Professional Documents

Culture Documents

Man 18v48 60ts

Uploaded by

Ujank ArtchOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Man 18v48 60ts

Uploaded by

Ujank ArtchCopyright:

Available Formats

MAN 18V48/60TS

Two-stage turbocharged diesel engine

MAN Diesel & Turbo

Powering the world – responsibly

MAN Diesel & Turbo is the world’s leading provider of large-bore diesel engines

and turbomachinery. Our product portfolio includes two-stroke and four-stroke en-

gines for marine and stationary applications, turbochargers and propellers, as well

as gas and steam turbines, compressors and chemical reactors.

MAN solutions can be found in ship propulsion, engine-based power plants and

turbomachinery trains for the oil & gas and process industries. We support our

global customers with a comprehensive range of after-sales services under the

MAN PrimeServ brand.

MAN Diesel & Turbo has always been committed to increasing fuel efficiency and

reducing emissions. Today, this commitment ensures that our customers are able

to meet increasingly strict emissions regulations and plays a vital role in reducing

the environmental impact of global trade and industry.

MAN 18V48/60TS – Two-stage turbocharged diesel engine 3

The Best in its Class

MAN 18V48/60TS

Two turbochargers in sequence provide a new dimension in engine performance

and operational flexibility. A wide load range from 1,050 to 1,200 kW/per cylinder,

a specific fuel oil consumption of 7323 kJ/kWh at 1,050 kW/cyl. and reduced NOX

emissions set a new benchmark for four stroke diesel engines.

Turbochargers from MAN Diesel & Turbo a limited pressure ratio. A specially designed com-

Turbochargers are the core of this innovative new con- pressor, as in the TCA88/RCF23, can increase the

cept – and MAN Diesel & Turbo is the only engine pressure ratio – but also has the effect of decreasing

manufacturer that also designs and builds turbo- efficiency. The only solution to this dilemma is two-

chargers. This unique expertise translates into excep- stage turbocharging.

tional efficiency and reliability.

The MAN 18V48/60TS deploys MAN Diesel & Turbo’s

Two-stage turbocharging tried and tested TCA88 and TCA77 standard turbo-

The idea is simple: just place two of MAN’s most effi- chargers in sequence. The TCA88 is located up-

cient turbochargers upstream from the engine, one stream and provides the low pressure turbocharger,

after the other. The result: the engine gets twice the while the TCA77 forms the high pressure turbocharg-

charge air pressure, while turbocharger efficiency is er, next to the engine. In this configuration, both tur-

increased significantly. bochargers can achieve pressure ratios over 6 bars

and efficiencies of more than 76 percent.

A single turbocharger, such as MAN Diesel & Turbo’s

well known TCA88, is highly efficient; however, it has

4 MAN 18V48/60TS – Two-stage turbocharged diesel engine

A New Dimension

Ultimate power

The diesel engine MAN 18V48/60TS For the two-stage turbocharged MAN 18V48/60TS,

The MAN 48/60 type diesel engine is a perfect exam- only a few modifications were made to the standard

ple of proven technology and robust design. Over engine:

800 units have been sold since the product was

launched in 1988. They are now operating in a range Adapted fuel injection nozzles

of applications in power generation and marine pro- Three-ring piston with higher compression ratio

pulsion. Thanks to its high efficiency, the 18 cylinder Modified camshaft for enhanced Miller timing

engine is the MAN 48/60 engine family’s best-selling Additional charge air bypass valve for low smoke

configuration. emissions during engine start up

Comparison two-stage (MAN 48/60TS) – one-stage turbo charging (MAN 48/60B)

78

MAN 48/60TS (TCA88 + TCA77)

TC efficiency tot-tot [%]

76

74

72

MAN 48/60B (TCA88)

70

68

66

64

1 1,5 2 2,5 3 3,5 4 4,5 5 5,5 6

Pressure ratio

MAN 18V48/60TS – Two-stage turbocharged diesel engine 5

Standard Components, Proven Design

Low pressure Turbocharger

Low pressure Turbocharger

Standard components, proven design Lowest fuel oil consumption or NOx emissions

The overall design of the two-stage turbocharged The excess combustion air from the turbochargers

MAN 18V48/60TS has been kept as simple as possi- provides greater operational flexibility. The high charge

ble. Apart from the modifications described above, air pressure can be used for enhanced Miller Cycling,

the engine is standard, with the high pressure turbo- delivering significant fuel savings and further reducing

charger directly mounted to it. NOx emissions.

The low pressure turbocharger is located upstream As a result, the MAN 18V48/60TS diesel engine’s

from the engine, on its own steel frame. The combus- extremely low specific fuel oil consumption of only

tion air and exhaust gas piping between both turbo- 7323 kJ/kWh makes it the most cost-effective in its

chargers is fitted with compensators, ensuring com- class.

plete insulation from vibrations.

Alternatively, the excess combustion air can be lev-

An air blower is situated below the steel frame of the eraged to significantly increase the engine’s power

low pressure turbocharger. Active during engine start- output, up to 1,200 kW/cylinder. Although this does

up and low part-load operation (up to 25 percent not save as much fuel, it does allow for a greater re-

load), it cares for low smoke emissions even during duction of NOx emissions within a wide operation

these operation phases. range. NOx emissions of 1,850 mg/Nm³ down to

1,480 mg/Nm³ make the MAN 18V48/60TS the clean-

est diesel engine in its power range.

6 MAN 18V48/60TS – Two-stage turbocharged diesel engine

Two-stage turbocharging is a modular system: its de- Effects of Two-Stage Turbocharging

sign enables most MAN Diesel & Turbo power plants 1,200

Power output kW/Cyl.

1,200

to be retrofitted with this solution.

1,150

1,100

1,100

Flexibility in fuels, flexibility in operations 1,050

1,050

1,000

Like the MAN 48/60 series standard engines the two-

stage turbocharged MAN 18V48/60TS can be oper- Op. mode 1 2 3

ated with a wide range of different fuels:

1,850

1,850

1,800

NOx mg/Nm3 @15%O2

Heavy fuel oils with a viscosity up to 700 cst

1,750

Marine diesel oil 1,740

1,700

Gas oil

1,650

1,600

Due to the unique features of two-stage turbocharging,

1,550

the MAN 18V48/60TS can be operated continuously

1,500

at shaft power outputs from 18,900 up to 21,600 kW. 1,480

For example, this allows power producers to operate Op. mode 1 2 3

the engines at a normal load of 18,900 kW – taking

7,400

Fuel consumption

advantage of the extremely low fuel oil consumption 7,379

7,375 7,366

and giving them the possibility of a spinning reserve

kJ/kWh

7,350

up to 21,600 kW. 7,323

7,325

7,300

MAN 18V48/60TS – Two-stage turbocharged diesel engine 7

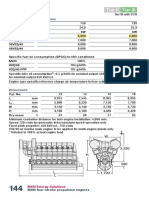

MAN 18V48/60TS Technical Data

Output, dimensions and weight

A B

C W

MAN 48/60TS

Bore 480 mm, stroke 600 mm 18V

Operational setup 1 2 3

Engine speed rpm 500 / 514 500 / 514 500 / 514

Frequency Hz 50 / 60 50 / 60 50 / 60

Electrical Genset power kWe 18,654 19,543 21,319

Electr. Genset heat rate at 100% load and efficiency 18V

World Bank 2007 / 2008 kJ/kWhe 7,419 7,463 7,678

Nominal generator efficiency: 98,7%; without pumps; 5% tolerance

Lube oil consumption kg / h 9.5 9.9 10.8

Tolerance: +20%

Dimensions

Genset A B C W H

dry mass (t) (mm) (mm) (mm) (mm) (mm)

407 13,148 5,410 24,510 4,700 9,023

Weights and dimensions are subject to final application

8 MAN 18V48/60TS – Two-stage turbocharged diesel engine

Engine type: MAN 18V48/60TS Reference conditions according

ISO 3046-1: 2002

Engine cycle: four-stroke

Turbocharging system: 2-stage, constant pressure The stated consumption figures refer to:

Low pressure TC type: MAN TCA88

High pressure TC type: MAN TCA77 Ambient air pressure: 1,000 mbar

Relative humidity: 30%

Number of cylinders: 18 Ambient air temperature: +25 °C (77 °F)

Bore: 480 mm Charge air temperature:

Stroke: 600 mm According to engine type, corresponding to 25 °C

Swept volume per cyl.: 108.6 dm³ cooling water temperature before charge air cooler

Engine speed 50/60Hz: 500 / 514 rpm

Mean piston speed: 10.0 / 10.3 m/s Abbreviations:

TC Turbocharger

Cooling: HP High pressure

Cylinder cooling: HT cooling water LP Low pressure

LP-TC charge air cooler: 2-stage HT and LT cooling water HT High temperature

HP-TC charge air cooler: 2-stage HT and LT cooling water LT Low temperature

Starting method: compressed air with

blower for low part load

operation up to 25% load

World-Class Service

Marine propulsion, gensets, and stationary plants

The PrimeServ offering PrimeServ’s aim is to provide:

The MAN Diesel & Turbo Group offers worldwide, Prompt delivery of high-demand OEM spare parts

round-the-clock service, 365 days a year. In addition within 24 hours

to MAN Diesel & Turbo’s service headquarters in Fast, reliable and competent customer support

Augsburg, Copenhagen, Frederikshavn, Saint-Nazaire, Individually tailored O&M contracts

Hamburg and Stockport, service centers on all contin Ongoing training and qualification of operators

ents provide comprehensive and continuous support. and maintenance staff

Global service, 24 hours a day,

MAN Diesel & Turbo engines are renowned for their 365 days a year

quality and durability. We are a global organization Diagnosis and troubleshooting with our high-

with a strong local presence, delivering exceptional performance Online Service

field service management, tailor-made solutions, and

first-class technical support.

PrimeServ provides advice and assistance to custom-

ers throughout the product life cycle, from delivery to

resale. With our far-reaching network of service centers,

we respond rapidly to customer needs. Furthermore,

we offer outstanding service and unrivalled technical

expertise. Plus, we only use genuine spare parts

– safeguarding the longevity of your engine.

10 MAN 18V48/60TS – Two-stage turbocharged diesel engine

All data provided in this document is non-binding. This data serves informational

purposes only and is not guaranteed in any way. Depending on the subsequent

specific individual projects, the relevant data may be subject to changes and will

be assessed and determined individually for each project. This will depend on

the particular characteristics of each individual project, especially

specific site and operational conditions. Copyright © MAN Diesel & Turbo.

D2366483EN-N4 Printed in Germany GGKMS-AUG-05161

MAN Diesel & Turbo

86224 Augsburg, Germany

Phone +49 821 322-3897

Fax +49 821 322-1460

powerplant@mandieselturbo.com

powerplants.man.eu

MAN Diesel & Turbo – a member of the MAN Group

You might also like

- 5160DF PowerDocument7 pages5160DF PowerPankaj Kamble100% (1)

- Wartsila O E RT82Document24 pagesWartsila O E RT82Gennadiy Kovalyov100% (1)

- Four-Stroke Diesel EngineDocument12 pagesFour-Stroke Diesel EnginedarioNo ratings yet

- Speed R/min Mep Bar KW KW 12V32/40 14V32/40 16V32/40 18V32/40 Specific Fuel Oil Consumption (SFOC) To ISO Conditions MCR V32/40 V32/40 FPPDocument1 pageSpeed R/min Mep Bar KW KW 12V32/40 14V32/40 16V32/40 18V32/40 Specific Fuel Oil Consumption (SFOC) To ISO Conditions MCR V32/40 V32/40 FPPghostt123No ratings yet

- D2842 Heavy DutyDocument4 pagesD2842 Heavy Dutym_najman100% (2)

- Marine Machi-Nery: Company ProfileDocument15 pagesMarine Machi-Nery: Company Profilenavy4No ratings yet

- Man BWDocument24 pagesMan BWDhanie KhruxzNo ratings yet

- Three Phase Synchronous Motor Features and SpecificationsDocument25 pagesThree Phase Synchronous Motor Features and Specificationsjcpp_18No ratings yet

- CUMMINS QSK19-DM SPECSDocument2 pagesCUMMINS QSK19-DM SPECSSoumya Ranjan Nayak100% (2)

- Marine Machinery & Engine: 1-1, Akunoura-Machi, Nagasaki, 850-8610, Japan Tel. +81-95-828-6970Document56 pagesMarine Machinery & Engine: 1-1, Akunoura-Machi, Nagasaki, 850-8610, Japan Tel. +81-95-828-6970Yanyan2009No ratings yet

- Shell Mysella S7 N Ultra 40: Performance, Features & BenefitsDocument2 pagesShell Mysella S7 N Ultra 40: Performance, Features & BenefitsMudabbir Shan AhmedNo ratings yet

- PIM130B1 - Daihatsu DT Series Archived JUN PDFDocument5 pagesPIM130B1 - Daihatsu DT Series Archived JUN PDFAnonymous XGsiY6rNo ratings yet

- ET13 ManualDocument21 pagesET13 ManualDaniel Ricardo Quintero SuavitaNo ratings yet

- Wartsila 20121 PDFDocument53 pagesWartsila 20121 PDFDan Alin Mircea100% (1)

- Mtu MT 881Document2 pagesMtu MT 881AndrewScotson100% (1)

- Cummins Kta38 M: Unit Injector Low RPM High Torque Heat Exchanger or Keel CoolingDocument2 pagesCummins Kta38 M: Unit Injector Low RPM High Torque Heat Exchanger or Keel CoolingMuhammad rizkiNo ratings yet

- Man 32-44CRDocument3 pagesMan 32-44CRturkertalayman1660No ratings yet

- 1 3 Diesel Emissions 2018 PDFDocument45 pages1 3 Diesel Emissions 2018 PDFJCA100% (1)

- Marine Axial Flow Fans GuideDocument58 pagesMarine Axial Flow Fans GuideDinesh Pillai100% (1)

- GI Sacos One Scope-Of-supply en 1.2Document2 pagesGI Sacos One Scope-Of-supply en 1.2Zizhang GuoNo ratings yet

- Maintenance ScheduleDocument22 pagesMaintenance ScheduleDen100% (2)

- Jenbacher: 1000-0099C Procedure For Testing Plant-Specific Oil Service LifeDocument3 pagesJenbacher: 1000-0099C Procedure For Testing Plant-Specific Oil Service LifeArîf100% (1)

- Himsen DG Catalog PDFDocument17 pagesHimsen DG Catalog PDFairtupasNo ratings yet

- MAN marine medium duty enginesDocument4 pagesMAN marine medium duty enginesKost KurniaNo ratings yet

- Tug Takes Limelight in Haifa: /pages 8-9Document12 pagesTug Takes Limelight in Haifa: /pages 8-9Kamal WanniarachchiNo ratings yet

- Datasheet Lm6000Document2 pagesDatasheet Lm6000zicko08No ratings yet

- Fuel Oil Specification For WÄRTSILÄ 32, Vasa 32 and 32LN EnginesDocument9 pagesFuel Oil Specification For WÄRTSILÄ 32, Vasa 32 and 32LN EnginesmohamedNo ratings yet

- 18V38A Instructions For Alignment of Flexible Mounted Engines PDFDocument7 pages18V38A Instructions For Alignment of Flexible Mounted Engines PDFRonald Bienemi100% (1)

- Power Plant EnginesDocument3 pagesPower Plant EnginesManuel Armando Salazar BravoNo ratings yet

- Tad730ge 111797s01Document8 pagesTad730ge 111797s01roozbehxoxNo ratings yet

- VTA Project GuideDocument39 pagesVTA Project GuideTapas ChaudhuriNo ratings yet

- MI - 1752 Rev MDocument16 pagesMI - 1752 Rev MSudarshan Dhumal100% (2)

- G Type EnginesDocument16 pagesG Type Enginespavlo_790317697No ratings yet

- Wartsila 18V34SGDocument392 pagesWartsila 18V34SGironiteNo ratings yet

- DPI - June 16Document76 pagesDPI - June 16Ratnin PanityingNo ratings yet

- Iso 8178.4.2007Document29 pagesIso 8178.4.2007camargohernandoNo ratings yet

- Recent Development in Marine EnginesDocument81 pagesRecent Development in Marine EnginesShashidhar ChandraiahNo ratings yet

- Man-Es l3 Man L48-60cr-Propulsion PreviewDocument2 pagesMan-Es l3 Man L48-60cr-Propulsion PreviewPiotrNo ratings yet

- Ge10 1Document4 pagesGe10 1Groover Contreras100% (2)

- Product Catalogue: Lubricants For Cars and TrucksDocument17 pagesProduct Catalogue: Lubricants For Cars and TrucksceljkoNo ratings yet

- ASTM D975 Specification TestDocument4 pagesASTM D975 Specification TestJaques ValleNo ratings yet

- Renk Planetary Gears Type Pls PwsDocument8 pagesRenk Planetary Gears Type Pls Pwshumayun121No ratings yet

- Wingd Low Speed Engines Booklet 2017Document39 pagesWingd Low Speed Engines Booklet 2017mohd badri bahari100% (1)

- WFI0032 DF Conversion PresentationDocument36 pagesWFI0032 DF Conversion PresentationDesri TandiNo ratings yet

- Ue60ls IiDocument5 pagesUe60ls IiHaziq IsmailNo ratings yet

- Wartsila O E W 38 TRDocument12 pagesWartsila O E W 38 TRbunguiaoNo ratings yet

- STX-MAN B&W 32/40 Power Plant SpecsDocument1 pageSTX-MAN B&W 32/40 Power Plant SpecsTen ApolinarioNo ratings yet

- May Phat Dien Cummins C275D5 (6CTAA8.9G2)Document1 pageMay Phat Dien Cummins C275D5 (6CTAA8.9G2)Long StevenNo ratings yet

- Abbtc Bro1100 Our RangeDocument15 pagesAbbtc Bro1100 Our RangearesobscureNo ratings yet

- Manual GeislingerDocument36 pagesManual GeislingerEge CNo ratings yet

- 7S60ME-C8.5 - 105.0 - RPM - 14400 - KW - HL Full ReportDocument10 pages7S60ME-C8.5 - 105.0 - RPM - 14400 - KW - HL Full ReportAnonymous dUXvWL61No ratings yet

- 1000-0099B enDocument3 pages1000-0099B enMuhammad Ishfaq100% (2)

- Operating Instruction ASL 94Document291 pagesOperating Instruction ASL 94Bayanaka Tehnik100% (1)

- Scania Technical Data - Issue-13Document51 pagesScania Technical Data - Issue-13kman548No ratings yet

- Brochure 60HzDocument24 pagesBrochure 60HzVicki AvolaNo ratings yet

- Catalogo de Pilas BulltronicDocument110 pagesCatalogo de Pilas Bulltroniccristobal_tl2277No ratings yet

- Series 60 Spec Sheet CollectionDocument6 pagesSeries 60 Spec Sheet CollectionAngel NaranjoNo ratings yet

- 18V46-60TS Brochure 1Document12 pages18V46-60TS Brochure 1Mohamed FahemNo ratings yet

- 18v48 60ts PDFDocument7 pages18v48 60ts PDFDaniel Ross FernandezNo ratings yet

- Fsae Turbo 430cc Inline TwinDocument15 pagesFsae Turbo 430cc Inline TwinmohsihummerNo ratings yet

- 2016-0629 Callisto Tower 1 - Project Presentation PDFDocument90 pages2016-0629 Callisto Tower 1 - Project Presentation PDFShop HereNo ratings yet

- Marine Engine Specifications GuideDocument22 pagesMarine Engine Specifications Guideoleg7962100% (1)

- Japanese Reports Electrical Fire CausesDocument55 pagesJapanese Reports Electrical Fire Causesal bauerNo ratings yet

- Engine With Mounting and EquipmentDocument141 pagesEngine With Mounting and EquipmentChiman100% (6)

- DX100 controller service manual alarm listDocument582 pagesDX100 controller service manual alarm listIsmael50% (2)

- Getting Started With Indexed 4TH Axis MillingDocument17 pagesGetting Started With Indexed 4TH Axis MillingMohamed IbrahimNo ratings yet

- The Role of Modularity in Sustainable Design - A Systematic ReviewDocument14 pagesThe Role of Modularity in Sustainable Design - A Systematic ReviewAlejandra QuintinNo ratings yet

- Agricultural Structures 2019Document71 pagesAgricultural Structures 2019Rabson NjaravavaniNo ratings yet

- M14 Spring GuidesDocument4 pagesM14 Spring Guideswatch_sutNo ratings yet

- DeaeratorDocument4 pagesDeaeratorAnonymous NFoZJKYNo ratings yet

- 420-030 PDFDocument10 pages420-030 PDFbel duranNo ratings yet

- JED Magazine 2011-06Document85 pagesJED Magazine 2011-06Park Sung100% (1)

- Service Manual: Color Television Chassis No. SN-81Document2 pagesService Manual: Color Television Chassis No. SN-81Manuel SierraNo ratings yet

- Raymond 7000 SeriesDocument26 pagesRaymond 7000 SeriesFrancisco BastidasNo ratings yet

- Comparison Test Report of PVC Packing Tape & Weight CalculationDocument3 pagesComparison Test Report of PVC Packing Tape & Weight CalculationjamilNo ratings yet

- BOBCAT Attachment Catalogue 2016 PDFDocument204 pagesBOBCAT Attachment Catalogue 2016 PDFGrecu Vali50% (2)

- The Bottom Up Refining Revolution Part4 PDFDocument1 pageThe Bottom Up Refining Revolution Part4 PDFOscar ViverosNo ratings yet

- Condition Echo Blueshift: Computational DemonologyDocument1 pageCondition Echo Blueshift: Computational DemonologyMandraw KayleNo ratings yet

- Arizona Engineer Fall 2006Document20 pagesArizona Engineer Fall 2006UA College of Engineering100% (1)

- 4206 PtoDocument3 pages4206 PtoHaidar Chandu100% (1)

- M3 - Alfa LavalDocument2 pagesM3 - Alfa Lavaljuan atahuaNo ratings yet

- Flexseal Expandible CementDocument2 pagesFlexseal Expandible CementAbd EnnacerNo ratings yet

- Lincoln Ranger 225Document6 pagesLincoln Ranger 225fdpc1987No ratings yet

- PC500LC 8RDocument20 pagesPC500LC 8RSabahNo ratings yet

- Epson R200, R210 Visão ExplodidaDocument8 pagesEpson R200, R210 Visão ExplodidaKedinaldoNo ratings yet

- Key Changes For 2017 BPVCDocument56 pagesKey Changes For 2017 BPVCJeganeswaranNo ratings yet

- Nasa TRL PDFDocument1 pageNasa TRL PDFDuddy EffNo ratings yet

- Lambda Americas Inc. power supply derating curvesDocument2 pagesLambda Americas Inc. power supply derating curvesnithinsmathew2004No ratings yet

- Geofoam Applications & Technical Data: Expanded Polystyrene (EPS)Document36 pagesGeofoam Applications & Technical Data: Expanded Polystyrene (EPS)eiudkNo ratings yet

- LR Sa Alna2 3 Trainingrev00Document282 pagesLR Sa Alna2 3 Trainingrev00Riders Rough67% (3)