Professional Documents

Culture Documents

TATA Painting Specification 43

Uploaded by

Suleman KhanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TATA Painting Specification 43

Uploaded by

Suleman KhanCopyright:

Available Formats

General Specification for Painting

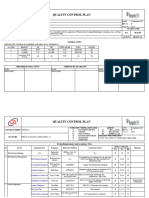

QAP No. TSL / New Fabrication-

TATA STEEL LIMITED QAP FOR SURFACE PREPARATIOPN & PAINT APPLICATION

001/Rev.0 Date:

Name of the Applicator: M/S .

Name of the Item to coated: Steel Plates, Bulb Bars etc. Name of Paint Manufacturer: M/S

Type of

Standards of Performed & Record No./

Sr. Acceptance Check(visual/ Qty/ Witnessed & Remarks if

Parameters to be checked Compliances/Work Hold Points documented Inspection

No. Criteria instrumental/ Frequency Recorded By Any

instruction by format

Both)

After abrasive blast

Surface Profile: Random, Blasting &

Surface Profile check by digital ISO 8503-4/ASTM- cleaning and prior Client Paint Inspection

C07 50micron (min.) Instrumental after one painting

surface roughness gauge D-4417 Method B to coating QC Mfg. Records

75 micron (Max.) hour each Contractor

application

Assessment of Dust Replica

contamination: After blast Not More than Blasting & Tape to

As per ISO 8502-3 Prior to coating Client Paint Inspection

C08 cleaning surface shall free from Class-2 ISO Instrumental 100% painting recorded in

10X Magnification application QC Mfg. Records

dust prior to application , check 8502-3 Contractor inspection

by pressure sensitive replica tape report

Accepted value

Maximum

Field method for the After satisfactory

80mg/m² for C5I Blasting &

conductometric determination of ISO 8502-6 surface preparation Random, Client Paint Inspection

C09 Environment & Instrumental painting

water soluble salt by elcometer ISO8502-9 prior to paint once a week QC Mfg. Records

Maximum Contractor

138 or equivalent instrument application

100mg/m² for C3

Environment

Prepared & Proposed By. TATA STEEL Ltd. Agreed & Approved By: M/s Committed By:

GSP-01-00-00-14-000-001-R2 42 44

Confidential. ©2016 TATA Steel Limited, All rights reserved

You might also like

- Chapin Columbus DayDocument15 pagesChapin Columbus Dayaspj13No ratings yet

- NDT Acceptance Criteria PDFDocument2 pagesNDT Acceptance Criteria PDFamit84indNo ratings yet

- 1986 Elektric M InfoDocument1 page1986 Elektric M InfoDanielDiasNo ratings yet

- Blasting and Painting Inspection and Test PlanDocument3 pagesBlasting and Painting Inspection and Test PlanNnamdi Amadi80% (5)

- Inspection report-GRVE BlankDocument2 pagesInspection report-GRVE BlankJoseph Perez100% (1)

- MNT - QC - BP - 001 Blasting & Painting ReportDocument1 pageMNT - QC - BP - 001 Blasting & Painting Reportsivagnanam sNo ratings yet

- (Painting Works) : Inspection and Test PlanDocument2 pages(Painting Works) : Inspection and Test Planrize1159No ratings yet

- Itp For Painting - FDocument5 pagesItp For Painting - FMudabbir HussainNo ratings yet

- TDC 004 CS Fittings r0Document1 pageTDC 004 CS Fittings r0samkarthik47No ratings yet

- Radiography Testing Procedure: Procedure No. BCE/RT/003-2018/Rev-1.0Document13 pagesRadiography Testing Procedure: Procedure No. BCE/RT/003-2018/Rev-1.0BCE DeNo ratings yet

- ISRO EOT Crane QAPDocument17 pagesISRO EOT Crane QAPSuleman Khan100% (1)

- ISRO EOT Crane QAPDocument17 pagesISRO EOT Crane QAPSuleman Khan100% (1)

- Cone Layout ToolDocument1 pageCone Layout ToolSaravanan ManiNo ratings yet

- Vc-Api 650 PDFDocument6 pagesVc-Api 650 PDFShinta ShowiantariNo ratings yet

- Storage Tank Foundation Settlement Quality Control and Inspection Report FormDocument1 pageStorage Tank Foundation Settlement Quality Control and Inspection Report FormKhepa BabaNo ratings yet

- QCP & Report Rev 03Document30 pagesQCP & Report Rev 03Heri FebriyantoNo ratings yet

- ITP Inspection and Test Plan 6MODocument2 pagesITP Inspection and Test Plan 6MOAS DevNo ratings yet

- ITPDocument1 pageITPVenkatesh PethurajNo ratings yet

- Burckhardt Compression (India) PVT - LTD.: 1.0 MaterialsDocument2 pagesBurckhardt Compression (India) PVT - LTD.: 1.0 MaterialsYOGESHNo ratings yet

- Fabrication Quality Dossier IndexDocument22 pagesFabrication Quality Dossier IndexAli KayaNo ratings yet

- Equipment For Tank InspectionDocument1 pageEquipment For Tank InspectionasikurNo ratings yet

- Painting ReportDocument1 pagePainting Reportbaidu1980No ratings yet

- 2015-21 Exterior PaintingDocument16 pages2015-21 Exterior PaintingmaxNo ratings yet

- 2019 09 20 New Balance Harvard Business CaseDocument7 pages2019 09 20 New Balance Harvard Business CaseFrans AdamNo ratings yet

- ARAMCO QM Number ListDocument3 pagesARAMCO QM Number ListMohamed Yousuf Syed MohamedNo ratings yet

- Certified Supplier Quality ProfessionalDocument12 pagesCertified Supplier Quality ProfessionalSuleman KhanNo ratings yet

- Certified Supplier QualityDocument6 pagesCertified Supplier QualityNandeesh Patel50% (2)

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Document17 pagesWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizNo ratings yet

- Government by Algorithm - Artificial Intelligence in Federal Administrative AgenciesDocument122 pagesGovernment by Algorithm - Artificial Intelligence in Federal Administrative AgenciesRone Eleandro dos SantosNo ratings yet

- Awais Inspector-PaintingDocument6 pagesAwais Inspector-PaintingMohammed GaniNo ratings yet

- TN Vision 2023 PDFDocument68 pagesTN Vision 2023 PDFRajanbabu100% (1)

- LV Switch Board 1.1.2 - Test Report For Visual Check Report: ClientDocument1 pageLV Switch Board 1.1.2 - Test Report For Visual Check Report: ClientsameershahzanNo ratings yet

- Test Pack Clearance FormatDocument2 pagesTest Pack Clearance FormatKarthikNo ratings yet

- NRP QapDocument10 pagesNRP QapKevin Mathew100% (1)

- Scientific Errors in The QuranDocument32 pagesScientific Errors in The QuranjibranqqNo ratings yet

- Inspection & Test Plan For Equipment Erection (Static) : ITP NO.:-9560/SITE/QAC/029/ITP-15Document4 pagesInspection & Test Plan For Equipment Erection (Static) : ITP NO.:-9560/SITE/QAC/029/ITP-15Shubham ShuklaNo ratings yet

- Standard - Bronze Age - World History Human Legacy TextbookDocument11 pagesStandard - Bronze Age - World History Human Legacy TextbookChris ChiangNo ratings yet

- Qad 01 2017 PDFDocument117 pagesQad 01 2017 PDFChaithanya Chatrathi0% (1)

- Reliance Industries Limited Line History Sheet For CS Piping Without PWHTDocument1 pageReliance Industries Limited Line History Sheet For CS Piping Without PWHTRavi ShankarNo ratings yet

- ITC Green Centre: Gurgaon, IndiaDocument19 pagesITC Green Centre: Gurgaon, IndiaAgastya Dasari100% (2)

- Blasting & Painting ReportDocument2 pagesBlasting & Painting ReportSanjay KumarNo ratings yet

- Oral Communication in ContextDocument31 pagesOral Communication in ContextPrecious Anne Prudenciano100% (1)

- Caregiving Learning Activity Sheet 3Document6 pagesCaregiving Learning Activity Sheet 3Juvy Lyn CondaNo ratings yet

- TATA Painting Specification 40Document1 pageTATA Painting Specification 40Suleman KhanNo ratings yet

- TATA Painting Specification 44Document1 pageTATA Painting Specification 44Suleman KhanNo ratings yet

- PTS-1012 - RA Hardness Test ReportDocument1 pagePTS-1012 - RA Hardness Test ReportPetrotrim ServicesNo ratings yet

- Lot Inspection Report For LPG New CylindersDocument3 pagesLot Inspection Report For LPG New CylindersJagannath MajhiNo ratings yet

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateDocument3 pagesBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARNo ratings yet

- Consultancy in Mechanical Integrity RBI, RCM, FFS, NDT & Vibration Analysis Services Training Based On API ASME and Other StandardsDocument6 pagesConsultancy in Mechanical Integrity RBI, RCM, FFS, NDT & Vibration Analysis Services Training Based On API ASME and Other StandardsShahbaz KhanNo ratings yet

- MS For Fabrication of Above-Ground Storage TankDocument8 pagesMS For Fabrication of Above-Ground Storage Tankdadz mingiNo ratings yet

- Sample Forms WPS PQRDocument22 pagesSample Forms WPS PQRGMNo ratings yet

- Working ITPDocument4 pagesWorking ITPStephen BoodooNo ratings yet

- HDPE Butt Fusion Weld Inspection and Imaging PDFDocument19 pagesHDPE Butt Fusion Weld Inspection and Imaging PDFelectroscribdNo ratings yet

- Fit Up Welding Visual Inspection ReportDocument2 pagesFit Up Welding Visual Inspection Reportgst ajah100% (1)

- ITP For Hydraulic BarrierDocument4 pagesITP For Hydraulic Barriermoytabura96No ratings yet

- Tank Inspection ReportDocument2 pagesTank Inspection ReportRavi Kumar VatturiNo ratings yet

- Roundness Before Weld TK012-strike 1Document2 pagesRoundness Before Weld TK012-strike 1yuwantoniNo ratings yet

- PTDocument7 pagesPTMohdHuzairiRusliNo ratings yet

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 pagesN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNo ratings yet

- Ask Team To Add Company Logo Her "Shri Ganesh Engineering"Document4 pagesAsk Team To Add Company Logo Her "Shri Ganesh Engineering"manoj thakkar100% (1)

- TWI CSWIP Training Plan - Dynaquest Energy LimitedDocument2 pagesTWI CSWIP Training Plan - Dynaquest Energy LimitedAdeniyi100% (1)

- QA-R-05 - Weld Traceability RecordDocument1 pageQA-R-05 - Weld Traceability RecordvinothNo ratings yet

- Chemical Resistance (LLDPE) PDFDocument24 pagesChemical Resistance (LLDPE) PDFrubyshreeNo ratings yet

- Inspection Plan NDTDocument7 pagesInspection Plan NDTEdison WalitNo ratings yet

- Material Safety Data Sheet: Poly Cell AdhesiveDocument8 pagesMaterial Safety Data Sheet: Poly Cell AdhesiveMinh BảoNo ratings yet

- Zinc Plating Reports 01Document2 pagesZinc Plating Reports 01Amandeep Singh100% (1)

- Hashik CV NewDocument4 pagesHashik CV NewHashik MohammedNo ratings yet

- How To Calculate Hydrostatic Test Height in TanksDocument4 pagesHow To Calculate Hydrostatic Test Height in TanksEric MagnayeNo ratings yet

- QAP For Conical StrainerDocument2 pagesQAP For Conical StrainersatishchidrewarNo ratings yet

- Circularity Inspection Report: Shell Course (LW) CW CWDocument14 pagesCircularity Inspection Report: Shell Course (LW) CW CWaszlizaNo ratings yet

- 1.13 Inspection & Test PlansDocument1 page1.13 Inspection & Test Plansabimanyubawono100% (2)

- Bs Tech: Electrodes Issue and Return RegisterDocument1 pageBs Tech: Electrodes Issue and Return RegisterRhannie GarciaNo ratings yet

- DFT Measurement Worksheet: Paint InspectionDocument1 pageDFT Measurement Worksheet: Paint Inspectionjay nathNo ratings yet

- 1 Imran Piping QC CVDocument4 pages1 Imran Piping QC CVkazim MirzaNo ratings yet

- CPVC ChecklistDocument1 pageCPVC Checklistchakravarthi kanugulaNo ratings yet

- Production Engineering 1 Year Marine FallDocument27 pagesProduction Engineering 1 Year Marine FallSuleman KhanNo ratings yet

- Production Engineering 1 Year Marine: Fall 2007Document26 pagesProduction Engineering 1 Year Marine: Fall 2007Suleman KhanNo ratings yet

- Liquid Penetrant Examination Report Report No. Date Page NoDocument1 pageLiquid Penetrant Examination Report Report No. Date Page NoSuleman KhanNo ratings yet

- Question # 1:: Production Engineering 1Document1 pageQuestion # 1:: Production Engineering 1Suleman KhanNo ratings yet

- Question # 1:: Production Engineering 1Document1 pageQuestion # 1:: Production Engineering 1Suleman KhanNo ratings yet

- Sheet Metal Bending: A. ElbadanDocument24 pagesSheet Metal Bending: A. ElbadanSuleman KhanNo ratings yet

- Production Engineering 1 Year Marine: Fall 2007Document12 pagesProduction Engineering 1 Year Marine: Fall 2007Suleman KhanNo ratings yet

- 3.5 Supporting Change Request FormDocument13 pages3.5 Supporting Change Request Formbadhur zaman hajaNo ratings yet

- Inspection Report - RollerDocument1 pageInspection Report - RollerSuleman Khan100% (1)

- Liquid Penetrant Examination Report Report No. Date Page NoDocument1 pageLiquid Penetrant Examination Report Report No. Date Page NoSuleman KhanNo ratings yet

- Hange Equest Emplate: Ompany AME Treet Ddress ITY Tate IP ODEDocument3 pagesHange Equest Emplate: Ompany AME Treet Ddress ITY Tate IP ODEPruebaNo ratings yet

- 0.5-3 Fab 0.2 Sr. No. Tolerance 1 2000 3 2005 10 0.5 25 0.5 36 0.8 78 0.8 205 1.2 390 1.2 400 1.2 Dimension As Per Drg. Actual DimensionDocument4 pages0.5-3 Fab 0.2 Sr. No. Tolerance 1 2000 3 2005 10 0.5 25 0.5 36 0.8 78 0.8 205 1.2 390 1.2 400 1.2 Dimension As Per Drg. Actual DimensionSuleman KhanNo ratings yet

- B2 - Hardy SpicerDocument136 pagesB2 - Hardy SpicerSuleman KhanNo ratings yet

- MITRE BEND-oldDocument5 pagesMITRE BEND-oldSuleman KhanNo ratings yet

- Katalog - Gumenih - Traka - TRANSPORTNI TRAKI REMA TIP TOP ELECTROLUX MACEDONIA ENDocument65 pagesKatalog - Gumenih - Traka - TRANSPORTNI TRAKI REMA TIP TOP ELECTROLUX MACEDONIA ENSuleman KhanNo ratings yet

- Conveyor Equipment Manufacturers Association: 2019 Cema Engineering Conference Bulk Handling SectionDocument8 pagesConveyor Equipment Manufacturers Association: 2019 Cema Engineering Conference Bulk Handling SectionSuleman KhanNo ratings yet

- Cone Design ToolDocument1 pageCone Design ToolPramod KumarNo ratings yet

- Engineers To Healthcare Industry®: Quality Assurance Protocol (QAP)Document9 pagesEngineers To Healthcare Industry®: Quality Assurance Protocol (QAP)Suleman KhanNo ratings yet

- NS - QAP-001 - Quality Assurance Provisions (QAPs) v6 - 0Document36 pagesNS - QAP-001 - Quality Assurance Provisions (QAPs) v6 - 0Suleman KhanNo ratings yet

- QAP 9.0 - Process Control - Rev C (G)Document6 pagesQAP 9.0 - Process Control - Rev C (G)Suleman KhanNo ratings yet

- AREVA NP Inc. Quality Assurance Plan (QAP) For Design Certification of The U.S. EPR™ Topical ReportDocument116 pagesAREVA NP Inc. Quality Assurance Plan (QAP) For Design Certification of The U.S. EPR™ Topical ReportSuleman KhanNo ratings yet

- Katalog - Gumenih - Traka - TRANSPORTNI TRAKI REMA TIP TOP ELECTROLUX MACEDONIA ENDocument65 pagesKatalog - Gumenih - Traka - TRANSPORTNI TRAKI REMA TIP TOP ELECTROLUX MACEDONIA ENSuleman KhanNo ratings yet

- Supplier Quality Development - A Review of Literature and Industry PracticesDocument24 pagesSupplier Quality Development - A Review of Literature and Industry PracticesSuleman KhanNo ratings yet

- Conveyor Equipment Manufacturers Association: 2019 Cema Engineering Conference Bulk Handling SectionDocument8 pagesConveyor Equipment Manufacturers Association: 2019 Cema Engineering Conference Bulk Handling SectionSuleman KhanNo ratings yet

- Surface Defects in Powder CoatingsDocument3 pagesSurface Defects in Powder CoatingsSuleman KhanNo ratings yet

- 2024 01 31 StatementDocument4 pages2024 01 31 StatementAlex NeziNo ratings yet

- Design of Corn ThresherDocument11 pagesDesign of Corn ThresherFrancisco ToroNo ratings yet

- ListeningDocument2 pagesListeningAndresharo23No ratings yet

- Theo Hermans (Cáp. 3)Document3 pagesTheo Hermans (Cáp. 3)cookinglike100% (1)

- People Vs Felipe Santiago - FCDocument2 pagesPeople Vs Felipe Santiago - FCBryle DrioNo ratings yet

- Nandurbar District S.E. (CGPA) Nov 2013Document336 pagesNandurbar District S.E. (CGPA) Nov 2013Digitaladda IndiaNo ratings yet

- Sample A: For Exchange Students: Student's NameDocument1 pageSample A: For Exchange Students: Student's NameSarah AuliaNo ratings yet

- Curriculum Vitae Mukhammad Fitrah Malik FINAL 2Document1 pageCurriculum Vitae Mukhammad Fitrah Malik FINAL 2Bill Divend SihombingNo ratings yet

- StatisticsAllTopicsDocument315 pagesStatisticsAllTopicsHoda HosnyNo ratings yet

- KalamDocument8 pagesKalamRohitKumarSahuNo ratings yet

- KBC Autumn Regatta 2023 Saturday Race ScheduleDocument2 pagesKBC Autumn Regatta 2023 Saturday Race SchedulezainNo ratings yet

- Matthew DeCossas SuitDocument31 pagesMatthew DeCossas SuitJeff NowakNo ratings yet

- Applied Thermodynamics - DraughtDocument22 pagesApplied Thermodynamics - Draughtpiyush palNo ratings yet

- LIM Gr7 Q4W3Document9 pagesLIM Gr7 Q4W3Eto YoshimuraNo ratings yet

- International Covenant On Economic Social and Cultural ReportDocument19 pagesInternational Covenant On Economic Social and Cultural ReportLD MontzNo ratings yet

- Fry 2016Document27 pagesFry 2016Shahid RashidNo ratings yet

- Rele A Gas BuchholtsDocument18 pagesRele A Gas BuchholtsMarco GiraldoNo ratings yet

- ED Tox PGS.2021Document4 pagesED Tox PGS.2021Jm uniteNo ratings yet

- CrisisDocument13 pagesCrisisAngel Gaddi LarenaNo ratings yet

- Harbin Institute of TechnologyDocument7 pagesHarbin Institute of TechnologyWei LeeNo ratings yet