Professional Documents

Culture Documents

MZ 350216 ZZ

Uploaded by

Rizky MotorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MZ 350216 ZZ

Uploaded by

Rizky MotorCopyright:

Available Formats

л

MITSUBISHI

MOTORS

OUTLANDER

Kit Part No: MZ350216ZZ

Reverse Parking Assist

Fitting Instructions

FI Doc No: FI7075 - Issue: 4 - 30/05/13

♦ OUTLANDER

MITSUBISHI

MOTORS

- General N o te s-------------------------------------------------------------------------—

- Read through the fitting instructions before installation of accessory.

- Always install the accessory following the fitting instructions. Failure to do so may cause damage to the vehicle or

the accessory.

- Ensure all recyclable discarded vehicle accessory components and packaging are recycled following local

recycling regulations.

- It is always recommended that this accessory is fitted by a qualified Mitsubishi Technician.

- Safely store and protect any removed vehicle components.

- Ensure all bare metal surfaces are protected using Automotive Bare Metal Primer and touch-up paint.

- Remove all metal swarf and dust from all vehicle surfaces if surface is used for accessory installation.

- Safety N o te s----------------------------------

- Check that all work practices comply with safety standards.

- Please wear appropriate clothing and use safety equipment.

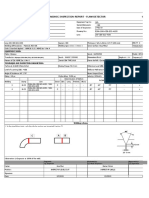

- Parts Supplied

0° Sensor H e a d A ssem bly

x4

C le a n in g P ad x2

M

■

O w n ers M a n u a l x l

R a tc h e t

A

Rust

Inhibitor

LJ

R o und File Rust Inh ib itor A d h e s iv e Ta pe

FI Doc No: FI7075 - Issue: 4 - 30/05/13 Page 02 of 18

OUTLANDER

MITSUBISHI

MOTORS

- Step 1

Im portant

A Always refer to the vehicle's Workshop Manual when

removing vehicle components.

Note down all clock and radio settings.

In the engine bay, disconnect the negative battery terminal.

Inside the luggage compartment, remove the parcel shelf (1).

- Step 2 ---------------------------------------------

• On the rear of the luggage compartment, open me rear storage

box compartment cover (1) and remove the two fasteners (2).

• Remove the storage box ( 3) by pulling in an upwards direction.

• Remove the rear boot luggage compartment trim (4) by pulling in

an upwards direction.

- Step 3 ---------------------------------------------

• On the LHS rear quarter of the luggage com partm ent, remove

the cargo h o o k(l).

FI Doc No: FI7075 - Issue: 4 - 30/05/13 Page 03 of 18

♦ OUTLANDER

MITSUBISHI

MOTORS

- Step 4 ------------------------------------------

• On the rear LHS of the passenger's side, fold the seats forward.

• Remove the rear door trim panel (1).

- Step 5

• Remove the LHS rear luggage compartment cargo hooks (1) and

fasteners ( 2 ).

• Remove the LHS luggage compartment trim (3) by first removing

the Phillips head screws (4).

- Step 6 ---------------------------------------------

• On the rear of the vehicle, remove four fasteners (1) from the top

inner bumper section.

• Remove four clips (2) from under the bumper.

• Remove four clips (3) in each wheel arch.

• Remove the two boot lid stops (4).

• Remove the rear bumperfascia (5).

FI Doc No: FI7075 - Issue: 4 - 30/05/13 Page 04 of 18

л

MITSUBISHI

MOTORS

OUTLANDER

Step 7 ---------------------------------------------

• Cut out the grommet template (1) (Page 15) and adhere to the

LHS rear quarter panel (2) using adhesive tape (3) as shown.

• Using a 020m m hole saw, drill through the LHS rear quarter panel

(2) as indicated.

• Discard the template (1) after drilling.

- Step 8

• Using a round file, file any rough or sharp edges from the

previously drilled hole (1).

• Spray any bare metal with rust inhibitor.

Im portant

Allow the area sprayed with rust inhibitor to dry

before continuing.

- Step 9 ----- ---------------------------------------

• On the LHS rear quarter luggage compartment, locate the

vehicle male and female 18-Way connectors (1).

• Disconnectthe male and female 18-Way connectors (1).

FI Doc No: FI7075 - Issue: 4 - 30/05/13 Page 05 of 18

♦ OUTLANDER

MITSUBISHI

MOTORS

Step 1 0 --------------------------------------------

If vehicle is fitted with a Genuine Mitsubishi Towbar Harness, please

proceed to Step 11.

• From outside the vehicle, remove the vent from the exterior of the

vehicle.

• Route the ECU harness connector 0 ) down through the vent

cavity (2) .

• Using the supplied 200mm Cable Tie (3), secure the ECU harness

(4) to the existing vehicle harness (5).

• Connect the ECU (6) to its mating wiring harness connector (1).

Im portant

A Ensure fuse (7) is located and retained at vehicle

harness clip location as shown.

Proceed to Step 12.

Step 11

The following step is for vehicle models fitted with a Genuine Towbar

Harness.

• From outside the vehicle, remove the vent from the exterior of the

vehicle.

• Route the ECU harness connector (1) down through the vent

cavity (2) .

• Using the supplied 200mm Cable Tie (3), secure the ECU harness

( 4) to the Trailer Wire Harness ( 5).

• Connect the ECU ( 6 ) to its mating wiring harness connector (1 )•

Im portant

Ensure fuse (7) is located and retained at vehicle

harness clip location as shown.

- S te p 12

Using the supplied Cleaning Pad, clean the area (1) on the inside

of the sheet metal where the ECU (2) will be mounted.

Im portant

A Allow the area cleaned with the supplied cleaning

pad to dry before proceeding.

Note: When mounting the ECU, ensure to clean the interior sheet

metal panel, NOT the exterior panel and mount ECU as high as

possible within the vehicle cavity.

• Apply double sided tape (3) to the ECU (2) on the previously

cleaned flat surface.

• Remove the backing (3) from the adhesive tape on the ECU(2).

• M ounttheEC U(2) onto the previously cleaned area (1), ensuring

the connector (4) is facing downwards on the inside of the

vehicle.

FI Doc No: FI7075 - Issue: 4 - 30/05/13 Page 06 of 18

OUTLANDER

MITSUBISHI

MOTORS

- S te p 13

If vehicle is fitted with a Genuine Mitsubishi Towbar Harness, please

proceed to Step 14.

• On the upper rear quarter panel, on the LHS of the luggage

compartment, connect the 2-way buzzer connector (1) to its

mating connector ( 2 ).

• Using the supplied Cleaning Pad, clean the area (3) where the

buzzer (4) will be mounted.

Im portant

A Allow the area cleaned with the supplied cleaning

pad to dry before proceeding.

Remove the backing (5) from the adhesive tape on the back of

the buzzer (4 ) and mount the buzzer (4) onto the previously

cleaned area ( 3).

Patch the RPA Harness 18-way connectors ( 6) in between the

vehicle harness 18-way connector(7).

Using the supplied 200 mm Cable Ties (8 ), secure the RPA harness

(9) to the existing vehicle harness.

Proceed to step 16.

Step 14----- -------------------------------

• On the upper rear quarter panel, on the LHS of the

compartment, connect the 2-way buzzer connector (1) to its

mating connector( 2 ).

Using the supplied Cleaning Pad, clean the area (3) where the

buzzer(4) will be mounted.

Im portant

Allow the area cleaned with the supplied cleaning

pad to dry before proceeding.

• Remove the backing (5) from the adhesive tape on the back of

the buzzer (4 ) and mount the buzzer (4 ) onto the previously

cleaned area ( 3).

• Patch the RPA Harness 18-way connectors (6) in between the

vehicle harness 18-way connectors (7).

• Using the supplied 200 mm Cable Ties ( 8 ), secure the RPA harness

(9) to the Trailer Wiring Harness (10).

FI Doc No: FI7075 Issue: 4 - 30/05/13 Page 07 of 18

♦ OUTLANDER

MITSUBISHI

MOTORS

- Step 15

• Disconnect the trailer interrupt terminals (1) on the RPA harness

(2).

• Tape back female terminal and cover completely (3) to the RPA

harness ( 2 ).

• Locate the taped back female spade terminal (4) on the trailer

harness (5).

• Remove the tape securing the female spade terminal (4) and

connect to the male terminal (6) on the RPA harness (2), ensuring

that the rubber insulator (7) covers female spade terminal (4).

• Tie back any excess wire with supplied cable ties.

- Step 1 6 --------------------------------------------

• On the LHS rear quarter panel, route the Sensor Harness (1)

through the previously drilled grommet hole (2) and towards the

rearof the vehicle.

Im portant

Ensure the grommet seal is seated correctly before

proceeding.

Step 17-

Route the Sensor Harness (1) along the vehicle wiring towards the RHS,

following the existing vehicle harness.

Using the supplied cleaning pad, clean the areas (2) where the

Cable Tie Mounts (3) will be mounted.

Im portant

A Allow the area cleaned with the supplied cleaning

pad to dry before proceeding.

Adhere the Cable Tie Mounts (3) to the previously cleaned areas

(2) and using the supplied 200mm Cable Tie (4), secure the Sensor

Harness (1) to the Cable Tie Mount (3) and the vehicle harness.

FI Doc No: FI7075 - Issue: 4 - 30/05/13 Page 08 of 18

♦ OUTLANDER

MITSUBISHI

MOTORS

- Step 1 8 --------------------------------------------

• Cut out and adhere the templates (Pages 16-18) (1) onto the RHS

of the rear bumper (2) as shown.

Repeat for the LHS.

- Step 1 9 --------------------------------------------

• Drill pilot holes through the templates (1) (Pages 16-18)using a

02m m drill bit ( 2 ).

- Step 2 0 --------------- ----------------------------

• Using a 024m m spade bit (1), drill out the centre pilot holes on the

templates ( 2 ).

• Discard the templates (2) after drilling.

FI Doc No: FI7075 Issue: 4 - 30/05/13 Page 09 of 18

OUTLANDER

MITSUBISHI

MOTORS

- Step 2 1 --------------------------------------------

• Insert the Sensor Head Assemblies (1) into the previously drilled

holes (2) on the bumperfascia (3).

• Secure the Sensor Head Assemblies (1) to the bumper fascia (3)

with the supplied C-Clips (4).

Im portant

Using the palm of your hand only, carefully push the

sensor head assemblies into place.

- Step 2 2 --------------------------------------------

• Refit the rear bumperfascia (1) and connect the Sensor Harness

(2) to its mating Sensor Head Assemblies (3) at the same time.

FI Doc No: FI7075 - Issue: 4 - 30/05/13 Page 10 of 18

♦ OUTLANDER

MITSUBISHI

MOTORS

Step 23

In the luggage compartment, secure all harnesses to the vehicle

wiring using the supplied Cable Ties.

In the engine bay, reconnect the negative battery terminal.

Test the Reverse Parking Assist System for correct operation as

follows:

-Start the vehicle.

- Select the Reverse gear.

- Reverse slowly towards a large flat object.

- Each sensor has 3 stages of detection.

Refer to the RPA Owner's Manual for further information and

troubleshooting.

Turn the ignition to the 'OFF' position after testing.

Im portant

Secure all harnesses to the vehicle using cable ties.

A Refit all removed parts and secure all fasteners to the

Service Manual torque specifications.

Im portant

A Reprogram all radio stations and clock settings by

referring to the vehicle's Owner Manual.

Please place the Fitting Instructions and Owner's

Manual in the glove box after installation is completed.

FI Doc No: FI7075 Issue: 4 - 30/05/13 Page 11 of 18

♦ OUTLANDER

MITSUBISHI

MOTORS

- Tro u b le sho o ting --------------------------------------------

Trouble Shooting

The details below will help determine whether your system has a

malfunction. If the system fails to operate after you have completed

all of the required actions, you will need to consult the Mitsubishi

Motors Dealer from which the unit was purchased or installed.

System Diagnostic Tones

In normal operation the Mitsubishi Reverse Park Assist System will emit

one beep when the reverse gear is selected. The following “diagnostic tones”

indicate abnormal operation.

W arning B u zze r co n tin u o u sly so unds two beeps._________________

Reason: One sensor is faulty.

Solution: - Clean sensors.

- Replace or reinstall sensor (Consult your installer).

W arning B u zze r co n tin u o u sly sounds three beeps.

Reason: Two or more sensors are faulty.

Solution: - Clean sensors.

- Replace or reinstall sensors (Consult your installer).

W arning B u zze r co n tin u o u sly so u n d s fo u r beeps.

Reason: Three or more sensors are faulty.

Solution: - Clean sensors.

- Replace or reinstall sensors (Consult your installer).

- QC Final Check L is t ------------------------------------------

QC FINAL CHECK LIST (ELECTRICAL FUNCTION & COMPONENT FIT)

□□□□□□□□□□a

1. Audio / Navi Functions properly (GPS, and Hazard Switch / SRS)........................................

2. Combination Meter operates properly...................................................................................

3. Ignition Push Start Switch (If equipped)....................................................................................

4. Info. Button operates properly...................................................................................................

5. Traction Control operates..........................................................................................................

6. Headlight Levelling Switch/Controls........................................................................................

7. Fog Lights (If equipped)..............................................................................................................

8. Daytime Running Lights (If equipped)......................................................................................

9. Check re-installed interior trim fit properly (No gaps, scratches and damage)................

10. Exterior (Front Fascia, Wheel Well Liner, etc.).........................................................................

11. Interior (Scuff Plate, Kick Panel, Knee Bolster, MeterTrim, Steering Column, Audio Trim)

FI Doc No: FI7075 - Issue: 4 - 30/05/13 Page 12 of 18

FI Doc No: FI7075

I

CO

О О со

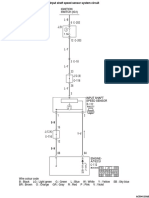

SCHEMATIC - CONNECTOR VIEW IS FRONT FACING (TERMINAL SIDE) 3- -J e=

О сэ

Ф rn

TERM. COLOUR FUNCTION 3

Q

1 RED REVERSE +VE Ш •

2 BROWN SENSOR CL О

3 GREEN SENSOR CR

-

4 -

Issue: 4 - 30/05/13

5 - -

6 -

7 . -

8 - -

16 9 BLUE SENSOR L

□□DOOOQOf 10 RED/WHITE SENSOR R SENSORS

a0 D 0 0 ош | 11 WHITE BUZZER -VE

' 1 12 ORANGE BUZZER +VE

13 . -

14 GREY SENSOR GND

15 BLACK POWER GND (1) B R O W N -S E N S O R SIGNAL

16 - - (2) G R E Y -S E N S O R GROUND

CUT-OUT

CONTROL RED - REVERSE +VE (1) B L U E -S E N S O R SIGNAL

RED - REVERSE +VE

2 (2) G R E Y -S E N S O R GROUND

MODULE

(1) RED/W HITE - SENSOR SIGNAL

(2) G R E Y -S E N S O R GROUND

FUSE

2A

(1) G R E E N -S E N S O R SIGNAL

1 !

(2) G R E Y -S E N S O R GROUND

BUZZER

(1) O R A N G E -B U Z Z E R +VE

(2) W H IT E - BUZZER -VE BACK UP LAMP - j | VEHICLE WIRING HARNESS

OUTLANDER

REVERSE SIGNAL PATCH

Page

(8) R ED/BLACK - REVERSE +VE

(9) B LA C K -G R O U N D

(1-7,10-18) GREY,GREY/BLACK - PATCH WIRES

13 of 18

♦ OUTLANDER

MITSUBISHI

MOTORS

This page has been intentionally left blank.

FI Doc No: FI7075 - Issue: 4 - 30/05/13 Page 14 of 18

OUTLANDER

, , LHS Reverse Park Assist Grommet Template

- Tempiates

Im portant

Always confirm the length of the 50mm scale markers

before drilling.

LHS Reverse Park Assist

Grommet Template

Sheet size: A4

Scale 1:1

Kit Part No: MZ350216ZZ

FI Doc No: FI7075 - Issue: 4 - 30/05/13 Page 15 of 18

You might also like

- Engine-Ecu: Removal and InstallationDocument1 pageEngine-Ecu: Removal and InstallationRizky MotorNo ratings yet

- Jadwal Training: DAY Waktu Deskripsi DAY Waktu DeskripsiDocument1 pageJadwal Training: DAY Waktu Deskripsi DAY Waktu DeskripsiRizky MotorNo ratings yet

- Cover Depan M3 ELCDocument1 pageCover Depan M3 ELCRizky MotorNo ratings yet

- Honda Civic ECU Diagram 1996-1998Document1 pageHonda Civic ECU Diagram 1996-1998Rizky Motor100% (1)

- AC504123AB00ENGDocument1 pageAC504123AB00ENGRizky MotorNo ratings yet

- Jadwal Mstep2 Ea 2017 DitoDocument1 pageJadwal Mstep2 Ea 2017 DitoRizky MotorNo ratings yet

- Ac800940ae00eng PDFDocument1 pageAc800940ae00eng PDFRizky MotorNo ratings yet

- SM 3Document539 pagesSM 3Rizky Motor100% (1)

- Ac706606af00eng PDFDocument1 pageAc706606af00eng PDFRizky MotorNo ratings yet

- System Wiring Diagrams 3.0L DOHC Turbo, Air Conditioning Circuits (1 of 2)Document1 pageSystem Wiring Diagrams 3.0L DOHC Turbo, Air Conditioning Circuits (1 of 2)Rizky MotorNo ratings yet

- Information On 2014 Mirage Workshop Manual: 1. DescriptionDocument13 pagesInformation On 2014 Mirage Workshop Manual: 1. DescriptionRizky MotorNo ratings yet

- Ac801566ae00eng PDFDocument1 pageAc801566ae00eng PDFRizky MotorNo ratings yet

- System Wiring Diagrams 3.0L DOHC Non-Turbo, Engine Performance Circuits (1 of 3)Document1 pageSystem Wiring Diagrams 3.0L DOHC Non-Turbo, Engine Performance Circuits (1 of 3)Rizky MotorNo ratings yet

- Mirage ManualDocument5 pagesMirage ManualPaulus Kokok CozaNo ratings yet

- 2004 Mitsubishi l200 113603Document264 pages2004 Mitsubishi l200 113603Antonio do Nascimento Sousa100% (2)

- Wiring Diagram ECU 2KD-FTVDocument13 pagesWiring Diagram ECU 2KD-FTVDam Nguyen87% (95)

- Ac801475au00eng PDFDocument1 pageAc801475au00eng PDFRizky MotorNo ratings yet

- Ac800940ae00eng PDFDocument1 pageAc800940ae00eng PDFRizky MotorNo ratings yet

- Obd1 CivicDocument3 pagesObd1 CivicRizky MotorNo ratings yet

- Testing Piezoelectric Injectors 1 PDFDocument2 pagesTesting Piezoelectric Injectors 1 PDFJaved IqbalNo ratings yet

- MZ 350216 ZZDocument15 pagesMZ 350216 ZZRizky MotorNo ratings yet

- GR00000300 90 PDFDocument248 pagesGR00000300 90 PDFRizky MotorNo ratings yet

- GR00000300 90 PDFDocument248 pagesGR00000300 90 PDFRizky MotorNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- NT140WHM N46Document34 pagesNT140WHM N46arif.fahmiNo ratings yet

- Ecma L1221BR3 PD02 05172016Document2 pagesEcma L1221BR3 PD02 05172016Anil JindalNo ratings yet

- UEME 1143 - Dynamics: AssignmentDocument4 pagesUEME 1143 - Dynamics: Assignmentshikai towNo ratings yet

- jk2 JAVADocument57 pagesjk2 JAVAAndi FadhillahNo ratings yet

- JMC250Document2 pagesJMC250abhijit99541623974426No ratings yet

- Cursos Link 2Document3 pagesCursos Link 2Diego Alves100% (7)

- PHCDocument1 pagePHCsinh24X7No ratings yet

- Big Data, Consumer Analytics, and The Transformation of MarketingDocument17 pagesBig Data, Consumer Analytics, and The Transformation of MarketingPeyush NeneNo ratings yet

- Ut ProcedureDocument2 pagesUt ProcedureJJ WeldingNo ratings yet

- Phenolic Compounds in Rice May Reduce Health RisksDocument7 pagesPhenolic Compounds in Rice May Reduce Health RisksMuhammad Usman AkramNo ratings yet

- C ProgrammingDocument205 pagesC ProgrammingSrinivasan RamachandranNo ratings yet

- Unit 4 AE Scan OCRed PDFDocument44 pagesUnit 4 AE Scan OCRed PDFZia AhmedNo ratings yet

- Class Prophecy 012Document11 pagesClass Prophecy 012Mythical Persues100% (2)

- Naruto Vol 4Document171 pagesNaruto Vol 4Andrew WongNo ratings yet

- TD EGGER Eurospan E1E05 TSCA Hydro P3 (Rec 224) enDocument2 pagesTD EGGER Eurospan E1E05 TSCA Hydro P3 (Rec 224) enClarencegiNo ratings yet

- FRP/HDPE septic tank specificationDocument2 pagesFRP/HDPE septic tank specificationpeakfortuneNo ratings yet

- Entrepreneurship: Ali Raza (Ph.D. Scholar, Near East University, North Cyprus, Mersin 10, Turkey)Document35 pagesEntrepreneurship: Ali Raza (Ph.D. Scholar, Near East University, North Cyprus, Mersin 10, Turkey)Ameen KolachiNo ratings yet

- BA50BCODocument6 pagesBA50BCOpedroarlindo-1No ratings yet

- 8510C - 15, - 50, - 100 Piezoresistive Pressure Transducer: Features DescriptionDocument3 pages8510C - 15, - 50, - 100 Piezoresistive Pressure Transducer: Features Descriptionedward3600No ratings yet

- Declarative and Procedural Knowledge (Lêda's Final Paper) 2010 01Document13 pagesDeclarative and Procedural Knowledge (Lêda's Final Paper) 2010 01Jair Luiz S. FilhoNo ratings yet

- Uvas CaractDocument10 pagesUvas CaractgondeluNo ratings yet

- CSIR AnalysisDocument1 pageCSIR Analysisசெபா செல்வாNo ratings yet

- Effects of Zero Moment of Truth On Consumer Behavior For FMCGDocument14 pagesEffects of Zero Moment of Truth On Consumer Behavior For FMCGBoogii EnkhboldNo ratings yet

- Chapter 4 and 5 - For StudentsDocument6 pagesChapter 4 and 5 - For Studentsdesada testNo ratings yet

- PENGARUH CYBERBULLYING BODY SHAMING TERHADAP KEPERCAYAAN DIRIDocument15 pagesPENGARUH CYBERBULLYING BODY SHAMING TERHADAP KEPERCAYAAN DIRIRizky Hizrah WumuNo ratings yet

- PP 12 Maths 2024 2Document21 pagesPP 12 Maths 2024 2Risika SinghNo ratings yet

- Mid Term Business Economy - Ayustina GiustiDocument9 pagesMid Term Business Economy - Ayustina GiustiAyustina Giusti100% (1)

- User Manual - Rev3Document31 pagesUser Manual - Rev3SyahdiNo ratings yet

- Valhalla Repair ManualDocument8 pagesValhalla Repair ManualKirby AllenNo ratings yet

- Wall Street Expose: Monkey Business Reveals Investment Banking RealitiesDocument2 pagesWall Street Expose: Monkey Business Reveals Investment Banking Realitiestorquewip100% (1)