Professional Documents

Culture Documents

Hose Reel Calculation (Malaysia)

Uploaded by

Kazehaya AliCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hose Reel Calculation (Malaysia)

Uploaded by

Kazehaya AliCopyright:

Available Formats

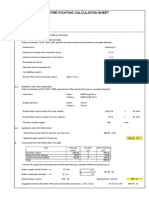

HOSE REEL PUMP CALCULATION

Flowrate required at landing valve outlet = 2.26 l/s

Therefore, select pump flowrate = 2.26 l/s

At 2.26 l/s for 50mm dia. G.I pumping mains, friction loss per metre

pipe length = 0.0408 m-head/m

Total pipe length from pump to furthest/most demand Hose Reel unit = 50.00 m

Elbow ( 8 nos. x 1.5 ) = 12.00 m

Tee ( 3 nos. x 3.1 ) = 9.30 m

Check valve ( 1 no. x 6.1 ) = 6.10 m

Strainer ( 1 no. x 9.2 ) = 9.20 m

Gate valve ( 2 nos. x 0.7 ) = 1.40 m

Total equivalent length = 88.00 m

Pipe Friction Loss

= 88.00 m x 0.0408 m-head/m = 3.593 m-head

+ 20 % Safety factor = 0.719 m-head

+ Static Head = 3.0 m-head

Maximum pressure head required at Hose outlet = 24.0 m-head

Total pump head required = 31.31 m-head

Selected pump head = 32.0 m-head

Recommeded Hose Reel pump capacity = 2.26 l/s @ 32.0 m-head

HOSE REEL SYSTEM HYDRAULIC CALCULATION

Project : NALURI PROPERTIES SDN. BHD. (ATLAN TOWER)

Fail Bomba JBPM / KL / BKK:700 - 3 / 1 / 5 / 0164

Flowrate required at Hose Reel tubing outlet = 0.75 ℓ/s

Therefore, with 3 Hose Reel operating at the same time the pump flowrate required is = 2.25 ℓ/s

Friction loss per metre pipe length (G.I pumping mains)

*At 2.25 ℓ/s for ø50mm = 0.0408 m-head/m

*At 0.75 ℓ/s for ø25mm = 0.1564 m-head/m

*Total number of activated Hose Reel unit ~ 3 nos.

*The supply for Hose Reel system is from ~ Pump, Roof

*Consider the furthest/most demand Hose Reel unit at level ~ 23rd Floor

Equivalent Pipe / fittings / valves ( ø50mm ) ( ø25mm )

Total pipe length = 38.10 m = 1.50 m

Elbow ( 6 nos. x 1.5 ) = 9.00 m

( 1 nos. x 0.8 ) = 0.80 m

Tee ( 0 nos. x 3.1 ) = 0.00 m

( 1 nos. x 1.6 ) = 1.60 m

Check valve ( 1 no. x 6.1 ) = 6.10 m

Gate valve ( 1 nos. x 0.7 ) = 0.70 m

( 1 nos. x 0.3 ) = 0.30 m

Flexible connector ( 1 nos. x 0.3 ) = 0.30 m

Total equivalent pipe length = 54.20 m = 4.20 m

Pipe Friction Loss :-

a) Through ø50mm piping ~ 54.20 m x 0.0408 m-head/m = 2.21 m-head

b) Through ø25mm piping ~ 4.20 m x 0.1564 m-head/m = 0.66 m-head

c) Through Hose Reel tubing (ø25mm@30m Double-braided, Rubber lining) = 0.32 m-head

d) Static Head = 0.00 m-head

e) Safety factor 20 % = 0.64 m-head

TOTAL head loss = 3.83 m-head

f) Pressure head required at Hose outlet = 24.00 m-head

= 27.83 m-head

Selected pump head required = 28.00 m-head

Recommeded Hose Reel pump capacity = 2.25 ℓ/s @ 28.0 m-head

HAZEN-WILLIAMS FORMULA (PIPE FRICTION LOSS)

P = 6.05 x 10 5 x Q1.85

C1.85 x d4.87

unit

P = Pressure Loss in Pipe bar/m

Q = Flow Through Pipe l/m

d = Internal Diameter mm

C = Constant (type & condition) - refer table 21

TABLE 21 - C values for various types of pipe

Type of pipe Value of C

Cast iron 100

Ductile iron 110

Mild Steel 120

Galvanized steel 120

Spun cement 130

Cement lined cast iron or ductile iron 130

Cement lined mild steel 140

Copper 140

Reinformend glass fible 140

Information:-

Q = 135 l/m

C = 120 Galvanised iron

d = 50 mm

P = 6.05 x 10 5 x 135 1.85

120 1.85 x 50 4.87

= 5282905551.35

1319681796992.27

= 0.0040 bar / m x 10.2 m

= 0.0408 m-head / m

Information:-

Q = 45 l/m

C = 120 Galvanised iron

d = 25 mm

P = 6.05 x 10 5 x 45 1.85

120 1.85 x 25 4.87

= 692147293.69

45128733691.16

= 0.0153 bar / m x 10.2 m

= 0.1564 m-head / m

You might also like

- Pump Sizing For Hose ReelDocument3 pagesPump Sizing For Hose ReelDennis Lai Zhan Wen100% (2)

- Fire Pumps CalculationDocument31 pagesFire Pumps CalculationArun DMK0% (1)

- Example Fire Fighting Calculation ReportDocument14 pagesExample Fire Fighting Calculation Reportkhairuddin shamsudin100% (1)

- Template Hose Reel CalculationDocument3 pagesTemplate Hose Reel CalculationMFaiz RHamira100% (7)

- 01 - Hose Reel SystemDocument4 pages01 - Hose Reel SystemJeghi100% (1)

- Hose Reel System DesignDocument1 pageHose Reel System DesignAli Aimran100% (2)

- Calculation of Smoke Spilled SystemDocument2 pagesCalculation of Smoke Spilled SystemMFaiz RHamira100% (1)

- Basi Calculation For Pump & Tank SelectionDocument28 pagesBasi Calculation For Pump & Tank SelectionJohn Son G84% (103)

- Booster Pump CalculationDocument3 pagesBooster Pump CalculationYe Myat Thu93% (14)

- Stair Pressurization CalculationDocument2 pagesStair Pressurization Calculationnaruto256100% (1)

- Fire Pro Design ComputationDocument6 pagesFire Pro Design ComputationAlvin Cris RongavillaNo ratings yet

- Basic Calculation For Pump Tank SelectionDocument19 pagesBasic Calculation For Pump Tank Selectionjonnel100% (2)

- Water Supply Pump CalculationDocument2 pagesWater Supply Pump Calculationnido77100% (4)

- Fire Pump Head CalculationDocument7 pagesFire Pump Head CalculationM.Jabar ali100% (12)

- Sump Pit CalculationDocument4 pagesSump Pit CalculationEng Mahmoud Hamdy33% (3)

- Bs 6700 Pipe SizingDocument20 pagesBs 6700 Pipe SizingVelan SivasakthiNo ratings yet

- Booster Pump Capacity CalculationDocument1 pageBooster Pump Capacity CalculationSHIBIN T100% (1)

- Template Wet Riser CalculationDocument4 pagesTemplate Wet Riser CalculationMFaiz RHamira100% (1)

- Hydraulic Calculation For FFDocument2 pagesHydraulic Calculation For FFAnsari1918No ratings yet

- Basi Calculation For Pump Tank SelectionDocument28 pagesBasi Calculation For Pump Tank SelectionSameera LakmalNo ratings yet

- Fire Sprinkler Hydraulic Calculation SheetDocument2 pagesFire Sprinkler Hydraulic Calculation SheetSameera Lakmal50% (2)

- Sprinkler CalculationDocument9 pagesSprinkler Calculationmeeng201467% (3)

- Fully Calculated Method For Fire Sprinkler SystemDocument18 pagesFully Calculated Method For Fire Sprinkler SystemKei Chan89% (9)

- Hydraulic Calculation Tutorial #1Document9 pagesHydraulic Calculation Tutorial #1Rahul Deva100% (1)

- Fire Pump Head CalculationDocument7 pagesFire Pump Head CalculationAry TubagusNo ratings yet

- Smoke Evacuation System CalculationsDocument3 pagesSmoke Evacuation System Calculationsamo3330100% (4)

- Plumbing CalculationsDocument14 pagesPlumbing CalculationsKarthy Ganesan100% (6)

- Fuel Pipe and Pump CalculationDocument2 pagesFuel Pipe and Pump Calculationomidzia100% (1)

- Fittings & Valves Equivalent LengthsDocument2 pagesFittings & Valves Equivalent LengthsSanthosh Kumar33% (3)

- Fire Fighting System DesignDocument1 pageFire Fighting System Designclique67% (6)

- Design of Hose Reel System: - Nozzle: P 200 Kpa 0.4 L/SDocument36 pagesDesign of Hose Reel System: - Nozzle: P 200 Kpa 0.4 L/Sمحمد القدومي100% (1)

- Fire Fighting Calculation En-20150403 - NutrecoDocument6 pagesFire Fighting Calculation En-20150403 - NutrecoTrang Ngo100% (3)

- Booster Pump CalculationDocument11 pagesBooster Pump CalculationSuhaimiNo ratings yet

- FFP Basi Calculation For Pump Amp Tank Selection CompressDocument28 pagesFFP Basi Calculation For Pump Amp Tank Selection CompressSopheareak ChhanNo ratings yet

- Design Installation Operation and Maintenance of Fire Sprinkler System Me421Document87 pagesDesign Installation Operation and Maintenance of Fire Sprinkler System Me421John Daniel100% (2)

- Sump PitDocument4 pagesSump PitDesigner Forever100% (1)

- Sump Pit Calculation 1Document29 pagesSump Pit Calculation 1Meeran Mohideen85% (13)

- Pump Head CalculationDocument6 pagesPump Head CalculationThushan Madu100% (16)

- BMC - Fire Fighting DBRDocument10 pagesBMC - Fire Fighting DBRAmit Kumar Mishra100% (3)

- PUMP CalculationDocument2 pagesPUMP CalculationzexonsmartNo ratings yet

- Fire Sprinkler Systems Hydraulic CalculationsDocument14 pagesFire Sprinkler Systems Hydraulic CalculationsSopi LabuNo ratings yet

- Water Flow and Pipe Size - As Per NBC 2016 - Flushing WaterDocument2 pagesWater Flow and Pipe Size - As Per NBC 2016 - Flushing Watertribhuvan ShankarNo ratings yet

- BUKU HIJAU (Mechanical System Design and Installation Guidelines For Architects and Engineers-2011)Document119 pagesBUKU HIJAU (Mechanical System Design and Installation Guidelines For Architects and Engineers-2011)Alex Chin67% (3)

- Stair Pressurization CalculationDocument9 pagesStair Pressurization CalculationHaymanot BaynesagnNo ratings yet

- 02 - Wet Riser SystemDocument2 pages02 - Wet Riser SystemJeghiNo ratings yet

- Fire Hydraulic CalculationsDocument46 pagesFire Hydraulic CalculationsBanang Mulia Permana100% (10)

- Name of Project Sample 2. Location 2.1. RMC Sample 2.2. Ward No: 2,3 3. District Kaski 4. Total Demand 2345 5. Total Rvts 2Document15 pagesName of Project Sample 2. Location 2.1. RMC Sample 2.2. Ward No: 2,3 3. District Kaski 4. Total Demand 2345 5. Total Rvts 2Rajendra K KarkiNo ratings yet

- Example Hydraulic Calculation For HR (With NOTE)Document1 pageExample Hydraulic Calculation For HR (With NOTE)Jevarajan GanasanNo ratings yet

- Edoc - Pub - Fire Hydrant Pump CalculationDocument3 pagesEdoc - Pub - Fire Hydrant Pump Calculationsushant_jhawerNo ratings yet

- Exercise Problems: By: Kristel Shane R. Lenon SPL Ce-5B (Inc)Document25 pagesExercise Problems: By: Kristel Shane R. Lenon SPL Ce-5B (Inc)Kristel Lenon0% (2)

- Pump CalculationDocument2 pagesPump Calculationapi-3728508100% (6)

- Sheet No1Document5 pagesSheet No1Ismail SakrNo ratings yet

- Cec603 24Document8 pagesCec603 24Swagstar SubhamNo ratings yet

- Perhitungan Ta Bayu FixDocument1,198 pagesPerhitungan Ta Bayu FixWeldy Armando YannesNo ratings yet

- Capacity Calculation of Fire Hose Pumps: Friction Loss RatesDocument1 pageCapacity Calculation of Fire Hose Pumps: Friction Loss RatesCharitha Ranwala100% (1)

- Hydrant Calc (Fire Fighting Zone)Document2 pagesHydrant Calc (Fire Fighting Zone)Arun FikdetcNo ratings yet

- Head Loss CalculationDocument3 pagesHead Loss CalculationalvinchuanNo ratings yet

- Capuno and Casas Chapter 3Document50 pagesCapuno and Casas Chapter 3JAYME JOSWANo ratings yet

- Lecture 03Document33 pagesLecture 03Mussema AbdurazakNo ratings yet

- PipingDocument34 pagesPipingsachinsaklani23No ratings yet

- Form A: Jabatan Bomba Dan Penyelamat, MalaysiaDocument3 pagesForm A: Jabatan Bomba Dan Penyelamat, MalaysiaKazehaya AliNo ratings yet

- Fire Fighting System Design For Industrial Complex Technical For Ideal Quality SDN BHDDocument9 pagesFire Fighting System Design For Industrial Complex Technical For Ideal Quality SDN BHDKazehaya AliNo ratings yet

- Form B - BlankDocument3 pagesForm B - BlankKazehaya AliNo ratings yet

- IEM PI C400 - PI Result Appeal Form PDFDocument1 pageIEM PI C400 - PI Result Appeal Form PDFKazehaya AliNo ratings yet

- Fire Fighting System Design For Industrial Complex Technical For Ideal Quality SDN BHDDocument9 pagesFire Fighting System Design For Industrial Complex Technical For Ideal Quality SDN BHDKazehaya AliNo ratings yet

- Emergency & Disaster Symposium: How Do You Get Started With This Template?Document2 pagesEmergency & Disaster Symposium: How Do You Get Started With This Template?Kazehaya AliNo ratings yet

- Non Compliance ListDocument1 pageNon Compliance ListKazehaya AliNo ratings yet

- Introduction To Quantitative RisK Assessment Webinar - Slides - tcm8-99019Document38 pagesIntroduction To Quantitative RisK Assessment Webinar - Slides - tcm8-99019Kazehaya AliNo ratings yet

- Water Demand CalculationDocument1 pageWater Demand CalculationKazehaya AliNo ratings yet

- Non-Compliance ListDocument1 pageNon-Compliance ListKazehaya AliNo ratings yet

- CFCD 002-019 Daikin SteelDocument2 pagesCFCD 002-019 Daikin SteelKazehaya AliNo ratings yet

- Tank Calculation TemplateDocument4 pagesTank Calculation TemplateKazehaya AliNo ratings yet

- 01 Site Plan PDFDocument1 page01 Site Plan PDFKazehaya AliNo ratings yet

- Dry Powder (Malaysia)Document1 pageDry Powder (Malaysia)Kazehaya AliNo ratings yet

- 89 Series Coupler - MoellerDocument3 pages89 Series Coupler - Moellermayadin yadin100% (1)

- Purchasing Guidelines 2019 2020Document238 pagesPurchasing Guidelines 2019 2020gemrisNo ratings yet

- Sistem Kendali Proportional Derivative Untuk Pressure Control Valve Di Metering Station Assigita Pt. Pertamina Gas Ssa.Document39 pagesSistem Kendali Proportional Derivative Untuk Pressure Control Valve Di Metering Station Assigita Pt. Pertamina Gas Ssa.Abdurrahman FathoniNo ratings yet

- Valves: FM Technical Interaction: 3Document42 pagesValves: FM Technical Interaction: 3Ravi KasaudhanNo ratings yet

- 0497 7 Flow Straightener Catalog Sheet 03 18Document2 pages0497 7 Flow Straightener Catalog Sheet 03 18senthilNo ratings yet

- 5-Cavitation in PumpsDocument52 pages5-Cavitation in PumpsFiraol DinaolNo ratings yet

- Fluid FlowDocument13 pagesFluid FlowTiti SindhuwatiNo ratings yet

- G. Dry and Wet StandpipeDocument10 pagesG. Dry and Wet Standpipehermano balbonNo ratings yet

- Valvulas JisDocument48 pagesValvulas Jisanon_387758396No ratings yet

- Appendix 2-1.ep11422 - h-16 PDFDocument15 pagesAppendix 2-1.ep11422 - h-16 PDFbsnegi111No ratings yet

- BSR Product Price List New 11-12-18Document41 pagesBSR Product Price List New 11-12-18Bala Ji G100% (2)

- Centrifugal Pump - Theory and ProceduresDocument4 pagesCentrifugal Pump - Theory and ProceduresJelyn BenjaminNo ratings yet

- Centrifugal Pump LabDocument3 pagesCentrifugal Pump LabGracey Sagario Dela TorreNo ratings yet

- Safety Valves NV Boiler PartsDocument7 pagesSafety Valves NV Boiler PartsFelipe SalvatierraNo ratings yet

- Pulsafeeder Pulsatron Series KOPkit DatasheetDocument2 pagesPulsafeeder Pulsatron Series KOPkit DatasheetMuthu MohammadNo ratings yet

- 804-904 Spare Parts Manual AMCO VEBA PDFDocument170 pages804-904 Spare Parts Manual AMCO VEBA PDFHidroil Neuquen Srl0% (1)

- Classification of Rotary PumpsDocument3 pagesClassification of Rotary Pumpsapi-26349602100% (2)

- BoQ MEP Club House KosongDocument53 pagesBoQ MEP Club House KosongkelikNo ratings yet

- 2148827a Mec AllDocument20 pages2148827a Mec Allsmason86No ratings yet

- t6cc t6ccw Denison Vane Pumps IndustrialDocument5 pagest6cc t6ccw Denison Vane Pumps IndustrialSamuel Lopez BenitesNo ratings yet

- 315B and 315B L Excavators Boom Lowering Control Valve Hydraulic System (Attachment)Document2 pages315B and 315B L Excavators Boom Lowering Control Valve Hydraulic System (Attachment)Adal Vera100% (4)

- General Overview of Types of Pumps On ShipDocument3 pagesGeneral Overview of Types of Pumps On ShipGiorgi KandelakiNo ratings yet

- 90 Series Manual PDFDocument13 pages90 Series Manual PDFHoney KumarNo ratings yet

- ENERPACDocument2 pagesENERPACingcalderonNo ratings yet

- 10 Metode de Marire Viteza Instalatii HidrauliceDocument4 pages10 Metode de Marire Viteza Instalatii Hidraulicecristi_amaNo ratings yet

- Basic Training HydralicDocument56 pagesBasic Training HydralicAneliese Enache100% (5)

- Deluge PosterDocument1 pageDeluge PosterAhamed KyanaNo ratings yet

- Centrifugal PumpDocument6 pagesCentrifugal PumpGilang AdityaNo ratings yet

- Under Cab View: 420F and 430F Backhoe Loader Hydraulic SystemDocument2 pagesUnder Cab View: 420F and 430F Backhoe Loader Hydraulic SystemFlorencio MaximilianoNo ratings yet

- Bacis Pneumatic Hydraulic SymbolsDocument7 pagesBacis Pneumatic Hydraulic Symbolsmailmohith2322No ratings yet