Professional Documents

Culture Documents

Ultrasonic Test Report: Tested by Ies-Industrial Engineering Services

Uploaded by

Amit HasanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultrasonic Test Report: Tested by Ies-Industrial Engineering Services

Uploaded by

Amit HasanCopyright:

Available Formats

Page 1 of 1

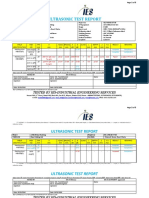

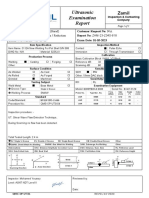

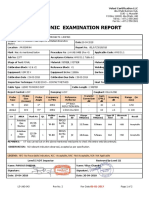

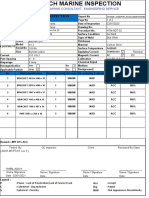

ULTRASONIC TEST REPORT

Inspection date : 13-April-19 Report no : IES /KCCL/PH-2K-2/UT-02

Project : Modern Erection Limited UT Equipment : ADVANSCAN AS-414

Contractor : BIX Range : 0 ~ 100

Vessel no : MEL 030 SWT-500-09 Search unit :MBW 70 N4 (9MM,70º, 4 MH

NDT no :05/2019 (Batch-8) Calibration block : IIW V2 Block, Reference blo

Total joint :2 / OD-1156 mm Welding process : ARC WELDING.

Welding process :GTAW/MMAW WeldingPrep : Single Vee

Surface condition : As Smooth

Couplent : Lube Oil

WELD INDI. THK X Y(yw) BPL(w) A d CLASS L DEPTH y Y-y RESULT REMARKS

IDENTIFICATION NO. mm mm mm mm. dB dB. mm. mm. mm. mm.

Top tube plate Weld - - - - 36.5 - - - - - Accepted Satisfactory

1 8

to shell

Bottom tube plate weld - - - - 36.5 - - - - - Accepted Satisfactory

1 8

to shell

T** LEGEND: X = Circumferential distance from datum, Y= Distance from weld C/L to probe index. BPL = Beam path length, y = Calculated distance from probe index, L =

Length, a = Indication level, d = Indication rating,

Defect Code: CR- Crack IP-Incomplete Penetration IF– Incomplete Fusion SL- Slag P- Porosity EP-Excess Penetration CP- Cluster Porosity CON – Concavity BSR – Before Stress Relief ASR – After Stress Rel

TESTED BY: KK JV Witness KK JV AUTHORITY approved

Name: Tarikul Islam Name: SUMSU UDIN Name:

ASNT Level –II (Ultrasonic Test) KK JV - Assistant Engineer

Signature: Signature:

Date: 10-08-2017 Date:

TEST CARRIED OUT AS PER CODE & STANDARD OF API Standard 1104

TESTED BY IES-INDUSTRIAL ENGINEERING SERVICES

House # 64, (1st Floor), Road # 06, Block # A, Sec # 12, Mirpur, Dhaka-1216, Phone : +8804477972245, 01710134359, 01711834576,

E-mail: iesbd2000@gmail.com, ahies.bd@gmail.comashik@iesndt.com, amit@iesndt.com, Web: www.iesndt.com

You might also like

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument4 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Industrial Engineering Services: Ultrasonic Test ReportDocument2 pagesIndustrial Engineering Services: Ultrasonic Test ReportShifat UllahNo ratings yet

- Ultrasonic Test ReportDocument3 pagesUltrasonic Test ReportMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- BC MT 1688-0000Document84 pagesBC MT 1688-0000Tuấn ĐậuNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument3 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument1 pageUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic inspection reportDocument1 pageUltrasonic inspection reportMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument3 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument4 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Arbab Polypack UT Inspection ReportDocument4 pagesArbab Polypack UT Inspection ReportMD Shadikul Huq ShezanNo ratings yet

- 1-UT-Pot Shell 588Document2 pages1-UT-Pot Shell 588Azhar GulzarNo ratings yet

- Ultrasonic Inspection ReportDocument1 pageUltrasonic Inspection ReportMD Shadikul Huq ShezanNo ratings yet

- CPP HT Pipeline ReportDocument301 pagesCPP HT Pipeline ReportAbdulkaderNo ratings yet

- Ultrasonic Inspection Report: REPORT NO.-UT-HB-1003723Document1 pageUltrasonic Inspection Report: REPORT NO.-UT-HB-1003723Ahmed GomaaNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Cold Test Report 3Document1 pageCold Test Report 3Venkitesh PG100% (1)

- CB-043 Mpi Exp-02 Apr 2024Document1 pageCB-043 Mpi Exp-02 Apr 2024Ahmed Abu EleninNo ratings yet

- Ut Report - 018 - Fab Tech Abudhabi LLC 19.04.2018Document2 pagesUt Report - 018 - Fab Tech Abudhabi LLC 19.04.2018ADOBEENo ratings yet

- Industrial Engineering Services: Ultrasonic Test ReportDocument2 pagesIndustrial Engineering Services: Ultrasonic Test ReportShifat UllahNo ratings yet

- Cold Test Report 2Document1 pageCold Test Report 2Venkitesh PGNo ratings yet

- UT REPORT 054 - Emirates CMS Power Company - 17.11.2019Document2 pagesUT REPORT 054 - Emirates CMS Power Company - 17.11.2019ADOBEENo ratings yet

- Gpti Qicl J931 Mut 041Document3 pagesGpti Qicl J931 Mut 041uselessinstaid52No ratings yet

- Paut Inspection Report: Client Rfi NoDocument6 pagesPaut Inspection Report: Client Rfi NoThiru Maran MasterscanNo ratings yet

- Gpti Qicl 032Document2 pagesGpti Qicl 032uselessinstaid52No ratings yet

- 75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Document1 page75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Mohamed El-SawahNo ratings yet

- Paut Inspection Report: Client Rfi NoDocument5 pagesPaut Inspection Report: Client Rfi NoThiru Maran MasterscanNo ratings yet

- Paut Inspection Report: Client Rfi NoDocument7 pagesPaut Inspection Report: Client Rfi NoThiru Maran MasterscanNo ratings yet

- Report No - 038 - NFT Specialized - 20.11.2018Document1 pageReport No - 038 - NFT Specialized - 20.11.2018ADOBEENo ratings yet

- Gpti Qicl J931 Mut 002Document2 pagesGpti Qicl J931 Mut 002uselessinstaid52No ratings yet

- Paut Inspection Report: Client Rfi NoDocument5 pagesPaut Inspection Report: Client Rfi NoThiru Maran MasterscanNo ratings yet

- Paut Inspection Report: Client Rfi NoDocument6 pagesPaut Inspection Report: Client Rfi NoThiru Maran MasterscanNo ratings yet

- PAUT INSPECTION REPORTDocument7 pagesPAUT INSPECTION REPORTThiru Maran MasterscanNo ratings yet

- Sievert Emirates Inspection L.L.C.: Magnetic Particle Testing ReportDocument1 pageSievert Emirates Inspection L.L.C.: Magnetic Particle Testing ReportAvijit DebnathNo ratings yet

- South Yoloten Gas Field Development Turkmenistan: Daily Welding ReportDocument2 pagesSouth Yoloten Gas Field Development Turkmenistan: Daily Welding ReportOctavian PanteaNo ratings yet

- Paut Inspection Report: Client Rfi NoDocument5 pagesPaut Inspection Report: Client Rfi NoThiru Maran MasterscanNo ratings yet

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- Magnetic Examination Report: International Inspection Services L.L.CDocument1 pageMagnetic Examination Report: International Inspection Services L.L.CAzhar AhmadNo ratings yet

- Liquid PenetrantDocument2 pagesLiquid PenetrantabdiNo ratings yet

- Dye Penetrant Testing Report SummaryDocument2 pagesDye Penetrant Testing Report SummaryyuwantoniNo ratings yet

- Paut Inspection Report: Client Rfi NoDocument6 pagesPaut Inspection Report: Client Rfi NoThiru Maran MasterscanNo ratings yet

- Content 20240115185834Document2 pagesContent 20240115185834BLY YEDEKPA NOEL BENITONo ratings yet

- Scip2 TGXDocument6 pagesScip2 TGXKarthikeyan Ganesan100% (1)

- Phased Array Ultrasonic Examination Report: Contractor: Report No.: Client: Exam DateDocument1 pagePhased Array Ultrasonic Examination Report: Contractor: Report No.: Client: Exam DateshervinyNo ratings yet

- Coflexip Hose (Tr1-031851clm301)Document1 pageCoflexip Hose (Tr1-031851clm301)RonniNo ratings yet

- Radiographic Testing Report: Project: ClientDocument8 pagesRadiographic Testing Report: Project: ClientĐăng ĐàoNo ratings yet

- Utl 001 002 PDFDocument2 pagesUtl 001 002 PDFfreeman11072000No ratings yet

- Thickness Gauging Report SummaryDocument1 pageThickness Gauging Report SummaryRonniNo ratings yet

- PQR FLow LineDocument2 pagesPQR FLow Linesar sarNo ratings yet

- Industrial Training Sir//Ices A L-Eading ND:F: Inspection (Iits) CornpanyDocument1 pageIndustrial Training Sir//Ices A L-Eading ND:F: Inspection (Iits) Cornpanyআশার আলোNo ratings yet

- Magnetic Particle Inspection: NDT Service - Marine Consultant - Engineering ServiceDocument4 pagesMagnetic Particle Inspection: NDT Service - Marine Consultant - Engineering ServiceSulthan HanifNo ratings yet

- Gpti Qicl J931 Mut 004Document3 pagesGpti Qicl J931 Mut 004uselessinstaid52No ratings yet

- ZWESB-XESSB-RT-007Document1 pageZWESB-XESSB-RT-007Aku DaudNo ratings yet

- Crown Specialized For Steel Contracting Co. Ltd. Welding Inspection ReportDocument1 pageCrown Specialized For Steel Contracting Co. Ltd. Welding Inspection ReportYasar AliNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Gpti Qicl J931 Mut 019Document3 pagesGpti Qicl J931 Mut 019uselessinstaid52No ratings yet

- Amir Construction & Company Ltd. Manlift UT Report-14 (06.10.22)(1)Document3 pagesAmir Construction & Company Ltd. Manlift UT Report-14 (06.10.22)(1)sumit singhNo ratings yet

- DPT Report 02Document2 pagesDPT Report 02Amit Hasan100% (1)

- NDT Works Offer 1Document2 pagesNDT Works Offer 1Amit HasanNo ratings yet

- Torque WrenchDocument6 pagesTorque WrenchAmit HasanNo ratings yet

- Defect ID: Lack of Fusion (LOF)Document5 pagesDefect ID: Lack of Fusion (LOF)Amit HasanNo ratings yet

- Hydrostatic Test Procedure PDFDocument2 pagesHydrostatic Test Procedure PDFLuis Pullas86% (43)

- Doc1 PDFDocument1 pageDoc1 PDFAmit HasanNo ratings yet

- IES Profile-Compressed UpdatedDocument29 pagesIES Profile-Compressed UpdatedAmit HasanNo ratings yet

- DPT ProcedureDocument3 pagesDPT ProcedureAmit HasanNo ratings yet

- Eeciflux Eeciflux Magnetic Particle Inspection Yokes Magnetic Particle Inspection YokesDocument2 pagesEeciflux Eeciflux Magnetic Particle Inspection Yokes Magnetic Particle Inspection YokesAmit HasanNo ratings yet

- List of Equipment Used For Tank CalibrationDocument1 pageList of Equipment Used For Tank CalibrationAmit HasanNo ratings yet

- Defect RadiographsDocument132 pagesDefect RadiographsAmit HasanNo ratings yet

- Om Ud2301Document71 pagesOm Ud2301Amit HasanNo ratings yet

- Tank 305Document74 pagesTank 305tutuionutNo ratings yet

- 02 Fluid Controls Instrumentation Valves PDFDocument58 pages02 Fluid Controls Instrumentation Valves PDFmohdrashidNo ratings yet

- Valve Uses ApplicationsDocument4 pagesValve Uses ApplicationsMD Shadikul Huq ShezanNo ratings yet

- 35Document1 page35Amit HasanNo ratings yet

- Valves InfoDocument43 pagesValves InfoNitin KumbleNo ratings yet

- UTMDocument4 pagesUTMAmit HasanNo ratings yet

- Echograph 1095 FeaturesDocument17 pagesEchograph 1095 FeaturesAmit HasanNo ratings yet

- Defect ID: Lack of Fusion (LOF)Document5 pagesDefect ID: Lack of Fusion (LOF)Amit HasanNo ratings yet

- Tank 305Document74 pagesTank 305tutuionutNo ratings yet

- Manual Ultrasonic Examination ProcedureDocument10 pagesManual Ultrasonic Examination ProcedureAmit HasanNo ratings yet

- 1.PA Machine 2. Connector 3. Probe 4chargerDocument2 pages1.PA Machine 2. Connector 3. Probe 4chargerAmit HasanNo ratings yet

- 52Document1 page52Amit HasanNo ratings yet

- Ultrasonic Test Results Accept All WeldsDocument4 pagesUltrasonic Test Results Accept All WeldsAmit HasanNo ratings yet

- 51Document1 page51Amit HasanNo ratings yet

- MRP Passport Form (Bangladesh Form)Document4 pagesMRP Passport Form (Bangladesh Form)Muhibbul Muktadir Tanim67% (3)

- Work Sheet: Meghna Ghat, Sonargaon, Narayanganj, BangladeshDocument1 pageWork Sheet: Meghna Ghat, Sonargaon, Narayanganj, BangladeshAmit HasanNo ratings yet

- Work Sheet: Meghna Ghat, Sonargaon, Narayanganj, BangladeshDocument1 pageWork Sheet: Meghna Ghat, Sonargaon, Narayanganj, BangladeshAmit HasanNo ratings yet

- Filler Metal - Bestseller - Engl - NT - BohlerDocument29 pagesFiller Metal - Bestseller - Engl - NT - BohlerMaher BmdNo ratings yet

- B.Tech. Automobile - Structure PDFDocument29 pagesB.Tech. Automobile - Structure PDFsaravana pandianNo ratings yet

- Weld Repair PDFDocument14 pagesWeld Repair PDFsarjasatyodayaNo ratings yet

- CE319 Design of Steel StructureDocument53 pagesCE319 Design of Steel StructureMD Mazharul Islam BappyNo ratings yet

- CAD Drawing M1911ADocument59 pagesCAD Drawing M1911AAngela Uselton100% (1)

- PGCIL approval request for structural steel manufacturerDocument3 pagesPGCIL approval request for structural steel manufacturervijaymandiNo ratings yet

- Fang Met Trans PaperDocument12 pagesFang Met Trans PaperSubham NayakNo ratings yet

- Iso 3834-5 - 2015Document14 pagesIso 3834-5 - 2015raghulramasamy100% (1)

- Welding For Nickel AlloysDocument20 pagesWelding For Nickel AlloysClodomiro Barril Club de Amigos de la CuecaNo ratings yet

- Aws A5.10Document38 pagesAws A5.10poulmackNo ratings yet

- Technical Specifications - ASTM A27 Grade 70-40Document1 pageTechnical Specifications - ASTM A27 Grade 70-40S.Mohsin AliNo ratings yet

- Welder Job Description For ResumeDocument5 pagesWelder Job Description For Resumef5dthdcd100% (2)

- Taha Associates. Surface Grinding WheelsDocument2 pagesTaha Associates. Surface Grinding WheelsTaha AssociatesNo ratings yet

- Material Data Sheet SB482 Steel Grade 38MnVS6Document3 pagesMaterial Data Sheet SB482 Steel Grade 38MnVS6Jaison JacobNo ratings yet

- Nickel Alloy Inconel 718 Properties and Applications by United Performance MetalsDocument4 pagesNickel Alloy Inconel 718 Properties and Applications by United Performance MetalsShubham SharmaNo ratings yet

- 01303610DTST60000 Exde06 53Document53 pages01303610DTST60000 Exde06 53jaleelNo ratings yet

- ITI Welder SyllabusDocument13 pagesITI Welder SyllabusER Hariram PrajapatNo ratings yet

- Die Science - Developing Forming Dies - Part I - The FabricatorDocument6 pagesDie Science - Developing Forming Dies - Part I - The FabricatorSIMONENo ratings yet

- Cswip 1.0Document4 pagesCswip 1.0KianToro YeoNo ratings yet

- Tablaestaca 9thedition PDFDocument448 pagesTablaestaca 9thedition PDFatman_1No ratings yet

- Ratio Analysis and Comparative Study at Bhushan Steel1Document45 pagesRatio Analysis and Comparative Study at Bhushan Steel1pujanswetalNo ratings yet

- CV - Linkedin 3Document5 pagesCV - Linkedin 3Samir ChaudharyNo ratings yet

- ASTM A194 Heavy Hex Nuts Specification & GradesDocument3 pagesASTM A194 Heavy Hex Nuts Specification & GradeskingstonNo ratings yet

- Ke01 00 000 KD P ST 0009 000 - F01Document16 pagesKe01 00 000 KD P ST 0009 000 - F01Maffone NumerounoNo ratings yet

- DesignDocument23 pagesDesignscribddisantoNo ratings yet

- METALLURGICAL DAMAGE MECHANISM AND ASSESSMENTDocument61 pagesMETALLURGICAL DAMAGE MECHANISM AND ASSESSMENTSACHIN PETKARNo ratings yet

- Material Selection For Unmanned Aerial Vehicle PDFDocument7 pagesMaterial Selection For Unmanned Aerial Vehicle PDFMunem Bushra100% (1)

- Hot Rod - Technical Paper Rod Mill Processes - NDT - 1099 - E PDFDocument11 pagesHot Rod - Technical Paper Rod Mill Processes - NDT - 1099 - E PDFradinasrNo ratings yet

- Grove G9 Wafer Gate ValveDocument9 pagesGrove G9 Wafer Gate Valvetxlucky80No ratings yet