Professional Documents

Culture Documents

528 410 Falk True Torque Type HF41, HF42, Sizes 185 420, 1420 Fluid Couplings Installation Manual

Uploaded by

rpazbOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

528 410 Falk True Torque Type HF41, HF42, Sizes 185 420, 1420 Fluid Couplings Installation Manual

Uploaded by

rpazbCopyright:

Available Formats

Falk™ Fluid Couplings • Installation & Maintenance Instructions

Sizes 185 thru 420 & 1420 • Types HF41 & 42 (Page 1 of 6)

How to Use This Manual ORANGE LABEL PERIMETER

FASTENERS

This manual applies to standard Falk Types HF41 & 42 couplings. FUSIBLE

FILL PLUG

Sizes 185 thru 370 utilize a QD type sheave (by purchaser). 392°F(200°C)

The sheave adapter is furnished and assembled at the Factory. (DRAIN PLUG ON

FACE FOR

The collet, sheave fasteners, draw bolt and washers are SIZE 320) SHEAVE

furnished unassembled. FASTENERS

Sizes 420 and 1420 utilize an integral sheave that is

manufactured and assembled at the Factory.

Table of Contents

General Information . . . . . . . . . . . . . . . . . . . . . . . . . Pages 1

Fluids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 1-2 SHEAVE (OUTPUT)

ADAPTER

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pages 2-4

COLLET

Orifice Plugs (1420HFD only) . . . . . . . . . . . . . . . . . . . Page 5 (INPUT)

Fusible Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 5 DELAY FILL

CHAMBER

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 5

Startup and Trouble Shooting . . . . . . . . . . . . . . . . . . . Page 6

FUSIBLE

Fluid Coupling Data Record . . . . . . . . . . . . . . . . . . . . Page 6 DRAIN

(FILL PLUG FOR

SIZE 320) PLUG

CAREFULLY FOLLOW THE INSTRUCTIONS IN THIS 284°F (140°C) COLLET

Figure 1

MANUAL FOR OPTIMUM PERFORMANCE AND TROUBLE DRAW BOLT

FREE SERVICE.

Identification:

Coupling size and M.O. Number (Mfg Order Number) are

Introduction stamped on the perimeter of the coupling. Where Rexnord has

Type HF fluid couplings are designed for horizontal and level been provided application data (HP, speed, start factor, driven

operation. Refer to the Factory for coupling operation other equipment), the coupling will also include an orange label on the

than horizontal. The Type HF41 coupling is designed for perimeter, indicating the approximate fill quantity in fluid ounces,

mounting on the driving shaft and the Type HF42 coupling is and the correct fill angle. Provide coupling size and M.O. number

designed for mounting on the driven shaft. Internal when ordering spare parts.

construction of these couplings are different and their

mounting positions are NOT interchangeable.

Each fluid coupling is shipped from the Factory with an angle Keep Records for Future Reference

finder (P/N 1224653). Simply place the angle finder on the filler Future maintenance of the fluid coupling can be greatly

plug boss and rotate the coupling to the required fill angle as simplified by keeping good records. It is strongly suggested

instructed in the “Fill Fluid Coupling” section of these instructions. that the Fluid Coupling Data Record, Table 6, be completed

and stored in the maintenance files.

Maximize Performance & Life

The performance and life of couplings depend largely upon Fluids

how you install and maintain them. Before installing couplings, The following specifications and fluids listed in Table 1 apply to

make certain that foundations of equipment to be connected Falk fluid couplings. Refer to the Factory for use of fire resistant

meet manufacturers’ requirements. Check for soft foot. The fluids. NOTE: Fluids listed are typical products ONLY and should

use of stainless steel shims is recommended. not be construed as exclusive recommendations.

WARNING: Lock out power source and remove external loads ISO Viscosity Grade, Petroleum Oils (R & O) . . . . . 46

from drive before servicing drive or accessories. ISO Viscosity Grade, Synthetic Oils . . . . . . . . . . 32

WARNING: When opening the drain plug, filler plug, or Viscosity at 104°F(40°C) — 46 cSt (215 SSU)

metering orifice access plug of a warm or hot fluid coupling, Viscosity Index — Equal to or greater than 95.

place a rag over the drain or filler plug hole and loosen the plug Pour Point — Must be 5°F(3°C) lower than minimum

slowly to relieve any internal pressure. starting temperature.

WARNING: Consult applicable local and national safety codes Flash Point — 400°F(204°C) when using 140°C and/or

for proper guarding of rotating members. Guard must not 180°C fusible plugs.

restrict free flow of air, but the portion of the guard in line with Flash Point — 425°F (218°C) when using 200°C fusible

fusible plugs must be solid construction. plugs at both fill and drain holes.

CAUTION: DO NOT PAINT fluid coupling. Painting will Specific Gravity — 0.87

reduce fluid coupling thermal heat dissipation characteristics. Antioxidant and Anti-foaming Additives

CAUTION: DO NOT spray water on a hot fluid coupling, as

this may result in cracking of aluminum components.

Rexnord Industries, LLC, Coupling Group 528-410

5555 S. Moorland Rd., New Berlin, WI 53151-7953 USA Telephone: 262-796-4060 June 2006

Fax: 262-796-4064 e-mail: info@rexnord.com web: www.rexnord.com Supersedes 11-04

Installation & Maintenance Instructions • Falk™ Fluid Couplings

(Page 2 of 6) Types HF41 & 42 • Sizes 185 thru 420 & 1420

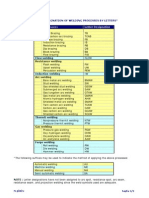

TABLE 1 — Fluids & Operating Temperatures WRENCH

FLATS

Petroleum Oils (R & O)

For Ambient Temperatures 20°F to 125°F (-6°C to 52°C)

Manufacturer Fluid

Amoco Oil Company American Industrial Oil 46

BP Oil Company Turbinol T-46

Chevron Products Company Hydraulic Oil AW 46

Exxon Company, USA Teresstic 46

Mobil Oil Corporation Mobil Fluid 424

Petro-Canada Products Harmony 46

Shell Oil Company Turbo T 46 Figure 2

Texaco Lubricants Company Rando Oil HD 46

76 Lubricants Company 76 Unax AW 46 Installation

Petroleum Oils (R & O) Only standard mechanics tools, torque wrenches, feeler gauges,

For Ambient Temperatures -20°F to 125°F (-28°C to 52°C) straight edges and a bevel protractor with spirit level or Angle

Manufacturer Fluid Finder (P/N 1224653) are required to install Falk fluid couplings.

Amoco Oil Company American Industrial Oil 46

Mobil Oil Corporation Mobilfluid 424

Synthetic Oils and Synthetic Transmission Fluids

1. Install Sheave

For Ambient Temperatures -40°F to 125°F (-40°C to 52°C) A. Check taper bore in sheave and taper fit on sheave

Manufacturer Fluid adapter for nicks or burrs.

Conoco Incorporated Syncon R&O 32 B. Clean surfaces with a non-flammable solvent.

Exxon Company, USA Teresstic SHP 32 C. Assemble sheave with furnished fasteners and lock

Mobil Oil Corporation SHC 624

Texaco Lubricants Company Pinnacle 32 washers, Figure 3. Tighten fasteners evenly to torque

specified in Table 2.

Mobil Oil Corp. Synthetic ATF

Chevron Synthetic All Weather THF

Citgo Transgard Fluid 250

2. Check Collet & Cut Off Key

Automatic Transmission Fluids (Dexron or Mercon Oils, etc.)

For Ambient Temperatures GreaterThan -40°F to 125°F (-40°C to 52°C) A. Lock out starting switch of prime mover.

NOTICE: Can only be used with two 140°C fusible plugs B. Check shaft, collet bore and taper fits for nicks and burrs.

Mobil Multi-purpose ATF C. Clean surfaces with a non-flammable solvent.

Texaco (Havoline) Mercon/Dexron-III or ATF

Citgo Transgard ATF,Type F D. For maximum collet shaft engagement, cut off key per

the following instructions:

Annual Maintenance Type HF41 — Cut motor shaft key to length specified in

An annual check of the coupling and fluid is recommended. For Table 2. NOTE: Maximum bore collets require customer

extreme or unusual operating conditions, or when the coupling is furnished rectangular keys. Dimensions for rectangular keys

subjected to overheating, check the coupling and fluid more are listed in Table 2.

frequently. Overheated fluid which becomes dark in color and Type HF42 — Assemble collet on driven shaft for

gives off a burnt odor must be changed. Fluid suppliers can test maximum engagement without key. Measure length of

coupling fluid samples periodically and recommend economical straight part of collet shaft keyway that is available and

change intervals based on the rate of degradation. Continuous cut key to that length.

operating temperature must not exceed 212°F (100°C).

Lifting

Install sheave as instructed in Step 1 and sling between coupling

and sheave using a complete wrap as shown in Figure 2.

CAUTION: Depending upon sheave size the balance will

change. Ensure proper balance before lifting.

Key Installation Tips

l

Do not exceed specified tightening torques for fusible

plugs at fill and drain holes (Step 6D). Excessive

tightening may strip aluminum threads.

l

Avoid excessive tensioning of V-Belts.

l

Carefully follow the instructions in this manual.

Figure 3

528-410 Rexnord Industries, LLC, Coupling Group

June 2006 5555 Moorland Rd., New Berlin, WI 53151-7953 USA Telephone: 262-796-4060

Supersedes 11-04 Fax: 262-796-4064 e-mail: info@rexnord.com web: www.rexnord.com

Falk™ Fluid Couplings • Installation & Maintenance Instructions

Sizes 185 thru 420 & 1420 • Types HF41 & 42 (Page 3 of 6)

C. Insert collet draw bolt with locking and flat washers

through hole in input shaft and thread into tapped hole

TABLE 2 — Collet/Sheave/Removal Bolt/ in collet (Figure 4).

Collet Key Information

(Dimensions – Inches) D. Hold input shaft using wrench flats illustrated in Figure

5, and tighten fastener to torque specified in Table 2.

Torque (lb-ft) Removal Collet Key – Type HF41

Cplg. Collet Bolt SE Motor Key Size

Size Sheave UNC (Min.)

Draw Shaft

Fasteners Dia x Lght Width Height Length

Bolt Size

1/2-13 .875 .187 .187 .875

185 5-6 9 2.00 .187

x 4.00 1.125 H .250 1.125

3/4-10 1.125 .250 .250 1.125

235 18-20 15 2.50

x 5.00 1.375 H .312 .250 1.250

1.125 .250 .250 1.125

7/8-9 1.375 .312 .312 1.375

270 32-35 30 2.50 .375 .375

x 3.75 1.625 1.625

1.875 H .500 .375 2.000

1.375 .312 .312 1.375

7/8-9 1.625 .375 .375 1.625

320 65-80 60 3.12 .500 .500

TORQUE

x 6.00 1.875 2.000 WRENCH

2.125 H .500 .375 2.000

1.625 .375 .375 1.625

1.875 .500 .500 2.000 Figure 5

370 130-145 60 1-8 3.75

x 6.50 2.125 .500 .500 2.000

2.375 H .625 .437 2.500

1.875 .500 .500 2.000

420 2.125 .500 .500 2.000

& 200-220 1 1/8-7 2.375 .625 .625 2.500

28 x 9.50 4.38

1420 2.875 .750 .750 3.000

3.375 H .875 .625 4.500

H Customer furnished rectangular key required with maximum bore collet.

3. Install Collet & Fluid Coupling

NOTE: Make certain belts will pass over coupling. If not,

place them on sheave before assembling.

A. Install cut off key in shaft keyway and slide collet on

shaft for maximum engagement. Minimum shaft

engagement (Dimension SE) is listed in Table 2.

B. Support fluid coupling weight and slide coupling onto

collet taper, being sure proper alignment and engagement

is obtained (Figure 4). Be sure collet and key have not

moved axially as this could cause the key to ride up the

shaft keyway end ramp and cause runout and vibration.

Continue to support fluid coupling through steps C & D.

Figure 6

4. Sheave Connection

A. Mount couplings and sheaves as close to drive or

motor housing as possible to avoid undue bearing

load or shaft deflection.

INSERT

DRAW BOLT CAUTION: Rotate sheave by hand to assure there is

Figure 4 enough clearance between sheave fasteners and driving

or driven equipment, Figure 6.

Rexnord Industries, LLC, Coupling Group 528-410

5555 S. Moorland Rd., New Berlin, WI 53151-7953 USA Telephone: 262-796-4060 June 2006

Fax: 262-796-4064 e-mail: info@rexnord.com web: www.rexnord.com Supersedes 11-04

Installation & Maintenance Instructions • Falk™ Fluid Couplings

(Page 4 of 6) Types HF41 & 42 • Sizes 185 thru 420 & 1420

B. Align sheaves square and parallel by placing a straight C. Slowly rotate fluid coupling until the required fill angle

edge across the face of the sheaves, Figure 7. is achieved, Figure 9. Fluid must appear at the lip of

the hole. Add or drain fluid until level is correct. Figure

10 shows fill angle example.

D. Reinstall fill plug with seal ring and tighten to required

torque: Sizes 185-270, 22 lb-ft; Sizes 320-420 and

1420, 33 lb-ft. DO NOT EXCEED SPECIFIED

SQUARE AND TIGHTENING TORQUE, as aluminum threads may

PARALLEL

Figure 7 strip.

C. Use matched belt sets to prevent belt whip and to

provide uniform tension. Adjust belt tension. The ideal

tension is the lowest tension at which the belt will not

slip under peak load conditions. Check the belt tension

frequently during the first 24 to 48 hours of run-in

operation. Over tightening belts will shorten belt and

bearing life. Avoid excessive tightening of the belts.

Keep belts free from foreign material which may cause Figure 9

slippage. Inspect the V-belt drive periodically;

re-tension the belts if they are slipping.

0°

5. Fill Fluid Coupling

E

0°

° GL

50 N

0° 0°

F A

A. Rotate fluid coupling until fill plug is on top and remove 50° GL

E

O ILL

AN0°

F

the fill plug. Both fill and drain plugs have metric L L

FI F 10

threads. Either plug may be used to fill coupling except O

for Size 320 which must use plug nearest sheave.

B. Fill with the required amount of fluid. Fill information is HIGH

found on the orange label that is affixed to the coupling LEVEL 100°

OF FILL LOW LEVEL

perimeter. Where no orange label is present, refer to OF FILL

fluid coupling Selection Guide 521-110 for fill data.

Fluid must meet the specifications listed in Table 1.

Do not remove orange fluid fill label that is affixed to the Figure 10

coupling perimeter. In cases where no orange label is

affixed, a blank label is furnished. Fill out the blank

orange label once proper fill data has been determined,

then affix that label to the coupling.

C. Before reinstalling fill plug, check fill angle as described

in the following step. Also, heed fill plug tightening

instructions, Step 6D.

6. Check Fill Angle

A. Refer to orange label described in the previous step for

required fill angle.

B. Use either an angle finder or a bevel protractor with

spirit level set for the required fill angle, and place it on

flat boss of filler hole as shown in Figure 8.

FILL ANGLE

Figure 8

528-410 Rexnord Industries, LLC, Coupling Group

June 2006 5555 Moorland Rd., New Berlin, WI 53151-7953 USA Telephone: 262-796-4060

Supersedes 11-04 Fax: 262-796-4064 e-mail: info@rexnord.com web: www.rexnord.com

Falk™ Fluid Couplings • Installation & Maintenance Instructions

Sizes 185 thru 420 & 1420 • Types HF41 & 42 (Page 5 of 6)

7. Size 1420HFD (orifice plugs) 8. Fusible Plugs

The Size 1420HFD fluid couplings contain three orifice plugs A. Fusible plugs in the fill or drain holes have solder cores that

(metric threaded) located near the outer part of the casing. They melt at the temperatures shown in Figure 1, Page 1. One

are located behind three metric hex socket seal plugs (see Figure extra 284°F (140°C) plug is furnished with each coupling.

11). The function of these orifice plugs is to meter the fluid exiting B. If solder in fusible plug melts due to overheating

from the delay fill chamber into the working circuit of the fluid

from stalling or overloading, refer to Table 5, Page

coupling. These plugs are initially drilled with a 2.5mm hole (Size

6 and correct the cause of overheating.

1420) which results in acceptable starting times for most

applications. Should your application require increased or reduced CAUTION: DO NOT replace fusible plugs with solid

starting times, refer to Table 3 below for other orifice hole sizes and plugs. Use of solid plugs can result in coupling failure

their estimated effect on starting time. These estimates are based on from overheating unless used in conjunction with a

the change in flow rate for the fluid to exit the delay fill chamber. proximity sensor cutout switch. Refer to Factory for

recommendation.

CAUTION: Increasing the starting time can result in overheating

the fluid coupling and discharging fluid via the fusible plugs. C. Replace fusible plugs as instructed in Step 6D. DO NOT

EXCEED SPECIFIED TIGHTENING TORQUES, as

Refer to Table 4 for orifice and seal plug sizes, tightening

aluminum threads may strip.

torques, and required hex “Allen” wrench sizes. DO NOT

EXCEED SPECIFIED TIGHTENING TORQUES, as aluminum D. Refill coupling with clean fluid as instructed in Steps 5 & 6.

threads may strip. Use an anti-seize compound such as

Loctite™AntiSeize Thread Compound #767 or equivalent on

orifice plugs to assist in future removal. 9. Coupling Removal

A. Lock out starting switch of prime mover.

B. Remove belts and support coupling with a sling as

ORIFICE PLUG

shown in Figure 2.

C. Loosen collet draw bolt until washers are free and

SEAL WASHER

complete one more turn. Sharply strike the bolt head to

break loose taper fit. If reasonable number of strikes are

unsuccessful, go to Step C. Notice: Use of Step C is

commonly required to remove size 420 & 1420 fluid

couplings. Excessive striking may damage shaft bearings.

SEAL

D. If Step B does not work; remove collet draw bolt and

PLUG refer to Table 2 for “Removal Bolt” dimensions. Insert

removal bolt and tighten. Strike bolt sharply with

hammer to break loose taper fit, Figure 12.

Figure 11

TABLE 3 — Fluid Coupling Starting Times

Estimated Starting Time - % of Original

Orifice Hole Diameter

1420HFD

3/64" (0.0469) 440

1/16" (0.0625) 250

5/64" (0.0781) 160

3/32" (0.0937) 110

2.5 mm (0.0984) 100

7/64" (0.1094) 80

1/8" (0.1250) 60

3.5 mm (0.1380) 50

5/32" (0.1562) 40

3/16" (0.1875) 30

TABLE 4 — Orifice Plug/Seal Plug/

Seal Washer Sizes

Orifice Plug Seal Plug

DIN906 DIN908 Seal Washer

CPLG DIN 7603

SIZE Thread Hex Key Tightening Thread Hex Key Tightening Type “A”

Torque Torque Copper

Size Size Size Size

Ft-lb Ft-lb

Figure 12

1420 1/8R BSPT 5 mm 7 18 x 1.5 mm 10 mm 33 18 x 22 x 1.5 mm

Rexnord Industries, LLC, Coupling Group 528-410

5555 S. Moorland Rd., New Berlin, WI 53151-7953 USA Telephone: 262-796-4060 June 2006

Fax: 262-796-4064 e-mail: info@rexnord.com web: www.rexnord.com Supersedes 11-04

Installation & Maintenance Instructions • Falk™ Fluid Couplings

(Page 6 of 6) Types HF41 & 42 • Sizes 185 thru 420 & 1420

TABLE 5 — Startup & Trouble Shooting

Problem Possible Cause Solution

Drive motor defective or Check motor connection, speed, amperage

incorrectly connected. draw and power draw.

Driven machine jammed. Check driven machine and remove jam.

Power consumption exceeds coupling H

Driven shaft fails to reach specified speed. capacity at specified fill angle.

Coupling over or under filled. Re-check fill angle per Step 6.

Correct source of leakage and re-check fill

Coupling leaking.

angle per Step 6.

1420HFD Only — Orifice plug hole plugged Clean orifice plug hole or use larger hole.

Coupling under filled. Re-check fill angle per Step 6.

Enlarge orifice hole size (See Table 3 for

1420HFD Only — Orifice plug hole too estimated start time reduction) or clean

small or plugged.

plugged hole.

Fusible plugs melt. Correct source of leakage and re-check fill

Coupling leaking.

angle per Step 6.

Driven machine jammed. Check driven machine and remove jam.

Power consumption exceeds coupling H

capacity at specified fill angle.

Re-install fluid coupling and collet per Step

Fluid coupling runout due to improper

assembly of collet and fluid coupling. 3. Check fluid coupling shaft for runout

near wrench flats.

Incorrect coupling or belt alignment. Re-align per instructions in service manual.

Coupling vibration exceeds acceptable limits.

Bent motor shaft. Replace motor.

Loose foundation, coupling or adapter fasteners. Check and tighten fasteners accordingly.

Return fluid coupling to Falk for bearing

Damaged fluid coupling bearing. replacement.

H Increase fluid fill by decreasing fill angle in 5° increments to a minimum of 50°. If drive shaft still does not reach specified speed, refer to the Factory.

TABLE 6 — Fluid Coupling Data Record (Installer – Fill out data below. Keep in coupling maintenance file)

Equipment Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor/Brake Hp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . @. . . . . . . . . . . Input RPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid Coupling Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fill Angle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Degrees. Fill Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fl. Oz.

Fluid Used (Mfg & Fluid Designation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Falk Master Order Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Date Installed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

528-410 Rexnord Industries, LLC, Coupling Group

June 2006 5555 Moorland Rd., New Berlin, WI 53151-7953 USA Telephone: 262-796-4060

Supersedes 11-04 Fax: 262-796-4064 e-mail: info@rexnord.com web: www.rexnord.com

You might also like

- How To Use This Manual: Sizes 370, 1420-1760/2760 Types HFD25 & HFDD25 (Page 1 of 6)Document6 pagesHow To Use This Manual: Sizes 370, 1420-1760/2760 Types HFD25 & HFDD25 (Page 1 of 6)jose_cruzNo ratings yet

- HF Couplings IM-ManualDocument6 pagesHF Couplings IM-ManualCancio FlorezNo ratings yet

- 163-130 - Falk Drive One Type DH3, Sizes M1130-M1210 Shaft Drives - Parts ManualDocument4 pages163-130 - Falk Drive One Type DH3, Sizes M1130-M1210 Shaft Drives - Parts ManualCagNo ratings yet

- 163 132 Falk Drive One Type DH3, Sizes M1220 M1250 Shaft Drives Parts ManualDocument4 pages163 132 Falk Drive One Type DH3, Sizes M1220 M1250 Shaft Drives Parts ManualLazzarus Az Gunawan100% (1)

- 163-120 - Falk Drive One Type DH2, Sizes M1130-M1210 Shaft Drives - Parts ManualDocument4 pages163-120 - Falk Drive One Type DH2, Sizes M1130-M1210 Shaft Drives - Parts ManualCagNo ratings yet

- 163-110 - Falk Drive One Type DHC1, Sizes M1130-M1190 Shaft Drives - Parts ManualDocument4 pages163-110 - Falk Drive One Type DHC1, Sizes M1130-M1190 Shaft Drives - Parts ManualCagNo ratings yet

- 163 332 Falk Drive One Type DB, Sizes M1120 M1250 Right Angle Shaft Conveyor Drives Parts ManualDocument4 pages163 332 Falk Drive One Type DB, Sizes M1120 M1250 Right Angle Shaft Conveyor Drives Parts ManualnoviyanthyNo ratings yet

- 1 - Manual Sutorbilt Legend 2-5, SB-7-621 V5 10-05Document42 pages1 - Manual Sutorbilt Legend 2-5, SB-7-621 V5 10-05Sandro Renteros LimaNo ratings yet

- Manual Rockford Fosgate RFR3110Document36 pagesManual Rockford Fosgate RFR3110Rafa SantosNo ratings yet

- Ingersoll Rand R37-45I IEDocument216 pagesIngersoll Rand R37-45I IELucas Garcia100% (1)

- Service Manual OK Toshiba Dvr80kfDocument123 pagesService Manual OK Toshiba Dvr80kfGfr FrnNo ratings yet

- Parts List Operating and Service Manual: LegendDocument49 pagesParts List Operating and Service Manual: LegendPlaneador MantenimientoNo ratings yet

- Ir Sd110 Instr Parts Manual 2 PDFDocument210 pagesIr Sd110 Instr Parts Manual 2 PDFLuis Manuel100% (3)

- Forcimat: Operating and Instructions ManualDocument12 pagesForcimat: Operating and Instructions ManualRohman AzizNo ratings yet

- 357 Series Control Valves (Obsolete Product)Document17 pages357 Series Control Valves (Obsolete Product)Yogurtu NngeNo ratings yet

- HPT Stage 1 Blades and Duct SegmentsDocument28 pagesHPT Stage 1 Blades and Duct SegmentsArabyAbdel Hamed SadekNo ratings yet

- Triplex Pump Model PZL, PZ-11Document28 pagesTriplex Pump Model PZL, PZ-11Wilson RiveraNo ratings yet

- D Series Installation&Maintenance PDFDocument56 pagesD Series Installation&Maintenance PDFPablo GarcíaNo ratings yet

- OMF383095_unlockedDocument160 pagesOMF383095_unlockedeliminar348No ratings yet

- 40RUM 50Hz IOM - tcm478-51384Document28 pages40RUM 50Hz IOM - tcm478-51384khaled salahNo ratings yet

- Disc Coupling Installation and Maintenance GuideDocument4 pagesDisc Coupling Installation and Maintenance Guidemarcelo castilloNo ratings yet

- LPHT312 Issue 2Document23 pagesLPHT312 Issue 2Mohammed Al-BayatiNo ratings yet

- Lafage & LafaieDocument17 pagesLafage & LafaiecathylorrainegalusNo ratings yet

- Parts List Operating and Service Manual: LegendDocument57 pagesParts List Operating and Service Manual: LegendAldo AlvarezNo ratings yet

- Parts List Operating and Service Manual: LegendDocument65 pagesParts List Operating and Service Manual: LegendAntonio CastroNo ratings yet

- CBA38MV Air Handler Maintenance ManualDocument59 pagesCBA38MV Air Handler Maintenance ManualmarkargentNo ratings yet

- FalkDocument4 pagesFalknoviyanthyNo ratings yet

- RFX 8220Document37 pagesRFX 8220Patrick Marc BrunelleNo ratings yet

- TGB Target 400 Service ManualDocument110 pagesTGB Target 400 Service ManualPiljek Matija100% (1)

- Punch p4004Document64 pagesPunch p4004Robert GonzálezNo ratings yet

- Model QRNG 340 Model QRNG 340 Model QRNG 340 Model QRNG 340 Model QRNG 340Document22 pagesModel QRNG 340 Model QRNG 340 Model QRNG 340 Model QRNG 340 Model QRNG 340roalcalo_uanNo ratings yet

- C5122Document12 pagesC5122apisituNo ratings yet

- RYCO Hydraulics Product Technical Manual RHY-RHC0707AUSDocument444 pagesRYCO Hydraulics Product Technical Manual RHY-RHC0707AUSAdiya PurevjavNo ratings yet

- TRSM0250 1007Document82 pagesTRSM0250 1007greasegrenade8468No ratings yet

- Carrete Serie 750Document16 pagesCarrete Serie 750JulioNo ratings yet

- Fisher 2052 Diaphragm Rotary Actuador PDFDocument20 pagesFisher 2052 Diaphragm Rotary Actuador PDFARMANDONo ratings yet

- ENVOY RAZOR-regulator-valve-service-manualDocument37 pagesENVOY RAZOR-regulator-valve-service-manualDon SheensNo ratings yet

- IRN37K–45K–OF Compressor Parts ManualDocument49 pagesIRN37K–45K–OF Compressor Parts Manualcherry vinesNo ratings yet

- Topworx DXP - Installation and ConfigurationDocument52 pagesTopworx DXP - Installation and ConfigurationJames Dawe100% (1)

- Parts List Operating and Service Manual: Blowers/Vacuum PumpsDocument55 pagesParts List Operating and Service Manual: Blowers/Vacuum PumpsEdinsonUribeTorresNo ratings yet

- Notice de Réparation RI9724 - 02 PDFDocument224 pagesNotice de Réparation RI9724 - 02 PDFBaciu NicolaeNo ratings yet

- Garco Drum Pump 307427EN-ZAADocument40 pagesGarco Drum Pump 307427EN-ZAATun Zaw TheinNo ratings yet

- INSTALLATION MANUAL TITLEDocument2 pagesINSTALLATION MANUAL TITLETTaanNo ratings yet

- Underwing Nozzles: Carter Ground FuelingDocument54 pagesUnderwing Nozzles: Carter Ground FuelingHenryNo ratings yet

- Falk V Class Type VP, Sizes 133 187 Shaft Drives Parts ManualDocument4 pagesFalk V Class Type VP, Sizes 133 187 Shaft Drives Parts ManualNils Ericsson Sánchez HuayanaNo ratings yet

- Terminais Reusáveis - PCT - 3234776Document68 pagesTerminais Reusáveis - PCT - 3234776Autieri AutieriNo ratings yet

- 50119-202Nov12Document30 pages50119-202Nov12josediazvensaludNo ratings yet

- PT 1968B MPD Parts ManualDocument28 pagesPT 1968B MPD Parts ManualBrandon CatronNo ratings yet

- Toshiba d-vr17kb SMDocument125 pagesToshiba d-vr17kb SMAlan JayceeNo ratings yet

- Ifs4000 - AquafluxDocument18 pagesIfs4000 - Aquafluxavikbhai100% (1)

- Advanced Hotplates, Stirrers, Hotplate-StirrersDocument17 pagesAdvanced Hotplates, Stirrers, Hotplate-StirrerswlarakcNo ratings yet

- Rotary Actuators, NAMUR Interface VDI - VDE 3845 & ISO 5211 (ATEX Certified) Series ARPDocument8 pagesRotary Actuators, NAMUR Interface VDI - VDE 3845 & ISO 5211 (ATEX Certified) Series ARPJhonata CavalcanteNo ratings yet

- ZF 9S1110-1310 Operation InstructionDocument6 pagesZF 9S1110-1310 Operation InstructionEsma KarabulutNo ratings yet

- Design 1018S Sliding-Stem Control ValveDocument24 pagesDesign 1018S Sliding-Stem Control ValveAmiroucheBenlakehalNo ratings yet

- V5032 Kombi-2-Plus: Double-Regulating Balancing ValveDocument12 pagesV5032 Kombi-2-Plus: Double-Regulating Balancing ValveDidik HariantoNo ratings yet

- SSR 125-200 Horsepower Parts List Recommended Spares 125-200 PTS '92Document40 pagesSSR 125-200 Horsepower Parts List Recommended Spares 125-200 PTS '92user100% (3)

- Del OI ERHARD Nozzle Check Valve DN80 600 enDocument18 pagesDel OI ERHARD Nozzle Check Valve DN80 600 enpppppp5No ratings yet

- Replacement Parts: Model FT4240 Close Circuit Track Mounted Impactor PlantDocument107 pagesReplacement Parts: Model FT4240 Close Circuit Track Mounted Impactor PlantEDWINNo ratings yet

- Fisher D4 Control Valve Assembly: Scope of ManualDocument24 pagesFisher D4 Control Valve Assembly: Scope of ManualJairo andres Guarnizo SuarezNo ratings yet

- Asce 14Th Tech Conf Computational ModelsDocument12 pagesAsce 14Th Tech Conf Computational ModelsrpazbNo ratings yet

- Civil Engineering - Bridge Design ManualDocument937 pagesCivil Engineering - Bridge Design ManualDeepali ChausalkarNo ratings yet

- Equipment PricesDocument3 pagesEquipment PricesrpazbNo ratings yet

- Slope Stabilization in Residual Soils of PeruDocument6 pagesSlope Stabilization in Residual Soils of PerurpazbNo ratings yet

- AASHTO Steel Bridge Erection Guide Specification Apr. 2004 DraftDocument23 pagesAASHTO Steel Bridge Erection Guide Specification Apr. 2004 DraftRoberto PazNo ratings yet

- Subsidence Due To Special Geological and Groundwater ConditionsDocument6 pagesSubsidence Due To Special Geological and Groundwater ConditionsrpazbNo ratings yet

- Asme Welding CodesDocument2 pagesAsme Welding CodesLuis Enrique Perfecto OchoaNo ratings yet

- Civil Engineering - Bridge Design ManualDocument937 pagesCivil Engineering - Bridge Design ManualDeepali ChausalkarNo ratings yet

- Civil Engineering - Bridge Design ManualDocument937 pagesCivil Engineering - Bridge Design ManualDeepali ChausalkarNo ratings yet

- Cost Estimating Guide For Road ConstructionDocument122 pagesCost Estimating Guide For Road ConstructionJose Maria100% (2)

- mc1696 PDFDocument4 pagesmc1696 PDFBala MuruganNo ratings yet

- 05-Standard Type Spring UnitsDocument4 pages05-Standard Type Spring UnitsrpazbNo ratings yet

- Seismic Soil PileDocument11 pagesSeismic Soil PilerpazbNo ratings yet

- Libro Cimentaciones CapDocument8 pagesLibro Cimentaciones CaprpazbNo ratings yet

- Enkei Catalog 2013Document32 pagesEnkei Catalog 2013Hakim 'n BilalNo ratings yet

- Enkei Catalog 2013Document32 pagesEnkei Catalog 2013Hakim 'n BilalNo ratings yet

- Plate GirderDocument11 pagesPlate GirderEzhil Kumar50% (2)

- Redacis42 ADocument10 pagesRedacis42 ArpazbNo ratings yet

- Andusia Alt FuelsDocument2 pagesAndusia Alt FuelsrpazbNo ratings yet

- Everything You Need To Know About The Chemistry of Kiln Feed and ClinkerDocument16 pagesEverything You Need To Know About The Chemistry of Kiln Feed and ClinkerrpazbNo ratings yet

- Drying RDF at SouselasDocument4 pagesDrying RDF at Souselasrpazb100% (1)

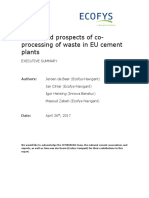

- EU cement plants boost waste recyclingDocument13 pagesEU cement plants boost waste recyclingrpazbNo ratings yet

- Compressed Air Filter SpecificationsDocument1 pageCompressed Air Filter SpecificationsrpazbNo ratings yet

- CSI Fuels and Raw MaterialsDocument38 pagesCSI Fuels and Raw MaterialsrpazbNo ratings yet

- The Use of Scrap Tires in Rotary Cement KilnsDocument9 pagesThe Use of Scrap Tires in Rotary Cement KilnsrpazbNo ratings yet

- Scale Factors and Paper Sizes ChartDocument1 pageScale Factors and Paper Sizes ChartrpazbNo ratings yet

- White Label Coprocessing in MoroccoDocument10 pagesWhite Label Coprocessing in MoroccorpazbNo ratings yet

- CSI Fuels and Raw MaterialsDocument38 pagesCSI Fuels and Raw MaterialsrpazbNo ratings yet

- Used To Do Vs Be Get Used To DoingDocument3 pagesUsed To Do Vs Be Get Used To DoingrpazbNo ratings yet

- Slide Gates Eng Guide BrochureDocument6 pagesSlide Gates Eng Guide Brochureraghunandanr1993No ratings yet

- Data Industri JabodetabekDocument669 pagesData Industri JabodetabekBudy Nugraha88% (24)

- Electro-mechanical broaching machine modelDocument16 pagesElectro-mechanical broaching machine modelStefanNo ratings yet

- Lec 6Document5 pagesLec 6Abderrahim HAMDAOUINo ratings yet

- BECE BDT Past Questions 2016Document9 pagesBECE BDT Past Questions 2016Anonymous lnC6IDg67% (3)

- pd10196 Tetra Alsafe PDFDocument2 pagespd10196 Tetra Alsafe PDFEusebio NavarroNo ratings yet

- Effects of On-Line Melt Blending of Polypropylene With Polyamide 6 On The Bulk and Strength of The Resulting BCF YarnDocument10 pagesEffects of On-Line Melt Blending of Polypropylene With Polyamide 6 On The Bulk and Strength of The Resulting BCF YarnianNo ratings yet

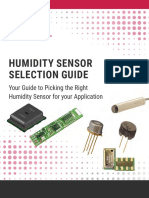

- Humidity Sensor SelectionDocument10 pagesHumidity Sensor Selectionmythri100% (1)

- Cable Selection Guide For Process InstrumentationDocument3 pagesCable Selection Guide For Process InstrumentationyoungfpNo ratings yet

- Inject Neutralizer To CDU OVHD Wash WaterDocument1 pageInject Neutralizer To CDU OVHD Wash WaterPhuong LeNo ratings yet

- Gas Chromatography Troubleshooting GuideDocument12 pagesGas Chromatography Troubleshooting GuideAbhishek Banerjee100% (1)

- G3516 LeDocument4 pagesG3516 Lericva_rj100% (3)

- DistillationDocument15 pagesDistillationRahul PalsNo ratings yet

- Properties and Changes of Matter Guided NotesDocument5 pagesProperties and Changes of Matter Guided Notesapi-337287913100% (1)

- Steel Coil AlignmentDocument1 pageSteel Coil AlignmentBalluff SensorsNo ratings yet

- Boqcomparativechart - 2023-05-27T100002.652Document10 pagesBoqcomparativechart - 2023-05-27T100002.652Abode ArtisanNo ratings yet

- Aibel PDF 18 Advanced MethodsDocument34 pagesAibel PDF 18 Advanced Methodsbaiju79No ratings yet

- Training Program - SudanDocument4 pagesTraining Program - SudanKhalid HafezNo ratings yet

- D-Erection Manual Vol.1 of 2 Maaden TCM A00226 Rev.0. 2011Document255 pagesD-Erection Manual Vol.1 of 2 Maaden TCM A00226 Rev.0. 2011ganesan 00110% (1)

- Waste Segregation Practices Among High School Students of Saint Michael College of CaragaDocument61 pagesWaste Segregation Practices Among High School Students of Saint Michael College of CaragaReinan Ezekiel Llagas100% (1)

- Swatch Case AnalysisDocument3 pagesSwatch Case Analysisgunjanbihani100% (1)

- AsphaltDocument182 pagesAsphaltEnd EndNo ratings yet

- PivsuexDocument7 pagesPivsuextthenryNo ratings yet

- Public Review Draft 2394Document82 pagesPublic Review Draft 2394Johan SetiawanNo ratings yet

- Rotho Peristaltic Pumps PDFDocument40 pagesRotho Peristaltic Pumps PDFxxxxxxxxxxxxNo ratings yet

- How to set out a circular building structureDocument5 pagesHow to set out a circular building structureAnania TashomeNo ratings yet

- Time: 03 Hours Maximum Marks: 100 Instructions To CandidatesDocument2 pagesTime: 03 Hours Maximum Marks: 100 Instructions To CandidatesMohammed ShamsuddinNo ratings yet

- Tute ProblemsDocument5 pagesTute Problemsralston204No ratings yet

- Impact of Covid-19 On The Automotive Industry: By: Raman ATUL (19109029) RohitDocument14 pagesImpact of Covid-19 On The Automotive Industry: By: Raman ATUL (19109029) RohitRaman BansalNo ratings yet

- 10 ElectrochemistryDocument77 pages10 ElectrochemistrySyamil Adzman100% (1)