Professional Documents

Culture Documents

015 Tray Efficiencies PDF

Uploaded by

Ali AlengineerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

015 Tray Efficiencies PDF

Uploaded by

Ali AlengineerCopyright:

Available Formats

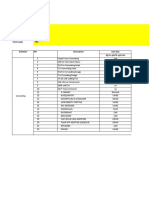

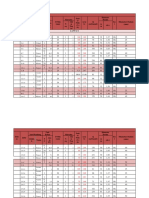

Table 7.

3

Overall Tray Efficiencies

Typical No.

Typical No. Typical

of

Column Service of Actual Overall

Theoretical

Trays Efficiency

Trays

Simple Absorber/Stripper 20 – 30 20 – 30

Steam Side Stripper 5–7 2

Reboiled Side Stripper 7 – 10 3–4

Reboiled Absorber 20 – 40 40 – 50

Deethanizer 25 – 35 65 – 75

Depropanizer 35 – 40 70 – 80

Debutanizer 38 – 45 85 – 90

Alky DeiC4 (reflux) 75 – 90 85 – 90

Alky DeiC4 (no reflux) 55 – 70 55 – 65

Naphtha Splitter 25 – 35 70 – 75

C2 Splitter 110 – 130 95 – 100

C3 Splitter 200 – 250 95 – 100

C4 Splitter 70 – 80 85 – 90

Amine Contactor 20 – 24 4–5

Amine Stripper 20 – 24 45 - 55 9 – 12

Crude Distillation 35 – 50 50 – 60 20 – 30

Stripping Zone 5–7 30 2

Flash Zone – 1st draw 3–7 30 1–2

1st Draw – 2nd Draw 7 – 10 45 – 50 3–5

2nd Draw – 3rd Draw 7 – 10 50 – 55 3–5

Top Draw – Reflux 10 – 12 60 – 70 6–8

Vacuum Column (G.O. Operation)

Stripping 2–4 1

Flash Zone – HGO Draw 2–3 1–2

HGO Section 3–5 2

LGO Section 3–5 2

FCC Main Fractionator 24 – 35 50 – 60 13 – 17

Quench Zone 5–7 2

Quench – HGO Draw 3–5 2–3

HGO – LCGO 6–8 3–5

LCGO – Top 7 – 10 5–7

Ref: G. L. Kaes, A Practical Guide to Steady State Modeling of Petroleum Processes

(Using Commercial Simulators), Athens Printing Company, 2000, pg. 68

You might also like

- Workshop Manual D16 Tai Lieu May Thuy Volvo PDFDocument228 pagesWorkshop Manual D16 Tai Lieu May Thuy Volvo PDFLonghuynh Lê100% (1)

- McCormick XTX185 Tractor Service Repair Manual PDFDocument40 pagesMcCormick XTX185 Tractor Service Repair Manual PDFfhsjdkkemmd100% (1)

- Service Manual: (450-S/N 561711001 & Above) (453-S/N 561811001 & Above)Document350 pagesService Manual: (450-S/N 561711001 & Above) (453-S/N 561811001 & Above)khaled boulahlib100% (1)

- Habitats Presentation New PDFDocument11 pagesHabitats Presentation New PDFIkhwan Hafiz100% (2)

- Compressor Dry Gas SealsDocument12 pagesCompressor Dry Gas SealsRajeev Domble100% (3)

- Farymann Technical Data Engines After 1981Document1 pageFarymann Technical Data Engines After 1981emreorakNo ratings yet

- Cavo Motor Operations ManualDocument132 pagesCavo Motor Operations Manualodscam100% (1)

- ECG - Deluge System CalculationDocument22 pagesECG - Deluge System CalculationzshehadehNo ratings yet

- The Mechanical Behaviour of Engineering Materials: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandThe Mechanical Behaviour of Engineering Materials: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- Upstream ChinaFocusS PDFDocument19 pagesUpstream ChinaFocusS PDFLow AlysNo ratings yet

- Shop Manual M400-V Sn3001-UpDocument730 pagesShop Manual M400-V Sn3001-UpPAOLO RINCON67% (3)

- Project Name: Project Number:: EXTERIOR (Insert Pipe Type)Document4 pagesProject Name: Project Number:: EXTERIOR (Insert Pipe Type)John ANo ratings yet

- Crude Tower Simulation-HYSYS v8.6 PDFDocument62 pagesCrude Tower Simulation-HYSYS v8.6 PDFrawadNo ratings yet

- Crude Tower Simulation-HYSYS v8.6 PDFDocument62 pagesCrude Tower Simulation-HYSYS v8.6 PDFrawadNo ratings yet

- Depropanizer Design PDFDocument19 pagesDepropanizer Design PDFAli AlengineerNo ratings yet

- AGFA Film Thickness FactorsDocument5 pagesAGFA Film Thickness FactorsibrahimNo ratings yet

- IFP SustainableDevelopmentDocument24 pagesIFP SustainableDevelopmentJorge BacaNo ratings yet

- Designing of Air Cooled Heat Exchangers: by Mehaboob Basha N.BDocument28 pagesDesigning of Air Cooled Heat Exchangers: by Mehaboob Basha N.Bgerty1818100% (2)

- Johnston Hydraulic Calculation PDFDocument40 pagesJohnston Hydraulic Calculation PDFMalbec WallaceNo ratings yet

- Module 4 - Gaseous FuelsDocument56 pagesModule 4 - Gaseous Fuelsermias100% (1)

- MFH Fi CalcDocument26 pagesMFH Fi CalcNethajiNo ratings yet

- Guideline For Technical Regulation: Design of Thermal Power Facilities Book 7/12 Liquefied Gas Handling FacilityDocument117 pagesGuideline For Technical Regulation: Design of Thermal Power Facilities Book 7/12 Liquefied Gas Handling Facilityshahjada100% (1)

- Mining CostDocument136 pagesMining CostyunediNo ratings yet

- Pipe Sizing for Optimal Steam FlowDocument6 pagesPipe Sizing for Optimal Steam Flowferdie14No ratings yet

- Manual of Medical Physics PDFDocument48 pagesManual of Medical Physics PDFAli AlengineerNo ratings yet

- Mcquay Refrigerant Application Guide AG31-007Document66 pagesMcquay Refrigerant Application Guide AG31-007john_shembrey2000No ratings yet

- Design of Vacuum Systems For Crude Oil Vacuum Tower DistillationDocument5 pagesDesign of Vacuum Systems For Crude Oil Vacuum Tower DistillationnasirmuzaffarNo ratings yet

- Organic Chem (Online Review)Document211 pagesOrganic Chem (Online Review)Spencer Thomas100% (1)

- Petroleum Refining Materials and Equipment PDFDocument754 pagesPetroleum Refining Materials and Equipment PDFAli AlengineerNo ratings yet

- Tray Efficiencies and Column SpecificationsDocument1 pageTray Efficiencies and Column SpecificationsIOCPCNo ratings yet

- Crude Distillation: Chapter 4Document22 pagesCrude Distillation: Chapter 4Arif IqbalNo ratings yet

- Outdoor unit specifications tableDocument2 pagesOutdoor unit specifications tableAhmed NajjarNo ratings yet

- Itams ListDocument32,767 pagesItams Listmangesh guptaNo ratings yet

- Laporan Jam Jalan DP & HWDPDocument2 pagesLaporan Jam Jalan DP & HWDPNovri IsrarNo ratings yet

- Packing List-Bintuni (1) NewDocument10 pagesPacking List-Bintuni (1) NewPutra NindyaNo ratings yet

- Thebault Dop01 Teboply Ext GBDocument2 pagesThebault Dop01 Teboply Ext GBDumitrache IulianNo ratings yet

- ACFFilmcomDocument7 pagesACFFilmcomBossNo ratings yet

- فورمى داشكاندن لة ستابلايزةرDocument11 pagesفورمى داشكاندن لة ستابلايزةرNasir BalakyNo ratings yet

- Trade Life Engineering and Consultancy Services: Gonzalo G. Ong, JR., Pee, RMP, Enp, Rea, RebDocument2 pagesTrade Life Engineering and Consultancy Services: Gonzalo G. Ong, JR., Pee, RMP, Enp, Rea, RebJoel ArjonaNo ratings yet

- Clinker IzationDocument30 pagesClinker Izationamaralinga chariNo ratings yet

- Choosing a Location for a New FacilityDocument3 pagesChoosing a Location for a New FacilityKim Kim VuongNo ratings yet

- 2016 ECI Catalogue RevE 03-2016 Section11 RO NPDocument13 pages2016 ECI Catalogue RevE 03-2016 Section11 RO NPAkuba AmanNo ratings yet

- CatalogueDocument212 pagesCataloguechinitnNo ratings yet

- Slide 07+330 I 7m h18 EstDocument1 pageSlide 07+330 I 7m h18 EstSebastián Molina AndradeNo ratings yet

- R32 MultiSplit Brochure UKEPCEN18-1075 FINALDocument40 pagesR32 MultiSplit Brochure UKEPCEN18-1075 FINALjdyg2jkt7kNo ratings yet

- Jadual Susut Voltan (Single Core Cable) (TABLE 4D1B) : Lampiran IVDocument1 pageJadual Susut Voltan (Single Core Cable) (TABLE 4D1B) : Lampiran IVzfn2rqvqgqNo ratings yet

- AC CASSETTE DAIKIN Sky Air InverterDocument4 pagesAC CASSETTE DAIKIN Sky Air Invertersurya liemzNo ratings yet

- ESP Calculation NAH SPF-1Document3 pagesESP Calculation NAH SPF-1Joy VergheseNo ratings yet

- Page 19Document1 pagePage 19Krishna PATELNo ratings yet

- Resumen SuperpaveDocument60 pagesResumen SuperpaveFranklinNo ratings yet

- (Ee) Rab CTPSDocument190 pages(Ee) Rab CTPSichsanNo ratings yet

- AquaCal Tropical Brochure PDFDocument2 pagesAquaCal Tropical Brochure PDFJC ParedesNo ratings yet

- Graphical Representation of DataDocument15 pagesGraphical Representation of DataAttique HussainNo ratings yet

- ★R90 5样本(总图2+2) 220718Document11 pages★R90 5样本(总图2+2) 220718Danyi ZhangNo ratings yet

- Data Table Translation FileDocument1 pageData Table Translation FileGat SolzaimaNo ratings yet

- Slide 07+330 I 7m h23 EstDocument1 pageSlide 07+330 I 7m h23 EstSebastián Molina AndradeNo ratings yet

- Calcul GrinziDocument107 pagesCalcul GrinziAndriana DeacuNo ratings yet

- ESIC InventoryDocument40 pagesESIC InventoryAsif IqbalNo ratings yet

- Spam Relay Settings in DRPDocument3 pagesSpam Relay Settings in DRPchandanhatwarNo ratings yet

- Slide 05+690 I 7M PSEUDDocument1 pageSlide 05+690 I 7M PSEUDSebastián Molina AndradeNo ratings yet

- HS 1.5 Thru 015 SpecsDocument8 pagesHS 1.5 Thru 015 SpecsvijaykumarnNo ratings yet

- HS CatalogDocument8 pagesHS CatalogvijaykumarnNo ratings yet

- HS CatalogDocument8 pagesHS CatalogMahesh NanayakkaraNo ratings yet

- Alta Denumire Denumire Otel Dimensiune Diametru Rezistenta de Rupere La Tractiune KGF/MM (Min.)Document6 pagesAlta Denumire Denumire Otel Dimensiune Diametru Rezistenta de Rupere La Tractiune KGF/MM (Min.)Ela KopoNo ratings yet

- Fiche Technique ODU 40KWDocument1 pageFiche Technique ODU 40KWHotel SétifNo ratings yet

- Slide 05+690 I 7M ESTDocument1 pageSlide 05+690 I 7M ESTSebastián Molina AndradeNo ratings yet

- Sony XBR-65X950G CNET Calibration ResultsDocument3 pagesSony XBR-65X950G CNET Calibration ResultsDavid Katzmaier0% (1)

- Slide 06+240 D 7M ESTDocument1 pageSlide 06+240 D 7M ESTSebastián Molina AndradeNo ratings yet

- Sample 1Document8 pagesSample 1api-3836468No ratings yet

- Information For Topics DiscussionDocument4 pagesInformation For Topics DiscussionSanthosh MohanNo ratings yet

- Civil Estimate of One Storey 60x30 RC SchoolDocument24 pagesCivil Estimate of One Storey 60x30 RC Schoolritesh patel67% (6)

- Lampiran - 1 Contoh Perhitungan Tebal Perkerasan Kaku Metode AASHTO 1993Document3 pagesLampiran - 1 Contoh Perhitungan Tebal Perkerasan Kaku Metode AASHTO 1993AtyatamaNo ratings yet

- Exposed concrete and water areasDocument6 pagesExposed concrete and water areassbmmkushanNo ratings yet

- 13 Week Power-Hypertrophy ProgramDocument40 pages13 Week Power-Hypertrophy ProgramTuteraipuni POTHIERNo ratings yet

- LG OLEDB9P CNET Review Calibration ResultsDocument3 pagesLG OLEDB9P CNET Review Calibration ResultsDavid KatzmaierNo ratings yet

- SistemDocument3 pagesSistemmerienza varoliaNo ratings yet

- 16 284-294 PVC FA - Indd PDFDocument11 pages16 284-294 PVC FA - Indd PDFKok WaiNo ratings yet

- SukadiDocument2 pagesSukadirumahsakit danausalakNo ratings yet

- Gmv5 - Ducted VRF Lo EspDocument1 pageGmv5 - Ducted VRF Lo EspAvk SanjeevanNo ratings yet

- 3DMM Cswpa SM 001Document2 pages3DMM Cswpa SM 001mlik borhenNo ratings yet

- FulltextDocument6 pagesFulltextAli AlengineerNo ratings yet

- Cmit 712 Ele 15.03 5002 - B - Specification For Solar Power UnitDocument14 pagesCmit 712 Ele 15.03 5002 - B - Specification For Solar Power UnitAli AlengineerNo ratings yet

- MesurmentDocument2 pagesMesurmentAli AlengineerNo ratings yet

- DegassingDocument4 pagesDegassingAli AlengineerNo ratings yet

- Crude Tower Simulation (HYSYS V8.6)Document2 pagesCrude Tower Simulation (HYSYS V8.6)Ali AlengineerNo ratings yet

- PN VS BarDocument1 pagePN VS BarTon PhichitNo ratings yet

- Lec.9 &10Document6 pagesLec.9 &10Abderrahim HAMDAOUINo ratings yet

- How bitumen is blown to gradeDocument1 pageHow bitumen is blown to gradeAli AlengineerNo ratings yet

- Tajarb PDFDocument67 pagesTajarb PDFbilalNo ratings yet

- Cmit 712 Ele 15.03 5002 - B - Specification For Solar Power UnitDocument14 pagesCmit 712 Ele 15.03 5002 - B - Specification For Solar Power UnitAli AlengineerNo ratings yet

- Two-Stage Compression and Separation of Natural Gas StreamDocument23 pagesTwo-Stage Compression and Separation of Natural Gas StreamAli AlengineerNo ratings yet

- All Crude Oil ProcessDocument7 pagesAll Crude Oil ProcessAli AlengineerNo ratings yet

- Plate Type Wet ScrubberDocument6 pagesPlate Type Wet ScrubberRoger IsidoreNo ratings yet

- PF-2303 RevCDocument6 pagesPF-2303 RevCAli AlengineerNo ratings yet

- Crude Distillation Technologies and ProcessesDocument19 pagesCrude Distillation Technologies and ProcessesAli AlengineerNo ratings yet

- Crude Tower Deisgn Very OokDocument22 pagesCrude Tower Deisgn Very OokAli AlengineerNo ratings yet

- Industrial Water Treatment ProceduresDocument153 pagesIndustrial Water Treatment ProceduresDonatas BertasiusNo ratings yet

- Astm DistillationDocument244 pagesAstm DistillationprocesspipingdesignNo ratings yet

- Asphalt Eia Neshap Final 02-2003 PDFDocument95 pagesAsphalt Eia Neshap Final 02-2003 PDFAli AlengineerNo ratings yet

- Industrial Water Treatment ProceduresDocument153 pagesIndustrial Water Treatment ProceduresDonatas BertasiusNo ratings yet

- Sugar Mill DetailsDocument19 pagesSugar Mill DetailsravandkumarNo ratings yet

- SEBU 6251 Oil - Engine Crankcase Fluid RecommendationsDocument6 pagesSEBU 6251 Oil - Engine Crankcase Fluid RecommendationsAndri Konyoa Konyoa0% (1)

- UNIservice Global Ecosolut 24 Supervision Tank Cleaning 02Document8 pagesUNIservice Global Ecosolut 24 Supervision Tank Cleaning 02Ian RidzuanNo ratings yet

- Contoh Soal HOTS Bahasa Inggris Tingkat SMP Mts PDFDocument17 pagesContoh Soal HOTS Bahasa Inggris Tingkat SMP Mts PDFAmin ArbaNo ratings yet

- ASTM D396 - 2001 - Standard Specification For Fuel Oils - NOT BUYDocument5 pagesASTM D396 - 2001 - Standard Specification For Fuel Oils - NOT BUYJOHNNo ratings yet

- iPRODUCT100: Ii 2 GD Ex D Iic T6 GB Ex TD Iiic T100°C DB I M2 Ex D I MBDocument1 pageiPRODUCT100: Ii 2 GD Ex D Iic T6 GB Ex TD Iiic T100°C DB I M2 Ex D I MBmlutfimaNo ratings yet

- Correct Operation and Maintenance of TC Engine PDFDocument3 pagesCorrect Operation and Maintenance of TC Engine PDFstefyharo100% (3)

- LAB (Detergent Alkylate) PresentationDocument35 pagesLAB (Detergent Alkylate) Presentationakgupta1946100% (2)

- Petroleum Facilites of Germany 1945 106Document10 pagesPetroleum Facilites of Germany 1945 106ENAK9000100% (2)

- India's Energy Crisis and Potential of Mahua Oil BiodieselDocument6 pagesIndia's Energy Crisis and Potential of Mahua Oil BiodieselShivam SarveshNo ratings yet

- Pumps: Bauzon, Gianpaolo B. Cabangal, DustinmarielDocument47 pagesPumps: Bauzon, Gianpaolo B. Cabangal, DustinmarielJohn Carl GuanlaoNo ratings yet

- Ceb 1393Document5 pagesCeb 1393turboshaftNo ratings yet

- Sabroe CMO Maintenance ScheduleDocument3 pagesSabroe CMO Maintenance ScheduleOprea MariusNo ratings yet

- Fuels & Combustion Technology (Major Elective Û I) (Chemical Group)Document2 pagesFuels & Combustion Technology (Major Elective Û I) (Chemical Group)raumil123759033% (3)

- Hoffmann Crump HocottDocument10 pagesHoffmann Crump HocottAzliyama Md ZainuddinNo ratings yet

- Liquid Fuel Systempdf PDFDocument23 pagesLiquid Fuel Systempdf PDFajo zinzoNo ratings yet