Professional Documents

Culture Documents

Roadmap On Solar Water Splitting

Uploaded by

Anonymous 0tqzNTWyyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Roadmap On Solar Water Splitting

Uploaded by

Anonymous 0tqzNTWyyCopyright:

Available Formats

VERUSCRIPT FUNCTIONAL NANOMATERIALS

www.veruscript.com/fnan

Photoelectrochemical solar water splitting: From

basic principles to advanced devices

Bandar Y. Alfaifi1,*, Habib Ullah1, Sulaiman Alfaifi2, Asif A. Tahir1,

Review

Tapas K. Mallick1

Article history: 1

Environment and Sustainability Institute (ESI), University of Exeter,

Received: 20 September 2017

Penryn Campus, Penryn, Cornwall, TR10 9FE, United Kingdom

Accepted: 29 October 2017 2

Department of Chemistry, King Abdulaziz University, Jeddah 21589,

Published: 12 February 2018

Saudi Arabia

*Correspondence: Abstract

BYA: ba283@exeter.ac.uk

Photoelectrochemical water splitting (PEC) offers a promising

Peer review:

path for sustainable generation of hydrogen fuel. However,

Double blind

improving solar fuel water splitting efficiency facing tremendous

Copyright: challenges, due to the energy loss related to fast recombination

© 2018 Alfaifi et al. c This is an open access of the photogenerated charge carriers, electrode degradation,

article distributed under the Creative as well as limited light harvesting. This review focuses on the

Commons Attribution License (CC‑BY 4.0), brief introduction of basic fundamental of PEC water splitting

which permits unrestricted use, distribution, and the concept of various types of water splitting approaches.

and reproduction in any medium, provided Numerous engineering strategies for the investgating of the

the original work is properly cited and its higher efficiency of the PEC, including charge separation, light

authors credited. harvesting, and co-catalysts doping, have been discussed.

Moreover, recent remarkable progress and developments for

Keywords: PEC water splitting with some promising materials are discussed.

photoelectrode; metal oxide; water splitting Recent advanced applications of PEC are also reviewed. Finally,

the review concludes with a summary and future outlook of this

Citation: hot field.

Alfaifi B. Y., Ullah H., Alfaifi S., Tahir A. A., and

Mallick T. K. Photoelectrochemical solar

water splitting: From basic principles to

Introduction

advanced devices. Veruscript Functional

Nanomaterials. 2018; 2: #BDJOC3.

The traditional sources of energy such as coal, oil and nat-

https://doi.org/10.22261/FNAN.BDJOC3 ural gas have supplied the world with energy that drives

society for long decades. But the energy consumption

around the world is incredibly increased and is estimated to

be double by 2050 [1]. Since the fossil fuel resources are

limited and concentrated in certain region around the world,

while global demand is increasing; subsequently, a secure

supply is increasingly challenging to assure [2]. Furthermore,

pollution created from fossil fuel plants has significant

impact on our health. Moreover, the emissions of green-

house gas and Carbon dioxide have negative impact on our

planet.

Renewable energy resources such as wind, biomass and solar

fuel have been investigated for years to help in the replace-

ment of fossil fuels. Extensive research and development are

required to produce such a technology that can compete the

fossil fuel and commercially available everywhere. However,

Veruscript Funct. Nanomater. | 2018 | 2: #BDJOC3 | https://doi.org/10.22261/FNAN.BDJOC3 1

Alfaifi et al. | Photoelectrochemical solar water splitting https://www.veruscript.com/a/BDJOC3/

the most developed renewable energy sources are based on electricity generation, producing trans-

portable and storable fuel, which is remains a challenge.

Among these energy resources, solar energy is considered a primary carrier that may hold potential

promise for a sustainable and clean energy future [3]. Solar energy focused on direct conversion of sun

light into chemical fuels in the form of hydrogen gas (H2) [4]. The advantages and attractiveness of

solar water splitting, include sufficient water resources, small reaction potential required (1.23 eV), and

zero CO2 emission [5].

In this review, we are aiming to briefly introduce the basic principles of PEC. An overview of the

common used materials that have been investigated for photoelctrochemical water splitting will be

presented. In addition, the current state of the technology is discussed. Finally, the review concluded

with a summary and future viewpoint in this hot topic of research.

Basic principles of photocatalytic water splitting

Generating Hydrogen fuel directly from sunlight, comes from natural phenomena called natural

photosynthesis (NP), exist in plants [6,7], where sunlight is used to convert water and carbon dioxide

into oxygen and carbohydrates. The potential technology that converts water into H2 and O2 using

sunlight for generation of solar fuel is called artificial photosynthesis (AP), which aims to mimic NP

using man-made materials [7,8].

The water splitting reactions (see reactions 1–3) is an uphill reaction with a net Gibbs free energy of

238 kj/mol or 1.23 eV, as shown in Equation (1),

O2 + 4H+ + 4e - U 2H2O Water Oxidation (1)

+ -

4H + 4e U 2H2 Water Reduction (2)

2H2O → 2H2 + O2 Water Splitting (3)

The basic mechanism of photocatalysis water splitting in general is based on the generation of photo-

excited charge carriers. Generally, photocatalytic water splitting reaction on semiconductor particles

involves three main steps: (1) absorption of light irradiation with energies exceeding the semiconductor

bandgap, generate electrons (e−) and holes (h+) pairs inside the semiconductor particles; (2) the

generated electrons and holes are separated followed by migration of these charges to the interface of

the semiconductor particles; (iii) surface chemical reactions between these carriers with various

compounds (e.g., H2O); electrons and holes to produce H2 and O2, respectively as it shown in

Figure 1 [9,10]. Recombination of electrons and holes may also occurs on a very fast timescale without

participating in any chemical reactions [5,9,11,12].

General approaches for water splitting

Production of Hydrogen, using water splitting technique mainly fall into three categories; pho-

tocatalyst system (PC), photoelectrochemical system (PEC), and photovoltaic-photoelectrochemical

system (PV-PEC) [13,14]. In photocatalytic system (PC), which is considered as the simplest,

cheapest, and for potential scalable method for water splitting. Photocatalyst which form as

powders are dispersed in water for water splitting under light irradiation (Figure 2). Photocatalysts

possess the advantage that the water splitting can occur in the homogeneous phase without the

need of transparent electrodes and without the need of directional illumination [10]. Whereas, PC

have many disadvantages that limit its use for water splitting. (1) Separation of the generated

hydrogen and oxygen immediately when formed are required, which will consume additional

energy, causing low efficiency of water splitting process. (2) The illumination of PC systems

without fast removal of the catalysts will eventually cause a photostationary state, where all forward

and backward reactions have identical rates, and no more water splitting can take place. (3)

Implementing PC system at high scale still challenging. Due to these limitation, PC system will not

be covered in this review.

Veruscript Funct. Nanomater. | 2018 | 2: #BDJOC3 | https://doi.org/10.22261/FNAN.BDJOC3 2

Alfaifi et al. | Photoelectrochemical solar water splitting https://www.veruscript.com/a/BDJOC3/

Figure 1. Fundamental principle of photocatalytic water splitting on semiconductor.

Adapted with permission from ref [8]. Copyright 2011 Materials Research Society.

Photoelectochemical water splitting has been reported for the first time early 1968 by illumination a

conductive electrode made from TiO2 in aqueous solution [15]. The interaction of incident light with

TiO2, generate electron hole pairs, where the holes oxidize water at the TiO2 surface to generate

oxygen, and the electrons travel to the Pt counter electrode to reduce water to produce hydrogen

(Figure 3a)[11–14]. In PEC technique, the photocatalysts initially prepared on conductive substrates

as electrodes and additional small bias applied for water splitting.

To make this cell, one or both electrodes should be a photoactive semiconductor, where the charge

separation forms at the semiconductor/liquid interface (Figure 3b and 3c). When the cell is exposed

to sun-light, photogenerated carriers are separated by the space-charge field and the minority charges

(holes for an n-type photoanode and electrons for a p-type photocathode) travel to the semi-

conductor electrode-liquid interface for reaction [17]. Compared to photocatalyst system (PC), PEC

have advantage that there is no need for gas separation in PEC systems because the generation of H2

and O2 is spatially separated at different electrode sides [17,18]. PEC will be described in this review

with focus on different semiconductor materials used to fabricate both photoanode and photo-

cathode.

Photocathode for hydrogen evolution

Water splitting photocathodes are generally p-type semiconductors and must generate the required

cathodic current to reduce water to hydrogen and need to have high stability in aqueous environments.

The optimal photocathode material, need to have the conduction band edge potential to be more

negative than the hydrogen redox potential. Many earlier studies on electrochemical photocathodes

mainly focused on p-type silicon and III–V semiconductor such as InP and GaP. Recently, p-type

semiconductor including oxides and sulphide have received lots of attention. In this section, the review

is focused on various photocathodes materials, which include monometallic and bimetallic oxides,

chalcopyrites, silicon, and III–V semiconductors.

Veruscript Funct. Nanomater. | 2018 | 2: #BDJOC3 | https://doi.org/10.22261/FNAN.BDJOC3 3

Alfaifi et al. | Photoelectrochemical solar water splitting https://www.veruscript.com/a/BDJOC3/

Figure 2. Schematic diagram for solar hydrogen via photocatalytic water splitting system (PC).

Adapted with permission from ref [8]. Copyright 2011 Materials Research Society.

Figure 3. General Illustration of photoelectrochemical water splitting (PEC).

(a) A single photoelectrode PEC configuration powered by a photovoltaic (PV) cell to allow water reduction at the

cathode. (b) A two photoelectrodes PEC configuration connected in parallel. (c) A two photoelectrodes connected in

series. Adapted with permission from ref [16]. Copyright 2010 Royal Society of Chemistry.

Single metallic

Cuprous oxide (Cu2O), cupric oxide (CuO), and nickel oxide (NiO) are among the forefront p-type

semiconductors oxide that have been investigated for solar water splitting. They are favourable

photocathodes having low cost, earth abundance, and ideal band-gap energies that allow for the

absorption of visible light.

Veruscript Funct. Nanomater. | 2018 | 2: #BDJOC3 | https://doi.org/10.22261/FNAN.BDJOC3 4

Alfaifi et al. | Photoelectrochemical solar water splitting https://www.veruscript.com/a/BDJOC3/

Cu2O

Cuprous oxide is one of the most investigated p-type semiconductors, used for solar water splitting.

Cu2O has a direct band gap of 1.9–2.2 eV [19], which makes it an excellent solar absorber; however

the photocorrosion is the major limitation of Cu2O [19,20]. Recent studies show that there is a

possibility to suppress the photocorrosion of Cu2O by adding a passivation layer on the surface of

Cu2O (Figure 4a). This layer prevent the direct contact between the Cu2O surface and the sur-

rounding electrolyte [21]. The best performance of Cu2O was demonstrated from cathodic reduction

of Cu2+ ions in aqueous solution with pH 12, where TiO2 was as a protective layer with photocurrent

of −7.6 mA/cm2 at 0V vs RHE as shown in Figure 4c [22].

CuO

Cupric oxide (CuO) is another p-type copper oxide with an indirect band gap of 1.2–1.8 eV [23,24],

where its small band gap allows CuO to achieve more photocurrent than Cu2O. However, CuO as a

photocathode for water splitting has received less attention than Cu2O, due to its conduction band,

more positive than that of the Cu2O [25–27]. Though, recent studies on hydrogen evolution by CuO

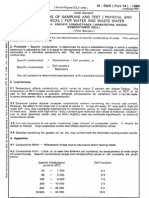

Figure 4. (a) Schematic diagram of Cu2O photocathodes deposited with ZnO:Al and TiO2 as a protective

layer and (b) SEM image of deposited Cu2O, (c) J-V plot of the FTO/Cu2O/TiO2 photocathodes.

Adapted with permission from ref [22]. Copyright 2011 Macmillan Publishers Ltd.

Veruscript Funct. Nanomater. | 2018 | 2: #BDJOC3 | https://doi.org/10.22261/FNAN.BDJOC3 5

Alfaifi et al. | Photoelectrochemical solar water splitting https://www.veruscript.com/a/BDJOC3/

Figure 5. (a) Photocurrent response of NiO/CdSe/CdSe:NiO electrodes under dark and visible light.

(b) UV/Vis absorption spectra of NiO/CdSe/CdSe:NiO electrodes.

Adapted with permission from ref [38]. Copyright 2015 Wiley and Sons.

with composites photocatalysts, confirm the possibility of CuO to reduce water to hydrogen [28–31].

Similar to Cu2O, photocorrosion is another major drawback with CuO as photocathode in water

splitting. However, some recent studies show that a reduction in photocorrosion of Cu2O may apply

to CuO [31–33].

NiO

Nickel oxide (NiO) is a semi-transparent p-type semiconductor with direct band gap of 3.6–4.0 eV

[34]. This wide band gap NiO possess low resistance, high p-type concentration, high hole mobility,

and low lattice mismatch with ZnO, which are favourable for formation of p-n heterojunction [34–37].

On the other hand, the photocurrents obtained by NiO photocathode are low due to low potential of

its valence band (0.3V vs RHE) [38]. However, sensitizing NiO photocathodes with quantum dots (e.

g., CdSe) possess high photocurrent and photopotential as shown in Figure 5a and 5b [37,39].

Bimetallic

CuFeO2

CuFeO2 has a ABO2-type semiconductor delafossite structure with bandgap of 1.5–1.6 eV, which can

absorb the entire range of visible light [40]. In addition to its small band gap, CuFeO2 is an earth

abundant material with high onset potential and good stability in aqueous solution [40,41]. However,

the lack of poor charge transfer, limit its performance for PEC water splitting. Recent studies show that

the fabrication techniques, involving post treatment in air with hybrid microwave annealing, enhanced

the activity of the electrode which make the CuFeO2 attractive candidate for PEC water splitting as

shown in Figure 6a [42]. In Figure 6b and 6c, photocurrent activity of CuFeO2 possess enhancement

after modifying with electrocatalyst such as nickel-iron (NiFe) and reduced graphene oxide (RGO) [42].

LaFeO3

Perovskite oxides are quite encouraging materials for PEC water splitting due to their high efficiency

and stability in water. LaFeO3 with ABO3 perovskite structure is a promising candidate to be used for

water splitting due to its high stability, optoelectronic properties and small band gap energy [43–46].

However, failure to improve their photoresponse limit their use as photocathode which is because of

the lack of preparative technique for LaFeO3 photocathode with effective quality [46]. Recent effort

Veruscript Funct. Nanomater. | 2018 | 2: #BDJOC3 | https://doi.org/10.22261/FNAN.BDJOC3 6

Alfaifi et al. | Photoelectrochemical solar water splitting https://www.veruscript.com/a/BDJOC3/

Figure 6. (a) J-V plot of untreated CuFeO2 electrode (CFO) and post treated at different annealing time

with using hybrid microwave annealing (HMA) comparing to the conventional thermal annealing (CTA).

(b) Chronoamperemetry of CuFeO2 treated with CTA, HMA, and HMA-NiFe/RGO. (c) J-V plot of HMA,

HMA-NiFe, and HMA-NiFe/RGO simulated in 1 sun irradiation in 1 M NaOH electrolyte.

Adapted with permission from ref [42]. Copyright 2014 American Chemical Society.

show that the efficiency of LaFeO3 as photocathode can be improved via doping with metals which

have 2+ oxidation state similar to that of Fe3+, such as Mg2+ and Zn2+. These dopant agents lead to

change the structure and electrical properties of the photocathode which enhanced the overall pho-

toelectrochemical response of LaFeO3 (Figure 7a and 7b) [47].

CaFe2O4

Calcium iron Oxide (CaFe2O4) has been discovered for the first time as a p-type semiconductor oxide

for use of electrolyse of water [48]. It has band gap of 1.9 eV with suitable conduction and valance

band edges of −0.6 and +1.3 V vs RHE, respectively, which is suitable for splitting water [49].

However, the photoresponse of CaFe2O4 is relatively low, because of its poor charge separation and

charge carrier mobility [50,51]. Moreover, CaFe2O4 photocathode with metal doping such as, CuO

and Au shows a higher photocurrent response due to the increase absorption wavelength range [52].

Furthermore, CaFe2O4 doped with Ag, exhibited 23 times higher photocurrent response than

undoped CaFe2O4 as shown in Figure 8 [53].

Chalcogenides

To date, some p-type chalcogenides have been studied as a photocathode for solar water splitting.

Semiconductors with chalcopyrite structure (e.g., CuInS2, CuGaS2), have recently shown significant

photocathode performance for solar water splitting due to their excellent photovoltaic properties.

Veruscript Funct. Nanomater. | 2018 | 2: #BDJOC3 | https://doi.org/10.22261/FNAN.BDJOC3 7

Alfaifi et al. | Photoelectrochemical solar water splitting https://www.veruscript.com/a/BDJOC3/

Figure 7. (a) FE-SEM images of pristine LaFeO3 comparing to doped LaFeO3 electrodes. (b) Photocurrent

transients for pristine LaFeO3, Mg, and Zn doped LaFeO3 electrodes at −0.25 V.

Adapted with permission from ref [47]. Copyright 2014 American Chemical Society.

Figure 8. J-V curves for the; Ag- CaFe2O4 (red line), Cuo- CaFe2O4 (blue line), Au- CaFe2O4 (green line),

and undoped CaFe2O4 (black line).

Adapted with permission from ref [53]. Copyright 2014 American Chemical Society.

CuInS2

Copper indium disulphide (CuInS2) is considered as a promising candidate to be used in thin film

solar cells due to its direct bandgap (1.5 eV) and large absorption coefficient (105 cm−1) in the visible

spectral range [54–56]. Moreover, it is environmentally friendly [56], but the fabrication of CuInS2

thin film is expensive. Fabrication techniques such as chemical deposition, especially spray pyrolysis

possess an attraction solution to this issue where the large area of thin film can easily be coated [57].

Veruscript Funct. Nanomater. | 2018 | 2: #BDJOC3 | https://doi.org/10.22261/FNAN.BDJOC3 8

Alfaifi et al. | Photoelectrochemical solar water splitting https://www.veruscript.com/a/BDJOC3/

Spray pyrolysis at low temperature (about 150–200°C) shows the possibility of CuInS2 thin film on

cheap and flexible substrates [57].

CuGaS2

Copper gallium disulphide (CuGaS2) is less interesting to be used as photocathode in solar cell than

CuInS2 due to its wide direct band gap of 2.4 eV [58]. However, CuGaS2 has conduction band

located at more negative potential than that of CuInS2 which make it a possible photocathode for solar

water splitting [21,59,60]. In addition to its wide band gap, gallium deposition requires more cathodic

potential than that of indium metal, where the fabrication of uniform film remain is challenging [21].

Recent studies suggested that doping CuGaS2 film with co-catalyst such as Zn and Ti enhanced the

morphology and phase structure of Cu-Ga photocathode film [61].

III-V Semiconductors

GaP

Gallium phosphide (GaP) has an indirect band gap (2.2−2.3 eV) and band edges above the reduction

potential of hydrogen which is make it suitable material for water splitting [62,63]. The n-type of GaP

is unstable in water, but the p-type form has more stability for longer periods of time in electrolytes

under cathodic conditions [62]. Despite the wide bandgap of GaP, still it does not show the expected

photocurrent [64,65]. Recent investigation show that the influence of the interface structure region

between the semiconductor and the electrolyte, depositing of platinum particles on top of GaP notable

increased the efficiency of the photoelectrochemical cell [63].

InP

Indium phosphide (InP) has a direct band gap of 1.35 eV, which makes it well-matched to the solar

spectrum [66–69]. Moreover, its conduction band edge is slightly above the water reduction potential

[69]. For these reasons, InP is considered as a promising photocathode for water splitting. Although

p-type InP is suffer from photocorrosion in acidic solution [70,71], but the stability and efficiency of

InP electrode can be enhanced with protective coat-layer of TiO2 [72]. Despite its efficiency, high cost

of bulk materials and fabrication process, InP photocathode limits its scalable application [72]. Latest

studies demonstrated a low-cost and high efficiency solar device, implemented using the thin-film

vapour–liquid–solid (TF-VLS) growth technique that decreases usage of feedstock materials [73].

Figure 9. (a) Current-voltage curve of Si coated with various STO thicknesses as protective layer.

(b) Voltage versus time curve.

Adapted with permission from ref [77]. Copyright 2015 Macmillan Publishers Ltd.

Veruscript Funct. Nanomater. | 2018 | 2: #BDJOC3 | https://doi.org/10.22261/FNAN.BDJOC3 9

Alfaifi et al. | Photoelectrochemical solar water splitting https://www.veruscript.com/a/BDJOC3/

Silicon

Silicon (Si) has been extensively used for water reduction over the past few decades due to its narrow

band gap (1.1 eV) [74,75]. In addition to its small band gap energy, silicon is one of the most

promising materials for photoelectrodes in a PEC due to its natural abundance, environmental

friendly and ability for large-scale production [76–78]. The practical use of Si as photocathode

electrode in water splitting was originally limited due to its instability in water [75]. However,

several approaches have been developed to protect its surface from corrosion using protective layers

(e.g., ALD of TiO2, Al2O3, and different catalysts layers) to enable more stable PEC performances

of Si electrodes in different aqueous environments [70,79–83]. Latest study indicated that Si

photocathode deposited with strontium titanate, SrTiO3 (STO), as protective layer achieved pho-

tocurrent density of (35 mA/cm2) and long-term stability as illustrated in Figure 9 [77].

Photoanode for water splitting

Photoanode materials, responsible for oxygen evolution must be; an n-type semiconductor, band gap

that are suitable for absorb wide range of spectrum, and efficient charge collection and charge carriers’

motilities. In addition to that, the materials must be stable in aqueous solution, low cost, and

environmental friendly. This section will focus on the n-type semiconductors that have been inves-

tigated as a photoanodic electrode in PEC water splitting. Examples of these materials are mono-

metallic and bimetallic oxides, chalcogenide, and nitride.

Monometallic

TiO2

Titanium dioxide (TiO2), which is an n-type semiconductor having band gap of ~3.2 eV, is con-

sidered to be the most promising oxides used in PEC [84–87]. It’s reported for the first PEC water

splitting as photoanode under UV irradiation by Honda and Fujishima in 1972 [11]. Due to its

excellent stability in aqueous solution, it has been implemented as protection layers for photo-

electrodes (e.g., Cu2O, Si, InP, etc.) that are not stable in water [72,81,82]. However, the applications

of TiO2 photoanode in PEC water splitting is limited due to its wide band gap. Several techniques

have been explored to improve the light absorption and charge carries transport of TiO2 such as

doping with cocatalyst (e.g., Co and Ag) (Figure 10). For example, N-modified TiO2 photoanode,

Figure 10. (a) Linear sweep voltammetry of, TiO2 nanowire arrays (blue), Cobalt doped TiO2. (b) Chro-

noamperometry measurement of TiO2 nanowire arrays and the same film after treated with cobalt and

silver.

Adapted with permission from ref [88]. Copyright 2012 American Chemical Society.

Veruscript Funct. Nanomater. | 2018 | 2: #BDJOC3 | https://doi.org/10.22261/FNAN.BDJOC3 10

Alfaifi et al. | Photoelectrochemical solar water splitting https://www.veruscript.com/a/BDJOC3/

which were synthesized via the nitridation of hydrothermally synthesized TiO2 nanowire arrays in

NH3 atmosphere, obtained a band gap of 2.4 eV [88]. Additionally, TiO2 nanotubes treated with heat

and chemical reduction demonstrated enhanced photocatalytic activity, with a photocurrent of

2.0 mA/cm2 at 1.23 V [89].

ZnO

Zinc oxide (ZnO) is also an n-type semiconductor which is environmentally friendly and inexpensive

[90–92]. It has band gap of 3.2 eV, similar to TiO2 but higher carrier mobility [91–96]. Nevertheless,

the effective applications of ZnO as photoanode for water splitting still requires the improved design

and synthesis technique to overcome the limitations of ZnO [97]. Recent studies revealed that by

controlling the morphology of ZnO, the light harvesting ability can be enhanced by thermal evapo-

ration approaches and a photocurrent of ~0.4 mA/cm2 at applied potential of 0.8 VAg/AgCl is achieved

[97,98].

WO3

Tungsten oxide (WO3), an n-type semiconductor has been well studied as photoanode for water

splitting compared to their other metal oxides. It has an indirect band gap of 2.5–2.8 eV which can

harvest about 12% of the solar spectrum [99]. WO3 is an inexpensive, nontoxic, and possess high

stability in acidic aqueous solution [99–101]. However, this material can only absorb a limited

portion of visible light due to its wide band gap [99]. Moreover, its conduction band is too low

(0.3 V vs RHE) comparing to Hydrogen evolution reaction redox potential [102]. Recent studies

have demonstrated that morphological control and hydrothermal treatment can significantly affect

the morphology of the synthesized electrode and may exhibit a far higher enhancing photocurrent of

WO3 [103,104]. In particular, it was shown that fabricated WO3 nanospheres by removing the top

platelets of WO3 via a hydrothermal method exhibited a photocurrent of 2.6 mA/cm2 at 1.2 V

[104].

α-Fe2O3

Alpha-Hematite (α-Fe2O3) is undoubtedly the most extensively studied n-type semiconductor to be

used in water splitting. It has band gap of 2.0–2.2 eV which absorb a significant portion of visible

light with efficiency exceeds 12% [17,105–107]. It is also stable in most of the aqueous media, and

has high resistance towards photocorrosion [17,108,109]. In addition, it is environmental friendly

and inexpensive but it has low absorption efficiency, low electrical conductivity, short diffusion

length (2–4 nm), and facile surface recombination are serious challenges for its used in practical

application as a photoanode [110]. To overcome these limitations, several synthesis techniques and

strategies have been developed, which include surface modification and composition [108,111,112].

Surface modification with catalysts such as IrO2, aim to reduce the overpotential and thus enhanced

the efficiency [113,114], while composition aims to increase charge mobility [114]. Recent study

reported that preparing α-Fe2O3 film by electrodeposition method followed by surface decorating

with Co-Pi catalyst showed a stable photocurrent of ~1.89 mA/cm2 at 1.23 V vs RHE as presented

in Figure 11 [115].

Bimetallic

BiVO4

Another n-type semiconductor is Bismuth vanadate (BiVO4), which is recently emerged as a viable

candidate for photocatalytic water splitting. It has band gap of 2.4 eV and can absorb a significant

portion of the visible spectrum [116,117]. It has a suitable conduction band position very near to the

H2 evolution potential, and relatively low onset potential for O2 evolution [118,119]. However,

BiVO4 lacks low photocurrent efficiency under solar radiation, fast electron–hole recombination, slow

charge transfer, and low water oxidation kinetics [120–122]. To overcome these drawbacks, several

Veruscript Funct. Nanomater. | 2018 | 2: #BDJOC3 | https://doi.org/10.22261/FNAN.BDJOC3 11

Alfaifi et al. | Photoelectrochemical solar water splitting https://www.veruscript.com/a/BDJOC3/

Figure 11. (a) J-V measurements with chopped light for Co-Pi/α-Fe2O3 films at different deposition times

(300 s, 600 s, and 1,200 s). (b) Photocurrent versus time curve of α-Fe2O3 and 600s Co-Pi/α-Fe2O3

photoanode.

Adapted with permission from ref [115]. Copyright 2015 Royal Society of Chemistry.

Figure 12. (a) PEC photocurrent potential (J-V) curves of five photoanodes (i.e., BVO = BiVO4, B/W =

BiVO4/WO3, B/S = BiVO4/SnO2, B/S/W = BiVO4/SnO2/WO3, B/W/S = BiVO4/WO3/SnO2). (b) Photocurrent

density and solar to hydrogen conversion efficiency as a function of time for the BiVO4/WO3/SnO2

photoanode tandem cell.

Adapted with permission from ref [125]. Copyright 2016 American Chemical Society.

techniques has be applied such as construction of heterojunction structures, morphology control, and

doping. Previous works have demonstrated that BiVO4 heterojunction WO3/BiVO4 less than

1.0 mA/cm2 at 1.0 V vs RHE [123,124]. A significant enhancement has been achieved using a

double-heterojunction photoanode based on BiVO4/WO3/SnO2 triple layers prepared by spin

coating, which has an increased the PEC photocurrent to 3.1 mA/cm2 at 1.23 V vs RHE as presented

in Figure 12 [125].

CuWO4

Copper tungstate, also known as copper tungsten oxide (CuWO4) is an n-type semiconductor with

indirect optical band gap of 2.3 eV [126–128]. It has been widely studied for different applications

such as detector, lasers, and optical sensor [127–129]. Due its small band gap, it is very close to ideal

Veruscript Funct. Nanomater. | 2018 | 2: #BDJOC3 | https://doi.org/10.22261/FNAN.BDJOC3 12

Alfaifi et al. | Photoelectrochemical solar water splitting https://www.veruscript.com/a/BDJOC3/

Figure 13. (a) Photocurrent versus voltage (j-v) curve of Current vs time curve for CuWO4 electrode

before and after decorating with TiO2-coated Au NPs. (b) Photocurrent versus time (j-t) curves at

1.23 V vs RHE under AM 1.5 irradiation.

Adapted with permission from ref [134]. Copyright 2014 American Chemical Society.

potential for PEC water spiting as promising photoanode material [128,130]. In addition, single

crystal of this materials have maximum conversion efficiency of 0.52% [127]. The PEC of CuWO4 is

significantly low due to its low absorption light and high bulk charge transfer resistance [130–133].

Several approaches such as surface modification and construction of heterojunction structures can help

to mitigate some of its PEC water splitting limitations. Recent studies demonstrated that modification

of the CuWO4 photoanode surface with TiO2-coated Au NPs can significantly increase the PEC

water-splitting performance and increased the water splitting photocurrent from 0.03 to 0.1 mA/cm2

(Figure 13) [134]. Coupling CuWO4 with WO3, to form heterojunction photoanode can enhanced

the absorbed photon density and charge mobility [135,136].

Nitride and Oxynitride

TaON

Tantalum oxynitride (TaON) with band gap of 2.5 eV is another n-type semiconductor, suitable for

solar water splitting [137–139]. It has achieved a maximum quantum efficiency of 34% [140].

Moreover, TaON shows reasonably alignment of its CB and VB edges relative to the OH-/O2

oxidation and H+/H2 reduction potentials, generate H2 and O2 [137]. However, the activities for H2

production is lower than those for O2 evolution, which is sufficiently negative for H2 production

[141]. TaON suffer from low stability due to the introduction of N 2p orbitals in the valence band

[137]. Recent studies has demonstrated that the photocatalytic activity of TaON for water splitting

can be enhanced through photo-deposition with noble nanoparticles such as Ru [142]. Also, a sig-

nificant enhancement to the photocurrent in TaON photoanode by heat treatment of the surface with

TiCl4 has been reported (Figure 14) [143].

Ta3N5

Tantalum nitride (Ta3N5) has received significant attention over the past years due to its small band

gap (2.1 eV) and stability [139,144–147]. It has CB lies at ca.−0.4 V vs. RHE, and VB lies at ca.

+1.6 V vs. RHE, which possibly allow Ta3N5 to perform unassisted solar water splitting [144,148].

Due to these band energies, Ta3N5 can theoretically split water spontaneously as a single photoanode

with maximum solar to hydrogen efficiency of about ~15% [148–150]. However, Ta3N5 suffer from

the poor charge transport, low photocurrent efficiency and insufficient light absorption [151–153].

Effective strategies have been developed to enhance the PEC performance of Ta3N5 photoanode, such

Veruscript Funct. Nanomater. | 2018 | 2: #BDJOC3 | https://doi.org/10.22261/FNAN.BDJOC3 13

Alfaifi et al. | Photoelectrochemical solar water splitting https://www.veruscript.com/a/BDJOC3/

Figure 14. Current–bias dependence over the TaON electrodes before and after the TiCl4 treatment

under chopped visible light irradiation.

Adapted with permission from ref [143]. Copyright 2005 The Chemical Society of Japan

as nanostructuring and morphology control [154,155]. Particularly, Ta3N5 photoanode with a 1D

configuration, such as nanotubes (NTs), nanorodes (NRs), have been considerably investigated

[151,152,156–160]. These 1D nanostructure offer advances of charge transfer to the solid-liquid

interface without recombination and high absorption of incident light. Ta3N5 nanorod arrays

modified by Co(OH)x co-catalyst yields a stable photocurrent density of 2.8 mA/cm2 at 1.23 V vs

RHE as illustrated in Figure 15 [157].

Chalcogenides

CdS

Cadmium sulphide (CdS) is the most investigated metal chalcogenide materials for water splitting

under visible light irradiation due to its favourable direct band gap (2.4 eV). Furthermore, its band

edge positions are suitable for water splitting to produce hydrogen and oxygen [161,162]. Despite

these advantages, the photocurrent activity of CdS is not sufficient due to the photpgenrated

charges (electrons and holes) which cannot be efficiently separated and transferred [162–164].

Additionally, CdS suffer from photocorrosion in aqueous media which hampers their long term

stability in solar water splitting [161,165]. To overcome these drawbacks, extensive studies have

been investigated to improve the stability and efficiency of CdS photoanode. Recent studies

demonstrated that, formation of CdS 2D-nanostructer offer significant advantages such as, reduc-

tion of the scattering rate which increase the carrier collection efficiency and increase the absorption

of incident light [166].

Veruscript Funct. Nanomater. | 2018 | 2: #BDJOC3 | https://doi.org/10.22261/FNAN.BDJOC3 14

Alfaifi et al. | Photoelectrochemical solar water splitting https://www.veruscript.com/a/BDJOC3/

Figure 15. (a) Photocurrent vs applied potential bias curve of Ta3N5 photoanode before and after loading

of the Co (OH)x co-catalyst. (b) Photocurrent vs time (j-t) curve.

Adapted with permission from ref [157]. Copyright 2013 Royal Society of Chemistry.

ZnS

Zinc sulphide (ZnS) is a promising candidate for photocatalysis of hydrogen production due to its

ability, generation of mobile photo excited charge carriers, and high conduction band potential which

ensures fast electron transfer [167–170]. Moreover, it has active sites for hydrogen evolution without

the need to deposit expensive charge transfer co-catalyst like Pt or RuO2 [171]. But due to its large

band gap (≈3.6 eV), the performance in photocatalysis is limited, which means that pure ZnS are only

active under UV irradiation [172,173]. Therefore, several studies have been investigated to improve

the light absorption behaviour of ZnS photoanode. For instance, it has been reported that doping ZnS

with transition metal ions such as Ni, Sn, and Cu has improved the H2 production under visible light

irradiation [174–176]. An alternative approach to doping is the defect engineering, which also increase

the overall efficiency of ZnS [177]. Moreover, the modification of the fabrication conditions can lead

to defect states in ZnS thin films which also enhance visible-light absorption, charge separation, and

photocurrent up to 1.6 mA/cm2 [177].

Current state of the art for water splitting

Tandem approach

Photoelectrochemical (PEC) water splitting is considered as a promising technology to convert solar

energy into storable and transportable fuel. Potential energy greater than 1.23 eV should be sufficient

to split water. However, the actual required energy is considerably greater due to the different kinetic

and thermodynamic non-idealities in the oxidation and reduction reactions. Therefore, using a single

semiconductor absorber, requires a semiconductor with large energy bandgap to absorb a maximum

portion of the solar spectrum [178]. This drawback, can be solved by dual-absorber-four photon (D4)

tandem approach (Figure 16) [179]. In PEC tandem device, the cell configuration is composed of two

sided light absorption electrodes, a p-type photoanode and a n-type photocathode, where hydrogen

evolution (water oxidization) and oxygen reduction (water reduction) reactions take place on the

photocathode and photoanode, respectively [179].

Tandem cell has an improved overall efficiency due to the two different band gaps used and the high

portion of the light absorbed. It show a theoretical estimated light conversion efficiency of 18% [180].

Tandem cell used a III–V semiconducting materials have been shown to perform with efficiencies of

12.4% under concentrated sun light [181]. Though, their commercial applications still far to achieve

Veruscript Funct. Nanomater. | 2018 | 2: #BDJOC3 | https://doi.org/10.22261/FNAN.BDJOC3 15

Alfaifi et al. | Photoelectrochemical solar water splitting https://www.veruscript.com/a/BDJOC3/

Figure 16. Schematic diagram of PEC water splitting approach using a dual-absorber tandem cell.

Adapted with permission from ref [179]. Copyright 2013 American Chemical Society.

Figure 17. Photovoltaic-integrated photoelectrochemical cells.

Adapted with permission from ref [190]. Copyright 2013 Royal Society of Chemistry.

due to poor stability, high cost and complexity of their fabrication [182]. To reduce the cost, increase

stability, and enhanced the efficiency, several methods have been proposed [179,183–188]. Recently,

Graetzel et al. reported a perovskite tandem solar cell based on CH3NH3PbI3 and achieved solar-

to-hydrogen efficiency of 12.3% [189].

PEC/PV approach

Due to the difficulties in designing PEC tandem cell with sufficient bandgap energies and band edge

positions of photocathodes and photoanodes; photovoltaic-integrated photoelectrochemical cells are

attractive approach for mitigating this aspect. In this configuration, the bandgap energy levels in

PEC cells have no role with the water redox due to PV cells could play the direct role of potential

supply; therefore, there are no limitations on selecting the material type (Figure 17) [184]. PV-PEC

systems possess many advantages for water splitting compared with PEC systems, excluding major

cost. PV-PEC device has been developed for the first time for hydrogen production via water

Veruscript Funct. Nanomater. | 2018 | 2: #BDJOC3 | https://doi.org/10.22261/FNAN.BDJOC3 16

Alfaifi et al. | Photoelectrochemical solar water splitting https://www.veruscript.com/a/BDJOC3/

splitting in 1998, using a GaInP2/GaAs tandem cell which has achieved more than 10% efficiency

[181].

Moreover, coupling a WO3/BiVO4 photoanode with a double junction GaAs/InGaAsP solar cell, to

build a self-operating integrated PEC device, generated solar to hydrogen efficiency of up to 8.1%

[118]. The highest efficiency of PV-PEC approach was recently achieved through fabrication of an

integrated system with Ni electrodes and multi-junction GaInP/GaAs/Ge solar cell, delivered solar

water splitting efficiency of about 22.4% [190]. Despite this high efficiency, the fabrication of PV-

PEC solar cells is complicated and expensive. Without considering the cost factor, PV-PEC systems are

the most viable hydrogen production method for the practical applications. PV-PEC system based

hydrogen production is expected to be primarily used in navigation, military, and aerospace appli-

cations to provide fuel for these special situations.

Conclusion and outlook

Significant increase in research activity around the solar hydrogen production via direct water splitting

under sunlight has been achieved in the last decade.

• In this review, we present the fundamental mechanisms and basic principle of water splitting.

• We investigated the common engineering strategies of hydrogen production via solar water

splitting.

• Many semiconducting materials such as p-type, n-type, nitride, and chalcogenide have been

successfully developed as a photocathode and photoanode for PEC.

• Advanced PEC applications such as tandem cell and PV-PEC hybrid system have possessed

significant solar to hydrogen efficiency.

• The solar to hydrogen efficiency of different approaches has been improved to more than 12.3%

and 22.4% for PEC and PV-PEC water splitting systems, respectively.

• Solar driven hydrogen production is ideal pathway to produce green energy but it faces many

challenges to achieve this goal.

• Significantly, several factors such as stability, electronic properties, structure, surface states and

morphology of catalysts, cost, and toxicity need to be carefully considered to drastically improve

the hydrogen production efficiency through solar water splitting in practical applications.

Acknowledgements

We would like to acknowledge The Saudi Arabian Cultural Bureau (SACB) for providing PhD

fellowship to Bandar Y. Alfaifi.

Funding sources

The partial financial support was provided by Engineering and Physical Science Research Council

(EPSRC), UK, under research grant No. EP/P510956/1.

Competing interests

All authors including Bandar Alfaifi, Habib Ullah, Sulaiman Alfaifi, Asif Tahir and Tapas Mallick

declare that they have no conflict of interest.

Veruscript Funct. Nanomater. | 2018 | 2: #BDJOC3 | https://doi.org/10.22261/FNAN.BDJOC3 17

Alfaifi et al. | Photoelectrochemical solar water splitting https://www.veruscript.com/a/BDJOC3/

References

1. Crabtree G. W., Dresselhaus M. S., and Buchanan M. V. The hydrogen economy. Physics Today. 2004; 57 (12): 39–

45. https://doi.org/10.1063/1.1878333.

2. Ginley D., Green M. A., and Collins R. Solar energy conversion toward 1 terawatt. MRS Bulletin. 2008; 33 (4): 355–

364. https://doi.org/10.1557/mrs2008.71.

3. Park H. G. and Holt J. K. Recent advances in nanoelectrode architecture for photochemical hydrogen production.

Energy and Environmental Science. 2010; 3 (8): 1028. https://doi.org/10.1039/b922057g.

4. Crabtree G. W. and Dresselhaus M. S. The hydrogen fuel alternative. MRS Bulletin. 2008; 33 (4): 421–428. https://

doi.org/10.1557/mrs2008.84.

5. Walter M. G., Warren E. L., McKone J. R., Boettcher S. W., Mi Q., et al. Solar water splitting cells. Chemical Reviews.

2010; 110 (11): 6446–6473. https://doi.org/10.1021/cr1002326.

6. Tachibana Y., Vayssieres L., and Durrant J. R. Artificial photosynthesis for solar water-splitting. Nature Photonics.

2012; 6 (8): 511–518. https://doi.org/10.1038/nphoton.2012.175.

7. Cogdell R. J., Brotosudarmo T. H. P., Gardiner A. T., Sanchez P. M., and Cronin L. Artificial photosynthesis – solar

fuels: Current status and future prospects. Biofuels. 2010; 1 (6): 861–876. https://doi.org/10.4155/bfs.10.62.

8. Osterloh F. E. and Parkinson B. A. Recent developments in solar water-splitting photocatalysis. MRS Bulletin. 2011;

36 (1): 17–22. https://doi.org/10.1557/mrs.2010.5.

9. Chen X., Shen S., Guo L., and Mao S. S. Semiconductor-based photocatalytic hydrogen generation. Chemical Reviews.

2010; 110 (11): 6503–6570. https://doi.org/10.1021/cr1001645.

10. Li R. Latest progress in hydrogen production from solar water splitting via photocatalysis, photoelectrochemical, and

photovoltaic-photoelectrochemical solutions. Chinese Journal of Catalysis. 2017; 38 (1): 5–12. https://doi.org/10.

1016/S1872-2067(16)62552-4.

11. Fujishima A. and Honda K. Electrochemical photolysis of water at a semiconductor electrode. Nature. 1972; 238: 37–

38. https://doi.org/10.1038/238037a0.

12. Navarro R. M., Alvarez-Galván M. C., Villoria de la Mano J. A., Al-Zahrani S. M., and Fierro J. L. G. A framework for

visible-light water splitting. Energy and Environmental Science. 2010; 3 (12): 1865. https://doi.org/10.1039/

c001123a.

13. Abe R. Recent progress on photocatalytic and photoelectrochemical water splitting under visible light irradiation.

Journal of Photochemistry and Photobiology C: Photochemistry Reviews. 2010; 11 (4): 179–209. https://doi.org/10.

1016/j.jphotochemrev.2011.02.003.

14. Hunter B. M., Gray H. B., and Muller A. M. Earth-abundant heterogeneous water oxidation catalysts. Chemical

Reviews. 2016; 116 (22): 14120–14136. https://doi.org/10.1021/acs.chemrev.6b00398.

15. Boddy P. J. Oxygen evolution on semiconducting TiO2. Journal of the Electrochemical Society. 1968; 115 (2): 199–

203. https://doi.org/10.1149/1.2411080.

16. Sun J. W., Zhong D. K., and Gamelin D. R. Composite photoanodes for photoelectrochemical solar water splitting.

Energy and Environmental Science. 2010; 3 (9): 1252–1261. https://doi.org/10.1039/c0ee00030b.

17. Sivula K., Le Formal F., and Grätzel M. Solar water splitting: Progress using hematite (α-Fe2O3) photoelectrodes.

ChemSusChem. 2011; 4 (4): 432–449. https://doi.org/10.1002/cssc.201000416.

18. Kumar P. Photoelectrochemical splitting of water to produce a power appetizer hydrogen: A green system for future (A

short review). Oriental Journal of Chemistry. 2016; 32 (3): 1473–1483. https://doi.org/10.13005/ojc/320321.

19. Hara M., Kondo T., Komoda M., Ikeda S., Shinohara K., et al. Cu2O as a photocatalyst for overall water splitting

under visible light irradiation. Chemical Communications. 1998; (3): 357–358. https://doi.org/10.1039/a707440i.

20. de Jongh P. E., Vanmaekelbergh D., and Kelly J. J. Cu2O: A catalyst for the photochemical decomposition of water?

Chemical Communications. 1999; (12): 1069–1070. https://doi.org/10.1039/a901232j.

21. Kang D., Kim T. W., Kubota S. R., Cardiel A. C., Cha H. G., et al. Electrochemical synthesis of photoelectrodes and

catalysts for use in solar water splitting. Chemical Reviews. 2015; 115 (23): 12839–12887. https://doi.org/10.1021/acs.

chemrev.5b00498.

22. Paracchino A., Laporte V., Sivula K., Grätzel M., and Thimsen E. Highly active oxide photocathode for photo-

electrochemical water reduction. Nature Materials. 2011; 10: 456–461. https://doi.org/10.1038/nmat3017.

23. Chiang C. Y., Shin Y., Aroh K., and Ehrman S. Copper oxide photocathodes prepared by a solution based process.

International Journal of Hydrogen Energy. 2012; 37 (10): 8232–8239. https://doi.org/10.1016/j.ijhydene.2012.02.

049.

24. Chiang C.-Y., Aroh K., Franson N., Satsangi V. R., Dass S., et al. Copper oxide nanoparticle made by flame spray

pyrolysis for photoelectrochemical water splitting – Part III. Photoelectrochemical study. International Journal of

Hydrogen Energy. 2012; 36 (24): 15519–15529. https://doi.org/10.1016/j.ijhydene.2011.09.041.

Veruscript Funct. Nanomater. | 2018 | 2: #BDJOC3 | https://doi.org/10.22261/FNAN.BDJOC3 18

Alfaifi et al. | Photoelectrochemical solar water splitting https://www.veruscript.com/a/BDJOC3/

25. Chauhan D., Satsangi V. R., Dass S., and Shrivastav R. Preparation and characterization of nanostructured CuO thin

films for photoelectrochemical splitting of water. Bulletin of Materials Science. 2006; 29: 709–716.

26. Koffyberg F. P. and Benko F. A. A photoelectrochemical determination of the position of the conduction and valence

band edges of p-type CuO. Journal of Applied Physics. 1982; 53 (2): 1173–1177. https://doi.org/10.1063/1.330567.

27. Hsu Y.-K., Yu C.-H., Lin H.-H., Chen Y.-C., and Lin Y.-G. Template synthesis of copper oxide nanowires for

photoelectrochemical hydrogen generation. Journal of Electroanalytical Chemistry. 2013; 704: 19–23. https://doi.org/

10.1016/j.jelechem.2013.06.008.

28. Xu S., Ng J., Du A. J., Liu J., and Sun D. D. Highly efficient TiO2 nanotube photocatalyst for simultaneous hydrogen

production and copper removal from water. International Journal of Hydrogen Energy. 2011; 36 (11): 6560–6568.

https://doi.org/10.1016/j.ijhydene.2011.02.103.

29. Zhang L., Liu Y. N., Zhou M., and Yan J. Improving photocatalytic hydrogen evolution over CuO/Al2O3 by

platinum-depositing and CuS-loading. Applied Surface Science. 2013; 282: 531–537. https://doi.org/10.1016/j.apsusc.

2013.06.006.

30. Jin Z., Li P., Liu G., Zheng B., Yuan H., et al. Enhancing catalytic formaldehyde oxidation on CuO-Ag2O nanowires

for gas sensing and hydrogen evolution. Journal of Materials Chemistry A. 2013; 1: 14736–14743. https://doi.org/10.

1039/c3ta13277c.

31. Barreca D., Fornasiero P., Gasparotto A., Gombac V., Maccato C., et al. The potential of supported Cu2O and CuO

nanosystems in photocatalytic H2 production. ChemSusChem. 2009; 2 (3): 230–233. https://doi.org/10.1002/cssc.

200900032.

32. Hang N. K., Kadir H. A., Minggu L. J., and Kassim M. B. Stability of WO3/CuO heterojunction photoelectrodes in

PEC system. Materials Science Forum. 2013; 756: 219–224. https://doi.org/10.4028/www.scientific.net/MSF.756.

219.

33. Emin S., Abdi F. F., Fanetti M., Peng W., Smith W., et al. A novel approach for the preparation of textured CuO thin

films from electrodeposited CuCl and CuBr. Journal of Electroanalytical Chemistry. 2014; 717–718: 243–249. https://

doi.org/10.1016/j.jelechem.2014.01.038.

34. Gupta R. K., Ghosh K., and Kahol P. K. Fabrication and characterization of NiO/ZnO p–n junctions by pulsed laser

deposition. Physica E. 2009; 41 (4): 617–620. https://doi.org/10.1016/j.physe.2008.10.013.

35. Wang J. Y., Lee C. Y., Chen Y. T., Chen C. T., Chen Y. L., et al. Double side electroluminescence from p-NiO/n-ZnO

nanowire heterojunctions. Applied Physics Letters. 2009; 95 (13): 131117. https://doi.org/10.1063/1.3232244.

36. Zhang Z., Shao C., Li X., Wang C., Zhang M., et al. Electrospun nanofibers of p-type NiO/n-type ZnO hetero-

junctions with enhanced photocatalytic activity. ACS Applied Materials & Interfaces. 2010; 2 (10): 2915–2923.

https://doi.org/10.1021/am100618h.

37. Hu C., Chu K., Zhao Y., and Teoh W. Y. Efficient photoelectrochemical water splitting over anodized p-type NiO

porous films. ACS Applied Materials & Interfaces. 2014; 6 (21): 18558–18568. https://doi.org/10.1021/am507138b.

38. Dong Y., Chen Y., Jiang P., Wang G., Wu X., et al. Efficient and stable MoS2/CdSe/NiO photocathode for pho-

toelectrochemical hydrogen generation from water. Chemistry–An Asian Journal. 2015; 10 (8): 1660. https://doi.org/

10.1002/asia.201500374.

39. Barceló I., Guillén E., Lana-villarreal T., and Gómez R. Preparation and characterization of nickel oxide photocathodes

sensitized with colloidal cadmium selenide quantum dots. Journal of Physical Chemistry C. 2013; 117 (44): 22509–

22517. https://doi.org/10.1021/jp406989v.

40. Read C. G., Park Y., and Choi K.-S. Electrochemical synthesis of p-type CuFeO2 electrodes for use in a photo-

electrochemical cell. Journal of Physical Chemistry Letters. 2012; 3 (14): 1872–1876. https://doi.org/10.1021/

jz300709t.

41. Oh Y., Yang W., Kim J., Jeong S., and Moon J. Enhanced photocurrent of transparent CuFeO2 photocathodes by self-

light-harvesting architecture. ACS Applied Materials & Interfaces. 2017; 9 (16): 14078–14087. https://doi.org/10.

1021/acsami.7b01208.

42. Jang Y. J., Park Y. B., Kim H. E., Choi Y. H., Choi S. H., et al. Oxygen-intercalated CuFeO2 photocathode fabricated

by hybrid microwave annealing for efficient solar hydrogen production. Chemistry of Materials. 2016; 28 (17): 6054–

6061. https://doi.org/10.1021/acs.chemmater.6b00460.

43. Milanova M., Zaharieva J., Todorovska R., and Todorovsky D. Polymetallic citric complexes as precursors for spray-

pyrolysis deposition of thin LaFeO3 films. Thin Solid Film. 2014; 562: 43–48. https://doi.org/10.1016/j.tsf.2014.03.

036.

44. Tang P., Tong Y., Chen H., Cao F., and Pan G. Microwave-assisted synthesis of nanoparticulate perovskite LaFeO3 as

a high active visible-light photocatalyst. Current Applied Physics. 2013; 13 (2): 340–343. https://doi.org/10.1016/j.

cap.2012.08.006.

45. Parida K. M., Reddy K. H., Martha S., Das D. P., and Biswal N. Fabrication of nanocrystalline LaFeO3: An efficient

sol-gel auto-combustion assisted visible light responsive photocatalyst for water decomposition. International Journal of

Hydrogen Energy. 2010; 35 (22): 12161–12168. https://doi.org/10.1016/j.ijhydene.2010.08.029.

Veruscript Funct. Nanomater. | 2018 | 2: #BDJOC3 | https://doi.org/10.22261/FNAN.BDJOC3 19

Alfaifi et al. | Photoelectrochemical solar water splitting https://www.veruscript.com/a/BDJOC3/

46. Yu Q., Meng X., Wang T., Li P., Liu L., et al. Highly durable p-LaFeO3/n-Fe2O3 photocell for effective water splitting

under visible light. Chemical Communications. 2015; 51: 3630–3633. https://doi.org/10.1039/C4CC09240F.

47. Díez-García M. I. and Gómez R. Metal doping to enhance the photoelectrochemical behavior of LaFeO2 photo-

cathodes. ChemSusChem. 2017; 10 (1): 1–8. https://doi.org/10.1002/cssc.201601831.

48. Matsumoto Y., Omae M., Sugiyama K., and Sato E. New photocathode materials for hydrogen evolution: CaFe2O4

and Sr7Fe10O22. Journal of Physical Chemistry. 1987; 91 (3): 577–581. https://doi.org/10.1021/j100287a018.

49. Ida S., Yamada K., Matsunaga T., Hagiwara H., Matsumoto Y., et al. Preparation of p-type CaFe2O4 photocathodes

for producing hydrogen from water. Journal of the American Chemical Society. 2010; 132 (49): 17343–17345. https://

doi.org/10.1021/ja106930f.

50. Kim E. S., Nishimura N., Magesh G., Kim J. Y., Jang J. W., et al. Fabrication of CaFe2O4/TaON heterojunction

photoanode for photoelectrochemical water oxidation. Journal of the American Chemical Society. 2013; 135 (14):

5375–5383. https://doi.org/10.1021/ja308723w.

51. Wang G., Ling Y., Wang H., Xihong L., and Li Y. Chemically modified nanostructures for photoelectrochemical water

splitting. Journal of Photochemistry and Photobiology C: Photochemistry Reviews. 2014; 19 (1): 35–51. https://doi.

org/10.1016/j.jphotochemrev.2013.10.006.

52. Huang Q., Ye Z., and Xiao X. Recent progress in photocathodes for hydrogen evolution. Journal of Materials

Chemistry A. 2015; 3 (31): 15824–15837. https://doi.org/10.1039/C5TA03594E.

53. Sekizawa K., Nonaka T., Arai T., and Morikawa T. Structural improvement of CaFe2O4 by metal doping toward

enhanced cathodic photocurrent. ACS Applied Materials & Interfaces. 2014; 6 (14): 10969–10973. https://doi.org/10.

1021/am502500y.

54. Klaer J., Bruns J., Henninger R., Siemer K., Klenk R., et al. Efficient thin-film solar cells prepared by a sequential

process. Semiconductor Science and Technology. 1998; 13: 1456–1458. https://doi.org/10.1088/0268-1242/13/12/

022.

55. Bihri H., Messaoudi C., Sayah D., Abd-Lefdil M., and Cadéne M. Structural and optical properties of sprayed CuInS2

thin films. Thin Solid Films. 1999; 338 (1–2): 125–130. https://doi.org/10.1016/S0040-6090(98)01069-4.

56. Yuan J., Shao C., Zheng L., Fan M., Lu H., et al. Fabrication of CuInS2 thin film by electrodeposition of Cu-In alloy.

Vacuum. 2014; 99: 196–203. https://doi.org/10.1016/j.vacuum.2013.06.005.

57. Fischereder A., Rath T., Haas W., Amenitsch H., Schenk D., et al. Investigation of CuInS2 thin film formation by a

low-temperature chemical deposition method. ACS Applied Materials & Interfaces. 2012; 4 (1): 382–390. https://doi.

org/10.1021/am2014579.

58. Kaga H. and Kudo A. Cosubstituting effects of copper(I) and gallium(III) for ZnGa2S4 with defect chalcopyrite

structure on photocatalytic activity for hydrogen evolution. Journal of Catalysis. 2014; 310: 31–36. https://doi.org/10.

1016/j.jcat.2013.08.025.

59. Quintans C. S., Kato H., Kobayashi M., Kaga H., Iwase A., et al. Improvement of hydrogen evolution under visible

light over Zn1-2x(CuGa)xGa2S4 photocatalysts by synthesis utilizing a polymerizable complex method. Journal of

Materials Chemistry A. 2015; 3 (27): 14239–14244. https://doi.org/10.1039/C5TA02114F.

60. Iwase A., Ng Y. H., Amal R., and Kudo A. Solar hydrogen evolution using a CuGaS2 photocathode improved by

incorporating reduced graphene oxide. Journal of Materials Chemistry A. 2015; 3 (16): 8566–8570. https://doi.org/10.

1039/C5TA01237F.

61. Li Q., Wu J., Wang Y., Fan W., Zhu J., et al. The effect of Zn incorporation on the optical band gap of CuGaS2: Ti

thin films. Materials Letters. 2018; 210: 70–72. https://doi.org/10.1016/j.matlet.2017.08.128.

62. Memming R. and Schwandt G. Electrochemical properties of gallium phosphide in aqueous solutions. Electrochimica

Acta. 1968; 13 (6): 1299–1310. https://doi.org/10.1016/0013-4686(68)80058-1.

63. Ziegler J., Fertig D., Kaiser B., Jaegermann W., Blug M., et al. Preparation and characterization of GaP semiconductor

electrodes for photoelectrochemical water splitting. Energy Procedia. 2012; 22: 108–113. https://doi.org/10.1016/j.

egypro.2012.05.220.

64. Aspnes D. E. and Studna A. A. Dielectric functions and optical parameters of Si, Ge, GaP, GaAs, GaSb, InP, InAs, and

InSb from 1.5 to 6.0 eV. Physical Review B Condens Matter. 1983; 27 (2): 985–1009. https://doi.org/10.1103/

PhysRevB.27.985.

65. Yoneyama H., Shiota H., and Tamura H. Photoelectrochemical properties of p-type gallium phosphide electrodes

coated with tetraphenylporphyrin. Journal of Electroanalytical Chemistry. 1983; 159 (2): 361–372. https://doi.org/10.

1016/S0022-0728(83)80634-2.

66. Heller A., Miller B., Lewerenz H. J., and Bachmann K. J. An efficient photocathode for semiconductor liquid junction

cells: 9.4% solar conversion efficiency with p-InP/VCl3-VCl2-HCl/C. Journal of the American Chemical Society.

1980; 102 (21): 6555–6556. https://doi.org/10.1021/ja00541a029.

67. Aharon-Shalom E. and Heller A. Efficient p-lnP (Rh-H alloy) and p-lnP (Re-H alloy) hydrogen evolving photo-

cathodes. Journal of the Electrochemical Society. 1982; 129 (12): 2865–2866. https://doi.org/10.1149/1.2123695.

Veruscript Funct. Nanomater. | 2018 | 2: #BDJOC3 | https://doi.org/10.22261/FNAN.BDJOC3 20

Alfaifi et al. | Photoelectrochemical solar water splitting https://www.veruscript.com/a/BDJOC3/

68. Szklarczykt M. and Bockris J. O. M. Photoelectrochemical evolution of hydrogen on p-indium phosphide. Journal of

Physical Chemistry. 1984; 88 (22): 5241–5245. https://doi.org/10.1021/j150666a026.

69. Lee M. H., Takei K., Zhang J., Kapadia R., Zheng M., et al. P-Type InP nanopillar photocathodes for efficient solar-

driven hydrogen production. Angewandte Chemie International Edition. 2012; 51 (43): 10760–10764. https://doi.

org/10.1002/anie.201203174.

70. Moriya M., Minegishi T., Kumagai H., Katayama M., Kubota J., et al. Stable hydrogen evolution from cds-modified

CuGaSe2 photoelectrode under visible-light irradiation. Journal of the American Chemical Society. 2013; 135 (10):

3733–3735. https://doi.org/10.1021/ja312653y.

71. Marsen B., Cole B., and Miller E. L. Photoelectrolysis of water using thin copper gallium diselenide electrodes. Solar

Energy Materials and Solar Cells. 2008; 92 (9): 1054–1058. https://doi.org/10.1016/j.solmat.2008.03.009.

72. Lin Y., Kapadia R., Yang J., Zheng M., Chen K., et al. Role of TiO2 surface passivation on improving the performance

of p-InP photocathodes. Journal of Physical Chemistry C. 2015; 119 (5): 2308–2313. https://doi.org/10.1021/

jp5107313.

73. Hettick M., Zheng M., Lin Y., Sutter-Fella C. M., Ager J. W., et al. Nonepitaxial thin-film InP for scalable and

efficient photocathodes. Journal of Physical Chemistry Letters. 2015; 6: 2177–2182. https://doi.org/10.1021/acs.

jpclett.5b00744.

74. Candea R. M., Kastner M., Goodman R., and Hickok N. Photoelectrolysis of water: Si in salt water. Journal of Applied

Physics. 1976; 47 (6): 2724–2726. https://doi.org/10.1063/1.322995.

75. Stephen R. G. and Riley F. L. Oxidation of silicon by water. Journal of the European Ceramic Society. 1989; 5 (4):

219–222. https://doi.org/10.1016/S0955-2219(89)80003-2.

76. Reece S. Y., Hamel J. A., Sung K., Jarvi T. D., Esswein A. J., et al. Wireless solar water splitting using silicon-based

semiconductors and earth-abundant catalysts. Science. 2011; 334 (6056): 645–648. https://doi.org/10.1126/science.

1209816.

77. Ji L., McDaniel M. D., Wang S., Posadas A. B., Li X., et al. A silicon-based photocathode for water reduction with an

epitaxial SrTiO3 protection layer and a nanostructured catalyst. Nature Nanotechnology. 2015; 10: 84–90. https://doi.

org/10.1038/nnano.2014.277.

78. Sun K., Shen S., Liang Y., Burrows P. E., Mao S. S., et al. Enabling silicon for solar-fuel production. Chemical Reviews.

2014; 114 (17): 8662–8719. https://doi.org/10.1021/cr300459q.

79. Ran J., Zhang J., Yu J., Jaroniec M., and Qiao S. Z. Earth-abundant cocatalysts for semiconductor-based photocatalytic

water splitting. Chemical Society Reviews. 2014; 43 (22): 7787–7812. https://doi.org/10.1039/C3CS60425J.

80. Shen L., He C., Qiu J., Lee S. M., Kalita A., et al. Nanostructured silicon photocathodes for solar water splitting

patterned by the self-assembly of lamellar block copolymers. ACS Applied Materials & Interfaces. 2015; 7 (47): 26043–

26049. https://doi.org/10.1021/acsami.5b08661.

81. Seger B., Tilley D. S., Pedersen T., Vesborg P. C. K., Hansen O., et al. Silicon protected with atomic layer deposited

TiO2: Durability studies of photocathodic H2 evolution. RSC Advances. 2013; 3 (48): 25902–25907. https://doi.org/

10.1039/c3ra45966g.

82. Seger B., Pedersen T., Laursen A. B., Vesborg P. C. K., Hansen O., et al. Using TiO2 as a conductive protective layer

for photocathodic H2 evolution. Journal of the American Chemical Society. 2013; 135 (3): 1057–1064. https://doi.

org/10.1021/ja309523t.

83. Bao X. Q. and Liu L. Improved photo-stability of silicon nanobelt arrays by atomic layer deposition for efficient

photocatalytic hydrogen evolution. Journal of Power Sources. 2014; 268: 677–682. https://doi.org/10.1016/j.jpowsour.

2014.06.098.

84. Ni M., Leung M. K. H., Leung D. Y. C., and Sumathy K. A review and recent developments in photocatalytic water-

splitting using TiO2 for hydrogen production. Renewable and Sustainable Energy Reviews. 2007; 11 (3): 401–425.

https://doi.org/10.1016/j.rser.2005.01.009.

85. Roy P., Berger S., and Schmuki P. TiO2 nanotubes: Synthesis and applications. Angewandte Chemie International

Edition. 2011; 50 (13): 2904–2939. https://doi.org/10.1002/anie.201001374.

86. Lee K., Mazare A., and Schmuki P. One-dimensional titanium dioxide nanomaterials: Nanotubes. Chemical Reviews.

2014; 114 (19): 9385–9454. https://doi.org/10.1021/cr500061m.

87. Tian J., Zhao Z., Kumar A., Boughton R. I., and Liu H. Recent progress in design, synthesis, and applications of one-

dimensional TiO2 nanostructured surface heterostructures: A review. Chemical Society Reviews. 2014; 43 (20): 6920–

6937. https://doi.org/10.1039/C4CS00180J.

88. Hoang S., Guo S., Hahn N. T., Bard A. J., and Mullins C. B. Visible light driven photoelectrochemical water oxidation

on nitrogen-modified TiO2 nanowires. Nano Letters. 2012; 12 (1): 26–32. https://doi.org/10.1021/nl2028188.

89. Cho I. S., Choi J., Zhang K., Kim S. J., Jeong M. J., et al. Highly efficient solar water splitting from transferred TiO2

nanotube arrays. Nano Letters. 2015; 15 (9): 5709–5715. https://doi.org/10.1021/acs.nanolett.5b01406.

Veruscript Funct. Nanomater. | 2018 | 2: #BDJOC3 | https://doi.org/10.22261/FNAN.BDJOC3 21

Alfaifi et al. | Photoelectrochemical solar water splitting https://www.veruscript.com/a/BDJOC3/

90. Jarup L. Hazards of heavy metal contamination. British Medical Bulletin. 2003; 68 (1): 167–182. https://doi.org/10.

1093/bmb/ldg032.

91. Kolodziejczak-Radzimska A. and Jesionowski T. Zinc oxide-from synthesis to application: A review. Materials (Basel).

2014; 7 (4): 2833–2881. https://doi.org/10.3390/ma7042833.

92. Djurišić A. B., Chen X., Leung Y. H., and Man Ching Ng A. ZnO nanostructures: Growth, properties and appli-

cations. Journal of Materials Chemistry. 2012; 22 (14): 6526. https://doi.org/10.1039/c2jm15548f.

93. Özgür Ü., Alivov Y. I., Liu C., Teke A., Reshchikov M. A., et al. A comprehensive review of ZnO materials and devices.

Journal of Applied Physics. 2005; 98 (4): 1–103. https://doi.org/10.1063/1.1992666.

94. Tang H., Prasad K., Sanjinès R., Schmid P. E., and Lévy F. Electrical and optical properties of TiO2 anatase thin films.

Journal of Applied Physics. 1994; 75 (4): 2042–2047. https://doi.org/10.1063/1.356306.

95. Wang Z. L. Zinc oxide nanostructures: Growth, properties and applications. Journal of Physics: Condensed Matter.

2004; 16 (25): R829–R858. https://doi.org/10.1088/0953-8984/16/25/R01.

96. Chandiran A. K., Abdi-Jalebi M., Nazeeruddin M. K., and Grätzel M. Analysis of electron transfer properties of ZnO

and TiO2 photoanodes for dye-sensitized solar cells. ACS Nano. 2014; 8 (3): 2261–2268. https://doi.org/10.1021/

nn405535j.

97. Hamid S. B. A., Teh S. J., and Lai C. W. Photocatalytic water oxidation on ZnO: A review. Catalysts. 2017; 7: 93.

https://doi.org/10.3390/catal7030093.

98. Islam M. S., Hossain M. F., and Razzak S. M. A. Enhanced photoelectrochemical performance of nanoparticle ZnO

photoanodes for water-splitting application. Journal of Photochemistry and Photobiology A: Chemistry. 2016; 326:

100–106. https://doi.org/10.1016/j.jphotochem.2016.04.002.

99. Liu X., Wang F., and Wang Q. Nanostructure-based WO3 photoanodes for photoelectrochemical water splitting.

Physical Chemistry Chemical Physics. 2012; 14 (22): 7894–7911. https://doi.org/10.1039/c2cp40976c.

100. Iwai T. Temperature dependence of the optical absorption edge of tungsten trioxide single crystal. Journal of the

Physical Society of Japan. 1960; 15: 1596–1600. https://doi.org/10.1143/JPSJ.15.1596.

101. Butler M. A. Photoelectrolysis and physical properties of the semiconducting electrode WO2. Journal of Applied

Physics. 1977; 48 (5): 1914–1920. https://doi.org/10.1063/1.323948.

102. Desilvestro J. and Grätzel M. Photoelectrochemistry of polycrystalline n-WO2 electrochemical characterization and

photoassisted oxidation processes. Journal of Electroanalytical Chemistry. 1987; 238 (1–2): 129–150. https://doi.org/

10.1016/0022-0728(87)85170-7.

103. Amano F., Tian M., Wu G., Ohtani B., and Chen A. Facile preparation of platelike tungsten oxide thin film electrodes

with high photoelectrode activity. ACS Applied Materials & Interfaces. 2011; 3 (10): 4047–4052. https://doi.org/10.

1021/am200897n.

104. Thind S. S., Tian M., and Chen A. Direct growth and photo-electrochemical study of WO3 nanostructured materials.

Electrochemistry Communications. 2014; 43: 13–17. https://doi.org/10.1016/j.elecom.2014.03.002.

105. Bak T., Nowotny J., Rekas M., and Sorrell C. C. Photo-electrochemical hydrogen generation from water using solar

energy. Materials-related aspects. International Journal of Hydrogen Energy. 2002; 27 (10): 991–1022. https://doi.org/

10.1016/S0360-3199(02)00022-8.

106. van de Krol R., Liang Y., and Schoonman J. Solar hydrogen production with nanostructured metal oxides. Journal of

Materials Chemistry. 2008; 18 (20): 2311–2320. https://doi.org/10.1039/b718969a.

107. Li J. and Wu N. Semiconductor-based photocatalysts and photoelectrochemical cells for solar fuel generation: A review.

Catalysis Science & Technology. 2015; 5 (3): 1360–1384. https://doi.org/10.1039/C4CY00974F.

108. Dotan H., Sivula K., Grätzel M., Rothschild A., and Warren S. C. Probing the photoelectrochemical properties of

hematite (α-Fe2O3) electrodes using hydrogen peroxide as a hole scavenger. Energy and Environmental Science. 2011;

4 (3): 958–964. https://doi.org/10.1039/C0EE00570C.

109. Katz M. J., Riha S. C., Jeong N. C., Martinson A. B. F., Farha O. K., et al. Toward solar fuels: Water splitting with

sunlight and “rust”? Coordination Chemistry Reviews. 2012; 256 (21–22): 2521–2529. https://doi.org/10.1016/j.ccr.

2012.06.017.

110. Chen S., Thind S. S., and Chen A. Nanostructured materials for water splitting - State of the art and future needs: A

mini-review. Electrochemistry Communications. 2016; 63: 10–17. https://doi.org/10.1016/j.elecom.2015.12.003.

111. Dare-Edwards M. P., Goodenough J. B., Hamnett A., and Trevellick P. R. Electrochemistry and photoelectrochemistry

of iron(III) oxide. Journal of the Chemical Society, Faraday Transactions. 1983; 79 (9): 2027. https://doi.org/10.1039/

f19837902027.

112. Hamann T. W. Splitting water with rust: Hematite photoelectrochemistry. Dalton Transactions. 2012; 41 (26): 7830–

7834. https://doi.org/10.1039/c2dt30340j.

113. Kay A., Cesar I., and Grätzel M. New benchmark for water photooxidation by nanostructured α-Fe2O3 films. Journal

of the American Chemical Society. 2006; 128 (49): 15714–15721. https://doi.org/10.1021/ja064380l.

Veruscript Funct. Nanomater. | 2018 | 2: #BDJOC3 | https://doi.org/10.22261/FNAN.BDJOC3 22

Alfaifi et al. | Photoelectrochemical solar water splitting https://www.veruscript.com/a/BDJOC3/

114. Malara F., Minguzzi A., Marelli M., Morandi S., Psaro R., et al. α-Fe2O3/NiOOH: An effective heterostructure for

photoelectrochemical water oxidation. ACS Catalysis. 2015; 5 (9): 5292–5300. https://doi.org/10.1021/acscatal.

5b01045.

115. Zeng Q., Bai J., Li J., Xia L., Huang K., et al. A novel in situ preparation method for nanostructured α-Fe2O3 films

from electrodeposited Fe films for efficient photoelectrocatalytic water splitting and the degradation of organic pol-

lutants. Journal of Materials Chemistry A. 2015; 3 (8): 4345–4353. https://doi.org/10.1039/C4TA06017B.

116. Park Y., McDonald K. J., and Choi K.-S. Progress in bismuth vanadate photoanodes for use in solar water oxidation.

Chemical Society Reviews. 2013; 42 (6): 2321–2337. https://doi.org/10.1039/C2CS35260E.

117. Kudo A., Omori K., and Kato H. A novel aqueous process for preparation of crystal form-controlled and highly

crystalline BiVO4 powder from layered vanadates at room temperature and its photocatalytic and photophysical

properties. Journal of the American Chemical Society. 1999; 121 (49): 11459–11467. https://doi.org/10.1021/

ja992541y.

118. Pihosh Y., Turkevych I., Mawatari K., Uemura J., Kazoe Y., et al. Photocatalytic generation of hydrogen by core-shell

WO3/BiVO4 nanorods with ultimate water splitting efficiency. Scientific Reports. 2015; 5: 11141. https://doi.org/10.

1038/srep11141.

119. Abdi F. F., Han L., Smets A. H. M., Zeman M., Dam B., et al. Efficient solar water splitting by enhanced charge

separation in a bismuth vanadate-silicon tandem photoelectrode. Nature Communications. 2013; 4: 1–7. https://doi.

org/10.1038/ncomms3195.

120. Huang Z.-F., Pan L., Zou J.-J., Zhang X., and Wang L. Nanostructured bismuth vanadate-based materials for solar-

energy-driven water oxidation: A review on recent progress. Nanoscale. 2014; 6 (23): 14044–14063. https://doi.org/10.

1039/C4NR05245E.

121. Wu Q., Voorhis T. V., Nocera D. G., Nocera D. G., Bansal A., et al. Nanoporous with dual-layer oxygen evolution

catalysts for solar water splitting. Science. 2014; 343 (6174): 990–994. https://doi.org/10.1126/science.1246913.

122. Chen Y. S., Manser J. S., and Kamat P. V. All solution-processed lead halide perovskite-BiVO4 tandem assembly for

photolytic solar fuels production. Journal of the American Chemical Society. 2015; 137 (2): 974–981. https://doi.org/

10.1021/ja511739y.

123. Su J., Guo L., Bao N., and Grimes C. A. Nanostructured WO3/BiVO4 heterojunction films for efficient photo-

electrochemical water splitting. Nano Letters. 2011; 11 (5): 1928–1933. https://doi.org/10.1021/nl2000743.

124. Hong S. J., Lee S., Jang J. S., and Lee J. S. Heterojunction BiVO4/WO3 electrodes for enhanced photoactivity of water

oxidation. Energy and Environmental Science. 2011; 4 (5): 1781–1787. https://doi.org/10.1039/c0ee00743a.

125. Baek J. H., Kim B. J., Han G. S., Hwang S. W., Kim D. R., et al. BiVO4/WO3/SnO2 double-heterojunction

photoanode with enhanced charge separation and visible-transparency for bias-free solar water-splitting with a

perovskite solar cell. ACS Applied Materials & Interfaces. 2017; 9 (2): 1479–1487. https://doi.org/10.1021/acsami.

6b12782.

126. Benko F. A., MacLaurin C. L., and Koffyberg F. P. CuWO4 and Cu3WO6 as anodes for the photoelectrolysis of water.

Materials Research Bulletin. 1982; 17 (1): 133–136. https://doi.org/10.1016/0025-5408(82)90194-5.

127. Arora S. K., Mathew T., and Batra N. M. Electrochemical characteristics of copper tungstate single crystals. Journal of

Physics D: Applied Physics. 1990; 23: 460–464. https://doi.org/10.1088/0022-3727/23/4/013.

128. Chang Y., Braun A., Deangelis A., Kaneshiro J., and Gaillard N. Effect of thermal treatment on the crystallographic,

surface energetics, and photoelectrochemical properties of reactively cosputtered copper tungstate for water splitting.

Journal of Physical Chemistry C. 2011; 115 (51): 25490–25495. https://doi.org/10.1021/jp207341v.

129. Ume V. O. I. Millimeter-wave paramagnetic resonance spectrum of 6S state impurity (Fe+++) in MgWO4. Physical

Review. 1959; 113 (3): 801–803. https://doi.org/10.1103/PhysRev.113.801.

130. Yourey J. E. and Bartlett B. M. Electrochemical deposition and photoelectrochemistry of CuWO4, a promising

photoanode for water oxidation. Journal of Materials Chemistry. 2011; 21: 7651–7660. https://doi.org/10.1039/

c1jm11259g.

131. Pandey P. K., Bhave N. S., and Kharat R. B. Spray deposition process of polycrystalline thin films of CuWO4 and study

on its photovoltaic electrochemical properties. Materials Letters. 2005; 59 (24–25): 3149–3155. https://doi.org/10.

1016/j.matlet.2005.05.018.

132. Gaillard N., Chang Y., Deangelis A., Higgins S., and Braun A. A nanocomposite photoelectrode made of 2.2 eV band

gap copper tungstate (CuWO4) and multi-wall carbon nanotubes for solar-assisted water splitting. International Journal

of Hydrogen Energy. 2013; 38 (8): 3166–3176. https://doi.org/10.1016/j.ijhydene.2012.12.104.

133. Yourey J. E. J., Pyper K. J. K., Kurtz J. B., and Bartlett B. M. Chemical stability of CuWO4 for photoelectrochemical

water oxidation. Journal of Physical Chemistry C. 2013; 117 (17): 8708–8718. https://doi.org/10.1021/jp402048b.

134. Valenti M., Dolat D., Biskos G., Schmidt-Ott A., and Smith W. A. Enhancement of the photoelectrochemical

performance of CuWO4 thin films for solar water splitting by plasmonic nanoparticle functionalization. Journal of

Physical Chemistry C. 2015; 119 (4): 2096–2104. https://doi.org/10.1021/jp506349t.