Professional Documents

Culture Documents

Blasting & Painting JHA

Uploaded by

Dedy KurniawanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Blasting & Painting JHA

Uploaded by

Dedy KurniawanCopyright:

Available Formats

Job Hazard Analysis (JHA) DATE: 12 / 10 / 13

REGISTERED No.

ENTITY: Direct Hire / SUBCONTRACTOR NAME__SMOE___________

PROJECT: Australia Pacific LNG Module Yard Project

ADDRESS: Jln. Hang Kesturi VI lot 5 -1 Kabil

LOCATION: Module Yard PHONE: 081372286076 (Elekson)

JOB DESCRIPTION: Blasting & touch up painting pipe spools (Rev 001)

EMERGENCY ACTION PLAN: As per site Emergency Response and Preparedness Plan (25509-100-GPP-GHX-00003) and site specific emergency response plans.

SMOE - Medical Clinic : 07788074112, Pisa – ES&H : 08127027441

PLANNED HIGH RISK ACTIVITY:

Excavation entry Explosives use Confined space entry Hazardous substance use Work at heights

Roof work Tilt Up/Precast use Structural alterations Mobile plant operations Work in/over water

Road/Rail work Gas/Chemical/Fuel line work Energised electrical work Temperature extremes Flammable/contaminated

Demolition work Marine activities Asbestos removal atmosphere

Demolition Cert. No. Asbestos Removal Cert. No.

DEVELOPED BY: REVIEWED BY:

Certificate

No Name Signature Position No Name Signature Position Date.

No.

Coating & Deputy ES&H

1 Elekson Saragi 1 Pisanuwat S 12 Oct 13

Insulation Supt. Manager

P.I.F Lead

2 John Lara Superintendent.

2

3 Fred Seale Propane Area Mgr. 3

4 Mike Murphy Cryo Area Mgr. 4

5 Waylon Johnson OSBL Area Mgr. 6

APPROVAL BY:

Name: Michael Dorris Signature: Position: General Superintendent Date: 17 October 2013

REVIEW: (NOTE: Work SHALL NOT proceed until the JHA is signed and dated by the HSE Manager or nominee and Construction Superintendent or nominee)

Name: Beng Kee Tan Signature: Position: Project ES&H Manager Date: 17 October 2013

HSE-FORM-012 5 July 2012 1

P.P.E REQUIREMENTS PLANT, EQUIPMENT & TOOLS FOR JOB TAGGING & SIGNS PERMITS &

INSTRUCTION

“Check ” “Check ” “Check ” “Check ”

Electrical power Welding

Hard hat Long pants Barrier mesh Confined Space

tools machine

Clear safety

Sock/Boot protectors Fans Winch Flagging Excavation

Glasses or goggles

Tinted safety

Safety Boots Fire controls Compressor Information tags Floor/Roof Opening

glasses

‘Out of Service’ High Pressure /

Hearing protection Blasting coverall First aid kit

tags Abrasive Blasting

Long sleeve HiVis Blasting hood with Personal Danger

Hand tools Hot Work

shirt hard hat Tags

Gloves -leather Ladder Personal locks HV Access

Gloves – Hyflex Persons working

Mobile plant Instruction Manual

(Nitrile) above

Gloves - PVC Scaffold Road cones Isolation

Blasting work in

Sunscreen Shovel MSDSs

Progress

Painting work in Suspended

Insect repellent Spill kit

Progress Personnel Platform

Skills/Competencies/Authorisations

“Check ”

Integrated Tool

Asbestos Removalist Dozer Rigger Intermediate Skid Steer

Carrier

Backhoe EWP Light Vehicle Roller Spreader

Compactor Excavator Marine craft Scaffolder Advanced Other

Concrete Placing boom Front end loader Materials hoist Scaffolder Basic

Crane type and

Forklift Personnel hoist Scaffolder Intermediate

capacity:

Demolisher Grader Rigger Advanced Scraper

Dogger Heavy vehicle Rigger Basic Skidder

HSE-FORM-012 5 July 2012 2

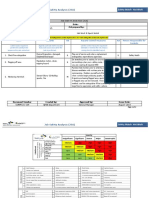

RISK SCORE CALCULATOR

Use the Risk Score Calculator to determine the level of risk of each hazard

What would the What is the LIKELIHOOD of an occurrence? Hierarchy of Controls

CONSEQUENCE of an Can the hazard be Eliminated or removed from

occurrence be? Unlikely Rare Possible Likely Almost Certain

the work place?

Minor Can the product or process be Substituted for

Low Low Low Low Medium

First aid treatment a less hazardous alternative?

Medium Can the hazard be Engineered away with

Low Low Medium Medium High

Medical treatment guards or barriers?

Serious Can Administration Controls be adopted

Low Medium Medium High High

Lost time incident ie procedures, job rotation etc

Major Low Medium High High High

Fatality or permanent impairment Can Personal Protective Equipment & Clothing

Catastrophic be worn to safe guard against hazards?

Medium High High High High

Multiple fatalities or permanent impairment

Control Methods & Monitoring Residual

Step Hazard Risk Risk

Action By

Score What control measures will be used? Score

Describe the job step by step? What are the hazards of each step?

How will the effectiveness of the controls be

determined? (Inspection & ongoing monitoring)

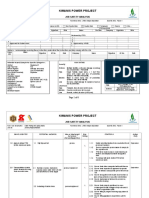

Avoid contact with blade teeth.

Lacerations / cut M L Worker

Be sure the tool is unplugged

Check inspection sticker on the electrical tools

Hand-Operate Power Tools and visual check conditon of the tools and

Preparation cables.

Worker

Electrocution H Ensure that all electrical equipment connected L

/Electrician

with ELCB and grounding.

Ensure that grounding is in place prior to start

using any electrical tools.

Always wear safety goggles.

Evaluate surroundings before turning on

power tool and be aware of others.

Make sure that cutting will not come into

contact with any utilities.

Don’t wear loose clothing. Supervisor/

Operating power tool Lacerations and other injuries M L

Make sure the blade or bit is not binding as it Worker

goes into the work. If blade or bit is binding,

cease operation of the tool and evaluate

reasons for binding.

Ensure that material being operated on is

secured.

HSE-FORM-012 5 July 2012 3

Control Methods & Monitoring Residual

Step Hazard Risk Risk

Action By

Score What control measures will be used? Score

Describe the job step by step? What are the hazards of each step?

How will the effectiveness of the controls be

determined? (Inspection & ongoing monitoring)

Ensure tool is unplugged and fully stopped

before changing any part of the tool.

Changing blade/bit/other tool parts Lacerations /Cut M L Worker

Using hand gloves while changing blade.

Using correct tool to change blade.

Blasting ( Garnet ) Noise M Wear ear protection. L Worker

HSE-FORM-012 5 July 2012 4

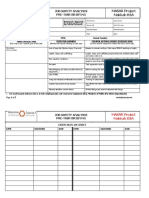

Control Methods & Monitoring Residual

Step Hazard Risk Risk

Action By

Score What control measures will be used? Score

Describe the job step by step? What are the hazards of each step?

How will the effectiveness of the controls be

determined? (Inspection & ongoing monitoring)

Wear goggles and blasting hood (which

Eye injury M L Worker

created double eye protections.)

Contain dust with plastic sheets.

Wearing air-line helmet properly.

Dust (eye and respiratory tract system) M Do not remove the helmet inside the blasting L Worker

area and brush up all dust deposited on the

helmet prior to remove it.

Wear blasting cover all and proper PPE.

Body injuries by blasting gun M Never point the gun tip to other people or co- L Worker

worker.

Set up work piece at elevated level to

Supervisor/

Muscle strain from awkward position M minimize chance of sitting in awkward L

Worker

position.

Check all leaks from hose connectors which

Supervisor/

Carbon monoxide H may deliver exhaust gas (CO contained) to L

Worker

the blasting area.

Ensure all cable managements are in place.

Slips and trips M L Worker

Provide adequate lighting to the working area.

Ensure that no hot work allowed in the

painting area.

Close painting container when not in use.

Flammable liquids shall be stored and Supervisor/

Fire / Explosion H L

dispensed only from approved type Worker

containers.

No bulk storage of paint material at site

(designated area only.)

In open area try to stay up wind rather than

Painting down wind.

Close painting container when not in use.

Chemical (inhalation) M MSDS for the paint need to be placed prior to L Worker

work starting.

Using respirator when working in close

proximity and/or ventilating the area.

Wear goggles (in close proximity) or safety

Eye irritation M L Worker

glasses (in open area).

Wear long sleeves shirt or coverall and rubber

Skin contaminated with chemical M L Worker

gloves.

HSE-FORM-012 5 July 2012 5

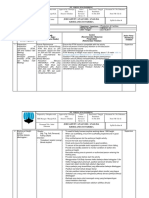

Control Methods & Monitoring Residual

Step Hazard Risk Risk

Action By

Score What control measures will be used? Score

Describe the job step by step? What are the hazards of each step?

How will the effectiveness of the controls be

determined? (Inspection & ongoing monitoring)

Wear ear protection.

Close all guards of the machine to reduce

noise.

Noise M L Worker

Daily checklist must be done properly.

Provide preventive maintenance to minimize

excessive noise from wear and tear.

The couplings must be secured with 2 R pins. Supervisor/

Hose dislodged and hit a person M L

And whip check. Worker

Operating portable air compressor

for air supply to pneumatic tools Try to set up compressor away from working

area. Supervisor/

Exhaust gas (CO and other gases) M L

Observe the exhaust gas move and adjust if Worker

they move into the work location.

Check the hose rated pressure on the hose

marking. They shall be higher pressure rating Supervisor/

Hose bursting M L

than working pressure they are intended to Worker

use.

Daily checklist must be done properly.

Fire H L Worker

Provide fire extinguisher at the machine.

Dust mask for housekeeping crew when

necessary.

Bundles bind or contained securely to prevent

Dust dispersion M slippage. L Worker

Housekeeping No overloading of trucks.

Cargo bed to be covered should loose in the

event of transporting of loose material.

Wear goggles (in close proximity) or safety

Eye irritation M L Worker

glasses (in open area).

HSE-FORM-012 5 July 2012 6

Job Hazard Analysis (JHA)

SIGN OFF SHEET

All persons performing any activity covered by this JHA MUST sign off prior to commencement of this task as recognition of having read and understood the work steps and

preventative actions required to reduce the risk of harm, and ensure safe work practices are maintained.

I, the undersigned, declare that I have read and understand the requirements of this JHA and will work in accordance with the prescribed controls.

Name Signature Position Date Name Signature Position Date

HSE-FORM-012 5 July 2012 7

HSE-FORM-012 5 July 2012 8

You might also like

- Method Statement For Painting of All Metallic Piping: Form 000.653.F0100Document9 pagesMethod Statement For Painting of All Metallic Piping: Form 000.653.F0100narmathaNo ratings yet

- Jha of PaintingDocument3 pagesJha of PaintingAllan Camacho Regalado100% (1)

- Job Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Document3 pagesJob Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Perwez21No ratings yet

- JSA For Rebar Works Includes Working in ScaffoldingDocument4 pagesJSA For Rebar Works Includes Working in Scaffoldingyc safetyNo ratings yet

- Jsa For Weld and GrindingDocument6 pagesJsa For Weld and GrindingTanzeel LiaqatNo ratings yet

- 1installation of Steel Structures JHA 1 (06!06!2015)Document33 pages1installation of Steel Structures JHA 1 (06!06!2015)Karthik babu100% (2)

- JSA Template 5 - Plumbing and Wastewater System InspectionsDocument13 pagesJSA Template 5 - Plumbing and Wastewater System InspectionsSayed Darwish100% (2)

- 15.tube Bundle Puller.Document3 pages15.tube Bundle Puller.Mohammad Fazal Khan100% (1)

- JSA Epoxy Coating Machine ShopDocument10 pagesJSA Epoxy Coating Machine ShopMarhendra100% (1)

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingDocument4 pagesJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- Installing Pneumatic Rubber Fenders Job Safety AnalysisDocument3 pagesInstalling Pneumatic Rubber Fenders Job Safety AnalysisIhwan AsrulNo ratings yet

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDocument17 pagesSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda Buksh0% (1)

- JHA PaintingDocument9 pagesJHA Paintingperquino oasan100% (1)

- Jsa Grinding Welding Gas CuttingDocument3 pagesJsa Grinding Welding Gas CuttingRyanNo ratings yet

- Concrete Cutting and Drilling PDFDocument2 pagesConcrete Cutting and Drilling PDFcityofdarwingis100% (1)

- JSA Template 2017-05-31 Cable Tray InstallationDocument19 pagesJSA Template 2017-05-31 Cable Tray InstallationJayvee Baradas ValdezNo ratings yet

- JSA-020-Safety Watch-Hot WorkDocument2 pagesJSA-020-Safety Watch-Hot WorkNishad MuhammedNo ratings yet

- Job Safety Analysis for Pipeline LoadingDocument8 pagesJob Safety Analysis for Pipeline LoadingMoaatazz NouisriNo ratings yet

- JHA For Blasting Painting Works FinalDocument7 pagesJHA For Blasting Painting Works Finalrosevelvet50% (10)

- JSA Machinal PipingDocument7 pagesJSA Machinal PipingNaitik Desai48100% (1)

- Jsa Welding Cutting and Grinding at Closing AreaDocument7 pagesJsa Welding Cutting and Grinding at Closing AreaDedy Kurniawan100% (1)

- JSA ScaffoldingDocument2 pagesJSA ScaffoldingHrishikesh UnnikrishnanNo ratings yet

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7Document4 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7abhijit janaNo ratings yet

- (JSA) For Cast-In-place Reinforced ConcreteDocument1 page(JSA) For Cast-In-place Reinforced ConcreteNazir Hussain100% (4)

- Job Safety AnalysisDocument2 pagesJob Safety AnalysisDamien MonizeNo ratings yet

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Document6 pagesJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganNo ratings yet

- KKNPP Grinding Job Hazard AnalysisDocument6 pagesKKNPP Grinding Job Hazard AnalysisMAHA LINGAMNo ratings yet

- Job Safety Analysis Construction, EtcDocument3 pagesJob Safety Analysis Construction, EtcCamilo Salvadora MasbateNo ratings yet

- Loading and Unloading Pile Pipes SafelyDocument4 pagesLoading and Unloading Pile Pipes SafelyOsiobe Ewomazino100% (1)

- Removing Staircase with Crane Lifts SteelDocument3 pagesRemoving Staircase with Crane Lifts Steelmarvin100% (1)

- JSA-RSS-HSE-005 Bristle Blasting, Needle Gun and Painting ActivityDocument7 pagesJSA-RSS-HSE-005 Bristle Blasting, Needle Gun and Painting ActivityRaditya PramudyaNo ratings yet

- Project No. 074-10 JHA No. 1Document20 pagesProject No. 074-10 JHA No. 1Adel SukerNo ratings yet

- JSA For NDTDocument4 pagesJSA For NDTMohammed Minhaj50% (2)

- Rebar Job Hazard AnalysisDocument1 pageRebar Job Hazard Analysisjoker batmanNo ratings yet

- Confined Space Rescue Plan-Fb EngineeringDocument17 pagesConfined Space Rescue Plan-Fb EngineeringPatrick Ruwona100% (1)

- Operating The Man LiftDocument1 pageOperating The Man LiftEllecer anthony Permejo67% (3)

- Refueling JSA 4 08 2019 Rev.03 Near WaterDocument9 pagesRefueling JSA 4 08 2019 Rev.03 Near Waterrisky indra antariNo ratings yet

- Duqm Refinery Project EPC Package One: JSA For Confined Space Rev.0Document8 pagesDuqm Refinery Project EPC Package One: JSA For Confined Space Rev.0balasubramaniamNo ratings yet

- Form Report Safety CampaignDocument1 pageForm Report Safety CampaignErlan Gus HermawanNo ratings yet

- Jsa FormDocument3 pagesJsa Formmiaicarba100% (1)

- Jha RebarsDocument7 pagesJha RebarsJaycee QuinNo ratings yet

- JHA PlumberDocument3 pagesJHA PlumberEko Susanto100% (1)

- JSA-010 Excavation Sampling PDFDocument5 pagesJSA-010 Excavation Sampling PDFArgaYurIstiawanNo ratings yet

- Jsa n2 Purging PDF FreeDocument1 pageJsa n2 Purging PDF FreeSKH CultureNo ratings yet

- Al - Osais Contracting Company Haradh Area Power Reliability EnhancementDocument3 pagesAl - Osais Contracting Company Haradh Area Power Reliability EnhancementREHAN IQBAL100% (3)

- JSA Cable Pulling and Laying WorksDocument6 pagesJSA Cable Pulling and Laying Workskabir100% (1)

- 972 99 100 (Mobile) : Job Safety AnalysisDocument8 pages972 99 100 (Mobile) : Job Safety AnalysisSreeraj Reghunathan Nair VanmazhyNo ratings yet

- Jsa Grinding W Angle GrinderDocument2 pagesJsa Grinding W Angle GrinderMichael Angelo SanteNo ratings yet

- Jsa SKDocument10 pagesJsa SKEngr Tahir UL Haq100% (2)

- Job Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSADocument2 pagesJob Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSAmahammed saleem100% (2)

- JSA For Piping-Hydro TestDocument10 pagesJSA For Piping-Hydro TestMuthu AlaguRajNo ratings yet

- JSA Arc WeldingDocument2 pagesJSA Arc WeldinganeshseNo ratings yet

- QP Blasting JSADocument6 pagesQP Blasting JSAMohammed Mujahid100% (1)

- Job Hazard Analysis FormDocument10 pagesJob Hazard Analysis FormJayson Escamillan100% (1)

- Hydro Jetting and Sludge RemovalDocument18 pagesHydro Jetting and Sludge Removalmarvin100% (1)

- Welding and Grinding HazardsDocument6 pagesWelding and Grinding HazardsJeremia Samosir100% (2)

- Sepcoii II: Job Safety Analysis (J S A)Document8 pagesSepcoii II: Job Safety Analysis (J S A)Abdus SamadNo ratings yet

- Civil & Piping Work at Cast HouseDocument8 pagesCivil & Piping Work at Cast HouseVinayaga MoorthiNo ratings yet

- Job Safety Analysis: Pt. Viking EngineeringDocument4 pagesJob Safety Analysis: Pt. Viking EngineeringDedy KurniawanNo ratings yet

- Confined Space Rescue PlanDocument2 pagesConfined Space Rescue PlanSara Scherer80% (5)

- Jsa Welding Cutting and Grinding at Closing AreaDocument7 pagesJsa Welding Cutting and Grinding at Closing AreaDedy Kurniawan100% (1)

- Jsa Working at HeightDocument4 pagesJsa Working at HeightDedy Kurniawan100% (1)

- JSA For Forklift ActivitiesDocument5 pagesJSA For Forklift ActivitiesDedy Kurniawan0% (1)

- Edi Wow ResearchDocument12 pagesEdi Wow ResearchElma BayaniNo ratings yet

- Packaging Development Strategy - ENDocument329 pagesPackaging Development Strategy - ENsheref_hamady100% (1)

- Warehouse SalesDocument1 pageWarehouse SalesCityNewsTorontoNo ratings yet

- Beko 30302350 DTGC8011Document24 pagesBeko 30302350 DTGC8011tk67qg98fcNo ratings yet

- FSG Final DesignDocument18 pagesFSG Final Designapi-215278760No ratings yet

- Tool Safety Is PriorityDocument45 pagesTool Safety Is PriorityOlsonNo ratings yet

- Amazon's Distribution StrategyDocument3 pagesAmazon's Distribution StrategyJaya Krishna SinguNo ratings yet

- Facade Fabrics PDFDocument66 pagesFacade Fabrics PDFGauri Puranik100% (1)

- Globalization and LogisticsDocument25 pagesGlobalization and LogisticsMyunghee LeeNo ratings yet

- Callebaut - Leaflet Chocolate Couv WhiteDocument2 pagesCallebaut - Leaflet Chocolate Couv WhiteCristian VasilescuNo ratings yet

- Econ201 Quiz 4Document10 pagesEcon201 Quiz 4arichard88215No ratings yet

- Basic Washes in Denim FabricDocument24 pagesBasic Washes in Denim FabricAbdullah Al HafizNo ratings yet

- Avance Collection Mixer Grinder SpecsDocument3 pagesAvance Collection Mixer Grinder SpecsfaNo ratings yet

- Zipper: Fabric Clothing Luggage Sporting Goods Camping Tents Sleeping Bags Whitcomb L. JudsonDocument8 pagesZipper: Fabric Clothing Luggage Sporting Goods Camping Tents Sleeping Bags Whitcomb L. JudsonmirmoinulNo ratings yet

- A Project Report On Market Research & Brand Activation: Submitted in Partial Fulfillment of The RequirementsDocument55 pagesA Project Report On Market Research & Brand Activation: Submitted in Partial Fulfillment of The Requirementskartik chauhan100% (1)

- Prada (Compatibility Mode)Document35 pagesPrada (Compatibility Mode)Tanvi MishraNo ratings yet

- PMT Classified Adverts 250215Document4 pagesPMT Classified Adverts 250215Digital MediaNo ratings yet

- 22 Easy Thanksgiving Recipes A Traditional Thanksgiving Menu From RecipeLion PDFDocument43 pages22 Easy Thanksgiving Recipes A Traditional Thanksgiving Menu From RecipeLion PDFMarshall W Thompson, SrNo ratings yet

- Top 10 Apparel Brands 2013Document4 pagesTop 10 Apparel Brands 2013Inder SinghNo ratings yet

- BUS 700 Economics - Micro Tutorial Seminar 1Document2 pagesBUS 700 Economics - Micro Tutorial Seminar 1Hashma KhanNo ratings yet

- DVD PlayersDocument42 pagesDVD PlayersKing Nitin AgnihotriNo ratings yet

- YO WEAR's Production and Marketing StrategiesDocument13 pagesYO WEAR's Production and Marketing Strategiesarslan0989No ratings yet

- What Is 2pl, 3pl, and 4pl?Document2 pagesWhat Is 2pl, 3pl, and 4pl?Ahmed AbdiwahabNo ratings yet

- Halal CertificationDocument12 pagesHalal CertificationNur Athirah Muhamad SobriNo ratings yet

- Ghid ConversatieDocument53 pagesGhid ConversatieFara NumeNo ratings yet

- The Bangladesh Accord Foundation Has Provided The Information On This Signatory Supplier List As of 1 September 2017 "As Is" Without Any Representations or Warranties, Express or ImpliedDocument30 pagesThe Bangladesh Accord Foundation Has Provided The Information On This Signatory Supplier List As of 1 September 2017 "As Is" Without Any Representations or Warranties, Express or ImpliedMd Mustafijur Rahman TusharNo ratings yet

- Group 3-Home Appliances For Rural HouseholdDocument14 pagesGroup 3-Home Appliances For Rural HouseholdSamantha MendisNo ratings yet

- Concept of Weaving and Passing of Yarns Through KhaddiDocument3 pagesConcept of Weaving and Passing of Yarns Through KhaddiZain QaziNo ratings yet

- NKE Bearings For RailwayDocument4 pagesNKE Bearings For RailwayRavindra AngalNo ratings yet

- P1 Unit 8 AbsorptionDocument51 pagesP1 Unit 8 AbsorptionNg ShyueJinnNo ratings yet