Professional Documents

Culture Documents

Explanation of Simplex Method

Uploaded by

Sam Denielle TugaoenCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Explanation of Simplex Method

Uploaded by

Sam Denielle TugaoenCopyright:

Available Formats

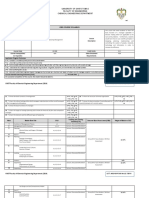

I.

Aspirin Production

Process Equipment Operating Operating Other Details

Pressure Temperature

Acetylation Agitated 1 atm 88-92˚C Reaction Time: 2-3 hrs

Batch

Reactor Heating Rate Constant: 0.3 l/mol-hr

Medium:

(To be Superheated 95% Conversion of Salicylic acid

designed) steam or hot

water 20% stoichiometric excess of acetic anhydride and 10% by wt concentrated sulfuric acid

(based on the mass of salicylic acid)

Optimum

Reaction Sources:

Temperature: https://www.chegg.com/homework-help/questions-and-answers/manufacture-

90˚C aspirin-acetylsalicylic-acid-synthesized-using-reaction-salicylic-acid-acetic--q5050378

Chemical Reactions and Chemical Reactors by George W. Roberts

Encyclopedia of Chemical Processing and Design- Volume 4 by John McKetta Jr.

http://eleceng.dit.ie/gavin/DT275/Module%201/Assignment.htm?fbclid=IwAR371JVkl

Raifzm6CrBiQplSw6SNVqmL3pxewgYE41J59foI72GhYUnevOo

Filtration Rotary 1 atm 90˚C

Vacuum Sources:

Drum Filter Chemical Reactions and Chemical Reactors by George W. Roberts

Crystallization Agitated 1 atm Cooling The cooling water from the cooling tower is used to precipitate aspirin at low temperature.

Batch water: 10-

Crystallizer 25˚C Aspirin Mixture Temperature: 10˚C

Sources:

(To be Encyclopedia of Chemical Processing and Design- Volume 4 by John McKetta Jr.

designed)

Centrifugation Centrifugal 1 atm 25˚C The mother liquor contains 10-20% aspirin.

Bowl/

Continuous Sources:

Centrifuge Encyclopedia of Chemical Processing and Design- Volume 4 by John McKetta Jr.

Drying Rotary 1 atm 60-70 ˚C Initial moisture content: 22% wet basis

Drum Final moisture content: 0.1% wet basis

Dryer

Source

(To be Perry’s Chemical Engineering Handbook 8th Edition

designed) Encyclopedia of Chemical Processing and Design- Volume 4 by John McKetta Jr.

Extractive Distillation 1 atm Feed: 29 wt% Acetic Acid (Subcooled Liquid)

Distillation Column Distillate: 99.5 wt% Water (Saturated Liquid)

Bottoms: 99% Acetic Acid (Saturated Liquid)

(To be Reflux Ratio: 4.76

designed)

Use Ponchon-Savarit Method (Acetic Acid-Water System) to determine the number of plates

and the duties of condenser and reboiler.

Sources:

Enthalpy- Concentration Diagram: https://www.oreilly.com/library/view/basic-

principles-and/9780132885478/app10.html

https://pdfs.semanticscholar.org/83c0/81efacca48e7807f0318f307a8de7eb3b78c.pdf

Cooling Cooling 1 atm Process water is cooled which will be used to precipitate aspirin in the crystallizer

Tower

Source: Perry’s Chemical Engineering Handbook 8th Edition

II. Caffeine Extraction

Process Equipment Operating Operating Other Details

Pressure Temperature

III. Packaging

Process Equipment Operating Operating Other Details

Pressure Temperature

Mixing Mixing Tank 1 atm 25˚C

Sieving Vibrating Screen 1 atm 25˚C

Size Reduction Hammer Mill 1 atm 25˚C

Compression Rotary Tablet 1 atm 25˚C

Machine

You might also like

- Aspirin PDFDocument3 pagesAspirin PDFRayan FuadNo ratings yet

- Thermal Effects On Hydrothermal Biomass Liquefaction: # Humana Press Inc. 2008Document8 pagesThermal Effects On Hydrothermal Biomass Liquefaction: # Humana Press Inc. 2008Amal ..No ratings yet

- Cyclohexane 123Document91 pagesCyclohexane 123IsmaelovfNo ratings yet

- Patent For ...Document2 pagesPatent For ...TriNurRahmaNo ratings yet

- Williamson Ether Synthesis Report 1Document3 pagesWilliamson Ether Synthesis Report 1Lukas AldridgeNo ratings yet

- Block Diagram of The Ammonium Sulphate Production PlantDocument3 pagesBlock Diagram of The Ammonium Sulphate Production PlantAkuwh SyaSya100% (1)

- Urea ManualDocument89 pagesUrea Manualabhay shuklaNo ratings yet

- The Response of Brewing Yeast To Acid WashingDocument9 pagesThe Response of Brewing Yeast To Acid WashingGary SadavageNo ratings yet

- A01 269Document11 pagesA01 269icingrockNo ratings yet

- Group 3 - Acetone Production Via The Dehydrogenation of IPADocument7 pagesGroup 3 - Acetone Production Via The Dehydrogenation of IPAQuỳnh Như PhạmNo ratings yet

- Desalination Plant: Let's Explore!Document33 pagesDesalination Plant: Let's Explore!saqlainNo ratings yet

- Synthesis of Carbovir and Abacavir From A Carbocyclic PrecursorDocument8 pagesSynthesis of Carbovir and Abacavir From A Carbocyclic PrecursorDANNA SOFIA SANCHEZ CAMACHONo ratings yet

- Sodium Cyanide Production by Andrussow Process of Ammonia and MethaneDocument3 pagesSodium Cyanide Production by Andrussow Process of Ammonia and MethaneAdel Ybañez-OdesteNo ratings yet

- AADocument30 pagesAAAhmed MajidNo ratings yet

- Microscale Organic Laboratory TechniquesDocument162 pagesMicroscale Organic Laboratory TechniquesAndréRochaNo ratings yet

- Cre Lab UbaidDocument40 pagesCre Lab UbaidHarry potterNo ratings yet

- Boiler Chemical Cleaning ProcedureDocument11 pagesBoiler Chemical Cleaning ProcedureDangol92% (12)

- PS45 Fisher Isoamyl AcetateDocument16 pagesPS45 Fisher Isoamyl AcetateNICOLAS GIL GUTIERREZNo ratings yet

- CT Course Project - Grpno.15Document16 pagesCT Course Project - Grpno.15Sanika TalathiNo ratings yet

- United States Patent Office: Ch-Ch-OnDocument3 pagesUnited States Patent Office: Ch-Ch-OnChanachai PuckNo ratings yet

- Mid-Term Training EvaluationDocument26 pagesMid-Term Training EvaluationVishalSharmaNo ratings yet

- Unit 3 and 4 Report Jan 2013Document13 pagesUnit 3 and 4 Report Jan 2013Lemia ELtyeb ELfadelNo ratings yet

- On-Site Generation of Sodium Hypochlorite Basic Operating Principles and Design ConsiderationsDocument8 pagesOn-Site Generation of Sodium Hypochlorite Basic Operating Principles and Design ConsiderationsyolyanNo ratings yet

- CH3-CH-OH CoohDocument105 pagesCH3-CH-OH CoohAniket GawdeNo ratings yet

- United States Patent (19) : Hu Et AlDocument4 pagesUnited States Patent (19) : Hu Et AlSepti WidyaNo ratings yet

- Kinetics of Catalytic Hydrogenation of Dimethyl-NitrobenzeneDocument9 pagesKinetics of Catalytic Hydrogenation of Dimethyl-NitrobenzeneRaven SwordNo ratings yet

- 0 0 1211812181211ManufacturingProcessDocument17 pages0 0 1211812181211ManufacturingProcessLUISNo ratings yet

- EO in Sesame Seed Using TQDocument6 pagesEO in Sesame Seed Using TQMailinda Mega LorensNo ratings yet

- Boiler Chemical Cleaning Procedure PDFDocument11 pagesBoiler Chemical Cleaning Procedure PDFheppy prastyo nugroho100% (1)

- 6 Installation System RefDocument48 pages6 Installation System Refcengiz kutukcuNo ratings yet

- Group 1A - Lab Report Combine PDFDocument87 pagesGroup 1A - Lab Report Combine PDFHanifatur AffiqNo ratings yet

- JMC PDFDocument4 pagesJMC PDFnurlianaNo ratings yet

- Arsenic: Silver Diethyldithiocarbamate Method Method 8013 0 To 0.200 MG/L AsDocument8 pagesArsenic: Silver Diethyldithiocarbamate Method Method 8013 0 To 0.200 MG/L AsaldiniNo ratings yet

- Arsenic: Silver Diethyldithiocarbamate Method Method 8013 0 To 0.200 MG/L AsDocument8 pagesArsenic: Silver Diethyldithiocarbamate Method Method 8013 0 To 0.200 MG/L AsAngel David Bedoya MartinNo ratings yet

- Batch Reactive DistillationDocument7 pagesBatch Reactive DistillationChalmer BelaroNo ratings yet

- S2G1DEE1STDocument53 pagesS2G1DEE1STAlex Koleman100% (1)

- Simulation and Heat recovery from sour water stripping process using Aspen HysysDocument8 pagesSimulation and Heat recovery from sour water stripping process using Aspen HysysMayurkumar patilNo ratings yet

- Acrylic Acid ProductionDocument10 pagesAcrylic Acid Productionstavros7No ratings yet

- Edta Cleaning PDFDocument18 pagesEdta Cleaning PDFDharansamNo ratings yet

- Acrylic Acid Production Process DescriptionDocument3 pagesAcrylic Acid Production Process DescriptionMauliduni M. AuniNo ratings yet

- Stage 1 Chemical Cleaning ProcedureDocument19 pagesStage 1 Chemical Cleaning ProcedureMarcos2089100% (3)

- CE 1 Viv&Kar Final Proj - RoughDocument16 pagesCE 1 Viv&Kar Final Proj - RoughvivektotalaNo ratings yet

- 1st CyclohexaneDocument27 pages1st CyclohexanePattrapon SamaikaewNo ratings yet

- Thenylchlor: Materials To Be Analyzed InstrumentationDocument5 pagesThenylchlor: Materials To Be Analyzed Instrumentationjuanvi.sanchoNo ratings yet

- 4072-An113 LPN0736Document8 pages4072-An113 LPN0736Manuja DamithNo ratings yet

- 60 KLPD Grain-Based Distillery - A SnapshotDocument9 pages60 KLPD Grain-Based Distillery - A SnapshotAmrit Agarwal100% (2)

- Nitrite Test KitDocument2 pagesNitrite Test Kitjohndmariner123No ratings yet

- TA17049Document10 pagesTA17049cek.lagukuNo ratings yet

- Propionico AireDocument11 pagesPropionico AireLaboratorio HelgueroNo ratings yet

- Separation of Liquids by Fractional Distillation and Analysis by Gas ChromatographyDocument4 pagesSeparation of Liquids by Fractional Distillation and Analysis by Gas ChromatographyRuby RichiezNo ratings yet

- Greene 1967 - Nylon 1313 Synthesis and Polymerization of MonomersDocument4 pagesGreene 1967 - Nylon 1313 Synthesis and Polymerization of MonomersRoy MustangNo ratings yet

- 25 2244700 Hach SdsDocument5 pages25 2244700 Hach Sdsajafri90No ratings yet

- Finalp 1Document47 pagesFinalp 1Imtiaz Hussain100% (1)

- Flowsheet MonsantoDocument3 pagesFlowsheet MonsantodelifaNo ratings yet

- Response of Brewing Yeast To Acid Washing, WhiteLabsDocument8 pagesResponse of Brewing Yeast To Acid Washing, WhiteLabsCRISTIAN ALEXIS CAZA PULUPANo ratings yet

- Yang 2017Document7 pagesYang 2017Muhammad Fakhar KhanNo ratings yet

- Kinetics of Acetic Anhydride Hydrolysis Reactions in an Adiabatic Batch ReactorDocument39 pagesKinetics of Acetic Anhydride Hydrolysis Reactions in an Adiabatic Batch ReactorStheh Ka NkosiNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Fuels, Chemicals and Materials from the Oceans and Aquatic SourcesFrom EverandFuels, Chemicals and Materials from the Oceans and Aquatic SourcesFrancesca M. KertonNo ratings yet

- Questions: 1. What Will Be Your Response Regarding Her Query On Breastfeeding As A Form of Family Planning?Document3 pagesQuestions: 1. What Will Be Your Response Regarding Her Query On Breastfeeding As A Form of Family Planning?Sam Denielle TugaoenNo ratings yet

- Questions: 1. What Will Be Your Response Regarding Her Query On Breastfeeding As A Form of Family Planning?Document3 pagesQuestions: 1. What Will Be Your Response Regarding Her Query On Breastfeeding As A Form of Family Planning?Sam Denielle TugaoenNo ratings yet

- Questions: 1. What Will Be Your Response Regarding Her Query On Breastfeeding As A Form of Family Planning?Document3 pagesQuestions: 1. What Will Be Your Response Regarding Her Query On Breastfeeding As A Form of Family Planning?Sam Denielle TugaoenNo ratings yet

- Get Started With Dropbox PDFDocument10 pagesGet Started With Dropbox PDFantonetteNo ratings yet

- ChE 600 Outline Activities AY 2016-2017Document2 pagesChE 600 Outline Activities AY 2016-2017Sam Denielle TugaoenNo ratings yet

- SGD 04Document11 pagesSGD 04Sam Denielle TugaoenNo ratings yet

- Sulfuric Acid Production Sulfuric Acid: By: Carl Cesar H. BibatDocument7 pagesSulfuric Acid Production Sulfuric Acid: By: Carl Cesar H. BibatSam Denielle TugaoenNo ratings yet

- Registration Form: Tugaoen, Sam Denielle SalvacionDocument1 pageRegistration Form: Tugaoen, Sam Denielle SalvacionSam Denielle TugaoenNo ratings yet

- Petroleum Refining Side ProductsDocument11 pagesPetroleum Refining Side ProductsSam Denielle TugaoenNo ratings yet

- ChE423 4 PDFDocument8 pagesChE423 4 PDFSam Denielle TugaoenNo ratings yet

- E-Portfolio Creation Guide: Try To Follow by Logging inDocument30 pagesE-Portfolio Creation Guide: Try To Follow by Logging inSam Denielle TugaoenNo ratings yet

- Answers: 280.7 Seconds 77.6 Seconds 6.459 Meters (In Runge Kutta)Document1,151 pagesAnswers: 280.7 Seconds 77.6 Seconds 6.459 Meters (In Runge Kutta)Sam Denielle TugaoenNo ratings yet

- Preparation of Homemade Powdered DetergentDocument3 pagesPreparation of Homemade Powdered DetergentSam Denielle TugaoenNo ratings yet

- Dangerous look-alike packaging leads to product confusionDocument4 pagesDangerous look-alike packaging leads to product confusionSam Denielle TugaoenNo ratings yet

- 1 - Perspective On Packaging PDFDocument33 pages1 - Perspective On Packaging PDFSam Denielle TugaoenNo ratings yet

- Problem Set Flip CrystallizationDocument2 pagesProblem Set Flip CrystallizationSam Denielle TugaoenNo ratings yet

- ProblemSet 1 - (NEW2) Screening and Size ReductionDocument7 pagesProblemSet 1 - (NEW2) Screening and Size ReductionSam Denielle Tugaoen0% (1)

- SGD Guide Questions Face PDFDocument1 pageSGD Guide Questions Face PDFSam Denielle TugaoenNo ratings yet

- Lipids and Proteins in Biological MembranesDocument20 pagesLipids and Proteins in Biological Membranescarlette11No ratings yet

- Pulp and Paper IndustryDocument3 pagesPulp and Paper IndustrySam Denielle TugaoenNo ratings yet

- Engineering Management Theory EvolutionDocument8 pagesEngineering Management Theory EvolutionSam Denielle TugaoenNo ratings yet

- IPD A ConformeDocument2 pagesIPD A ConformeSam Denielle TugaoenNo ratings yet

- GE302 Rev02 OBE SyllabusDocument4 pagesGE302 Rev02 OBE SyllabusSam Denielle TugaoenNo ratings yet

- Probset1 PDFDocument1 pageProbset1 PDFSam Denielle TugaoenNo ratings yet

- ChE600 Compiled 2A-APPDocument83 pagesChE600 Compiled 2A-APPSam Denielle TugaoenNo ratings yet

- Unit 3 - Crystallization 2015Document21 pagesUnit 3 - Crystallization 2015Sam Denielle TugaoenNo ratings yet

- Lipids and Proteins in Biological MembranesDocument20 pagesLipids and Proteins in Biological Membranescarlette11No ratings yet

- ChE 521 LauritoE Rev02 SyllabusDocument3 pagesChE 521 LauritoE Rev02 SyllabusSam Denielle TugaoenNo ratings yet

- Nh3-Water at 10 C and 101.325 KpaDocument4 pagesNh3-Water at 10 C and 101.325 KpaSam Denielle TugaoenNo ratings yet

- Science: Quarter 1 Module 1: MatterDocument47 pagesScience: Quarter 1 Module 1: MatterLeilani Pelisigas95% (42)

- Identifying Sterilizing FilterDocument7 pagesIdentifying Sterilizing FilterMWJornitz100% (1)

- Tutorial 5 - CLL271Document2 pagesTutorial 5 - CLL271CuriousNo ratings yet

- Chemical process pilot plant equipment and coursesDocument38 pagesChemical process pilot plant equipment and coursesxguille17xNo ratings yet

- B.E. CHEMICAL 2011-12 SYLLABI AND SCHEMEDocument65 pagesB.E. CHEMICAL 2011-12 SYLLABI AND SCHEMERajat MittalNo ratings yet

- Jig 1 Issue 12 PDFDocument117 pagesJig 1 Issue 12 PDFHoàng Thuý Trang100% (7)

- 06 - Drilling FluidsDocument18 pages06 - Drilling FluidsnapoNo ratings yet

- Lab Protocal I Revised PDFDocument40 pagesLab Protocal I Revised PDFAswathyNo ratings yet

- Precautions in Gravimetric & Volumetric AnalysisDocument23 pagesPrecautions in Gravimetric & Volumetric AnalysisJAFFER YOUSUF89% (9)

- E7106 1 2 11 16 - RFM 4 Loch - KatalogversionDocument12 pagesE7106 1 2 11 16 - RFM 4 Loch - KatalogversionCamila PenhaNo ratings yet

- Filtration (Final Report)Document13 pagesFiltration (Final Report)Noel Jeffrey PintonNo ratings yet

- HOTSY - 7660 Automatic Parts Washer (Operators Manual)Document54 pagesHOTSY - 7660 Automatic Parts Washer (Operators Manual)SodaProp100% (1)

- The Treatment Technology of Recycling Scrap Wire and CableDocument4 pagesThe Treatment Technology of Recycling Scrap Wire and CableOvijit DasNo ratings yet

- DuPont Teflon AF Processing GuideDocument2 pagesDuPont Teflon AF Processing GuidewuaiyouNo ratings yet

- Hardened Concrete Methods of Test: Indian StandardDocument12 pagesHardened Concrete Methods of Test: Indian StandardTsc TechnoNo ratings yet

- Japanese Pharmacopoeia 15 EdDocument1,802 pagesJapanese Pharmacopoeia 15 Eddeepanmb007100% (10)

- Preparation, Characterization and Photocatalytic Activity of Nano-Sized Zno/Sno Coupled PhotocatalystsDocument11 pagesPreparation, Characterization and Photocatalytic Activity of Nano-Sized Zno/Sno Coupled PhotocatalystsMuhammad IsmailNo ratings yet

- Seapak Series: Integrated Ultrafiltration and Seawater Reverse Osmosis Platform For 1,000 - 10,000 M /dayDocument2 pagesSeapak Series: Integrated Ultrafiltration and Seawater Reverse Osmosis Platform For 1,000 - 10,000 M /dayadalcayde2514100% (1)

- Science RevisionDocument17 pagesScience RevisionHend HamedNo ratings yet

- Solvent Dewaxing of Heavy Crude Oil With Methyl Ethyl Ketone 2157 7463 1000213Document5 pagesSolvent Dewaxing of Heavy Crude Oil With Methyl Ethyl Ketone 2157 7463 1000213PrinceNo ratings yet

- 1100D Fuel System Installation Guide PDFDocument18 pages1100D Fuel System Installation Guide PDFjAVIER GARCIA MORIANANo ratings yet

- Ek Series Hermetic Liquid Line Filter Driers Catalog en Us 1620596Document4 pagesEk Series Hermetic Liquid Line Filter Driers Catalog en Us 1620596agus sutiawanNo ratings yet

- NHS - Water Sources and Potential Pseudomonas Aeruginosa Contamination of Taps and Water SystemsDocument26 pagesNHS - Water Sources and Potential Pseudomonas Aeruginosa Contamination of Taps and Water SystemsSérgio GnipperNo ratings yet

- Lecture 1 - Matter and Its Properties (Corrected)Document5 pagesLecture 1 - Matter and Its Properties (Corrected)katey perryNo ratings yet

- Norovirus Outbreak at Vermont Swim ClubDocument14 pagesNorovirus Outbreak at Vermont Swim ClubAlp BaykalNo ratings yet

- Sauer Danfoss Hydraulic Gear Pump Group 3Document33 pagesSauer Danfoss Hydraulic Gear Pump Group 3Enrique Murgia100% (1)

- Black Powder in Gas Pipeline PDFDocument4 pagesBlack Powder in Gas Pipeline PDFMohammad Kh100% (1)

- Hydraulic Engine Controls: Installation and ServiceDocument36 pagesHydraulic Engine Controls: Installation and ServiceRAJ KOTINo ratings yet