Professional Documents

Culture Documents

Cleanroom Panel Specifications

Uploaded by

Marko AnticOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cleanroom Panel Specifications

Uploaded by

Marko AnticCopyright:

Available Formats

Cleanroom Panel Specifications

Advantages of our Cleanroom panel system

v

Custom-made design to suit specific applications

v

Turnkey solutions for entire Cleanrooms

v

Execution of projects on fast track

Implementation of cGMP and regulatory requirements in panel system

v

Providing required documentation & validation of Cleanrooms

v

WALL PANELS

SIZE : Standard Size: 1200mm width and 3000mm height.

Other sizes can be customized based on layout.

MOC : Powder coated / Precoated Galvanized Steel /

Stainless Steel

INFILL : PUF (Polyurethane Foam)

PIR ( Poly ISO Rinate)

Mineral wool/ Glass wool / Rockwool

Honeycomb kraft paper

PROFILES : Aluminum / GI

FLOOR TRACK : Level adjustable floor track to compensate floor undulations

INTEGRATION : Concealed system provided by using inbuilt conduit

with electrical module boxes installed within the panel.

All cutouts are factory made and properly sealed

Optional items like Wall Guard, Crash Panel for the

emergency exit, Removable panels for the equipment

movement can be given.

An ISO 9001-2000 Certified Company

Windows:

vDouble glazed flush view panels

vTwo glasses of 6 mm thick

vRounded angles on the corners

vSilica gel filled in the frame

vSizes ranging up to 2.4 m in width

Doors:

vCleanroom flush doors

vFire rated door

vEmergency doors with panic hardware

vFlushed frame profile.

vStandard door hardware like:

- D handles / push plates / kick plates

- Door closures (Heavy duty / Medium duty)

with Concealed / Hold open options

- Drop seal in the door bottom and door gasket

CEILING PANELS - See through double glazed glass of standard size

We offer walkable ceiling / Non- walkable ceiling depending on - Various infill options like Honeycomb kraft paper

the requirement. PUF / PIR and Mineral wool

Walk-on ceilings We provide GMP compliance sliding door wherever required.

SIZE : Standard Size: 1200mm width and

3000mm height.

Other sizes can be customized

based on layout.

Progressive ceiling

Concealed grid

Load bearing capacity of 150 Kg/m2

MOC : Powder coated / Pre-coated

Galvanized Steel / Stainless Steel

INFILL : PUF (Polyurethane Foam)

PIR ( Poly ISO Rinate)

Mineral wool/ Glass wool / Rockwool Quality Control Mechanism

Honeycomb kraft paper At IClean, every product & process undergoes stringent quality

control tests complying with international standards.

HARDWARE : All supporting hardware in GI

v Scratch Hardness Test

Non progressive ceiling v Salt Spray Test

v Service panel between two ceiling panels v Impact loading Test

v Concealed wiring / conduits within the ceiling v Conical Mandrel Test

v Panel Grid made of GI powder coated

v Cross Hatch Test

Factory made cutouts for filter module and light fixture. These v Powder Coating Thickness Test

cutouts are properly sealed and finished with powder coating.

We carry out the leveling of ceiling by using laser device.

Inhouse Equipment

vPowder Coating booth

Ceiling grid for class 100 areas. vHigh pressure INSITU PUF injection machine

v Specially designed ceiling grid suitable for class vCNC punch press

100 laminar with filtration for entire room

vCNC press brake

v Tear drop light fixtures shall be used in class 100

areas / laminar areas vFolding machine

v HEPA / Gel filled HEPA modules can be placed vPress Zig

over the ceiling grid.

Coving

Aluminum (R-70 & R-50) Covings /PVC Covings are integrated

for wall to wall and wall to ceilings.

Specially designed 3 dimensional corner

clipon coves will be used in the corners.

www.icleantech.com

You might also like

- HMD Kojak SelingeDocument2 pagesHMD Kojak SelingeHMD Healthcare100% (1)

- Cleanroom Management (2017 Ed)Document1 pageCleanroom Management (2017 Ed)Tim Sandle50% (2)

- Cleanroom WelderDocument6 pagesCleanroom WelderYoNo ratings yet

- Waterproof and Cleanroom Luminaires PDFDocument13 pagesWaterproof and Cleanroom Luminaires PDFdwi wahyu sugiartoNo ratings yet

- Myfab Cleanroom Introduction Course PDFDocument67 pagesMyfab Cleanroom Introduction Course PDFTanim MoniruzzamanNo ratings yet

- HVAC Design For Cleanroom FacilitiesDocument48 pagesHVAC Design For Cleanroom FacilitiesSNMNo ratings yet

- Introduction To Pharmaceutical Clean Room 1Document61 pagesIntroduction To Pharmaceutical Clean Room 1Abdul KalimNo ratings yet

- Introduction to clean-room software engineeringDocument3 pagesIntroduction to clean-room software engineeringRupali ChawlaNo ratings yet

- Risk Assessment APDocument47 pagesRisk Assessment APSandy PiccoloNo ratings yet

- Clean Room Metal Doors by Wonzone ConstructionDocument4 pagesClean Room Metal Doors by Wonzone ConstructionMohamed Khaldi100% (1)

- Cleanroom Production WorkflowDocument1 pageCleanroom Production Workflowjirt2011No ratings yet

- CPG Sec. 555.425 Foreign Objects in FoodDocument3 pagesCPG Sec. 555.425 Foreign Objects in FoodAnous AlamiNo ratings yet

- Guideline On Dossier Requirements For Type - 1A N 1BDocument40 pagesGuideline On Dossier Requirements For Type - 1A N 1BRambabu komati - QA100% (1)

- Cleanroom Classifications: US FED STD 209E Cleanroom StandardsDocument2 pagesCleanroom Classifications: US FED STD 209E Cleanroom StandardsJulianna BakerNo ratings yet

- Current Trend in Sterile MFGDocument5 pagesCurrent Trend in Sterile MFGRajneeshNo ratings yet

- Sri Balaji Pharma Limited Quality PolicyDocument1 pageSri Balaji Pharma Limited Quality PolicyChilaNo ratings yet

- Bottle Washing MachineryDocument11 pagesBottle Washing MachineryharikrushnamachineNo ratings yet

- Maintenance Strategies and Innovative Approaches in The Pharmaceutical Industry: An Integrated Management System (IMS)Document9 pagesMaintenance Strategies and Innovative Approaches in The Pharmaceutical Industry: An Integrated Management System (IMS)Fawaz Nasser AL-HeibshyNo ratings yet

- TC (Cleanroom Precision Positioning Table)Document28 pagesTC (Cleanroom Precision Positioning Table)chidambaram kasiNo ratings yet

- Cleanroom Airlock Performance and Beyond: Column Ieq ApplicationsDocument6 pagesCleanroom Airlock Performance and Beyond: Column Ieq ApplicationsGuilhermeValadaresNo ratings yet

- Oxley Bizhub Singapore - Ebrochure & Floor PlansDocument27 pagesOxley Bizhub Singapore - Ebrochure & Floor PlansRichard Sng100% (1)

- VT20L DRUVATHERM Laboratory Vacuum Shovel Dryer-201205 PDFDocument2 pagesVT20L DRUVATHERM Laboratory Vacuum Shovel Dryer-201205 PDFKalpesh KhedekarNo ratings yet

- PICs Annex1 Consultation Document Dec. 2017Document50 pagesPICs Annex1 Consultation Document Dec. 2017DholakiaNo ratings yet

- Modular Operation Theatre Manufacturers, Suppliers & Dealers in IndiaDocument5 pagesModular Operation Theatre Manufacturers, Suppliers & Dealers in IndiaDhanashree TayadeNo ratings yet

- Cleanroom Construction 20401067 HDocument22 pagesCleanroom Construction 20401067 HJon100% (1)

- Containment GuardDocument36 pagesContainment GuardSatish HiremathNo ratings yet

- PVC Resin Presentation Group Introduction SWOT AnalysisDocument68 pagesPVC Resin Presentation Group Introduction SWOT AnalysisYasir PerwezNo ratings yet

- Everything You Need to Know About CleanroomsDocument2 pagesEverything You Need to Know About CleanroomsMai Phuong Phan TranNo ratings yet

- BFS Technology: Blow-Fill-Seal Manufacturing ProcessDocument12 pagesBFS Technology: Blow-Fill-Seal Manufacturing ProcessDeepakNo ratings yet

- TSI PANDA 341 User ManualDocument38 pagesTSI PANDA 341 User ManualHernan RomeroNo ratings yet

- Usp 797GCDocument61 pagesUsp 797GCAwni1989No ratings yet

- Stationary Bin Lifter Systems Innovation in CLEAN Lift TechnologyDocument2 pagesStationary Bin Lifter Systems Innovation in CLEAN Lift Technologymmk111No ratings yet

- EU Declaration of Conformity (DoC) - CPH1851 - ENDocument2 pagesEU Declaration of Conformity (DoC) - CPH1851 - ENAlejandro Jimenez GonzalezNo ratings yet

- 1 1 VentilationDocument33 pages1 1 VentilationNanmathi Balachandran 10G 21No ratings yet

- Guide to Paint Booths from PaintBooth.comDocument24 pagesGuide to Paint Booths from PaintBooth.comAmirul AkmalNo ratings yet

- Microbiology Clean Room Design SpecificationDocument2 pagesMicrobiology Clean Room Design SpecificationMHNADNo ratings yet

- Cleanroom Design That Terra Recommends: Cost vs. Coverage: Evaluating FFU PlacementDocument3 pagesCleanroom Design That Terra Recommends: Cost vs. Coverage: Evaluating FFU PlacementdesignselvaNo ratings yet

- HEPA Cleanroom Filter Testing PDFDocument4 pagesHEPA Cleanroom Filter Testing PDFprovaoralNo ratings yet

- HeatPipe WrapAroundDocument2 pagesHeatPipe WrapAroundJohnson ChuaNo ratings yet

- ImmiticideDocument3 pagesImmiticidedoc_abdullahNo ratings yet

- Needle SiliconizatonDocument5 pagesNeedle SiliconizatonIlayaraja BoopathyNo ratings yet

- Lindner KatalogDocument64 pagesLindner KatalogAnonymous hISvHbfiB1No ratings yet

- Bio Compatibility Assessment FDA Japanese GuidelineDocument19 pagesBio Compatibility Assessment FDA Japanese GuidelineAnonymous BcT42WLnNo ratings yet

- TSB 2000010 Technical Overview of The STERILIZABLEBAGDocument4 pagesTSB 2000010 Technical Overview of The STERILIZABLEBAGdatinjacabNo ratings yet

- 1 Cable Tray CatalogueDocument82 pages1 Cable Tray CatalogueHamouda YaseenNo ratings yet

- Temperature Monitor Alert System UAE Qatar OmanDocument2 pagesTemperature Monitor Alert System UAE Qatar OmanmrikovsteyneNo ratings yet

- Plastistrength™: Acrylic Process Aids For PVC ApplicationsDocument28 pagesPlastistrength™: Acrylic Process Aids For PVC ApplicationsJaved Iqbal100% (1)

- Company Profile Incepta PharmaDocument9 pagesCompany Profile Incepta PharmaNobo AhmedNo ratings yet

- Incubator Shaker: MODEL NO. - ACM-22063-IDocument8 pagesIncubator Shaker: MODEL NO. - ACM-22063-Iwatson123No ratings yet

- Vaisala On-Demand Webinar:: Listen To The Recording atDocument46 pagesVaisala On-Demand Webinar:: Listen To The Recording atMohammad IsmailNo ratings yet

- Group 3: Plant Layout and Industrial SafetyDocument16 pagesGroup 3: Plant Layout and Industrial Safetylove ofmylifeNo ratings yet

- India's No. 1 Security & Community AppDocument4 pagesIndia's No. 1 Security & Community AppAkshat MNo ratings yet

- FMEADocument51 pagesFMEAELAMPARITHINo ratings yet

- Airborne Particulate Cleanliness ClassesDocument4 pagesAirborne Particulate Cleanliness ClassesaKureishiNo ratings yet

- Sagar Rubber Products: Leading Indian Manufacturer of Pharmaceutical Packaging SolutionsDocument19 pagesSagar Rubber Products: Leading Indian Manufacturer of Pharmaceutical Packaging SolutionsSunil PrajapatiNo ratings yet

- Complete Magnetic Filtration Mini-CatalogDocument19 pagesComplete Magnetic Filtration Mini-Catalog15 FFNo ratings yet

- 5.transformer Room DoorsDocument4 pages5.transformer Room DoorsMasauso BandaNo ratings yet

- Easy Move: Tailor-Made Solutions For Private and Public PremisesDocument12 pagesEasy Move: Tailor-Made Solutions For Private and Public PremisesAlex NgNo ratings yet

- Tecno Spa - W80: Double and Single Partition SystemDocument51 pagesTecno Spa - W80: Double and Single Partition SystemEugeneNo ratings yet

- Custom Noise Control EnclosuresDocument2 pagesCustom Noise Control EnclosuresVõ Ngọc Phát ĐặngNo ratings yet

- Drawing Number (EPI) Drawing Name - SER Drawing Name - Eng Ifc DateDocument4 pagesDrawing Number (EPI) Drawing Name - SER Drawing Name - Eng Ifc DateMarko AnticNo ratings yet

- #3.. 12-12-22 Mat Slab ReinforcementDocument10 pages#3.. 12-12-22 Mat Slab ReinforcementMarko AnticNo ratings yet

- Secant Pile Grouting Inspection ReportDocument10 pagesSecant Pile Grouting Inspection ReportMarko AnticNo ratings yet

- #10..1!19!23 Shearwalls and Columns 1st To 2nd Fl.Document6 pages#10..1!19!23 Shearwalls and Columns 1st To 2nd Fl.Marko AnticNo ratings yet

- #5... 12!22!22 Foundation Walls G, H and Half C ReinforcementDocument5 pages#5... 12!22!22 Foundation Walls G, H and Half C ReinforcementMarko AnticNo ratings yet

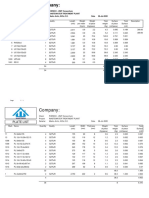

- Wastewater treatment plant material listDocument5 pagesWastewater treatment plant material listMarko AnticNo ratings yet

- China Metallurgical Construction Engineering Group Serbiad.o.o. BeogradDocument5 pagesChina Metallurgical Construction Engineering Group Serbiad.o.o. BeogradMarko AnticNo ratings yet

- Structural Engineering Report for 494 East 23rd Street JobDocument1 pageStructural Engineering Report for 494 East 23rd Street JobMarko AnticNo ratings yet

- China Metallurgical Construction Engineering Group Serbiad.o.o. BeogradDocument1 pageChina Metallurgical Construction Engineering Group Serbiad.o.o. BeogradMarko AnticNo ratings yet

- Single Parts-Blower HouseDocument87 pagesSingle Parts-Blower HouseMarko AnticNo ratings yet

- Assemblies-Ferric ChlorideDocument38 pagesAssemblies-Ferric ChlorideMarko AnticNo ratings yet

- Parts List-Ferric ChlorideDocument64 pagesParts List-Ferric ChlorideMarko AnticNo ratings yet

- Social Building - BoQDocument1 pageSocial Building - BoQMarko AnticNo ratings yet

- Material List Summary-WaptechDocument5 pagesMaterial List Summary-WaptechMarko AnticNo ratings yet

- Parts List-Disinfection roof-UV TroughDocument22 pagesParts List-Disinfection roof-UV TroughMarko AnticNo ratings yet

- Assemblies-Disinfection roof-UV TroughDocument13 pagesAssemblies-Disinfection roof-UV TroughMarko AnticNo ratings yet

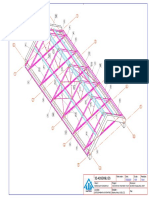

- Erection DrawingsDocument5 pagesErection DrawingsMarko AnticNo ratings yet

- Tanks, Containers & Silos References - WebDocument2 pagesTanks, Containers & Silos References - WebMarko AnticNo ratings yet

- Beam ListDocument2 pagesBeam ListMarko AnticNo ratings yet

- Bolt ListDocument1 pageBolt ListMarko AnticNo ratings yet

- Plate ListDocument2 pagesPlate ListMarko AnticNo ratings yet

- Wastewater Treatment Plant Steel Structure DetailsDocument22 pagesWastewater Treatment Plant Steel Structure DetailsMarko AnticNo ratings yet

- Assembly List-Blower HouseDocument7 pagesAssembly List-Blower HouseMarko AnticNo ratings yet

- Beam ListDocument2 pagesBeam ListMarko AnticNo ratings yet

- Overview Main Test Reports On Zinga: Galvanic ProtectionDocument9 pagesOverview Main Test Reports On Zinga: Galvanic ProtectionMarko AnticNo ratings yet

- Ral ChartDocument10 pagesRal ChartShravan ThangallapalliNo ratings yet

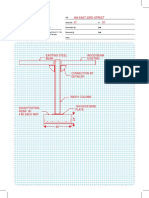

- Info - Cross SectionDocument1 pageInfo - Cross SectionMarko AnticNo ratings yet

- Interspec: EnergoprojektDocument3 pagesInterspec: EnergoprojektMarko AnticNo ratings yet

- Interzinc - 52 (Primer)Document4 pagesInterzinc - 52 (Primer)Marko AnticNo ratings yet

- Interseal 670 HSDocument4 pagesInterseal 670 HSFikru DdienNo ratings yet

- Redwood Outdoors CatalogDocument24 pagesRedwood Outdoors CatalogRedwood AdminNo ratings yet

- Civil ParametersDocument32 pagesCivil Parametersjohn philip s garciaNo ratings yet

- Santam Commercial SurveyDocument19 pagesSantam Commercial SurveyNgulube SothiniNo ratings yet

- Univer Eng Digitale2 PDFDocument76 pagesUniver Eng Digitale2 PDFMohsin MukulNo ratings yet

- Elevator Catalog EnglishDocument43 pagesElevator Catalog EnglishmohammadrezaNo ratings yet

- Wall Mount EnclosureDocument8 pagesWall Mount Enclosurejfmg1971No ratings yet

- Caracteristicas Getinge-400-500hc-Series-Hc-And-Steam-SterilizersDocument8 pagesCaracteristicas Getinge-400-500hc-Series-Hc-And-Steam-SterilizersUlises RuizNo ratings yet

- Narayanpet Municipality Construction of Community Hall in Ward No-12 in Narayanpet Town. General Abstract S.No Description of Item Amount in RsDocument422 pagesNarayanpet Municipality Construction of Community Hall in Ward No-12 in Narayanpet Town. General Abstract S.No Description of Item Amount in Rsnikita meshramNo ratings yet

- Aircraft Cabin Cleaning and Disinfection in Relations To The COVID PDFDocument3 pagesAircraft Cabin Cleaning and Disinfection in Relations To The COVID PDFAnushka SeebaluckNo ratings yet

- Hafele ArchitecturalDocument797 pagesHafele ArchitecturalDindandut SayNo ratings yet

- Palladio Door Collection Brochure Edition 4 Oct 2021Document68 pagesPalladio Door Collection Brochure Edition 4 Oct 2021Focus WindowsNo ratings yet

- CabinDocument157 pagesCabinESRANo ratings yet

- Adventurers Guild Admissions OfficeDocument22 pagesAdventurers Guild Admissions OfficeПетр Вараксин100% (1)

- Timber Construction - DETAIL - DETAILDocument28 pagesTimber Construction - DETAIL - DETAILTriet Nguyen100% (2)

- Capsule LiftDocument4 pagesCapsule LiftSurendra SinghNo ratings yet

- 2010handbookerrataDocument249 pages2010handbookerrataAmir R Toro TorresNo ratings yet

- 978 1259278211 Scanned PDF Strategic Management Text and Cases 8th EditionDocument61 pages978 1259278211 Scanned PDF Strategic Management Text and Cases 8th Editionaudrey.walston606100% (44)

- WOSON Maintenance Manual IIC 2009-9-08Document40 pagesWOSON Maintenance Manual IIC 2009-9-08Biomedical MagicNo ratings yet

- Inlab Profire ManualDocument42 pagesInlab Profire ManualMiranda Da CostaNo ratings yet

- DW-M6011 Dishwasher Service ManualDocument25 pagesDW-M6011 Dishwasher Service Manualsmomis100% (1)

- Estimate FormatDocument63 pagesEstimate FormatMARY LORRAINE MENDOZANo ratings yet

- 11M56 Item Description With Rates PDFDocument42 pages11M56 Item Description With Rates PDFHasmukh KesariaNo ratings yet

- F BCompleteDocument97 pagesF BCompletedemullu reddiNo ratings yet

- Sliding Door Operator Besam SL500 T Installation and Service Manual Original Instructions, NADocument86 pagesSliding Door Operator Besam SL500 T Installation and Service Manual Original Instructions, NAjackyNo ratings yet

- Fire Life Safety TrainingDocument29 pagesFire Life Safety Trainingdiegos70100% (1)

- Bom Sarmiento Feb. 15, 2022 For BLDG PermitDocument3 pagesBom Sarmiento Feb. 15, 2022 For BLDG Permitarchangel luga100% (1)

- Everything You Need to Know About Ramprastha GroupDocument21 pagesEverything You Need to Know About Ramprastha GroupvkagarwaNo ratings yet

- TN Bus Tender India 2022 - TE Irt202899 Nit Technicalspecifications 12m Long 400mm Floorheight Lowfloor Citybus SignedDocument75 pagesTN Bus Tender India 2022 - TE Irt202899 Nit Technicalspecifications 12m Long 400mm Floorheight Lowfloor Citybus SignedDisability Rights AllianceNo ratings yet

- Proposed Godown at Gikomba Market - BQ-1Document28 pagesProposed Godown at Gikomba Market - BQ-1michaelNo ratings yet

- IV Pump Flo-Gard 6301Document48 pagesIV Pump Flo-Gard 6301Dba BiomedtechNo ratings yet