and was known in older times as

18/8 stainless steel.

What is DIN EN 10088? 1.4301 is also identified in the standard EN 10088. The scope of

the standard covers specifications for bars, rods, wire, sections, semi-finished products and

bright products of corrosion resistance.

Why 1.4301 called AISI 304 Steel? 304 austenite stainless steel is the American

equivalent of grade 1.4301, and is the reason why there two terms are interchangeably

used.

Available Forms in Market: Following are the available forms of 1.4301 steels in the

global market:

Flat bars

Blocks

Hexagon bar

Rebar

Wire

Tube and pipe

Plates

Round bars

Square bars

Sheets

Dimensional Characteristics of 1.4301 Steels: The applicable thickness for this 1.4301

material as obtained by online statistics in the market starts from 1 mm to 120 mm

depending upon the final shape and the type of processes. However the width of this

material varies and it is available in 10 mm to 80 mm. As it is available in different forms,

dimensional aspects should be confirmed from traders, manufacturers and dealers. Steel

round bars are available from 1 to 120 mm diameter.

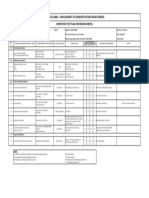

The Indicative Chemical Composition of 1.4301 Steels: The chemical composition of

this grade is indicated as under:

Maximum percentage of Carbon (C) is .07 percent.

Maximum percentage of Manganese (Mn) is 2.0 percent

Minimum percentage of Chromium (Cr) is 17.5 percent and maximum percentage of

Chromium is 19.50 percent.

Material Grades PDF Resources www.materialgrades.com

1.4301 Austenite Stainless Steel

Maximum percentage of Silicon (Si) is 1.00 percent.

Maximum percentage of Phosphorous (P) is 0.05 percent.

Maximum percentage of Sulphur (S) is 03 percent

Range of Nickel (Ni) percentage is from 8.0 to 10.5 percent.

Nitrogen (N) impurities are about 0.11 percent.

Remaining is iron (Fe) percentage and with few negligible impurities.

Mechanical Properties of 1.4301 Steels: Following are some of the mechanical

properties of 18/8 material:

The yield strength of the subject steel is expressed in Newton per millimeters and it must be

at-least 235 N/mm2 (MPa).

The elongation property of 1.4301 steel varies with the heat treatment process and

thickness but it is indicated typically 40%.

Tensile strength range is around 530 N/mm2 to 730 N/mm2.

Different forms

Equivalent Material Grades in Other International Standards: Read more about the

Equivalent grade of this type in US is 304 stainless steel.

In UNS designation, the corresponding material is referred as UNS S30400.

In AFNOR standard, it is referred as Z7CN 18-09

Applications of 1.4301 Stainless Steels: Applications are as under

Making of Heat exchangers

Making of pipe lines

Material Grades PDF Resources www.materialgrades.com

1.4301 Austenite Stainless Steel

Making of pressure vessels

Making of valves

Making of flanges and fittings

Making of threaded bard

Making of fasteners and fittings

Making of surgical instruments

Heat Treatment Processes

Effects of Cold Forming: According to ASTM A213, the austenitic stainless steel is

subjected to heat treatment to eradicate the impacts of cold forming or to make precipitated

chromium carbides dissolved.

Solution Annealing: The most certain heat treatment to have both requirements is the

solution anneal which is done at 1850 degree Fahrenheit to 2050 degree Fahrenheit range

(equivalence to 1010 degree Celcius to 1121 degree Celcius).

Post-annealing Cooling: Cooling from the anneal temperature should be at adequtely high

rates through 1500 degree Fahrenheit to800 degree Fahrenheit (816 degree Celcius to 427

degree Celcius) to pevent re-precipitation of chromium carbides.

Suppliers of 1.4301 Steel: Suppliers are also listed below:

Supplier M. Woite GmbHbearing contact number 49 (211) 29 26 00 – 00. The supplier

address is Freiheitstraße 8 a · 40699 Erkrath · Germany.

Supplier Steelinox BV bearing contact number +31(0) 186 651004 .The supplier address is

Einsteinstraat 9,3281 NJ Numansdorp, The Netherlands

Material Grades PDF Resources www.materialgrades.com

You might also like

- Corrosion Test PiecesDocument23 pagesCorrosion Test PiecesGijoNo ratings yet

- Case Study on Sulfide Stress Corrosion Cracking of an A216-WCC Wellhead Flow Control Valve BodyDocument12 pagesCase Study on Sulfide Stress Corrosion Cracking of an A216-WCC Wellhead Flow Control Valve Bodypinkan25No ratings yet

- ICHAZ Microstructure Impacts HSLA Steel ToughnessDocument10 pagesICHAZ Microstructure Impacts HSLA Steel ToughnessFilipe RenanNo ratings yet

- Effect of Heat Input On Microstructure of Weld by Using 308L As Filler Metal and 304L As Base MetalDocument8 pagesEffect of Heat Input On Microstructure of Weld by Using 308L As Filler Metal and 304L As Base Metalshrikant tambeNo ratings yet

- EGW Welding Wire Guide for 490MPa SteelDocument2 pagesEGW Welding Wire Guide for 490MPa SteelpratishgnairNo ratings yet

- TighteningofStructuralBolts 31-35Document5 pagesTighteningofStructuralBolts 31-35masaud akhtarNo ratings yet

- En ASME ComparisonDocument18 pagesEn ASME ComparisonPeterWay100% (1)

- A 1092 - 15Document3 pagesA 1092 - 15Pavan KumarNo ratings yet

- Thermanit MTS 3 - GTAWDocument1 pageThermanit MTS 3 - GTAWdnageshm4n244No ratings yet

- Geometric Unsharpness FormulaDocument2 pagesGeometric Unsharpness FormulaJayaneela Prawin0% (1)

- 16mo3 MıgMagDocument4 pages16mo3 MıgMagKerem İnanNo ratings yet

- 625 Characterization of Microstructures in Inconel 625 Using X-RAY PDFDocument5 pages625 Characterization of Microstructures in Inconel 625 Using X-RAY PDFKara WhiteNo ratings yet

- Spatter Reduction ChecklistDocument6 pagesSpatter Reduction ChecklistJorge perezNo ratings yet

- Sa 435 (Ed 2013)Document4 pagesSa 435 (Ed 2013)Mohd Idris MohiuddinNo ratings yet

- File - 4houldcroft Weldability Test of Aluminium Alloy EN AW 6082 T6 7 - Part - 254-1Document8 pagesFile - 4houldcroft Weldability Test of Aluminium Alloy EN AW 6082 T6 7 - Part - 254-1Corey DodsonNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Propulsion Shafting Material Requirements & DesignDocument1 pagePropulsion Shafting Material Requirements & DesignCRISTHIAN PIERR PAUSIC BAZALARNo ratings yet

- 20G Boiler Steel Pipe Resource GuideDocument5 pages20G Boiler Steel Pipe Resource GuideHeza FirdausNo ratings yet

- Temper Embrittlement - J and X FactorDocument2 pagesTemper Embrittlement - J and X Factorgovimano100% (2)

- Check ValveDocument2 pagesCheck ValveVaitheeswaran PalaniNo ratings yet

- Sa 961 PDFDocument10 pagesSa 961 PDFaruntpeNo ratings yet

- En 12451 1999Document24 pagesEn 12451 1999victoraghiNo ratings yet

- BS en 00287-6-2010Document26 pagesBS en 00287-6-2010Shan Sandaruwan AbeywardeneNo ratings yet

- BA GRaville - 1973 Cooling Rates and HAZ Hardness in Carbon SteelsDocument9 pagesBA GRaville - 1973 Cooling Rates and HAZ Hardness in Carbon SteelsBhavana ValetiNo ratings yet

- 25CrMo4Document1 page25CrMo4Hans GoetheNo ratings yet

- Inspection of CastingDocument23 pagesInspection of CastingRaghu SanthNo ratings yet

- ITP For Drum Screen InspectionDocument1 pageITP For Drum Screen InspectionkapsarcNo ratings yet

- Tubular Heat ExchangerDocument4 pagesTubular Heat Exchangerprashant_dc_inNo ratings yet

- Definition of Buttering From ASME Section IXDocument2 pagesDefinition of Buttering From ASME Section IXsanket100% (3)

- Weld Decay 2Document8 pagesWeld Decay 2Ahmed M. HashimNo ratings yet

- 253 MA Austenitic - High - Temperature - Grades - Datasheet PDFDocument12 pages253 MA Austenitic - High - Temperature - Grades - Datasheet PDFAbdulNo ratings yet

- Astm A 450Document10 pagesAstm A 450Telmo VianaNo ratings yet

- MCE Welder Performance Qualification ReportDocument2 pagesMCE Welder Performance Qualification ReporthamidjoyiaNo ratings yet

- API 510 Case Study - 7Document2 pagesAPI 510 Case Study - 7Khaled FatnassiNo ratings yet

- ITP For PipingDocument5 pagesITP For PipingAldeline SungahidNo ratings yet

- Submerged arc welding consumablesDocument7 pagesSubmerged arc welding consumablesMuhammed SulfeekNo ratings yet

- ISO 9692 joint preparation guideDocument46 pagesISO 9692 joint preparation guidebiancogallazziNo ratings yet

- PI Tectyl-506 TE031-01Document2 pagesPI Tectyl-506 TE031-01nicusebpNo ratings yet

- Application for Certification according to DIN 18800-7Document9 pagesApplication for Certification according to DIN 18800-7gorgika papandNo ratings yet

- ASME P-NumbersDocument9 pagesASME P-NumbersAamer MohammedNo ratings yet

- Astm e 428 Rev A 2005 PDFDocument7 pagesAstm e 428 Rev A 2005 PDFJORGE ARTURO TORIBIO HUERTANo ratings yet

- Basic Points of P91Document4 pagesBasic Points of P91Asad Bin Ala QatariNo ratings yet

- Asme CCase 1987-2Document2 pagesAsme CCase 1987-2ADAMJSRAONo ratings yet

- Asme IxDocument95 pagesAsme Ixjoseph.maquez24No ratings yet

- Fabrication of Components at Dillinger Huette Heavy FabricationDocument82 pagesFabrication of Components at Dillinger Huette Heavy Fabrication66apenlullenNo ratings yet

- Asme Ix QuizDocument5 pagesAsme Ix Quizamalhaj2013No ratings yet

- Severin FinalDocument26 pagesSeverin Finalcristasocum_trans1758No ratings yet

- Surfacing of 3.25% Nickel Steel With Inconel 625 by The Gas Metal Arc Welding-Pulsed Arc ProcessDocument8 pagesSurfacing of 3.25% Nickel Steel With Inconel 625 by The Gas Metal Arc Welding-Pulsed Arc ProcessMoses_JakkalaNo ratings yet

- EN 10298-2005 Steel Tubes and Fittings For On Shore and Offshore Pipelines - Internal Lining With CementDocument11 pagesEN 10298-2005 Steel Tubes and Fittings For On Shore and Offshore Pipelines - Internal Lining With CementChrisNo ratings yet

- Er 100 S 1Document1 pageEr 100 S 1Oliver Quezada Inostroza100% (1)

- Zero Defect in P91-Report-2005Document20 pagesZero Defect in P91-Report-2005sbmmla100% (1)

- API 510 PWHT RequirementsDocument30 pagesAPI 510 PWHT RequirementsKandregula Mohan BabuNo ratings yet

- Procedure For: J164 (Rev 11/02)Document21 pagesProcedure For: J164 (Rev 11/02)tomcanNo ratings yet

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsFrom EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsNo ratings yet

- Is Stainless Steel Magnetic or Non-Magnetic in External FieldDocument3 pagesIs Stainless Steel Magnetic or Non-Magnetic in External FieldSM Waqas Imam100% (1)

- AISI 316 Austenitic Nonmagnetic Stainless SteelDocument3 pagesAISI 316 Austenitic Nonmagnetic Stainless SteelSM Waqas ImamNo ratings yet

- 316L Stainless Steel Low Carbon Austenite MaterialDocument5 pages316L Stainless Steel Low Carbon Austenite MaterialSM Waqas ImamNo ratings yet

- 1.4571 Stainless Steel & Titanium Austenite MaterialDocument5 pages1.4571 Stainless Steel & Titanium Austenite MaterialSM Waqas ImamNo ratings yet

- 1.4404 Material & Low Carbon Austenite Stainless SteelDocument5 pages1.4404 Material & Low Carbon Austenite Stainless SteelSM Waqas ImamNo ratings yet

- Jason Cafer Biosketch 8-2009Document3 pagesJason Cafer Biosketch 8-2009Jason CaferNo ratings yet

- Murat Kenedy: Bu Içerik Tarafından HazırlanmıştırDocument2 pagesMurat Kenedy: Bu Içerik Tarafından HazırlanmıştırChatorg. orgNo ratings yet

- Safety Steering System Alarm Code GuideDocument43 pagesSafety Steering System Alarm Code GuideIsrael Michaud84% (19)

- TableDocument9 pagesTableShamlakan elghaoucheNo ratings yet

- Research Proposal of SheepDocument37 pagesResearch Proposal of SheepDabalo Garama67% (3)

- Embraer ePerf Tablet App Calculates Takeoff & Landing Performance OfflineDocument8 pagesEmbraer ePerf Tablet App Calculates Takeoff & Landing Performance OfflinewilmerNo ratings yet

- Strategic Marketing Plan For Red Bull - Elvis Asiedu - Academia - Edu PDFDocument23 pagesStrategic Marketing Plan For Red Bull - Elvis Asiedu - Academia - Edu PDFThomas Diwo0% (1)

- Fire Risk Assessment FormDocument16 pagesFire Risk Assessment Formmukamat safiiNo ratings yet

- Cylindrical Plug Gage DesignsDocument3 pagesCylindrical Plug Gage DesignskkphadnisNo ratings yet

- Sunward Rotary Drilling Rig Maintenance ManualDocument35 pagesSunward Rotary Drilling Rig Maintenance ManualPaul Kenneth AbayataNo ratings yet

- Create Login Application In Excel Macro Using Visual BasicDocument16 pagesCreate Login Application In Excel Macro Using Visual Basicfranklaer-2No ratings yet

- Ravindar ReddyDocument4 pagesRavindar ReddysaanaprasadNo ratings yet

- General Format Feasibility StudyDocument7 pagesGeneral Format Feasibility StudyRynjeff Lui-Pio100% (1)

- Preview-9780429675119 A38620781Document53 pagesPreview-9780429675119 A38620781Milton Alexandre ZiehlsdorffNo ratings yet

- Vocabulary Extension Starter Without AnswersDocument1 pageVocabulary Extension Starter Without AnswersPatrcia CostaNo ratings yet

- EPC Contractor Rep. Authority/Authority's EngineerDocument6 pagesEPC Contractor Rep. Authority/Authority's Engineersunil kuldeepNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolssierroNo ratings yet

- ETEEAP Application SummaryDocument9 pagesETEEAP Application SummaryAlfred Ronuel AquinoNo ratings yet

- In The Shadow of The CathedralDocument342 pagesIn The Shadow of The CathedralJoy MenezesNo ratings yet

- Unit 30 WorkDocument2 pagesUnit 30 WorkThanh HàNo ratings yet

- PGSuperDocument71 pagesPGSuperVietanh PhungNo ratings yet

- Plagiarized Bio-Nanoelectronics in "Journal of The American Chemical Society"Document7 pagesPlagiarized Bio-Nanoelectronics in "Journal of The American Chemical Society"Rostyslav SKLYAR, Dr. (Eng)No ratings yet

- Ese 570 Mos Inverters Static Characteristics: Kenneth R. Laker, University of Pennsylvania, Updated 13feb12 1Document44 pagesEse 570 Mos Inverters Static Characteristics: Kenneth R. Laker, University of Pennsylvania, Updated 13feb12 1het shahNo ratings yet

- Animated Film Techniques for Phrasing Action and DialogueDocument10 pagesAnimated Film Techniques for Phrasing Action and Dialoguevall-eNo ratings yet

- Chapter 2 Planning Business MessagesDocument15 pagesChapter 2 Planning Business MessagesNuriAisyahHikmahNo ratings yet

- SATA Product Manual: Standard ModelsDocument32 pagesSATA Product Manual: Standard ModelsEdy AprilyantoNo ratings yet

- Multiple Choice Bubble Sheet Template Customize This WordDocument3 pagesMultiple Choice Bubble Sheet Template Customize This WordAl Bin0% (1)

- Speech Sound Disorders First Edition Ebook PDF VersionDocument57 pagesSpeech Sound Disorders First Edition Ebook PDF Versionzelma.bennett128100% (39)

- 104 Joycecaroloates Wrug ElectraDocument1 page104 Joycecaroloates Wrug ElectraAnca LascuNo ratings yet

- Myers Et Al - Clear and Present ThinkingDocument214 pagesMyers Et Al - Clear and Present ThinkingAENo ratings yet