Professional Documents

Culture Documents

Rslogix 500 Project Report

Uploaded by

my pedroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rslogix 500 Project Report

Uploaded by

my pedroCopyright:

Available Formats

RSLogix 500 Project Report

DEMOTEST.RSS

Processor Information

Processor Type: Bul.1766 MicroLogix 1400 Series A

Processor Name: UNTITLED

Total Memory Used: 338 Instruction Words Used - 163 Data Table Words Used

Total Memory Left: 12096 Instruction Words Left

Program Files: 10

Data Files: 10

Program ID: c6e

Page 1 Friday, March 18, 2016 - 12:43:04

DEMOTEST.RSS

I/O Configuration

0 Bul.1766 MicroLogix 1400 Series A

1 1762-IF2OF2 Analog 2 Chan. Input, 2 Chan. Output

2 1762-IT4 4-Channel Thermocouple Input Module

3

4

5

6

7

Page 1 Friday, March 18, 2016 - 12:43:04

DEMOTEST.RSS

Channel Configuration

CHANNEL 0 (SYSTEM) - Driver: DF1 Full Duplex

CHANNEL 0 (SYSTEM) - Driver: DF1 Full Duplex Edit Resource/Owner Timeout: 60

CHANNEL 0 (SYSTEM) - Driver: DF1 Full Duplex Passthru Link ID: 1

CHANNEL 0 (SYSTEM) - Driver: DF1 Full Duplex Write Protected: No

CHANNEL 0 (SYSTEM) - Driver: DF1 Full Duplex Comms Servicing Selection: Yes

CHANNEL 0 (SYSTEM) - Driver: DF1 Full Duplex Message Servicing Selection: Yes

CHANNEL 0 (SYSTEM) - Driver: DF1 Full Duplex 1st AWA Append Character: \d

CHANNEL 0 (SYSTEM) - Driver: DF1 Full Duplex 2nd AWA Append Character: \a

Source ID: 1 (decimal)

Baud: 19200

Parity: NONE

Control Line : No Handshaking

Error Detection: CRC

Embedded Responses: Auto Detect

Duplicate Packet Detect: Yes

ACK Timeout(x20 ms): 50

NAK Retries: 3

ENQ Retries: 3

CHANNEL 1 (SYSTEM) - Driver: Ethernet

CHANNEL 1 (SYSTEM) - Driver: Ethernet Edit Resource/Owner Timeout: 60

CHANNEL 1 (SYSTEM) - Driver: Ethernet Passthru Link ID: 1

CHANNEL 1 (SYSTEM) - Driver: Ethernet Write Protected: No

CHANNEL 1 (SYSTEM) - Driver: Ethernet Comms Servicing Selection: Yes

CHANNEL 1 (SYSTEM) - Driver: Ethernet Message Servicing Selection: Yes

Hardware Address: 00:00:00:00:00:00

IP Address: 0.0.0.0

Subnet Mask: 0.0.0.0

Gateway Address: 0.0.0.0

Msg Connection Timeout (x 1mS): 15000

Msg Reply Timeout (x mS): 3000

Inactivity Timeout (x Min): 30

Bootp Enable: Yes

Dhcp Enable No

SMTP Enable: No

SNMP Enable: Yes

HTTP Enable: Yes

Auto Negotiate Enable: Yes

Port Speed Enable: 10/100 Mbps Full Duplex/Half Duplex

Contact:

Location:

CHANNEL 2 (SYSTEM) - Driver: DF1 Full Duplex

CHANNEL 2 (SYSTEM) - Driver: DF1 Full Duplex Edit Resource/Owner Timeout: 60

CHANNEL 2 (SYSTEM) - Driver: DF1 Full Duplex Passthru Link ID: 1

CHANNEL 2 (SYSTEM) - Driver: DF1 Full Duplex Write Protected: No

CHANNEL 2 (SYSTEM) - Driver: DF1 Full Duplex Comms Servicing Selection: Yes

CHANNEL 2 (SYSTEM) - Driver: DF1 Full Duplex Message Servicing Selection: Yes

CHANNEL 2 (SYSTEM) - Driver: DF1 Full Duplex 1st AWA Append Character: \d

CHANNEL 2 (SYSTEM) - Driver: DF1 Full Duplex 2nd AWA Append Character: \a

Source ID: 1 (decimal)

Baud: 19200

Parity: NONE

Control Line : No Handshaking

Error Detection: CRC

Embedded Responses: Auto Detect

Duplicate Packet Detect: Yes

ACK Timeout(x20 ms): 50

NAK Retries: 3

ENQ Retries: 3

Page 1 Friday, March 18, 2016 - 12:43:04

DEMOTEST.RSS

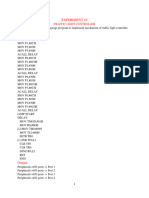

Program File List

Name Number Type Rungs Debug Bytes

[SYSTEM] 0 SYS 0 No 0

1 SYS 0 No 0

MAIN 2 LADDER 10 No 116

D INPUT 3 LADDER 9 No 131

D OUTPUT 4 LADDER 6 No 83

A INPUT 5 LADDER 3 No 254

A OUTPUT 6 LADDER 2 No 121

CONTROLS 7 LADDER 13 No 641

ALARMS 8 LADDER 21 No 920

DISPLAY 9 LADDER 2 No 42

Page 1 Friday, March 18, 2016 - 12:43:04

DEMOTEST.RSS

LAD 2 - MAIN --- Total Rungs in File = 10

S:1/15 ONLY ENERGIZES ON FIRST SCAN. USED HERE FOR SYSTEM INITIALIZATION, SUCH AS ENSURING THE SYSTEM IS IN

"OFF" MODE ON START.

SYSTEM MODE

0 = OFF

1 = ON

2 = FAULTED

First Pass SYSTEM_MODE

S:1 MOV

0000 Move

15 Source 0

0<

Dest N7:4

2<

BLOWER MODE

0 = OFF

1 = HAND

2 = AUTO

BLOWER_MODE

MOV

Move

Source 2

2<

Dest N7:11

2<

JSR (JUMP SUB-ROUTINE) BLOCKS EXECUTE THE REMAINING PROGRAM FILES IN OUT PLC PROGRAM.

DIGITAL INPUTS

JSR

0001 Jump To Subroutine

SBR File Number U:3

DIGITAL OUTPUTS

JSR

0002 Jump To Subroutine

SBR File Number U:4

ANALOG INPUTS

JSR

0003 Jump To Subroutine

SBR File Number U:5

ANALOG OUTPUTS

JSR

0004 Jump To Subroutine

SBR File Number U:6

CONTROLS

JSR

0005 Jump To Subroutine

SBR File Number U:7

ALARMS

JSR

0006 Jump To Subroutine

SBR File Number U:8

Page 1 Friday, March 18, 2016 - 12:43:04

DEMOTEST.RSS

LAD 2 - MAIN --- Total Rungs in File = 10

DISPLAY

JSR

0007 Jump To Subroutine

SBR File Number U:9

UNLATCHING THE S:5/0 BIT PERMANENTLY IS A COMMON PRACTICE. THIS PREVENTS MATH ERRORS (SUCH AS DIVIDING BY

ZERO) FROM KILLING YOUR PROGRAM DURING EXECUTION.

Overflow

Trap

S:5

0008 U

0

0009 END

Page 2 Friday, March 18, 2016 - 12:43:04

DEMOTEST.RSS

LAD 3 - D INPUT --- Total Rungs in File = 9

EACH DIGITAL INPUT IS TIED TO A BIT TO BE USED THROUGHOUT THE PROGRAM. WHILE THE ACTUAL INPUT CAN BE USED,

THIS IS PREFERABLE AS IT GREATLY SIMPLIFIES FUTURE CHANGES TO INPUT LOCATIONS.

BUTTON "ON" BUTTON "ON" IN BIT

I:0 B3:0

0000

0 0

Bul.1766

BUTTON "OFF" BUTTON "OFF" IN BIT

I:0 B3:0

0001

1 1

Bul.1766

PRESSURE SWITCH

IN BIT

PRESSURE SWITCH IN PRESSURE_SWITCH

I:0 B3:0

0002

2 2

Bul.1766

FLOW SWITCH IN BIT

FLOW SWITCH IN FLOW_SWITCH

I:0 B3:0

0003

3 3

Bul.1766

LOW-LOW LEVEL SWITCH

LOW-LOW LEVEL SWITCH IN BIT

IN LVL_LL_SW

I:0 B3:0

0004

4 4

Bul.1766

LOW LEVEL SWITCH

LOW LEVEL SWITCH IN BIT

IN LVL_L_SW

I:0 B3:0

0005

5 5

Bul.1766

HIGH LEVEL SWITCH

HIGH LEVEL SWITCH IN BIT

IN LVL_H_SW

I:0 B3:0

0006

6 6

Bul.1766

HIGH-HIGH LEVEL

HIGH-HIGH LEVEL SWITCH IN BIT

SWITCH IN LVL_HH_SW

I:0 B3:0

0007

7 7

Bul.1766

0008 END

Page 1 Friday, March 18, 2016 - 12:43:04

DEMOTEST.RSS

LAD 4 - D OUTPUT --- Total Rungs in File = 6

EACH DIGITAL OUTPUT IS TRIGGERED BY A SINGLE BIT CONTROLLED ELSEWHERE IN THE PROGRAM. WHILE THE ACTUAL

OUTPUT CAN BE USED IN THE CONTROL LOGIC, THIS METHOD IS PREFERABLE AS IT GREATLY SIMPLIFIES FUTURE CHANGES

TO OUTPUT LOCATIONS.

BLOWER OUT BIT

BLOWER BLOWER OUT

B3:1 O:0

0000

0 0

Bul.1766

TANK FILL PUMP OUT

BIT

PUMP TANK FILL PUMP OUT

B3:1 O:0

0001

1 1

Bul.1766

SUPPLY VALVE OUT

BIT

VALVE SUPPLY VALVE OUT

B3:1 O:0

0002

2 2

Bul.1766

HEATER RELAY OUT BIT

HEATER HEATER RELAY OUT

B3:1 O:0

0003

3 3

Bul.1766

ALARM HORN OUT BIT

HORN ALARM HORN OUT

B3:1 O:0

0004

4 4

Bul.1766

0005 END

Page 1 Friday, March 18, 2016 - 12:43:04

DEMOTEST.RSS

LAD 5 - A INPUT --- Total Rungs in File = 3

THE SCP (SCALE WITH PARAMETERS) BLOCK DOES THE CONVERSION OF A RAW INPUT SIGNAL INTO A VALUE YOU WANT TO

USE IN YOUR PROGRAM. THERE ARE MANY USES FOR THIS BLOCK, AND MANY WAYS TO SCALE SIGNALS. AS THIS

PROGRAM IS WRITTEN FOR A PLC CAPABLE OF PROCESSING ANALOG SIGNALS WITH 14 BITS OF RESOLUTION, WE WANT TO

MAKE SURE OUR INPUT AND OUTPUT RANGES BOTH HAVE AROUND 16,383 (2^14) DIFFERENT LEVELS. FOR EXAMPLE, 0-100

WOULD BE TERRIBLE IF WE WERE STORING THE RESULT AS AN INTERGER BECAUSE THERE ARE ONLY 101 LEVELS AND WE

WOULD BE LOSING MOST OF OUR RESOLUTION (PRECISION). HOWEVER, IF WE STORED THAT 0-100 AS A FLOAT WITH TWO

DECIMAL PLACES, IT'S BETTER BECAUSE WE THEN HAVE 10,001 LEVELS. HOWEVER, THIS STILL ISN'T IDEAL.

TANK LEVEL

(SCALED 0-100%)

LEVEL SENSOR IN TANK_LEVEL

LIM SCP

0000 Limit Test Scale w/Parameters

Low Lim 0 Input I:1.0

0< 3000<

Test I:1.0 Input Min. 0.0

3000< 0.0<

High Lim 16383 Input Max. 16383.0

16383< 16383.0<

Scaled Min. 0.0

0.0<

Scaled Max. 100.0

100.0<

Output F8:0

18.31166<

TANK LEVEL

(SCALED 0-100%)

LEVEL SENSOR IN TANK_LEVEL

LES MOV

Less Than (A<B) Move

Source A I:1.0 Source 0.0

3000< 0.0<

Source B 0 Dest F8:0

0< 18.31166<

TANK LEVEL

(SCALED 0-100%)

LEVEL SENSOR IN TANK_LEVEL

GRT MOV

Greater Than (A>B) Move

Source A I:1.0 Source 100.0

3000< 100.0<

Source B 16383 Dest F8:0

16383< 18.31166<

Page 1 Friday, March 18, 2016 - 12:43:04

DEMOTEST.RSS

LAD 5 - A INPUT --- Total Rungs in File = 3

SOMETIMES, STRANGE SIGNALS CAN COME INTO OUR SYSTEM AS A RESULT OF NOISE, FAULTY SENSORS / WIRING, OR

FAULTY MODULES. TO KEEP MY VALUES IN A USEFUL RANGE IN SUCH CASES, I'VE PUT CONDITIONAL LOGIC AROUND THE

SCP BLOCK TO HANDLE ANOMALOUS INPUTS. THE LIM (LIMIT) BLOCK CHECKS TO SEE IF MY RAW INPUT IS WITHIN THE

DESIRED RANGE BEFORE SCALING. A LES (LESS THAN <) BLOCK AND A GRT (GREATER THAN >) BLOCK ON SEPARATE

BRANCHES SET MINIMUM OR MAXIMUM VALUES RESPECTIVELY IF AND ONLY IF THE RAW INPUT SIGNAL IS OUT OF RANGE.

THE LAST BRANCH ON THE TEMPERATURE RUNG (0001) IS JUST STORING THE RAW INPUT (WHICH IS ALREADY SCALED FOR

PID 0-16383) TO AN INTERGER REGISTER IN MEMORY FOR USE IN A PID CONTROL LOOP. THIS PREVENTS ME FROM

REFERRING TO THE ACTUAL INPUT WITHIN THE REST OF THE PROGRAM. THUS, IF IN THE FUTURE WE NEED TO REMAP OUR

IO, WE ONLY HAVE TO MAKE CHANGES IN THE IO PROGRAM FILES INSTEAD OF HUNTING EACH ADDRESS THROUGHOUT

THE ENTIRE PROGRAM.

TEMPERATURE

(SCALED -40 TO 750F)

THERMOCOUPLE IN TEMPERATURE

LIM SCP

0001 Limit Test Scale w/Parameters

Low Lim 0 Input I:2.0

0< 3000<

Test I:2.0 Input Min. 0.0

3000< 0.0<

High Lim 16383 Input Max. 16383.0

16383< 16383.0<

Scaled Min. -40.0

-40.0<

Scaled Max. 750.0

750.0<

Output F8:1

104.6621<

TEMPERATURE

(SCALED -40 TO 750F)

THERMOCOUPLE IN TEMPERATURE

LES MOV

Less Than (A<B) Move

Source A I:2.0 Source -40.0

3000< -40.0<

Source B 0 Dest F8:1

0< 104.6621<

TEMPERATURE

(SCALED -40 TO 750F)

THERMOCOUPLE IN TEMPERATURE

GRT MOV

Greater Than (A>B) Move

Source A I:2.0 Source 750.0

3000< 750.0<

Source B 16383 Dest F8:1

16383< 104.6621<

TEMPERATURE PV

MOV

Move

Source F8:1

104.6621<

Dest N7:8

105<

0002 END

Page 2 Friday, March 18, 2016 - 12:43:04

DEMOTEST.RSS

LAD 6 - A OUTPUT --- Total Rungs in File = 2

THIS RUNG IS CONTROLLING THE ANALOG OUTPUT SIGNAL TO TELL OUR HEATER HOW MUCH HEAT TO PRODUCE. THE

OUTPUT MODULE CONVERTS OUR 0-16383 PID VALUE INTO A 4-20mA SIGNAL. HERE WE ARE CHECKING TO SEE IF THE

HEATER IS ENERGIZED. IF IT ISN'T, OR IF FOR SOME REASON OUR PID CV (CONTROL VARIABLE) IS BELOW 0, WE'RE SENDING

A ZERO OUTPUT TO THE HEATER - NO HEAT. IF HOWEVER THE HEATER IS ENERGIZED, WE CHECK TO SEE IF THE PID CV IS

WITHIN RANGE OR OVER RANGE. IF IT'S IN RANGE, WE MOVE OUR VALUE DIRECTLY TO THE OUTPUT (WHICH IS

CONFIGURED FOR A PID RANGE OF 0-16383). ON THE OTHER HAND, IF FOR SOME REASON OUR CV IS OVER THE RANGE,

WE'RE MOVING A MAXIMUM ACCEPTABLE VALUE TO THE OUTPUT.

HEATER RELAY OUT BIT HEATER SIGNAL OUT

HEATER HEATER CV (SCALED 0-16383)

B3:1 LIM MOV

0000 Limit Test Move

3 Low Lim 0.0 Source N7:9

0.0< 0<

Test N7:9 Dest O:1.0

0< 0<

High Lim 16383.0

16383.0<

HEATER SIGNAL OUT

HEATER CV (SCALED 0-16383)

GRT MOV

Greater Than (A>B) Move

Source A N7:9 Source 16383

0< 16383<

Source B 16383.0 Dest O:1.0

16383.0< 0<

HEATER RELAY OUT BIT HEATER SIGNAL OUT

HEATER (SCALED 0-16383)

B3:1 MOV

Move

3 Source 0

0<

HEATER CV Dest O:1.0

LES 0<

Less Than (A<B)

Source A N7:9

0<

Source B 0.0

0.0<

0001 END

Page 1 Friday, March 18, 2016 - 12:43:04

DEMOTEST.RSS

LAD 7 - CONTROLS --- Total Rungs in File = 13

HERE WE LOOK FOR THE PHYSICAL "ON" BUTTON OR THE HMI SYSTEM ON PUSHBUTTON TO BE PRESSED BY THE OPERATOR.

IF AND ONLY IF THE SYSTEM IS IN THE "OFF" MODE, WE CHANGE THE MODE TO ON BY MOVING THE VALUE "1" INTO THE

ADDRESS N7:4 (AN ARBITRARILY CHOSEN INTERGER LOCATION TO BE USED THROUGHOUT THE CONTROL LOGIC AND HMI

DISPLAYS TO INDICATE SYSTEM MODE). THE EQU (EQUALS) BLOCK COMPARES THE VALUE STORED IN N7:4 TO THE VALUE

"0" AND IS EVALUATED AS TRUE WHEN THESE TWO VALUES ARE THE SAME. THE ONS (ONE-SHOT) BLOCK ALLOWS THE

OUTPUT TO THE RIGHT TO EXECUTE FOR ONLY ONE SCAN FOR EACH TIME THE CONDITIONS TO THE LEFT OF THE BLOCK

ARE ALL TRUE.

SYSTEM MODE

0 = OFF

1 = ON

2 = FAULTED BUTTON "ON"

BUTTON "ON" IN BIT SYSTEM_MODE ONE-SHOT

B3:0 EQU B3:2

0000 Equal ONS

0 Source A N7:4 6

2<

SYSTEM ON Source B 0

PUSHBUTTON BIT 0<

(FROM HMI)

PB_ON

B3:4

SYSTEM MODE

ALARM RESET 0 = OFF

PUSHBUTTON BIT 1 = ON

(FROM HMI) 2 = FAULTED

ALM_RESET SYSTEM_MODE

B3:4 EQU

Equal

0 Source A N7:4

2<

Source B 2

2<

SYSTEM MODE

0 = OFF

1 = ON

2 = FAULTED

SYSTEM_MODE

MOV

Move

Source 1

1<

Dest N7:4

2<

Page 1 Friday, March 18, 2016 - 12:43:05

DEMOTEST.RSS

LAD 7 - CONTROLS --- Total Rungs in File = 13

HERE WE LOOK FOR THE PHYSICAL "OFF" BUTTON OR THE HMI SYSTEM OFF PUSHBUTTON TO BE PRESSED BY THE

OPERATOR. WHENEVER PRESSED, WE CHANGE THE MODE TO OFF BY MOVING THE VALUE "0" INTO THE ADDRESS N7:4.

SYSTEM MODE

0 = OFF

1 = ON

BUTTON "OFF" 2 = FAULTED

BUTTON "OFF" IN BIT ONE-SHOT SYSTEM_MODE

B3:0 B3:2 MOV

0001 ONS Move

1 7 Source 0

0<

SYSTEM OFF Dest N7:4

PUSHBUTTON BIT 2<

(FROM HMI)

PB_OFF

B3:4

HERE WE LOOK FOR AN ALARM CONDITION TO. WHEN ANY ALARM OCCURS, WE CHANGE THE MODE TO FAULTED BY

MOVING THE VALUE "2" INTO THE ADDRESS N7:4.

SYSTEM MODE

0 = OFF

1 = ON

GENERAL ALARM "FAULTED" 2 = FAULTED

NOTIFICATION BIT ONE-SHOT SYSTEM_MODE

B3:7 B3:2 MOV

0002 ONS Move

3 10 Source 2

2<

Dest N7:4

2<

Page 2 Friday, March 18, 2016 - 12:43:05

DEMOTEST.RSS

LAD 7 - CONTROLS --- Total Rungs in File = 13

HERE IS A SIMPLE DEMONSTRATION OF AN HOA (HAND - OFF - AUTO) CONTROL SCHEME FOR A DIGITAL DEVICE. IN THIS

RUNG WE'RE USING PUSHBUTTONS ON OUR HMI TO SET A STATUS WORD (IN THIS CASE THE INTERGER N7:11) TO

REFERENCE BLOWER CONTROL MODE IN THE REST OF THE PROGRAM AND ON THE HMI.

BLOWER MODE

BLOWER HAND 0 = OFF

PUSHBUTTON BIT 1 = HAND

(FROM HMI) 2 = AUTO

BLOWER_HAND_PB BLOWER HAND ONE-SHOT BLOWER_MODE

B3:0 B3:2 MOV

0003 ONS Move

8 11 Source 1

1<

Dest N7:11

2<

BLOWER MODE

BLOWER OFF 0 = OFF

PUSHBUTTON BIT 1 = HAND

(FROM HMI) 2 = AUTO

BLOWER_OFF_PB BLOWER OFF ONE-SHOT BLOWER_MODE

B3:0 B3:2 MOV

ONS Move

9 12 Source 0

0<

Dest N7:11

2<

BLOWER MODE

BLOWER AUTO 0 = OFF

PUSHBUTTON BIT 1 = HAND

(FROM HMI) 2 = AUTO

BLOWER_AUTO_PB BLOWER AUTO ONE-SHOT BLOWER_MODE

B3:0 B3:2 MOV

ONS Move

10 13 Source 2

2<

Dest N7:11

2<

Page 3 Friday, March 18, 2016 - 12:43:05

DEMOTEST.RSS

LAD 7 - CONTROLS --- Total Rungs in File = 13

ON THIS RUNG, WE ENERGIZE OUR BLOWER ANYTIME THE SYSTEM IS IN A MODE OTHER THAN OFF --- AND --- THE BLOWER

IS IN AUTO CONTROL. WE ALSO ENERGIZE THE BLOWER IF THE BLOWER IS IN HAND MODE REGARDLESS OF THE SYSTEM

MODE. THE NEQ (NOT EQUALS) BLOCK IS EVALUATED AS TRUE ANYTIME THE VALUE STORED IN N7:4 AND THE VALUE "0"

ARE DIFFERENT. SOMETHING IMPORTANT TO NOTE IS THAT EACH OUTPUT OR DIGITAL MEMORY LOCATION IS ONLY EVER

ENERGIZED IN ONE PLACE THROUGHOUT THE ENTIRE PROGRAM! WHILE THIS IS NOT IMPERATIVE, IT IS AN EXCELLENT

PRACTICE AS IT MAKES THE PROGRAM SMALLER, SIMPLER, AND MUCH EASIER TO READ, TROUBLESHOOT AND MODIFY IN

THE FUTURE.

SYSTEM MODE BLOWER MODE

0 = OFF 0 = OFF

1 = ON 1 = HAND

2 = FAULTED 2 = AUTO BLOWER OUT BIT

SYSTEM_MODE BLOWER_MODE BLOWER

NEQ EQU B3:1

0004 Not Equal Equal

Source A N7:4 Source A N7:11 0

2< 2<

Source B 0 Source B 2

0< 2<

BLOWER MODE

0 = OFF

1 = HAND

2 = AUTO

BLOWER_MODE

EQU

Equal

Source A N7:11

2<

Source B 1

1<

ON THIS RUNG, AS LONG AS THE SYSTEM IS NOT OFF, WE COMPARE OUR TANK LEVEL (F8:0) TO N7:1 WHICH IS DECLARED AS

"TANK LOW LEVEL SETPOINT" IN THE PROGRAM. IF THE ACTUAL TANK LEVEL IS LOWER THAN THIS LOW SETPOINT, WE

ENERGIZE A DELAY TIMER ON THE TOP BRANCH. IF OUR TANK LEVEL REMAINS BELOW THE LOW SETPOINT FOR FIVE

STRAIGHT SECONDS, THE TIMER TIMES OUT AND ENERGIZED IT'S OWN DN (COUNTED DOWN) BIT WHICH IS BEING

EVALUATED ON THE LOWER BRANCH OF THIS RUNG. WHEN IT IS TRUE / CLOSED, WE ENERGIZE A TRIGGER BIT WHICH

INITIATES THE TANK FILL PROCESS GOVERNED BELOW ON RUNG 0005.

SYSTEM MODE

0 = OFF ALARM RESET

1 = ON TANK LEVEL PUSHBUTTON BIT

2 = FAULTED (SCALED 0-100%) (FROM HMI)

SYSTEM_MODE TANK_LEVEL ALM_RESET

NEQ LES B3:4

0005 Not Equal Less Than (A<B)

Source A N7:4 Source A F8:0 0

2< 18.31166<

Source B 0 Source B N7:1

0< 20<

TANK FILL START

DELAY

TON

Timer On Delay EN

Timer T4:6

Time Base 1.0 DN

Preset 5<

Accum 5<

TANK FILL START TANK FILL START TANK FILL

DELAY ONE-SHOT TRIGGER BIT

T4:6 B3:2 B3:3

ONS

DN 8 6

Page 4 Friday, March 18, 2016 - 12:43:05

DEMOTEST.RSS

LAD 7 - CONTROLS --- Total Rungs in File = 13

THIS IS THE RECIPROCAL RUNG TO 0003. IT IS USED TO INITIATE THE TANK DRAIN PROCESS THUS DISABLING OUT PUMP

UNTIL NEEDED AGAIN. THE MECHANICS OF THIS RUNG ARE FUNDAMENTALLY IDENTICAL TO THOSE OF RUNG 0003. THE

DIFFERENCE HERE IS THAT WE ARE COMPARING OUR TANK LEVEL TO A HIGH SETPOINT TO SEE IF THE TANK LEVEL IS

GREATER.

SYSTEM MODE

0 = OFF ALARM RESET

1 = ON TANK LEVEL PUSHBUTTON BIT

2 = FAULTED (SCALED 0-100%) (FROM HMI)

SYSTEM_MODE TANK_LEVEL ALM_RESET

NEQ GRT B3:4

0006 Not Equal Greater Than (A>B)

Source A N7:4 Source A F8:0 0

2< 18.31166<

Source B 0 Source B N7:2

0< 80<

TANK FILL STOP

DELAY

TON

Timer On Delay EN

Timer T4:7

Time Base 1.0 DN

Preset 5<

Accum 0<

TANK FILL STOP TANK FILL STOP TANK DRAIN

DELAY ONE-SHOT TRIGGER BIT

T4:7 B3:2 B3:3

ONS

DN 9 7

SINCE OUR TANK FILL TRIGGER BIT IS PRECEDED BY A ONS (ONE-SHOT) ON RUNG 003, IT WILL ONLY BE ENERGIZED FOR

ONE SCAN. ON THIS RUNG, ASSUMING THE SYSTEM IS NOT OFF AND WE DO NOT HAVE AN ACTIVE PUMP ALARM OR

HIGH-HIGH LEVEL ALARM, THE TANK FILL PUMP WILL ENERGIZE. THE SUB-BRANCH WHICH BYPASSES THE TANK FILL

TRIGGER BIT PROVIDES A HOLD-IN TO KEEP THE PUMP RUNNING AFTER B3:3/6 DE-ENERGIZES (WHICH IT WILL DO

IMMEDIATELY). HERE, THE TANK FILL PUMP OUT BIT (B3:1/1) HOLDS ITSELF IN SO LONG AS THE TANK DRAIN TRIGGER BIT

(B3:3/7 - ENERGIZED ON RUNG 0004) REMAINS DE-ENERGIZED. ONCE B3:3/7 ENERGIZES, IT WILL TERMINATE THE PUMP'S

OUTPUT WHICH WILL REMAIN OFF UNTIL TRIGGERED AGAIN BY THE TANK FILL TRIGGER BIT (RUNG 0003).

SYSTEM MODE

0 = OFF

1 = ON TANK FILL PUMP ALARM

2 = FAULTED TANK FILL NOTIFICATION BIT

SYSTEM_MODE TRIGGER BIT ALM_PUMP

NEQ B3:3 B3:7

0007 Not Equal

Source A N7:4 6 1

2<

Source B 0 TANK FILL PUMP OUT

0< BIT TANK DRAIN

PUMP TRIGGER BIT

B3:1 B3:3

1 7

TANK FILL PUMP OUT

TANK LEVEL HIGH-HIGH BIT

ALARM BIT PUMP

B3:5 B3:1

1 1

Page 5 Friday, March 18, 2016 - 12:43:05

DEMOTEST.RSS

LAD 7 - CONTROLS --- Total Rungs in File = 13

HERE WE'RE CONTROLLING THE SUPPLY VALVE LEADING OUT FROM OUR TANK TO WHATEVER WE'RE SUPPLYING.

(DRINKING WATER FOR A TRAILER PARK IN INDIANA PERHAPS?) ASSUMING OUR SYSTEM IS NOT TURNED OFF, AND OUR

WATER LEVEL ISN'T SO LOW THAT WE HAVE A LOW-LOW LEVEL ALARM ACTIVE, THE VALVE WILL BE ENERGIZED OPEN,

AND THE PEOPLE CAN DRINK. WE WOULDN'T WANT TO RUN THE TANK DRY FOR RISK OF SEDIMENT (CRUD THAT SETTLES

AT THE BOTTOM OF THE TANK) GETTING INTO THE SUPPLY LINE, WHICH WOULD TASTE HORRIFIC.

SYSTEM MODE

0 = OFF

1 = ON SUPPLY VALVE OUT

2 = FAULTED TANK LEVEL LOW-LOW BIT

SYSTEM_MODE ALARM BIT VALVE

NEQ B3:5 B3:1

0008 Not Equal

Source A N7:4 0 2

2<

Source B 0

0<

ON RUNG 0007 WE'RE CONTROLLING OUR HEATER RELAY THE SAME WAY WE DID OUR SUPPLY VALVE IN THE PREVIOUS

RUNG. WHILE THE SYSTEM IS NOT OFF AND WE DON'T HAVE A HIGH-HIGH TEMPERATURE ALARM, THE HEATER RELAY IS

ENERGIZED. (THE AMOUNT OF HEAT OUTPUT IS BEING CONTROLLED BY A SEPARATE ANALOG SIGNAL.)

SYSTEM MODE

0 = OFF

1 = ON HIGH-HIGH

2 = FAULTED TEMPERATURE HEATER RELAY OUT BIT

SYSTEM_MODE ALARM BIT HEATER

NEQ B3:5 B3:1

0009 Not Equal

Source A N7:4 5 3

2<

Source B 0

0<

Page 6 Friday, March 18, 2016 - 12:43:05

DEMOTEST.RSS

LAD 7 - CONTROLS --- Total Rungs in File = 13

THIS IS UNDOUBTEDLY THE MOST COMPLICATED AND ENIGMATIC RUNG IN THE ENTIRE PROGRAM. THIS RUNG IS

CONTROLLING THE ANALOG OUTPUT TO THE HEATER, VIA A PID (PROPORTIONAL INTEGRAL DIFFERENTIAL) CONTROL

LOOP. IN SIMPLEST TERMS, THIS IS HOW IT WORKS: THE PID CONTROL IS GIVEN A SETPOINT. IN THIS CASE, THE OPERATOR

ENTERS ONE INTO THE HMI. THIS IS THE EQUIVALENT OF TURNING YOUR OVEN DIAL TO 350. THAT IS THE DESIRED

TEMPERATURE. THE PID THEN READS THE PV (PROCESS VARIABLE) WHICH TELLS IT WHAT THE TEMPERATURE ACTUALLY

IS (INSIDE THE OVEN FOR INSTANCE). DEPENDING ON A VERY COMPLEX SET OF EQUATIONS CONSIDERING SEVERAL

PROGRAMMER-CONFIGURABLE VARIABLES TOO COMPLEX TO GET INTO IN THIS TUTORIAL, IT ADJUSTS THE CV (CONTROL

VARIABLE) UP OR DOWN TO TRY TO MAINTAIN THE TEMPERATURE AT THE SETPOINT. THE CV IS WHAT WE USE IN THE

ANALOG OUTPUT PROGRAM FILE TO ESTABLISH A SIGNAL TO SEND TO THE HEATER. THE MOV (MOVE) BLOCK HERE IS JUST

STORING THE OPERATOR'S SETPOINT INTO THE PID SO IT CAN BE EVALUATED THERE. THERE ARE BOOKS, PROGRAMS AND

ENTIRE COURSES ON HOW TO SETUP AND 'TUNE' PID'S. FOR SMALLER APPLICATIONS OR APPLICATIONS BEING USED BY

LESS-THAN-FLUENT OPERATORS, MANY PROGRAMMERS RIGHTLY SHY AWAY FROM USING PID'S TO CONTROL PROCESS IN

ALL BUT CRITICAL PROCESSES.

SYSTEM MODE

0 = OFF

1 = ON

2 = FAULTED TEMPERATURE CONTROL

SYSTEM_MODE LOOP

NEQ MOV

0010 Not Equal Move

Source A N7:4 Source N7:6

2< 90<

Source B 0 Dest PD9:0.SPS

0< 0<

TEMPERATURE CONTROL

LOOP

PID

PID

PID File PD9:0

Process Variable N7:8

Control Variable N7:9

Setup Screen <

IS THERE AN ALARM? THEN LET'S SOUND A LOUD AND ANNOYING HORN THROUGHOUT THE PLANT!

SYSTEM MODE

0 = OFF

1 = ON

2 = FAULTED GENERAL ALARM ALARM HORN OUT BIT

SYSTEM_MODE NOTIFICATION BIT HORN

NEQ B3:7 B3:1

0011 Not Equal

Source A N7:4 3 4

2<

Source B 0

0<

0012 END

Page 7 Friday, March 18, 2016 - 12:43:05

DEMOTEST.RSS

LAD 8 - ALARMS --- Total Rungs in File = 21

OK, NOW FOR ALARMS. THERE ARE MANY WAYS TO CREATE, TERMINATE AND MANAGE ALARMS. SOME WAYS ARE WAY

BETTER, MORE PRACTICAL, MORE USEFUL, AND MORE OPERATOR-FRIENDLY THAN OTHERS! SOME PROGRAMMERS LET

THE PLC HANDLE ALARMS, OTHERS DELEGATE THAT FUNCTIONALITY TO THEIR HMI PROGRAM. SOME HMI'S DO IT WELL,

OTHERS DON'T. I'VE WRITTEN THIS ALARM LOGIC ASSUMING THE PLC WILL BE HANDLING ALL ALARM FUNCTIONALITY,

WHICH MEANS THIS PROGRAM IS SUITABLE FOR USE WITH A MUCH WIDER VARIETY OF HMI'S. MORE IMPORTANTLY, YOU

WILL BE ABLE TO LEARN A LOT ABOUT PRACTICAL ALARM MANAGEMENT.

EACH ALARM IN THIS PROGRAM WILL BE GOVERNED BY TWO OR THREE RUNGS. THIS FIRST ALARM IS GOVERNED BY TWO.

FOR THE TANK ALARMS, WE ASSUME WE HAVE DUAL LEVEL CONTROLS IN OUR TANK. IMAGINE WE HAVE FOUR LEVEL

SWITCHES (FLOAT SWITCHES), ONE AT THE LOW-LOW LEVEL, ONE AT THE LOW LEVEL, ONE AT THE HIGH LEVEL AND

ANOTHER AT THE HIGH-HIGH LEVEL. WE ALSO HAVE AN ANALOG SENSOR (RADAR OR HYDROSTATIC PRESSURE FOR

INSTANCE). ON THE LEFT OF OUR RUNG, WE ARE EXAMINING BOTH CONTROLS, EITHER OF WHICH CAN TELL US WE HAVE A

LOW-LOW LEVEL. IF OUR ANALOG-MEASURED TANK LEVEL (F8:0) IS LOWER THAN OUR LOW-LOW LEVEL SETPOINT

(STORED IN N7:0), --- OR --- IF OUR LOW-LOW LEVEL SWITCH IS CLOSED, THEN WE ENERGIZE OUR DELAY TIMER. ONCE THE

FIVE SECONDS ON THE TIMER EXPIRE, WE'LL TRIGGER OUR LOW-LOW ALARM BIT --- AND --- A SEPARATE LOW-LOW

NOTIFICATION BIT (IN THE RUNG BELOW - 0001) USING THE FAMILIAR ONE-SHOT AND TRIGGER BIT (JUST LIKE WE USED IN

CONTROLS 0004 AND 0005).

IN THIS ALARM, ONCE THE LOW-LOW LEVEL CONDITION DISAPPEARS, THE ALARM DOES AS WELL - AUTOMATICALLY, ---

BUT --- THE NOTIFICATION REMAINS!!! WHY? IF A LEVEL ALARM OCCURS AT 3 O'CLOCK IN THE MORNING AND THEN FIXES

ITSELF, DO WE WANT TO SHUT THE SYSTEM DOWN UNTIL SOMEBODY SHOWS UP AT TEN? MEANWHILE, A LOT OF PEOPLE

HAVE NO WATER. OF COURSE NOT. SO WE'LL LET THE ALARM CLEAR ITSELF, --- BUT --- WE WANT THE NOTIFICATION TO

STILL BE THERE WHEN THE OPERATOR SHOWS UP FOR WORK. THAT WAY, HE CAN SEE THAT SOMETHING NEEDS HIS

ATTENTION. THE NOTIFICATION BIT REMAINS ENERGIZED UNTIL HE PRESSES THE ALARM RESET --- OR --- THE ALARM

SILENCE BUTTON ON THE HMI. THESE ARE DIFFERENT. ONE (ALARM SILENCE) MAKES THE HORNS SHUT OFF AND THE

MESSAGES ON THE HMI DISAPPEAR. THE OTHER (ALARM RESET) CAN ACTUALLY RESET ALARMS THAT ARE LOCKED IN.

THE ALARM RESET WILL ALSO RESET THE ALARM TIMERS AND MAKE THE ALARMS DISAPPEAR --- HOWEVER --- IF THE

CONDITION THAT PRECIPITATED THE ALARM REMAINS, THE ALARM AND NOTIFICATION WILL REAPPEAR ONCE THE DELAY

TIMER COUNTS DOWN ANEW.

WE WON'T BE LOCKING OUR LEVEL ALARMS IN, BUT YOU CAN BET WE'LL BE LOCKING IN OUR PUMP AND TEMPERATURE

ALARMS! THOSE CAN BECOME EXPENSIVE / DANGEROUS IF LEFT UNATTENDED (AS COULD LEVEL ALARMS IF THE TANK

WAS STORING BATTERY ACID OR ANTHRAX SPORES OR SOMETHING...)

ALARM RESET

TANK LEVEL PUSHBUTTON BIT

(SCALED 0-100%) (FROM HMI)

TANK_LEVEL ALM_RESET

LES B3:4

0000 Less Than (A<B)

Source A F8:0 0

18.31166<

Source B N7:0

15<

LOW-LOW LEVEL SWITCH

IN BIT

LVL_LL_SW

B3:0

TANK LEVEL LOW-LOW

ALARM DELAY

TON

Timer On Delay EN

Timer T4:0

Time Base 1.0 DN

Preset 5<

Accum 0<

Page 1 Friday, March 18, 2016 - 12:43:05

DEMOTEST.RSS

LAD 8 - ALARMS --- Total Rungs in File = 21

TANK LEVEL LOW-LOW TANK LEVEL LOW-LOW

ALARM DELAY ALARM BIT

T4:0 B3:5

DN 0

TANK LEVEL LOW-LOW

ALARM TRIGGER TANK LEVEL LOW-LOW

ONE-SHOT ALARM TRIGGER BIT

B3:2 B3:3

ONS

0 0

ALARM RESET ALARM SILENCE

PUSHBUTTON BIT PUSHBUTTON BIT TANK LEVEL LOW-LOW

TANK LEVEL LOW-LOW (FROM HMI) (FROM HMI) NOTIFICATION BIT

ALARM TRIGGER BIT ALM_RESET ALM_SILENCE ALM_LVL_LL

B3:3 B3:4 B3:4 B3:6

0001

0 0 1 0

TANK LEVEL LOW-LOW

NOTIFICATION BIT

ALM_LVL_LL

B3:6

Page 2 Friday, March 18, 2016 - 12:43:05

DEMOTEST.RSS

LAD 8 - ALARMS --- Total Rungs in File = 21

THESE TWO RUNGS CONTROL THE HIGH-HIGH TANK LEVEL ALARM (AND NOTIFICATION) IN THE SAME MANNER AS THE

LAST TWO CONTROLLED THE LOW-LOW LEVEL ALARM.

ALARM RESET

TANK LEVEL PUSHBUTTON BIT

(SCALED 0-100%) (FROM HMI)

TANK_LEVEL ALM_RESET

GRT B3:4

0002 Greater Than (A>B)

Source A F8:0 0

18.31166<

Source B N7:3

90<

HIGH-HIGH LEVEL

SWITCH IN BIT

LVL_HH_SW

B3:0

TANK LEVEL HIGH-HIGH

ALARM DELAY

TON

Timer On Delay EN

Timer T4:1

Time Base 1.0 DN

Preset 5<

Accum 0<

TANK LEVEL HIGH-HIGH TANK LEVEL HIGH-HIGH

ALARM DELAY ALARM BIT

T4:1 B3:5

DN 1

TANK LEVEL HIGH-HIGH

ALARM TRIGGER TANK LEVEL HIGH-HIGH

ONE-SHOT ALARM TRIGGER BIT

B3:2 B3:3

ONS

1 1

ALARM RESET ALARM SILENCE

PUSHBUTTON BIT PUSHBUTTON BIT TANK LEVEL HIGH-HIGH

TANK LEVEL HIGH-HIGH (FROM HMI) (FROM HMI) NOTIFICATION BIT

ALARM TRIGGER BIT ALM_RESET ALM_SILENCE ALM_LVL_HH

B3:3 B3:4 B3:4 B3:6

0003

1 0 1 1

TANK LEVEL HIGH-HIGH

NOTIFICATION BIT

ALM_LVL_HH

B3:6

Page 3 Friday, March 18, 2016 - 12:43:05

DEMOTEST.RSS

LAD 8 - ALARMS --- Total Rungs in File = 21

FROM HERE ON DOWN, THE ALARMS WILL BE GOVERNED BY THREE RUNGS EACH. THE FIRST RUNG WILL TRIGGER THE

ALARM. THE SECOND RUNG WILL GOVERN THE ALARM BIT. THE THIRD RUNG WILL GOVERN THE NOTIFICATION BIT.

UNLIKE THE LEVEL ALARMS, THE PUMP AND TEMPERATURE ALARMS WILL HAVE A HOLD-IN. THUS, EVEN IF THE

CONDITION DISAPPEARS, THE ALARM WILL REMAIN UNTIL THE OPERATOR PRESSES THE ALARM RESET BUTTON (AND OF

COURSE THE PROBLEM IS CORRECTED).

IF A PUMP IS OVER-PRESSURIZING A PIPE, WE WANT THE OPERATOR TO CHECK IT OUT. OTHERWISE, SOMETHING COULD

EXPLODE.

IF A PUMP IS NOT CREATING FLOW, WE WANT THE OPERATOR TO CHECK IT OUT. OTHERWISE, THE PUMP COULD CAVITATE.

IF A HEATER IS OVER- HEATING, WE WANT THE OPERATOR TO CHECK IT OUT. OTHERWISE, SOMETHING COULD CATCH ON

FIRE.

IF A HEATER IS NOT CREATING HEAT, WE WANT THE OPERATOR TO CHECK IT OUT. OTHERWISE, A SENSOR COULD BE BAD

AND SOMETHING COULD EXPLODE.

ALARM RESET

TANK FILL PUMP OUT PRESSURE SWITCH PUSHBUTTON BIT

BIT IN BIT (FROM HMI)

PUMP PRESSURE_SWITCH ALM_RESET

B3:1 B3:0 B3:4

0004

1 2 0

TANK FILL PUMP HIGH

PRESSURE

ALARM DELAY

TON

Timer On Delay EN

Timer T4:2

Time Base 1.0 DN

Preset 5<

Accum 0<

TANK FILL PUMP HIGH

TANK FILL PUMP HIGH PRESSURE TANK FILL PUMP HIGH

PRESSURE ALARM TRIGGER PRESSURE

ALARM DELAY ONE-SHOT ALARM TRIGGER BIT

T4:2 B3:2 B3:3

ONS

DN 2 2

ALARM RESET

TANK FILL PUMP HIGH PUSHBUTTON BIT TANK FILL PUMP HIGH

PRESSURE (FROM HMI) PRESSURE

ALARM TRIGGER BIT ALM_RESET ALARM BIT

B3:3 B3:4 B3:5

0005

2 0 2

TANK FILL PUMP HIGH

PRESSURE

ALARM BIT

B3:5

Page 4 Friday, March 18, 2016 - 12:43:05

DEMOTEST.RSS

LAD 8 - ALARMS --- Total Rungs in File = 21

ALARM RESET ALARM SILENCE TANK FILL PUMP HIGH

TANK FILL PUMP HIGH PUSHBUTTON BIT PUSHBUTTON BIT PRESSURE

PRESSURE (FROM HMI) (FROM HMI) NOTIFICATION BIT

ALARM TRIGGER BIT ALM_RESET ALM_SILENCE ALM_PUMP_HP

B3:3 B3:4 B3:4 B3:6

0006

2 0 1 2

TANK FILL PUMP HIGH

PRESSURE

NOTIFICATION BIT

ALM_PUMP_HP

B3:6

ALARM RESET

TANK FILL PUMP OUT PUSHBUTTON BIT

BIT FLOW SWITCH IN BIT (FROM HMI)

PUMP FLOW_SWITCH ALM_RESET

B3:1 B3:0 B3:4

0007

1 3 0

TANK FILL PUMP LOW

FLOW

ALARM DELAY

TON

Timer On Delay EN

Timer T4:3

Time Base 1.0 DN

Preset 5<

Accum 0<

TANK FILL PUMP LOW

TANK FILL PUMP LOW FLOW TANK FILL PUMP LOW

FLOW ALARM TRIGGER FLOW

ALARM DELAY ONE-SHOT ALARM TRIGGER BIT

T4:3 B3:2 B3:3

ONS

DN 3 3

ALARM RESET

TANK FILL PUMP LOW PUSHBUTTON BIT TANK FILL PUMP LOW

FLOW (FROM HMI) FLOW

ALARM TRIGGER BIT ALM_RESET ALARM BIT

B3:3 B3:4 B3:5

0008

3 0 3

TANK FILL PUMP LOW

FLOW

ALARM BIT

B3:5

Page 5 Friday, March 18, 2016 - 12:43:05

DEMOTEST.RSS

LAD 8 - ALARMS --- Total Rungs in File = 21

ALARM RESET ALARM SILENCE TANK FILL PUMP LOW

TANK FILL PUMP LOW PUSHBUTTON BIT PUSHBUTTON BIT FLOW

FLOW (FROM HMI) (FROM HMI) NOTIFICATION BIT

ALARM TRIGGER BIT ALM_RESET ALM_SILENCE ALM_PUMP_LF

B3:3 B3:4 B3:4 B3:6

0009

3 0 1 3

TANK FILL PUMP LOW

FLOW

NOTIFICATION BIT

ALM_PUMP_LF

B3:6

NOTICE THAT INSTEAD OF THE TYPICAL 5 SECOND DELAY, THERE IS A 15 MINUTE (900 SECOND) TIMER. THIS IS OBVIOUSLY

SUBJECTIVE DEPENDING ON THE SIZE OF THE HEATER, TIME REQUIRED UNDER WORST-CASE TO ACHEIVE OPERATING

TEMPERATURE AND ETC..

ALARM RESET

TEMPERATURE PUSHBUTTON BIT

(SCALED -40 TO 750F) (FROM HMI)

TEMPERATURE ALM_RESET

LES B3:4

0010 Less Than (A<B)

Source A F8:1 0

104.6621<

Source B N7:5

20<

LOW-LOW TEMPERATURE

ALARM DELAY

TON

Timer On Delay EN

Timer T4:4

Time Base 1.0 DN

Preset 900<

Accum 0<

LOW-LOW TEMPERATURE

LOW-LOW TEMPERATURE ALARM TRIGGER LOW-LOW TEMPERATURE

ALARM DELAY ONE-SHOT ALARM TRIGGER BIT

T4:4 B3:2 B3:3

ONS

DN 4 4

ALARM RESET

PUSHBUTTON BIT

LOW-LOW TEMPERATURE (FROM HMI) LOW-LOW TEMPERATURE

ALARM TRIGGER BIT ALM_RESET ALARM BIT

B3:3 B3:4 B3:5

0011

4 0 4

LOW-LOW TEMPERATURE

ALARM BIT

B3:5

Page 6 Friday, March 18, 2016 - 12:43:05

DEMOTEST.RSS

LAD 8 - ALARMS --- Total Rungs in File = 21

ALARM RESET ALARM SILENCE

PUSHBUTTON BIT PUSHBUTTON BIT LOW-LOW TEMPERATURE

LOW-LOW TEMPERATURE (FROM HMI) (FROM HMI) NOTIFICATION BIT

ALARM TRIGGER BIT ALM_RESET ALM_SILENCE ALM_TEMP_LL

B3:3 B3:4 B3:4 B3:6

0012

4 0 1 4

LOW-LOW TEMPERATURE

NOTIFICATION BIT

ALM_TEMP_LL

B3:6

ALARM RESET

TEMPERATURE PUSHBUTTON BIT

(SCALED -40 TO 750F) (FROM HMI)

TEMPERATURE ALM_RESET

GRT B3:4

0013 Greater Than (A>B)

Source A F8:1 0

104.6621<

Source B N7:7

120<

HIGH-HIGH

TEMPERATURE

ALARM DELAY

TON

Timer On Delay EN

Timer T4:5

Time Base 1.0 DN

Preset 5<

Accum 0<

HIGH-HIGH

HIGH-HIGH TEMPERATURE HIGH-HIGH

TEMPERATURE ALARM TRIGGER TEMPERATURE

ALARM DELAY ONE-SHOT ALARM TRIGGER BIT

T4:5 B3:2 B3:3

ONS

DN 5 5

ALARM RESET

HIGH-HIGH PUSHBUTTON BIT HIGH-HIGH

TEMPERATURE (FROM HMI) TEMPERATURE

ALARM TRIGGER BIT ALM_RESET ALARM BIT

B3:3 B3:4 B3:5

0014

5 0 5

HIGH-HIGH

TEMPERATURE

ALARM BIT

B3:5

Page 7 Friday, March 18, 2016 - 12:43:05

DEMOTEST.RSS

LAD 8 - ALARMS --- Total Rungs in File = 21

ALARM RESET ALARM SILENCE HIGH-HIGH

HIGH-HIGH PUSHBUTTON BIT PUSHBUTTON BIT TEMPERATURE

TEMPERATURE (FROM HMI) (FROM HMI) NOTIFICATION BIT

ALARM TRIGGER BIT ALM_RESET ALM_SILENCE ALM_TEMP_HH

B3:3 B3:4 B3:4 B3:6

0015

5 0 1 5

HIGH-HIGH

TEMPERATURE

NOTIFICATION BIT

ALM_TEMP_HH

B3:6

THIS IS A CATEGORY ALARM BIT. IF WE HAVE A LOW-LOW OR HIGH-HIGH LEVEL ALARM, WE WILL ENERGIZE THIS BIT. THIS

MAY BE READ BY ANOTHER SYSTEM OVER A NETWORK OR DISPLAYED ON THE HMI.

TANK LEVEL LOW-LOW TANK LEVEL ALARM

NOTIFICATION BIT NOTIFICATION BIT

ALM_LVL_LL ALM_TANK

B3:6 B3:7

0016

0 0

TANK LEVEL HIGH-HIGH

NOTIFICATION BIT

ALM_LVL_HH

B3:6

THIS IS A CATEGORY ALARM BIT. IF WE HAVE A LOW FLOW OR HIGH PRESSURE ALARM, WE WILL ENERGIZE THIS BIT. THIS

MAY BE READ BY ANOTHER SYSTEM OVER A NETWORK OR DISPLAYED ON THE HMI.

TANK FILL PUMP HIGH

PRESSURE TANK FILL PUMP ALARM

NOTIFICATION BIT NOTIFICATION BIT

ALM_PUMP_HP ALM_PUMP

B3:6 B3:7

0017

2 1

TANK FILL PUMP LOW

FLOW

NOTIFICATION BIT

ALM_PUMP_LF

B3:6

THIS IS A CATEGORY ALARM BIT. IF WE HAVE A LOW-LOW OR HIGH-HIGH TEMPERATURE ALARM, WE WILL ENERGIZE THIS

BIT. THIS MAY BE READ BY ANOTHER SYSTEM OVER A NETWORK OR DISPLAYED ON THE HMI.

LOW-LOW TEMPERATURE TEMPERATURE ALARM

NOTIFICATION BIT NOTIFICATION BIT

ALM_TEMP_LL ALM_TEMP

B3:6 B3:7

0018

4 2

HIGH-HIGH

TEMPERATURE

NOTIFICATION BIT

ALM_TEMP_HH

B3:6

Page 8 Friday, March 18, 2016 - 12:43:05

DEMOTEST.RSS

LAD 8 - ALARMS --- Total Rungs in File = 21

IF WE HAVE AN ALARM IN ANY CATEGORY (TANK, PUMP OR TEMPERATURE), WE WILL ENERGIZE THE GENERAL ALARM BIT.

THIS MAY BE READ BY ANOTHER SYSTEM OVER A NETWORK OR DISPLAYED ON THE HMI.

TANK LEVEL ALARM

NOTIFICATION BIT GENERAL ALARM

ALM_TANK NOTIFICATION BIT

B3:7 B3:7

0019

0 3

TANK FILL PUMP ALARM

NOTIFICATION BIT

ALM_PUMP

B3:7

TEMPERATURE ALARM

NOTIFICATION BIT

ALM_TEMP

B3:7

0020 END

Page 9 Friday, March 18, 2016 - 12:43:05

DEMOTEST.RSS

LAD 9 - DISPLAY --- Total Rungs in File = 2

HEATER OUTPUT FOR

DISPLAY (0-100%)

HEATER_OUTPUT

SCP

0000 Scale w/Parameters

Input N7:9

0<

Input Min. 0

0<

Input Max. 16383

16383<

Scaled Min. 0

0<

Scaled Max. 100

100<

Output N7:10

0<

0001 END

Page 1 Friday, March 18, 2016 - 12:43:05

DEMOTEST.RSS

Instruction Comment Database

Address Instruction Description

Page 1 Friday, March 18, 2016 - 12:43:05

DEMOTEST.RSS

Symbol Group Database

Group_Name Description

Page 1 Friday, March 18, 2016 - 12:43:05

You might also like

- E1 Pri TroubleshootingDocument4 pagesE1 Pri TroubleshootingAlemseged HabtamuNo ratings yet

- AOS-CX Simulator - MSTP Lab GuideDocument14 pagesAOS-CX Simulator - MSTP Lab Guidetest testNo ratings yet

- CONVERSÃO ANSI Nos PTSs HUAWEIDocument3 pagesCONVERSÃO ANSI Nos PTSs HUAWEIrobelmouraNo ratings yet

- RSLogix 500 Project Report SummaryDocument26 pagesRSLogix 500 Project Report SummaryJOXin1No ratings yet

- Airtelligence 2.0 Modbus Anbindung enDocument9 pagesAirtelligence 2.0 Modbus Anbindung enPiotrNo ratings yet

- Basic ONOS Tutorial: Eueung MulyanaDocument35 pagesBasic ONOS Tutorial: Eueung MulyanaAnderson OlivierNo ratings yet

- 20EC3352 LAB EXPERIMENTS OldDocument47 pages20EC3352 LAB EXPERIMENTS Oldswathi kesanaNo ratings yet

- Documento de Impresora Redirigido de Escritorio RemotoDocument37 pagesDocumento de Impresora Redirigido de Escritorio RemotoluisNo ratings yet

- Laboratory Manual: Microcontroller & Embedded System Lab (EEE-433-F) (Vii Semester)Document26 pagesLaboratory Manual: Microcontroller & Embedded System Lab (EEE-433-F) (Vii Semester)Aanandha SaravananNo ratings yet

- ProgramsDocument24 pagesProgramsP HAMSA DATTA0% (1)

- LCD 16 X 2Document9 pagesLCD 16 X 2Pradeev Balakrishnan100% (1)

- 8.delapan (Counter Dan FSM)Document20 pages8.delapan (Counter Dan FSM)muhammad naufalNo ratings yet

- LED Control ExperimentsDocument142 pagesLED Control ExperimentsAulia NurletteNo ratings yet

- FB1 RampDocument3 pagesFB1 RampDhrubajyoti BoraNo ratings yet

- Easyveep DW 16Document20 pagesEasyveep DW 16Elby NurdinNo ratings yet

- Micro Task 4 - Merged - CompressedDocument32 pagesMicro Task 4 - Merged - Compresseddipak6541.6615No ratings yet

- To DiprintDocument8 pagesTo DiprintnenykurniawatiNo ratings yet

- PLC Program File ListDocument12 pagesPLC Program File ListmariossalasNo ratings yet

- Input and Output For Microprocessors: State University Ofnew York, Buffalo, New York 14226Document5 pagesInput and Output For Microprocessors: State University Ofnew York, Buffalo, New York 14226ٍْبـٌـًُغـٰٓـدادِ كَــشِْــَخةَٓNo ratings yet

- Alu-5 Upgrade Firmware Turn-Up-1830pss32 - CliDocument14 pagesAlu-5 Upgrade Firmware Turn-Up-1830pss32 - CliAnonymous sV02Ggn4TONo ratings yet

- Rslogix 500 Project ReportDocument30 pagesRslogix 500 Project ReportMiguel AngelNo ratings yet

- EXPT 1 LCD InterfacingDocument8 pagesEXPT 1 LCD InterfacingdharmaNo ratings yet

- Data HazardsDocument15 pagesData HazardsPetreMaziluNo ratings yet

- AN0308 Setting Up Cyclic Links With CTNet Using SyPT ProDocument8 pagesAN0308 Setting Up Cyclic Links With CTNet Using SyPT ProSamir TahaNo ratings yet

- Modbus RTUDocument15 pagesModbus RTUHans MortenNo ratings yet

- Lecture Slide 4Document48 pagesLecture Slide 4Sunil SahooNo ratings yet

- OpenLdap Documentation1Document14 pagesOpenLdap Documentation1kourosh nosrati heraviNo ratings yet

- 6es7315 2ah14 0ab0Document17 pages6es7315 2ah14 0ab0شريف الشربينىNo ratings yet

- 8051 Interfacing GuideDocument37 pages8051 Interfacing GuidedhikacelvinNo ratings yet

- Lab Sheet For Chapter 9Document26 pagesLab Sheet For Chapter 9karnsushantlalNo ratings yet

- Lab1 - 2 EngDocument11 pagesLab1 - 2 EngMai Huỳnh TháiNo ratings yet

- 037 P6 PDFDocument24 pages037 P6 PDFMário FonsecaNo ratings yet

- SAPDocument32 pagesSAPAnjali RanaNo ratings yet

- Lab - Use A Port Scanner To Detect Open PortsDocument7 pagesLab - Use A Port Scanner To Detect Open PortsAsepNo ratings yet

- 1.2.10 Lab Use A Port Scanner To Detect Open Ports Answer KeyDocument7 pages1.2.10 Lab Use A Port Scanner To Detect Open Ports Answer KeyVivek GaonkarNo ratings yet

- Lifeline Test ProcedureDocument10 pagesLifeline Test ProcedureHaseeb Shaikh0% (1)

- Programmable Logic Controllers LogixPro PLC Lab Manual (5th Ed.)Document180 pagesProgrammable Logic Controllers LogixPro PLC Lab Manual (5th Ed.)RAUL NNo ratings yet

- Microprocessor Systems Lab Experiment 4 BodyDocument6 pagesMicroprocessor Systems Lab Experiment 4 BodyRuth Abegail de VeraNo ratings yet

- 2524 LacpDocument6 pages2524 LacpamisheraNo ratings yet

- Network Security Lab-2: Port Scanning: 1. Output of Discovery ScanDocument10 pagesNetwork Security Lab-2: Port Scanning: 1. Output of Discovery ScanashokatmellonNo ratings yet

- IA2 - Scheme & Sol MC - by TauseefDocument6 pagesIA2 - Scheme & Sol MC - by Tauseefjvgirish74No ratings yet

- Verify CoS VMXDocument80 pagesVerify CoS VMXTùng Phạm Nguyễn ViệtNo ratings yet

- Modified Flashing LED ALGORITHMDocument24 pagesModified Flashing LED ALGORITHMDinesh Loitongbam100% (1)

- Report Exp 3Document14 pagesReport Exp 3Sampath ReddyNo ratings yet

- Programa Espesador de Relaves ColquisiriDocument33 pagesPrograma Espesador de Relaves ColquisiriCarlos MejiaNo ratings yet

- Microcontroller 8051Document72 pagesMicrocontroller 8051vaibhav sharmaNo ratings yet

- Queue ManualDocument18 pagesQueue ManualTakeshi KogaNo ratings yet

- Network Scanning Using NmapDocument6 pagesNetwork Scanning Using Nmapmillanu6275No ratings yet

- TNS Listener FailedDocument2 pagesTNS Listener Failedvaasudevaa2005No ratings yet

- Unit 5Document9 pagesUnit 5Suresh MeesalaNo ratings yet

- I/O Devices (: Peripherals)Document32 pagesI/O Devices (: Peripherals)sivanagaprasadnaiduNo ratings yet

- MicrocontrollerDocument16 pagesMicrocontrollerClips HUBNo ratings yet

- Simatic 300Document9 pagesSimatic 300Emil PramonoNo ratings yet

- 15BMD0020 - 1Document14 pages15BMD0020 - 1Broklen Hawk Jr.No ratings yet

- Procedimento para Calibração de Cola PDFDocument1 pageProcedimento para Calibração de Cola PDFDeyler SaquettoNo ratings yet

- Release Name Year NotesDocument19 pagesRelease Name Year NotesAnkur JainNo ratings yet

- AOS-CX Switch Simulator - RPVST Lab GuideDocument14 pagesAOS-CX Switch Simulator - RPVST Lab Guidetest testNo ratings yet

- ESIOT LAB Mannual - CseDocument59 pagesESIOT LAB Mannual - CseTamil Vanan100% (1)

- ECC BW APO Daily Health Checks 24th Feb 2015Document232 pagesECC BW APO Daily Health Checks 24th Feb 2015Vigghnnaesh DamertlaNo ratings yet

- Learn Digital and Microprocessor Techniques On Your Smartphone: Portable Learning, Reference and Revision Tools.From EverandLearn Digital and Microprocessor Techniques On Your Smartphone: Portable Learning, Reference and Revision Tools.No ratings yet

- 3 Indicators Appear Before Big BreakoutsDocument4 pages3 Indicators Appear Before Big Breakoutsmy pedroNo ratings yet

- Elliott Wave enDocument37 pagesElliott Wave enMishu Aqua100% (1)

- GET CLARITY Lesson 2 PDFDocument1 pageGET CLARITY Lesson 2 PDFmy pedroNo ratings yet

- Wave enDocument1 pageWave enmy pedroNo ratings yet

- Sample1 PDFDocument714 pagesSample1 PDFmy pedroNo ratings yet

- 1747 br005 - en PDocument8 pages1747 br005 - en PkondNo ratings yet

- 1 Rule Exercise 1 2 Answers PDFDocument2 pages1 Rule Exercise 1 2 Answers PDFmy pedroNo ratings yet

- Get Clarity Lesson 2Document1 pageGet Clarity Lesson 2my pedroNo ratings yet

- Exerc PDFDocument2 pagesExerc PDFmy pedroNo ratings yet

- Elliott Wave enDocument37 pagesElliott Wave enMishu Aqua100% (1)

- 1 Rule Exercise 1 2Document2 pages1 Rule Exercise 1 2my pedroNo ratings yet

- BackwashDocument1 pageBackwashmy pedroNo ratings yet

- Starter DiagramDocument39 pagesStarter Diagramlam nguyenNo ratings yet

- Hydrogenolysis System Control OverviewDocument183 pagesHydrogenolysis System Control Overviewmy pedroNo ratings yet

- PLC Command Index: A.B. Micrologix and SLC FamilyDocument26 pagesPLC Command Index: A.B. Micrologix and SLC Familymy pedroNo ratings yet

- Setting Page PDFDocument1 pageSetting Page PDFmy pedroNo ratings yet

- Build Muscle with This Isometrics WorkoutDocument40 pagesBuild Muscle with This Isometrics Workoutaeroartonline87% (31)

- Setting Page PDFDocument1 pageSetting Page PDFmy pedro0% (1)

- Photo EyeDocument1 pagePhoto Eyemy pedroNo ratings yet

- Labview Based Self Tuning Fuzzy Logic Controller For Sterilizing Equipments in HospitalsDocument4 pagesLabview Based Self Tuning Fuzzy Logic Controller For Sterilizing Equipments in Hospitalsmy pedroNo ratings yet

- Cheatsheetv2 1 PDFDocument2 pagesCheatsheetv2 1 PDFsybaritzNo ratings yet

- Begin Guitar - Douglas NobleDocument35 pagesBegin Guitar - Douglas NobleConstable & Robinson91% (23)

- Cheatsheetv2 1 PDFDocument2 pagesCheatsheetv2 1 PDFsybaritzNo ratings yet

- Design Projects in A PLCDocument10 pagesDesign Projects in A PLCSam B.medNo ratings yet

- Industrial Networks PDFDocument39 pagesIndustrial Networks PDFlakshmi_innovatorNo ratings yet

- 02learning RSLogix 5000 Programming Sample Chapter PDFDocument25 pages02learning RSLogix 5000 Programming Sample Chapter PDFmy pedroNo ratings yet

- Design Projects in A PLCDocument10 pagesDesign Projects in A PLCSam B.medNo ratings yet

- 02learning RSLogix 5000 Programming Sample ChapterDocument108 pages02learning RSLogix 5000 Programming Sample Chaptermy pedroNo ratings yet

- Month 1 - CalendarDocument1 pageMonth 1 - Calendarmy pedroNo ratings yet

- Gpib ControllerDocument14 pagesGpib ControllerPranab PrajapatiNo ratings yet

- BSNL Handout Summar TrainingDocument266 pagesBSNL Handout Summar TrainingAnna Joy KandathilNo ratings yet

- Application of Software Load Balancing or SLB For SDNDocument9 pagesApplication of Software Load Balancing or SLB For SDNAtt SamNo ratings yet

- Interfaces FundamentalsDocument555 pagesInterfaces FundamentalsVandana SinghNo ratings yet

- TP Link CPE210 Client Side 5 KM - PharOS User GuideDocument112 pagesTP Link CPE210 Client Side 5 KM - PharOS User GuideAshrafAliNo ratings yet

- Network N10 007 Exam ObjectivesDocument19 pagesNetwork N10 007 Exam Objectivessalah_elgazzarNo ratings yet

- Ex 3300Document263 pagesEx 3300simplyredwhiteandblueNo ratings yet

- Ds-7200Huhi-K1 Series Turbo HD DVR: Features and FunctionsDocument3 pagesDs-7200Huhi-K1 Series Turbo HD DVR: Features and FunctionsdamindaNo ratings yet

- DSR-Series Manual v3.04Document337 pagesDSR-Series Manual v3.04ChrisHeathNo ratings yet

- Mbusmaster Delphi PDFDocument230 pagesMbusmaster Delphi PDFadesa2013No ratings yet

- c439 Course Outline 2023Document11 pagesc439 Course Outline 2023nNo ratings yet

- Subnetting Feb 04, 2021Document6 pagesSubnetting Feb 04, 2021RakibNo ratings yet

- FortiGate and FortiManager-7.2-Azure vWAN DeploymentDocument51 pagesFortiGate and FortiManager-7.2-Azure vWAN DeploymentSayed Ashraf Husaini KaziNo ratings yet

- CCNA Routing BasicsDocument56 pagesCCNA Routing BasicsNazmi HadiNo ratings yet

- CO Line Features GuideDocument43 pagesCO Line Features Guidepam7164No ratings yet

- Ceragon Ceragon Licenses Secure Management Licens IP 20 SL SEC MAN SICE Distributore ItalianoDocument258 pagesCeragon Ceragon Licenses Secure Management Licens IP 20 SL SEC MAN SICE Distributore Italianoosvaldo franciscoNo ratings yet

- VoIP Basics: An Introduction to Voice over IP TechnologyDocument21 pagesVoIP Basics: An Introduction to Voice over IP TechnologyWayne HarrisNo ratings yet

- Moxa Managed Ethernet Switch Redundancy Protocol User's Manual (UI 2.0)Document31 pagesMoxa Managed Ethernet Switch Redundancy Protocol User's Manual (UI 2.0)xuyen tranNo ratings yet

- AN6001-G16 Optical Line Terminal Equipment CLI Configuration Guide (Version A)Document264 pagesAN6001-G16 Optical Line Terminal Equipment CLI Configuration Guide (Version A)Ivan AlvesNo ratings yet

- Network and Cyber Security Exam QuestionsDocument1 pageNetwork and Cyber Security Exam QuestionssudarshanNo ratings yet

- Bedienungsanleitung Winter DSP Control SystemDocument57 pagesBedienungsanleitung Winter DSP Control SystemOgnjen BanjacNo ratings yet

- Eclipse DAC GE3 Product Presentation 25 - 10 - 12 ReadyDocument32 pagesEclipse DAC GE3 Product Presentation 25 - 10 - 12 ReadyabdallaNo ratings yet

- Huawei NetEngine 8000 Series All-Scenario Intelligent Routers Brochure V1.0Document5 pagesHuawei NetEngine 8000 Series All-Scenario Intelligent Routers Brochure V1.0alan s balantimuheNo ratings yet

- Palo Alto Day in The Life of A PacketDocument38 pagesPalo Alto Day in The Life of A PacketDede Rizki100% (1)

- Comparing GPON and EPON Technologies for Fiber Access NetworksDocument6 pagesComparing GPON and EPON Technologies for Fiber Access NetworksTalha JavaidNo ratings yet

- HG8245H5 DatasheeDocument3 pagesHG8245H5 DatasheeDEPO KELAPA BANG WAHYUNo ratings yet

- Digital Cross Connect Systems (DCS) - A TechnologySurvey, Key Challenges, Architectures and ApplicationsDocument9 pagesDigital Cross Connect Systems (DCS) - A TechnologySurvey, Key Challenges, Architectures and Applicationsaman lakherwalNo ratings yet

- Recursive Internetwork Architecture, Investigating Rina As An Alternative To Tcp/Ip (Irati)Document30 pagesRecursive Internetwork Architecture, Investigating Rina As An Alternative To Tcp/Ip (Irati)Fauzan RamadhanNo ratings yet

- Resolve Wi-Fi Issues with Static IPDocument3 pagesResolve Wi-Fi Issues with Static IPAndrei ZebreniucNo ratings yet

- Wireless Access Point Configuration and Ethernet Cable ConstructionDocument9 pagesWireless Access Point Configuration and Ethernet Cable ConstructionJunaid NasirNo ratings yet