Professional Documents

Culture Documents

Eddify Lyft Presentation Document

Uploaded by

Bernardo FariasCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eddify Lyft Presentation Document

Uploaded by

Bernardo FariasCopyright:

Available Formats

E D D Y F I LY F T

Pulsed Eddy Current Reinvented

PEC REINVENTED: CUI PROGRAMS REDEFINED

Corrosion under insulation (CUI), corrosion blistering and scabs, flow-accelerated corrosion (FAC), corrosion under

fireproofing (CUF), and corrosion under coatings are possibly the greatest unresolved asset integrity problems in the

industry. Current methods used to measure wall thickness over liftoff, without removing insulation, all have severe

limitations and existing pulsed eddy current (PEC) solutions rely on outdated technology. It’s time for evolution.

THE EVOLUTION OF PEC RELIABLE AND REPEATABLE RESULTS

Lyft is a high-performance solution reinventing PEC. The

®

The Lyft software is packed with automation and advanced

patent-pending Eddyfi® solution features: algorithms that remove operator-specific dependence, thanks

• State-of-the-art portable instrument to the power of SmartPULSE™ technology. It automatically

optimizes pulser and receiver parameters (gain, duration, time

• Standard pulsed eddy current array (PECA) technology

gates, filters, etc.). SmartPULSE also optimizes wall thickness

• Real-time C-scan imaging measurements, which ensures optimal performance and

• Fast data acquisition repeatability.

• Grid and dynamic scanning modes

THE BEST OF PEC MADE PORTABLE

Lyft can scan through thick metal and insulation, as well as

aluminum, stainless steel, and galvanized steel weather jackets. Lyft is sealed and designed for IP65. Its magnesium alloy casing

is tough, water and dust resistant, and cools without any

POWERFUL EMBEDDED SOFTWARE external air exchange. The adjustable stand, the top handle,

and four corner anchor points make it practical for on-site

The user-friendly multi-touch software includes several inspections. The embedded Windows® PC offers standard

innovative features, including real-time C-scan imaging, connect-anywhere capabilities and advanced productivity tools

complete wall thickness measurements (ID and OD corrosion), that optimize field testing. The premium-quality 26.4 cm (10.4 in)

as well as complete inspection management and reporting LED display is optically bonded, non-reflective, comes with

capabilities. 3 mm (1/8 in) strengthened glass, and is designed for gloved

Undersizing is a well-known phenomenon for PEC where defects hands, under any lighting conditions. The system also comes

smaller than a probe’s averaging area appear shallower than with two, hot-swappable batteries for extended autonomy.

they really are. The Lyft compensated wall thickness (CWT) tool

mitigates this phenomenon by more precisely quantifying the

minimum wall thickness of a specific region in a C-scan.

www.eddyfi.com/lyft

H e a v y- d u t y b u m p e r s ,

hooked for harnessing

Quick Copy: Transfer all

inspection files to USB at

the touch of a button

Powerful connectivity

10.4“, non-reflec tive, backlit,

h i g h-re s o l u ti o n m u l ti-to u c h

display

Protective doors

Battery life (typical):

6–8 hours

A NEW KIND OF PEC

Eddyfi has garnered R&D, a world-class portable instrument, software, sensors, and accessories, as well as

dedicated application engineers and support teams to transform PEC into a technique capable of achieving

its full potential. Who else but Eddyfi to reinvent an eddy current technique and redefine CUI programs?

OPTIMIZED PERFORMANCE FOR The patent-pending PEC-GS probe is dedicated to insulated

structures protected by galvanized steel weather jackets. The

WALL THICKNESS AND LIFTOFF

probe offers better signal penetration, detection capabilities

The Lyft solution includes several sizes of plug-and-play probes and sizing accuracy, and signal-to-noise ratio (SNR) compared

for the right balance between wall thickness and liftoff. to single-element PEC probes.

The 6-element PECA probe is capable of a single-pass coverage Details at www.eddyfi.com/pulsed-eddy-current-pec-probes/.

of 457 mm (18 in) in grid or high-resolution, dynamic mode. It

supports metal thicknesses 6–25 mm (0.25–1.00 in), insulation ANALYSIS AND REPORTING SOFTWARE

25–102 mm (1–4 in), and stainless steel / aluminum. Displaying

The Lyft Pro desktop software enables advanced Lyft data

C-scans has never been this fast, improving overall inspection

analysis through the same graphical user interface as the Lyft

productivity as much as 10 times.

software, making it easy to learn and benefiting from larger

The single-element PEC probe family supports metal thicknesses data layouts. Lyft Pro makes it easier to plan inspections for

up to 100 mm (4 in), insulation as thick as 300 mm (12 in), and several Lyft instruments — they can be out in the field acquiring

stainless steel / aluminum / galvanized steel weather jackets. data while analysts are hard at work extracting value from

The splash-zone and underwater probes enable tackling offshore acquired data. The software also has features to generate richer

applications with their rugged design — watertight down to 15 m reports and tools to bridge calibration parameters between

(49.2 ft) and 100 m (328 ft). scan zones.

The tank floor probe targets the in-service inspection of storage SurfacePro 3D is an advanced visualization and reporting

tank floor annular rings. Its super-thin 4.8 mm (0.2 in) titanium software designed to automatically create components and

blade enables the probe can slide up to 400 mm (16 in) under overlay stitched C-scan data.

tank floor edges.

GET EDDYFI CERTIFIED ANYWHERE

We are geared to offer PEC training: a blend of e-learning and

hands-on training at our offices or yours that will give you the

necessary knowledge and skills to efficiently use PEC when

inspecting assets.

Rugged, easy-to-use keypads

12-pin I/O connector

27-pin PEC connector

Rugged por table casing

designed for IP65

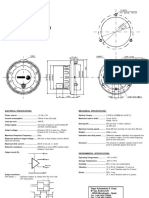

SPECIFICATIONS

INSTRUMENTS INSTRUMENTS (CONT.)

Dimensions (W×H×D) 355×288×127 mm (14.0×11.3×5.0 in) 26.4 cm (10.4 in)

Non-reflective (AR coating)

Weight With batteries 6.6 kg (14.5 lb) Anti-fingerprint (oleophobic coating)

Display

Volume 13 L (791 in3) 3 mm (1/8 in), chemically strengthened glass cover

Optically bonded LCD and touchscreen

Power requirements 100–240 VAC, 50–60 Hz Passive backlight enhancement

Power supply Direct VAC or onboard batteries Storage SSD, 100 GB

Type Li-ion, rechargeable, DOT compliant Cooling Sealed and fanless

Batteries

Typical life 6–8 hours Encoders 2 axes, quadrature (GDA model only)

Video output HDMI Gigabit Ethernet,Wi-Fi, Dual Mode Bluetooth® 2.1,

Connectivity

2.1+EDR, 3.0, 3.0+HS, 4.0 (BLE), USB 2.0 (×3)

Number of channels 6 (GD/GDA)

Probe recognition and setup Automatic

PERFORMANCE PERFORMANCE (CONT.)

Dynamic data acquisition Up to 15 points/s Automatic PEC pulser-receiver parameters config.

Full thickness sensitivity (OD and ID defects)

Dynamic scan speed Up to 75 mm/s (3 in/s) Reliable measurements with liftoff variations, weather jackets

SmartPULSE

Grid mapping scan speed Instant, less than 1 second (typical) overlaps, straps, corrosion scabs

1-point calibration (on nominal or known thickness),

auto-normalization, repeatability optimization

PROBES* PROBES (CONT.)

Remote control keypad Minimum measurable

15 % from nominal

Features Lyft 27-pin Fischer connector remaining wall thickness

Heavy-duty 5 m (16.4 ft) cable

Stainless steel up to 1.5 mm (0.06 in)

Nominal wall thickness Up to 100 mm (4 in) Weather jackets Aluminum up to 1 mm (0.04 in)

Galvanized steel up to 1.0 mm (0.04 in)

PECA-6CH-MED: 25–102 mm (1–4 in)

PEC-152-G2: 0–300 mm (0–12 in) Pipe diameters 25 mm (1 in) up to flat surfaces

Liftoffs

PEC-089-G2: 0–203 mm (0–8 in)

PEC-025-G2: 0–76 mm (0–3 in) Carbon steel: –150 –500 °C (–238 –932 °F)

Test temperatures Max. weather jacket, direct contact: 70 °C (158 °F)

Smallest detectable defect volume 15 % of footprint volume Max. weather jacket, probe shoe: 120 °C (248 °F)

ENVIRONMENTAL APPLICATION-SPECIFIC PROBES

IP rating Designed for IP65 Splash zone

Operating temperature 0–40 °C (32–104 °F) Available models Underwater

Operating humidity 95 %, non-condensing (Visit website for details) CUI under galvanized steel cladding

ASME, EN 61010-1, CE, WEEE, FCC Part 15B, Tank floor

Compliance

ICES-003, AS/NZS CISPR 22, RoHS

*Refer to the Understanding PEC Probe Selection and Footprint on www.eddyfi.com/lyft.

The information in this document is accurate as of its publication. Actual products may differ

from those presented herein.

©2018 Eddyfi NDT, Inc. Eddyfi, Lyft, SmartPULSE, and their associated logos are trademarks or

registered trademarks of Eddyfi NDT, Inc. in the United States and/or other countries.

Eddyfi Technologies reserves the right to change product offerings and specifications without

notice.

2018-10-03

www.eddyfi.com info@eddyfi.com

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- EMAT Probe Exploded ViewDocument1 pageEMAT Probe Exploded ViewBernardo FariasNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Electromagnatic Acostic Testing PDFDocument20 pagesElectromagnatic Acostic Testing PDFSenakeNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Pipeline Inspection Using EMATDocument5 pagesPipeline Inspection Using EMATBernardo FariasNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- BP Stats Review 2018 Full ReportDocument56 pagesBP Stats Review 2018 Full ReportLorena DominguezNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Track ListDocument1 pageTrack ListBernardo FariasNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Fluid Mechanics Lecture - HydrostaticsDocument15 pagesFluid Mechanics Lecture - HydrostaticsBernardo FariasNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Electromagnetic Generation of Ultrasonic Waves in Metals (Dobbs - 1970)Document11 pagesElectromagnetic Generation of Ultrasonic Waves in Metals (Dobbs - 1970)Bernardo FariasNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Eprom COP8SAB720N8 Central AlarmeDocument60 pagesEprom COP8SAB720N8 Central AlarmeSergio MarcioNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- NetworkingDocument38 pagesNetworkingSandhuSukhamNo ratings yet

- Types of Loudspeakers ExplainedDocument12 pagesTypes of Loudspeakers ExplainedPositive pKNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Electrical BtechDocument27 pagesElectrical BtechNikhil AnandNo ratings yet

- Ksha Khedekar - Bel Micro-ProjeectDocument15 pagesKsha Khedekar - Bel Micro-ProjeectKHEDEKAR HRUTUJANo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- ZTE LTE Random AccessDocument65 pagesZTE LTE Random AccessGauthier Toudjeu100% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Mobile PhonesDocument41 pagesMobile Phonesphilenius kalumu aNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- BOQ of Fire Alarm, PA 05-08-14Document5 pagesBOQ of Fire Alarm, PA 05-08-14abdullahNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- GIKI Students Develop Bluetooth Home Automation SystemDocument2 pagesGIKI Students Develop Bluetooth Home Automation SystemMuneebNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Multiplexing and Demultiplexing ExplainedDocument16 pagesMultiplexing and Demultiplexing ExplainedHarsh IsamaliaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Experiment 2Document5 pagesExperiment 2Lea VillafuerteNo ratings yet

- PCM 5862startupDocument4 pagesPCM 5862startupjnesaNo ratings yet

- Plant Maintenance, Proof of Performance and Signal Leakage Rev (1) - ADocument255 pagesPlant Maintenance, Proof of Performance and Signal Leakage Rev (1) - AhailemebrahtuNo ratings yet

- Dell Inspiron N5010-AMDDocument95 pagesDell Inspiron N5010-AMDDeddy Suyanto100% (1)

- ECLine BT8500 PDFDocument80 pagesECLine BT8500 PDFJuan CNo ratings yet

- High Performance, Single Synchronous Step-Down Controller For Notebook Power SupplyDocument27 pagesHigh Performance, Single Synchronous Step-Down Controller For Notebook Power Supplyzigmund zigmundNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- South Tse Tank Addc Electrical Drawing Approval (1) ..Document1 pageSouth Tse Tank Addc Electrical Drawing Approval (1) ..Swami NathanNo ratings yet

- Arduino GSM Shield Web PDFDocument20 pagesArduino GSM Shield Web PDFLuis Prieto100% (1)

- Exam 2016 RadarDocument13 pagesExam 2016 Radaradib50% (2)

- Man Handwheel UfoDocument2 pagesMan Handwheel UfoAloisio GonzagaNo ratings yet

- W65C02S Microprocessor Data Sheet: The Western Design Center, IncDocument40 pagesW65C02S Microprocessor Data Sheet: The Western Design Center, IncJayath GayanNo ratings yet

- Centralised Systems CB For Emergency LightingDocument3 pagesCentralised Systems CB For Emergency Lightingnicky_balanNo ratings yet

- Tables of max spurious emissions limitsDocument11 pagesTables of max spurious emissions limitsbum704No ratings yet

- SIP Trunking For Dummies PreviewDocument12 pagesSIP Trunking For Dummies PreviewManish GandhiNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Communication Systems by B P Lathi PDFDocument2 pagesCommunication Systems by B P Lathi PDFAshley0% (3)

- Panimalar Engineering College: Answer ALL Questions, Choose The Best Answer Part - A (30 X 1 30)Document6 pagesPanimalar Engineering College: Answer ALL Questions, Choose The Best Answer Part - A (30 X 1 30)sivaNo ratings yet

- PowerFlex 4 Class Modbus Errors - 1Document2 pagesPowerFlex 4 Class Modbus Errors - 1sunjoy1234No ratings yet

- Broadcast Audio ProcessorDocument5 pagesBroadcast Audio Processorduct2611No ratings yet

- Catalog Pneumercator tms3000 Spec SheetDocument2 pagesCatalog Pneumercator tms3000 Spec SheetEdgar P. Putong Jr.No ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)