Professional Documents

Culture Documents

Unstiffened Cylinders en 13445-3 - 8.5.2

Uploaded by

met-calc0 ratings0% found this document useful (0 votes)

82 views4 pagesUnstiffened Cylinders en 13445-3

Original Title

Unstiffened Cylinders en 13445-3_8.5.2

Copyright

© © All Rights Reserved

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document0 ratings0% found this document useful (0 votes)

82 views4 pagesUnstiffened Cylinders en 13445-3 - 8.5.2

Uploaded by

met-calcYou are on page 1of 4

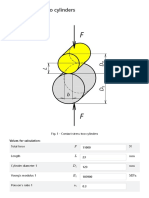

8.5.

2 Unstiffened cylinders

The minimum yield strength or 0,2% proof strength at

calculation temperature: Rp0,2T 345 [Mpa]

The nominal elastic limits for shell:

Ferritic material

𝜎 =𝑅 , /

Austenitic material

𝑅 , /

𝜎 =

1,25

Fer

σe 345 [Mpa]

The nominal thickness: en 35 [mm]

The corrosion allowance: c 2 [mm]

The absolute value of the possible negative tolerance

on the nominal thickness (EN 10029): quality C

de1 0 [mm]

Limit values of weld joint defects (EN ISO 5817): quality D

Linear offset between plates (EN 5817):

𝐵 → 𝛿 = 𝑚𝑖𝑛 0,2 + 0,1𝑒 ; 3

𝐶 → 𝛿 = 𝑚𝑖𝑛 0,2 + 0,15𝑒 ; 4

𝐷 → 𝛿 = 𝑚𝑖𝑛 0,2 + 0,25𝑒 ; 5

de2 5 [mm]

Defects of welds:

𝐵 → 𝛿 = 0,2𝑒 ∗ 0,04

𝐶 → 𝛿 = 0,3𝑒 ∗ 0,08

𝐷 → 𝛿 = 0,4𝑒 ∗ 0,16

de3 2,2 [mm]

The analysis thickness:

𝑒 =𝑒 −𝛿 −𝛿 −𝛿 −𝑐

ea 25,8 [mm]

The mean radius of a cylindrical: R 467 [mm]

The elastic modulus: E 210000 [MPa]

The unsupported length of the shell: L 800 [mm]

The pressure at which mean circumferential stress in a

cylindrical, reaches yield point:

𝜎 ∗𝑒

𝑃 =

𝑅

Py 19,0 [MPa]

L/2R 0,9

ea/2R 0,028

The number of circumferential waves for an

unstiffened part of a cylinder: ncyl 3 []

Parameter:

𝜋∗𝑅

𝑍=

𝐿

Z 1,8 []

Poisson's ratio: ν 0,3 []

The mean elastic circumferential strain at collapse:

1 1 𝑒

𝜀= + 𝑛 −1+𝑍

𝑍 𝑛 12𝑅 1 − 𝜈

𝑛 −1+

2 +1

𝑍

ε 0,011 []

The theoretical elastic instability pressure for collapse

of a perfect cylindrical:

𝐸∗𝑒 ∗𝜀

𝑃 =

𝑅

Pm 131,6 [MPa]

Pm/Py 6,9 [MPa]

Pr/Py 0,953 [MPa]

The calculated lower bound collapse pressure:

𝑃

𝑃 = ∗𝑃

𝑃

Pr 18,1 [MPa]

The calculation pressure: P 2,5 [Mpa]

The test pressure: Ptest 4 [Mpa]

𝑃 < 𝑃 /1,5 Pr/1,5 12,1 [Mpa]

𝑃 < 𝑃 /1,1 Pr/1,1 16,5 [Mpa]

Tolerance for calculation pressure:

𝑃

𝑇𝑜𝑙𝑒𝑟𝑎𝑛𝑐𝑒 = 0,005 ∗ ∗𝑅

𝑃 ∗ 1,5

tolerance 11,3 [mm]

Tolerance for test pressure:

𝑃

𝑇𝑜𝑙𝑒𝑟𝑎𝑛𝑐𝑒 = 0,005 ∗ ∗𝑅

𝑃 ∗ 1,1

tolerance 9,6 [mm]

You might also like

- ISO 1609 - 5PA-701-880-D - Flange - Fittings - 2009.1Document42 pagesISO 1609 - 5PA-701-880-D - Flange - Fittings - 2009.1markosdistefanoNo ratings yet

- Marking Non Electrical Equipment Ex PDFDocument1 pageMarking Non Electrical Equipment Ex PDFAgus RianNo ratings yet

- PZ SeriesDocument28 pagesPZ SeriesSomiar TradingNo ratings yet

- Stevan Stojanovic Mokranjac Duhovna MuzikaDocument108 pagesStevan Stojanovic Mokranjac Duhovna MuzikamelNo ratings yet

- Din 17177-79Document8 pagesDin 17177-79savanNo ratings yet

- CENTC267 MHD Questions 2016Document30 pagesCENTC267 MHD Questions 2016pmr80_2004No ratings yet

- Mesh BlanketsDocument13 pagesMesh BlanketsmodestyNo ratings yet

- Breviar de Calcul - Cos C.R.Document63 pagesBreviar de Calcul - Cos C.R.tulvyNo ratings yet

- PD CR 12953-14-2002Document16 pagesPD CR 12953-14-2002navaronefraNo ratings yet

- 06 NGubeljakDocument6 pages06 NGubeljakvahid_shoeibiNo ratings yet

- Guiding Principles Assessment AssembliesDocument10 pagesGuiding Principles Assessment AssembliesGiannis ApostolouNo ratings yet

- Comparing ASME Code Fatigue Evaluation Methods for Nuclear PipingDocument65 pagesComparing ASME Code Fatigue Evaluation Methods for Nuclear PipingOtso Cronvall100% (1)

- Strainer DescriptionDocument321 pagesStrainer DescriptionChirag ShahNo ratings yet

- 16-Preiss-Study en 13445-Asme VIIIDocument26 pages16-Preiss-Study en 13445-Asme VIIISivi NallamothuNo ratings yet

- BS en 00287-6-2010Document26 pagesBS en 00287-6-2010Shan Sandaruwan AbeywardeneNo ratings yet

- En 13445 Background To The Rules in Part 3 Design (2004)Document87 pagesEn 13445 Background To The Rules in Part 3 Design (2004)David CubillosNo ratings yet

- EN13480-3 Chap12 ModificationsDocument37 pagesEN13480-3 Chap12 ModificationsPrashant ChauhanNo ratings yet

- COSMOS FloWorks TutorialDocument238 pagesCOSMOS FloWorks Tutorialblacklili123No ratings yet

- Elektrode Jesenice Consumables CatalogueDocument384 pagesElektrode Jesenice Consumables CatalogueValvemakerNo ratings yet

- SRPS M.e3.151 1996Document14 pagesSRPS M.e3.151 1996makimagNo ratings yet

- Na 131121Document50 pagesNa 131121Mukund KashyapNo ratings yet

- 0526 16 2004 07 en - enDocument6 pages0526 16 2004 07 en - envtsusr fvNo ratings yet

- Valves Shell Design StrengthDocument10 pagesValves Shell Design Strengthمحمد عبدالدايمNo ratings yet

- Asme Viii Calculation Xls PDF FreeDocument28 pagesAsme Viii Calculation Xls PDF FreeMisbachul ChoirNo ratings yet

- GISF92Document14 pagesGISF92Jigs FelixNo ratings yet

- Simply Supported Rectangular Plate Fourier SeriesDocument17 pagesSimply Supported Rectangular Plate Fourier SeriesJoshua MagatNo ratings yet

- Plate Analysis GuideDocument20 pagesPlate Analysis GuideDobromir DinevNo ratings yet

- WHRB-265!08!00 Front and Rear Mirrors, Shell CalculationDocument2 pagesWHRB-265!08!00 Front and Rear Mirrors, Shell CalculationmehmacarNo ratings yet

- Visual Vessel Design FAQDocument23 pagesVisual Vessel Design FAQsierthinNo ratings yet

- Piping Stress Handbook - by Victor Helguero - Part 2Document121 pagesPiping Stress Handbook - by Victor Helguero - Part 2namdq-1No ratings yet

- p355n NH Nl1 Nl2 TubesDocument4 pagesp355n NH Nl1 Nl2 TubesMiclea Dragos-CostinNo ratings yet

- List of Questions EN 13445 - 2014 PDFDocument14 pagesList of Questions EN 13445 - 2014 PDFwindsurferke007No ratings yet

- Importing Nozzle Loads From Autopipe Into Autopipe NozzleDocument3 pagesImporting Nozzle Loads From Autopipe Into Autopipe NozzlegchammaNo ratings yet

- 603 DDocument8 pages603 DreluNo ratings yet

- Alloy CuCr1ZrDocument53 pagesAlloy CuCr1ZrPrashant PuriNo ratings yet

- Ge Radin 1984Document15 pagesGe Radin 1984Phuor TyNo ratings yet

- Formule Ploce I LjuskeDocument18 pagesFormule Ploce I LjuskeAmar MušovićNo ratings yet

- DIN CatalogDocument60 pagesDIN CatalogAndor MolitoriszNo ratings yet

- BS 1591 PDFDocument9 pagesBS 1591 PDFAdesina AlabiNo ratings yet

- 1.4404 enDocument5 pages1.4404 enyraju88No ratings yet

- DIN 2460 Steel Pipes WaterDocument5 pagesDIN 2460 Steel Pipes WaterAhmed BoussoffaraNo ratings yet

- HB D KomplettDocument181 pagesHB D KomplettGabriel BourguignonNo ratings yet

- The in Uence of The Bourdon Effect On Pipe Elbow: September 2016Document11 pagesThe in Uence of The Bourdon Effect On Pipe Elbow: September 2016araz_1985No ratings yet

- Pressure testing methods for gas supply systemsDocument27 pagesPressure testing methods for gas supply systemsMatej ZirdumNo ratings yet

- Dimensional Engineering: Based On The ASME Y14.5M-1994 Dimensioning and Tolerancing StandardDocument77 pagesDimensional Engineering: Based On The ASME Y14.5M-1994 Dimensioning and Tolerancing StandardPankaj PatilNo ratings yet

- ANSI 58.2 Design Basis For Protection of Light Water Nuclear Power Plants Against Effects of Postulated Pipe RuptureDocument80 pagesANSI 58.2 Design Basis For Protection of Light Water Nuclear Power Plants Against Effects of Postulated Pipe RuptureWeiNo ratings yet

- En 10028Document2 pagesEn 10028ado31No ratings yet

- ASME Section 1 and Pressure Equipment DirectiveDocument5 pagesASME Section 1 and Pressure Equipment DirectivealextentwentyNo ratings yet

- Stainless Steel Tubes Dimensions, Tolerances and Conventional Masses Unit LengthDocument15 pagesStainless Steel Tubes Dimensions, Tolerances and Conventional Masses Unit LengthOctavio Cotillo LubiánNo ratings yet

- Unstiffened Cylinders EN 13445-3 - 8.5.2 PDFDocument4 pagesUnstiffened Cylinders EN 13445-3 - 8.5.2 PDFfrlamontNo ratings yet

- Interstiffener Collapse en 13445-3 - 8.6.3Document4 pagesInterstiffener Collapse en 13445-3 - 8.6.3met-calcNo ratings yet

- Ellipsoidal Ends en 13445-3 - 8.8.3Document2 pagesEllipsoidal Ends en 13445-3 - 8.8.3met-calcNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Hydrodynamic Calculation Howell-Jet ValveDocument17 pagesHydrodynamic Calculation Howell-Jet Valvemet-calcNo ratings yet

- Hydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)Document24 pagesHydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)met-calcNo ratings yet

- Hydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)Document19 pagesHydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)met-calcNo ratings yet

- Hydrodynamic Calculation Needle ValveDocument23 pagesHydrodynamic Calculation Needle Valvemet-calcNo ratings yet

- Hydrodynamic Calculation Gate Valve (Through-Conduit)Document23 pagesHydrodynamic Calculation Gate Valve (Through-Conduit)met-calcNo ratings yet

- Threaded Holes (11.4.3.3) EN 13445-3Document1 pageThreaded Holes (11.4.3.3) EN 13445-3met-calcNo ratings yet

- Spherical Shells (7.4.3) EN 13445-3Document3 pagesSpherical Shells (7.4.3) EN 13445-3met-calcNo ratings yet

- Multi-Stage ValveDocument2 pagesMulti-Stage Valvemet-calcNo ratings yet

- Rolled Shells (7.4.2) According To Standards EN 13445-3: Values For CalculationDocument3 pagesRolled Shells (7.4.2) According To Standards EN 13445-3: Values For Calculationmet-calcNo ratings yet

- Nuts (11.4.3.2) EN 13445-3Document1 pageNuts (11.4.3.2) EN 13445-3met-calcNo ratings yet

- Hydrodynamic Calculation Spherical ValveDocument40 pagesHydrodynamic Calculation Spherical Valvemet-calcNo ratings yet

- Hydrodynamic Calculation Needle Valve Closing Flow Against The Direction of Movement of The PistonDocument23 pagesHydrodynamic Calculation Needle Valve Closing Flow Against The Direction of Movement of The Pistonmet-calcNo ratings yet

- Contact Stress Two CylindersDocument3 pagesContact Stress Two Cylindersmet-calcNo ratings yet

- Hydrodynamic Calculation Butterfly Valve (Lattice Disc)Document31 pagesHydrodynamic Calculation Butterfly Valve (Lattice Disc)met-calcNo ratings yet

- Hydrodynamic Calculation Howell-Bunger ValveDocument34 pagesHydrodynamic Calculation Howell-Bunger Valvemet-calcNo ratings yet

- Hydrodynamic Calculation Gate Valve (Through Conduit)Document14 pagesHydrodynamic Calculation Gate Valve (Through Conduit)met-calcNo ratings yet

- Hydrodynamic Calculation Butterfly Valve (Lenticular Disc)Document28 pagesHydrodynamic Calculation Butterfly Valve (Lenticular Disc)met-calcNo ratings yet

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Document31 pagesHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcNo ratings yet

- Allowable Stress: R Mpa C SDocument1 pageAllowable Stress: R Mpa C Smet-calcNo ratings yet

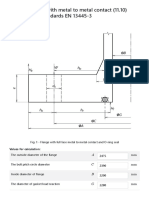

- Flange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3Document4 pagesFlange With Hole With Continuous Sealing Surface With Metal To Metal Contact (11.10.0) EN 13445-3met-calcNo ratings yet

- Contact Stress of The Cylinder in The Cylindrical SocketDocument3 pagesContact Stress of The Cylinder in The Cylindrical Socketmet-calcNo ratings yet

- Full Face Flange With Metal To Metal Contact (11.10) EN 13445-3Document5 pagesFull Face Flange With Metal To Metal Contact (11.10) EN 13445-3met-calcNo ratings yet

- Contact Stress of Cylinder On Flat SurfaceDocument3 pagesContact Stress of Cylinder On Flat Surfacemet-calcNo ratings yet

- Allowable Hertz PressureDocument1 pageAllowable Hertz Pressuremet-calcNo ratings yet

- Conical Shells (7.6.4) EN 13445-3Document3 pagesConical Shells (7.6.4) EN 13445-3met-calcNo ratings yet

- Hydrodynamic Calculation Butterfly Valve (Lattice Disc)Document18 pagesHydrodynamic Calculation Butterfly Valve (Lattice Disc)met-calcNo ratings yet

- BucklingDocument2 pagesBucklingmet-calcNo ratings yet

- Multi-Hole CageDocument7 pagesMulti-Hole Cagemet-calcNo ratings yet

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Document18 pagesHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcNo ratings yet

- The Flow Characteristic On The Position of The DriveDocument7 pagesThe Flow Characteristic On The Position of The Drivemet-calcNo ratings yet

- Wopho ProblemsDocument17 pagesWopho Problemshantarto5844100% (1)

- CFD Simulation of A Counter Flow Heat ExchangerDocument22 pagesCFD Simulation of A Counter Flow Heat ExchangerVIRGIL CABALLERONo ratings yet

- ARCHESDocument10 pagesARCHESABUBAKARR BANGURANo ratings yet

- ME8693 Heat and Mass Transfer L T P C 3 2 0 4 ObjectivesDocument2 pagesME8693 Heat and Mass Transfer L T P C 3 2 0 4 ObjectivesGEJENDHIRAN SNo ratings yet

- Structural Dynamics - WebDocument3 pagesStructural Dynamics - WebVhong NeoNo ratings yet

- Aqa MM2B QP Jan13 PDFDocument24 pagesAqa MM2B QP Jan13 PDFastargroupNo ratings yet

- Laboratory #8: Student Horsepower: ObjectiveDocument4 pagesLaboratory #8: Student Horsepower: Objectivealpha omegaNo ratings yet

- Davies, M.W - Theory and Practice of Bridge Construction in Timber, Iron and Steel (1908, ICE) PDFDocument607 pagesDavies, M.W - Theory and Practice of Bridge Construction in Timber, Iron and Steel (1908, ICE) PDFCuneyt VatanseverNo ratings yet

- 2E4B BucklingDocument4 pages2E4B BucklingMohd Ridzuan Ahmad100% (1)

- Heat Transfer Chip PowerDocument6 pagesHeat Transfer Chip PowerSherryNo ratings yet

- Simply SupportedDocument9 pagesSimply Supportedpackya7191No ratings yet

- Determine The Magnitude and Sense of The Couple Moment.: Problem 4-71Document35 pagesDetermine The Magnitude and Sense of The Couple Moment.: Problem 4-71김승연No ratings yet

- Powell (1983) - Ductile Anchor Bolts For Tall ChimneysDocument11 pagesPowell (1983) - Ductile Anchor Bolts For Tall Chimneystimur sibaevNo ratings yet

- Design and Analysis of Tire Coupling: November 2018Document8 pagesDesign and Analysis of Tire Coupling: November 2018Basu SbNo ratings yet

- Strength of Materials Basics and Equations - Mechanics of Materials PDFDocument6 pagesStrength of Materials Basics and Equations - Mechanics of Materials PDFEmil Lawrence EspirituNo ratings yet

- Influence of Non-Glide Stresses On Plastic Flow: From Atomistic To Continuum ModelingDocument7 pagesInfluence of Non-Glide Stresses On Plastic Flow: From Atomistic To Continuum ModelingGURUDAS KARNo ratings yet

- امتحان شركة جابكوDocument3 pagesامتحان شركة جابكوMohamed BalbaaNo ratings yet

- Chemical engineering thermodynamics tutorial questionsDocument2 pagesChemical engineering thermodynamics tutorial questionsAngelina PutriNo ratings yet

- Design of Self Supporting Steel Chimney For Wind Loads As Per India StandardsDocument41 pagesDesign of Self Supporting Steel Chimney For Wind Loads As Per India StandardsREVATHY GOPALNo ratings yet

- @StudyTime - Channel 09 - Work, Energy, Power (TH)Document12 pages@StudyTime - Channel 09 - Work, Energy, Power (TH)Legendary MathematicianNo ratings yet

- Effects of Rotational Direction and Rotation-To-Revolution Speed Ratio in Planetary Ball MillingDocument6 pagesEffects of Rotational Direction and Rotation-To-Revolution Speed Ratio in Planetary Ball Millingsuresh_501No ratings yet

- Analysis of Structural Members Under Elevated Temperature ConditionsDocument12 pagesAnalysis of Structural Members Under Elevated Temperature ConditionsRakesh ReddyNo ratings yet

- Bolted Connection ModuleDocument5 pagesBolted Connection ModuleMakolNo ratings yet

- SKF Bearing Select PDFDocument9 pagesSKF Bearing Select PDFBharat KumarNo ratings yet

- Turbomachine Example QuestionDocument4 pagesTurbomachine Example QuestionSteven MilwardNo ratings yet

- Linear Induction MotorDocument10 pagesLinear Induction MotorKhalid MahmudNo ratings yet

- Chapter 13 ModifiedDocument5 pagesChapter 13 Modifiedapi-248642018100% (1)

- Roco207 208 DH KinematicsDocument27 pagesRoco207 208 DH KinematicsSerafimRodriguesNo ratings yet

- Shear and Moment Equations in BeamsDocument53 pagesShear and Moment Equations in BeamsKd CaisedoNo ratings yet