Professional Documents

Culture Documents

R19012 PMB STR 004 - Change Rooms Foundation Layout

Uploaded by

forbeskaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

R19012 PMB STR 004 - Change Rooms Foundation Layout

Uploaded by

forbeskaCopyright:

Available Formats

CONCRETE NOTES

1. CONCRETE CONSTRUCTION SHALL BE PERFORMED TO SANS 1200

10580 10580 2. ALL CONCRETE SHALL BE

600 9380 600 600 9380 600 FOUNDATIONS - 30 MPa AT 28 DAYS U.O.N.

3. BLINDING CONCRETE TO BE MINIMUM 10 MPa

4. ALL EXPOSED CORNERS TO HAVE 25mm CHAMFER

5. ALL REINFORCEMENT TO HAVE

600

600

50mm COVER - FOUNDATIONS AND GROUND FLOOR SLAB

30mm COVER - ALL OTHER SECTIONS

6. ALL REINFORCEMENT TO LAP WITH MIN 45 DIAMETERS U.O.N.

7. REINFORCEMENT DIMENSIONS ARE ACCORDING TO SANS 282

8. ALL CONCRETE SHALL BE PROPERLY CURED FOR AT LEAST

3130

3130

7 DAYS U.O.N.

9. FINISHES ON CONCRETE FLOOR MUST CONFORM TO SABS 0109.

10. AT LEAST 6 CONCRETE TEST CUBES MUST BE TAKEN BY TRAINED PERSONNEL

A A A A 4100 FOR EVERY 12 CUBES OF READY MIX CONCRETE.

B B 600 2900 600

7520

7520

MASONRY NOTES

600

600

1. ALL MORTAR TO BE CLASS II TO SANS 10164 (MIN. 7 MPa).

600

2. SAND IN MORTAR SHALL COMPLY TO SANS 1090.

B B 3. ALL BRICKS TO HAVE A MINIMUM COMPRESSIVE STRENGTH

A A OF 7 MPa AND A MAXIMUM WATER ABSORPTION OF 10%.

4. MANUFACTURING CONTROL OF MASONRY TO BE CATEGORY II TO SANS 10164.

2590

2590

2400

3600

5. CONSTRUCTION CONTROL OF MASONRY TO BE CATEGORY II TO SANS 10164.

6. BRICK-FORCE TO BE PROVIDED EVERY THIRD COURSE IN ALL WALLS . ADDITIONAL

BRICK-FORCE ABOVE ALL OPENINGS SHALL BE EXTENDED AT LEAST 350MM ON

BOTH SIDES OF THE OPENING.

7. BRICK FORCE SHALL BE PROVIDED IN EVERY LAYER FOR THE FIRST FIVE COURSES

600

600

600

OVER OPENINGS WIDER THAN 1.0 m.

8. MORTAR TO BE CONTINUOUS BETWEEN SKINS OF DOUBLE WALLS.

9. HOLLOW CORE IN BRICKS TO BE FILLED WITH MORTAR.

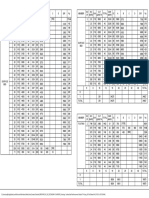

FOUNDATIOND LAYOUT:FEMALE FOUNDATIOND LAYOUT:MALE FOUNDATIOND LAYOUT:GUARD HOUSE

10. ALL LINTOLS TO COMPLY TO SANS 1504 AND EXTEND MIN 250 BEYOND OPENINGS.

SCALE 1:50 SCALE 1:50 SCALE 1:50

11. DPC UNDER ALL FLOORS AS SHOWN ON THE DRAWING DETAILS. DPC TO BE

250 MICRON BRICK GRIP TYPE.

12. BRICK TIES FOR ALL CAVITY WALLS, MILD STEEL VERTICAL TWIST TIES 4mm THICK

AND 200mm LONG AT 5 TIES PER SQUARE METER AS PER SANS 10164-1: 1980.

375 MICRON DPC 12 mm ISOLATION JOINT 12 mm ISOLATION JOINT 12 mm ISOLATION JOINT 13. THE CONTRACTOR TO SUPPLY THE DESIGN ENGINEER WITH MASONRY TEST RESULT

125 THK. MESH-REINFORCED 125 THK. MESH-REINFORCED 125 THK. MESH-REINFORCED FROM THE SUPPLIERS FOR QUALITY CONTROL.

GROUND SLAB GROUND SLAB GROUND SLAB 14. RANDOM SAMPLES OF MASONRY UNITS DELIVERED ON SITE TO BE TAKEN FOR TESTING

FOR THE DURATION OF THE PROJECT, RESULTS TO BE APPROVED BY THE ENGINEER.

125

125

N.G.L N.G.L N.G.L EXCAVATION NOTES

300

1. CAUTION TO BE TAKEN DURING EXCAVATIONS ON SANDY COLLAPSIBLE MATERIAL.

300

26Y8-01-250 3Y12-02-250 T2 26Y8-01-250 725 250 MICRON DPM 250 MICRON DPM

3Y12-02-250 B2

725

BACKFILL WITH SELECTED G6 MATERIAL BACKFILL WITH SELECTED G6 MATERIAL 2. ALL DISCOVERIES DURING EXCAVATION MUST BE COMMUNICATED TO THE ENGINEER.

COMPACTED TO 95% MOD AASTHO COMPACTED TO 95% MOD AASTHO 3. AT LEAST 300 mm THICK G5 MATERIAL UNDER ALL GROUND SLABS AND FOOTINGS.

300

300

39Y8-01-250

R.C. STRIP FOOTING R.C. STRIP FOOTING COMPACTED AT 150 mm THICK LAYERS AT 95% MOD AASHTO U.O.N.

50 mm BLINDING LAYER 50 mm BLINDING LAYER 4. ALL EXISTING SERVICES TO BE DISCONNECTED AND RELOCATE BEFORE THE

COMMENCEMENT OF EXCAVATIONS.

5. REQUIREMENTS FROM OCCUPATIONAL HEALTH AND SAFETY ACT TO BE COMPLIED WITH

185 230 185 SOLID NATURAL GROUND 185 230 185 SOLID NATURAL GROUND

600 600 AT ALL TIMES

3Y12-03-250 T2 3Y12-03-250 T2 SECTION A-A SECTION B-B

3Y12-03-250 B2 3Y12-03-250 B2 SCALE 1:20 SCALE 1:20

C C

3Y12-02-250 T2 11Y8-01-250 3Y12-04-250 T2 11Y8-01-250

3Y12-02-250 B2 3Y12-04-250 B2

39Y8-01-250 13Y8-01-250

3Y12-05-250 T2 3Y12-05-250 T2

3Y12-05-250 B2 3Y12-05-250 B2

3Y12-02-250 T2

3Y12-02-250 B2

01

13Y8-01-250

39Y8-01-250

No BARS TOTAL BENDING

3Y12-03-250 T2 3Y12-04-250 T2

3Y12-04-250 B2 MEMBER PER DIA. LENGTH NUM- MARK SC

3Y12-03-250 B2

OF MEMB BER A B C D E/r

FOUNDATIOND REINFORCEMENT LAYOUT:FEMALE & MALE SECTION C-C FOUNDATIOND REINFORCEMENT LAYOUT:GUARD HOUSE FOUNDATIONS 2 169

18

Y8

Y12

1550

10480

338

36

01

02

60

20

200 500

SCALE 1:50 SCALE 1:20 SCALE 1:50 12 Y12 7420 24 03 20

1 22 Y8 1550 22 01 60 200 500

12 Y12 4000 12 04 20

12 Y12 3500 12 05 20

8 10 12 16 20 25 32 40 TOT Date 2019/04/05

R Det. by N MALINDISA

Y 220 573 793 Ref Dwg R19012-PMB-STR-004

TOT 220 573 793 Revision 01

REFERENCE DRAWINGS APPROVER: Q.M.S CHECKING SYSTEM No. 11 MALOKIBA INDUSTRIAL PARK

Scale.

NAME: 1 BRUNEL ROAD

DRAWN BY: N MALINDISA EVANDER, MPUMALANGA

Drawing no.

Pr. No. 2280 PROPOSED SPORTSFIELD GRANDSTAND

DRAWING CHECK: V CHIYA R19012-PMB-STR-004

P.O. Box 3211

For: ROBUST CONSULTING SECUNDA CHANGE ROOMS FOUNDATION LAYOUT

DRAWING REVIEW: M WAYITI Client drawing no.

Revisions

ENGINEERS (PTY) LTD 2302

Sign: DESIGN ENG.: F KAMBA Tell: 086 117 7726

01 2019/04/05 ISSUED FOR INFORMATION NM Fax: 086 535 3817

Date:

No. Date Description Initial

DESIGN REVIEW: M WAYITI E-mail: info@robustengineers.co.za Revision No. A1

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- South African Pavement Engineering Manual Chapter 3 - Materials TestingDocument108 pagesSouth African Pavement Engineering Manual Chapter 3 - Materials TestingKevin TangNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Plans Proposed Completion Three Storey Building For Isolation RoomsDocument72 pagesPlans Proposed Completion Three Storey Building For Isolation RoomsJake CanlasNo ratings yet

- Africa HandBook 2022-23Document65 pagesAfrica HandBook 2022-23Govinda NaidooNo ratings yet

- CHAPTER 20 1ST WORKING DRAFT FOR COMMENT 20 Apr 2018 PDFDocument55 pagesCHAPTER 20 1ST WORKING DRAFT FOR COMMENT 20 Apr 2018 PDFforbeskaNo ratings yet

- Low Voltage ATS GuideDocument50 pagesLow Voltage ATS GuideAnom Pletot Badoger100% (1)

- Final Circuit and Load Estimation British StandardDocument28 pagesFinal Circuit and Load Estimation British Standardhaidarkukum5686100% (3)

- INDUSTRY GUIDE T48 Guide To Industrial Floors and Pavements Design Construction and Specification PDFDocument121 pagesINDUSTRY GUIDE T48 Guide To Industrial Floors and Pavements Design Construction and Specification PDFHeriberto Yau B100% (1)

- Design Office PracticeDocument10 pagesDesign Office PracticeSandeep Varma100% (1)

- Hager Protection Devices TechnicalDocument70 pagesHager Protection Devices TechnicalerreagaaNo ratings yet

- 6 - Lightning Protection of Wind Turbines - ERICHSENDocument26 pages6 - Lightning Protection of Wind Turbines - ERICHSENemy_mogosNo ratings yet

- Peugeot Partner Owners Manual 2005Document73 pagesPeugeot Partner Owners Manual 2005grangreca100% (1)

- PPS Building Works 1Document179 pagesPPS Building Works 1forbeskaNo ratings yet

- End of Job and Site Records: The Resident EngineerDocument1 pageEnd of Job and Site Records: The Resident EngineerMichelle MatthewsNo ratings yet

- 5 - Sections PDFDocument1 page5 - Sections PDFforbeskaNo ratings yet

- The Potential of South African Timber Products To Reduce The Environmental Impact of BuildingsDocument8 pagesThe Potential of South African Timber Products To Reduce The Environmental Impact of BuildingsforbeskaNo ratings yet

- CIV - 262 - SECONDARY CLARIFIERS - Footings Surface Bed Reinforcement Details TH1-ModelDocument1 pageCIV - 262 - SECONDARY CLARIFIERS - Footings Surface Bed Reinforcement Details TH1-ModelforbeskaNo ratings yet

- Part C - Wayeni Tender DrawingsDocument26 pagesPart C - Wayeni Tender DrawingsforbeskaNo ratings yet

- Ac 2009-131: China Megastructures: Learning by Experience: Richard Balling, Brigham Young UniversityDocument9 pagesAc 2009-131: China Megastructures: Learning by Experience: Richard Balling, Brigham Young UniversityforbeskaNo ratings yet

- 5 - Sections PDFDocument1 page5 - Sections PDFforbeskaNo ratings yet

- 5 - Sections PDFDocument1 page5 - Sections PDFforbeskaNo ratings yet

- Lab 1 Qual Ana F11Document9 pagesLab 1 Qual Ana F11Kroya HunNo ratings yet

- Civ Ui 0801a 242 ExtractDocument1 pageCiv Ui 0801a 242 ExtractforbeskaNo ratings yet

- 5 - Sections PDFDocument1 page5 - Sections PDFforbeskaNo ratings yet

- BK Series Kilcher Bearing StripsDocument6 pagesBK Series Kilcher Bearing Stripsforbeska100% (1)

- P2000 Checklist For Design Approval of Minor Sewer Extension 21 April 2011Document3 pagesP2000 Checklist For Design Approval of Minor Sewer Extension 21 April 2011forbeskaNo ratings yet

- Pineapple Beer - How To Make Tepache (Mexican Pineapple Beer) - 7 Steps - InstructablesDocument11 pagesPineapple Beer - How To Make Tepache (Mexican Pineapple Beer) - 7 Steps - InstructablesforbeskaNo ratings yet

- A8002 3 X Type A Unit Rev 01-315 R01Document1 pageA8002 3 X Type A Unit Rev 01-315 R01forbeskaNo ratings yet

- A8002 3 X Type A Unit Rev 01-STR 315Document1 pageA8002 3 X Type A Unit Rev 01-STR 315forbeskaNo ratings yet

- VCE Study TiepsDocument2 pagesVCE Study TiepsforbeskaNo ratings yet

- A8001 2 X Type B Unit Rev 01-STR 310Document1 pageA8001 2 X Type B Unit Rev 01-STR 310forbeskaNo ratings yet

- A8001 2 X Type B Unit Rev 01-310 R01Document1 pageA8001 2 X Type B Unit Rev 01-310 R01forbeskaNo ratings yet

- Municipal stamps guide history and ownershipDocument1 pageMunicipal stamps guide history and ownershipforbeskaNo ratings yet

- A8001 2 X Type B Unit Rev 02-310 R01Document1 pageA8001 2 X Type B Unit Rev 02-310 R01forbeskaNo ratings yet

- Easy Homemade Pineapple Beer Recipe With Three Ingredients - PDFDocument1 pageEasy Homemade Pineapple Beer Recipe With Three Ingredients - PDFforbeskaNo ratings yet

- VCE Study TiepsDocument2 pagesVCE Study TiepsforbeskaNo ratings yet

- Coffer Slab ThokoDocument8 pagesCoffer Slab ThokoforbeskaNo ratings yet

- Rain Alarm ProjectDocument28 pagesRain Alarm Projectrinkoo067% (6)

- Echlin Part No RefDocument85 pagesEchlin Part No Refpilveni100% (1)

- Ac and DC Machines Objectives Type QuestionsDocument6 pagesAc and DC Machines Objectives Type QuestionsJohn Norie BaydalNo ratings yet

- 750-2 KTA38-G2B Caracteristica Motor y AlternadorDocument4 pages750-2 KTA38-G2B Caracteristica Motor y AlternadorjosegqNo ratings yet

- t-030f Spanish p35-48Document4 pagest-030f Spanish p35-48Juan ContrerasNo ratings yet

- Daewoo Matiz 2000-2013 Airbags 1-6 PDFDocument6 pagesDaewoo Matiz 2000-2013 Airbags 1-6 PDFsheoNo ratings yet

- ASHRAE 90.1 Building Envelope RequirementsDocument51 pagesASHRAE 90.1 Building Envelope RequirementsRam RamisettiNo ratings yet

- Product Data Sheet 3RH1440-1BM40: Contactor Relay, Latched, 4-Pole, 4 NO, SIZE S00, DC 220VDocument5 pagesProduct Data Sheet 3RH1440-1BM40: Contactor Relay, Latched, 4-Pole, 4 NO, SIZE S00, DC 220VRazvan MaresNo ratings yet

- Selection of Circuit BreakersDocument12 pagesSelection of Circuit BreakersPrudhvi RajNo ratings yet

- Miniature Aluminum Electrolytic Capacitors: NRSA Series NrsaDocument3 pagesMiniature Aluminum Electrolytic Capacitors: NRSA Series NrsaMinh VuNo ratings yet

- Maxwell High SchoolDocument25 pagesMaxwell High SchoolBrandon DonNo ratings yet

- NG125 MCBDocument9 pagesNG125 MCBSaswita SaktiNo ratings yet

- JS200 Excavator Electrical Parts CatalogDocument3 pagesJS200 Excavator Electrical Parts CatalogLiliana GarciaNo ratings yet

- Web Par 5020Document2 pagesWeb Par 5020Rosel TeliNo ratings yet

- 8 Speed Shift Lock Solenoid ProblemsDocument12 pages8 Speed Shift Lock Solenoid ProblemsDerek ChanNo ratings yet

- Wall+Footing+ +Quantity+SurveyDocument6 pagesWall+Footing+ +Quantity+SurveyGemmby Labing DizonNo ratings yet

- Sahl stock list document with parts numbers and descriptionsDocument123 pagesSahl stock list document with parts numbers and descriptionsAnonymous t8U6sKtYSNo ratings yet

- Installation Guide For 20/20: Profile Ridge, Rollridge, Roll Hip, Profile Mono Ridge and 20/20 Verge InstallationDocument6 pagesInstallation Guide For 20/20: Profile Ridge, Rollridge, Roll Hip, Profile Mono Ridge and 20/20 Verge Installationslindelft-cool7056No ratings yet

- 6A 12v Solar MPPT AnalogDocument4 pages6A 12v Solar MPPT AnalogRyn YahuFNo ratings yet

- Moglix Material PendencyyDocument12 pagesMoglix Material Pendencyylucky sharmaNo ratings yet

- Simbologia Eletrica 1Document4 pagesSimbologia Eletrica 1SarjitoNo ratings yet

- Zenoah 3366 G620PUDocument8 pagesZenoah 3366 G620PUMuhammad Indra RespatiNo ratings yet

- Is-Iec 60309-2 (2002)Document74 pagesIs-Iec 60309-2 (2002)Lean_Heredia100% (1)

- Take Ac Generator Quiz To Test Your KnowledgeDocument5 pagesTake Ac Generator Quiz To Test Your KnowledgeRubab MalikNo ratings yet