Professional Documents

Culture Documents

PBGGD

Uploaded by

Luis RodriguezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PBGGD

Uploaded by

Luis RodriguezCopyright:

Available Formats

HOMELAB PROJECT

Self-calibrating

Frequency Meter

No alignment necessary

By Willem den Hollander (The Netherlands)

In the May & June issue of ElektorLabs Magazine we described a 10-MHz reference frequency source that

uses the signals from GPS satellites to provide an extremely accurate reference frequency. The author has

designed a self-calibrating frequency counter based on that circuit.

A brief history Another measurement method became

Features The 10-MHz reference frequency gener- popular with the advent of microcon-

• Self-calibrating with GPS signal ator uses a precise 20-MHz voltage con- trollers: reciprocal frequency measure-

• Input frequency range trolled temperature compensated crystal ment. With this method, the input signal

5 Hz to 80 MHz oscillator (VCTCXO) that is locked to the defines a time window with a duration

• Input signal amplitude 1 pps output signal from a GPS receiver that depends on the desired accuracy.

0.2 to 30 V module. Under ideal conditions, the out- Two counters run during the gate time of

• Resolution 6, 7 or 8 digits put signal has an accuracy of 1 part in this window. The first counts the number

• Accuracy (after locking) 1010. A commercial reference frequency of cycles of the input signal, while the

±1 count pulse generator with comparable accuracy is a second counts the number of cycles of

lot more expensive than our DIY version. the reference signal. The frequency of the

input signal can then be determined from:

Reciprocal measurement

input pulse count

There are various ways to measure sig- The easiest (and conventional) way to frequency =

nal frequencies. They all have one thing measure signal frequency is to count

( reference pulse count ) × tc

in common: they require a stable and the number of cycles of the input sig- Here tc is the period of the reference fre-

precisely known reference frequency. A nal during a precisely defined 1-second quency, which is equal to 1/fref. Assuming

suitable reference frequency source was time window. The uncertainty with this a reference frequency of 10 MHz, the

described in the May& June 2018 issue of measurement method is ±1 digit. That resolution of the frequency measurement

ElektorLabs Magazine [1]. Here we use it corresponds to an error of ±1 Hz, which is 6, 7 or 8 digits with a measurement

as the basis for a full-fledged frequency is of course unacceptable for measure- window (gate time) of 0.1, 1 or 10 sec-

counter with self-calibration capability. ment of low frequencies. onds, respectively.

64 September & October 2018 www.elektormagazine.com

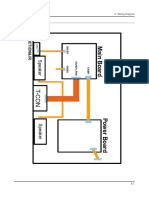

Block diagram

The block diagram of the digital portion

1pps from counter count=16

of the frequency counter is shown in divide by 16

Q

GPS receiver

Figure 1. The counter essentially con- flipflop

sists of the gate timing logic and the

two subsequent 32-bit counters, along

with part of the microcontroller. The

10MHz

other blocks are responsible for gener- Q 32-bit counter

flipflop

ating the reference frequency. For more 20MHz

gate

information about that, please consult VCO

the article in the May & June issue [1].

It’s worth noting that with the exception

DAC

of the VCTCXO (marked ‘20 MHz VCO’ µController Display

DAC

in the block diagram), everything shown

DAC

on the block diagram is integrated into

the microcontroller.

The maximum frequency that the micro-

32-bit counter

controller inputs can handle is 16 MHz, Window gate

so the oscillator frequency is divided generator

by 2 to obtain a 10-MHz signal. That is Input

32-bit counter

well within the specified capability of the signal

gate

microcontroller.

By the way, the microcontroller data-

sheet is not entirely clear on the maxi-

Figure 1. Block diagram of the frequency counter. Except for the display, everything shown here is

mum allowable frequency for the I/Os.

located in the microcontroller.

Sometimes you think it is 16 MHz, and

sometimes you think it is 20 MHz. That

makes it anybody’s guess. However, the signal frequency by a factor of 4 to avoid at least 5 Hz to 80 MHz. The amplitude

author’s prototype certainly did not have confronting the microcontroller input with of the input signal should be between

any problem with frequencies of 20 MHz frequencies too high for it to handle. The 0.2 V and 30 V.

or even higher, corresponding to 80 MHz frequency range of the input circuit, from The display used is a DOG type from

or more at the input. the BNC input to the counter output, is Electronic Assembly with two rows of six-

Input amplifier

As we all know, digital circuits are only

VCC VCC

happy with digital signals, so the input

signal has to be conditioned before it is R6 R7 R9 R11

C6 C7 16

applied to the microcontroller port. Fig-

560R

560R

VCC

15k

1k2

10

TE

ure 2 shows the relevant part of the cir- 100n 2u2 7

PE

9

LD

cuit (top half). The display module is also C2 R3

C4

IC1 1

CLR

22R 1 4 Q1 14

IC2

shown here in the bottom half, because J1 C1

47p T1 R5

22u TLV3501

5 2

CLK

Q2 13

R2

R13 Q3 12

that part of the circuit is located on the T3 3

74AC161

220k

100k

J309 Q4 11

T2 2 3

100n P1

10k

C3 6

display board. You might wonder why it D1 BC849C

4

P2

5

R1 22u P3

is on the display board. The answer is R4 BC849C R8 R10

C5

R12 6

P4 TC

15

1M

GND

330R

that the circuit needs to be as close as

1k5

15k

1k2

8

47p

possible to the input connector, because

BAT18-04

VCC

long wire leads should always be avoided

with high-frequency analogue signals. R16 C9 C10 C11 C12

The signal from the BNC connector J1 is

1R6

1u 10u 10u 100n J2

limited by the dual diode D1 and buff- 40 36 25 24 35 34 33 32 31 30 26

INP 1 VCC

VDD

D0

D1

D2

D3

D4

D5

VOUT

RST

VIN

E

2

ered by the FET T1. This input circuit is 1

A1 RS

39

RS 3

20 38

LCD1

required to obtain an input impedance A2

LCD- DISPLAY

CSB CSB 4

R14 R15

CK 5

of 1 MΩ and to avoid overloading due to 2 EA DOG-M 29

10k

10k

C1 D6 SI 6

19 28

C2 D7 7

high-amplitude input signals. R/W PSB CAP1N CAP1P VSS 8

37 23

Transistors T2 and T3 provide enough 21

C8

22 27 9 HOLD

10 RANGE

gain to allows the comparator IC1 to con- 1u

SW1 SW2

vert the analogue signal into a respect-

able digital signal. The amplifier does not 160706 - 12

need to be especially linear, since all we

actually need is the timing of the rising

Figure 2. Schematic diagram of the input amplifier. It is shown on this diagram because it is

and falling edges. Counter IC2 divides the

located on the display board.

www.elektormagazine.com September & October 2018 65

• the buffered 10-MHz and 1-MHz

VCC

outputs are also deleted because

R1

Vdisp they are no longer necessary, but a

VCC

10-MHz signal is still available on the

10k

C3 C4 RC5 output of the microcontroller

J2 100n 10u (pin 16);

1

20

2 • a second 3.3-V voltage regulator

VCC 3 4 5

1

VDD

28 4 VCC V_BCKP (IC4) has been added to provide the

MCLR RB7/ICSPDAT

X1 2

RA0 RB6/ICSPCLK

27 5 1

RXD1 IC2 TIMER

7 supply voltage for the display, the

4 1 3 26 6 2 8

VCC

20MHz

ADJ

4

RA1

RA2

RB5

RB4

25 10

TXD1

RESET

AADET_N

NC

9

J3

input amplifier and the GPS receiver.

IC1

C1 C2 5

6

RA3 RB3

24

23

6

1PPS

L80

EX_ANT

11

That way the VCTCXO and the micro-

RA4 RB2 SMA

100n

VCTCXO

10u 7

RA5 RB1

22 GND GND controller have their own power sup-

2 3 9 21 3 12

GND OUT

10

RA7

RA6

PIC16F1778

RB0

RC7

18 ply and the stability of the reference

11

12

RC0 RC6

17

VCC

frequency is assured.

RC1 LM1117-3.3

VDISP

13

RC2 RC5

16 10MHz

IC3

14 15 3 2

J4

RC3 RC4 VIN VOUT

Connector J2 is intended for in-circuit

VSS VSS GND

1

2

INP

8 19

C12

1

C5 C6 C7

programming of the microcontroller, and

3 RS 100n 22u 100n 100n

J4 provides the connection to the dis-

4 CSB

5 CK play board.

6 SDO J1 LM1117-3.3

7 IC4 Vdisp

8

1 3

VIN VOUT

2

Construction

9 HOLD GND

10 WINDOW 2 C8 C9

1

C10 C11 As previously mentioned, the input ampli-

22u 100n 22u 100n fier and the display are located on the

160706 - 13

display board. With the exception of the

connectors and switches, which should

preferably be leaded types because they

Figure 3. Schematic diagram of the microcontroller portion. There aren’t many components, so the

are subject to physical stress, all compo-

PCB is remarkably empty.

nents are SMDs. That keeps the overall

package pleasantly compact (see Fig-

teen characters and white LED backlight- shown in Figure 3. It is largely the same ure 4). It’s a pity that for proper oper-

ing. The display is driven by the micro- as the 10 MHz reference frequency proj- ation the GPS receiver has to be kept

controller over an SPI bus (connector J2). ect in the May & June issue. For more as far away from the oscillator as pos-

details, see the article in that issue. The sible; otherwise it could have also been

Microcontroller portion only differences are: mounted on this circuit board.

The microcontroller, the clock crystal and • the two indicator LEDs are deleted Figure 5 shows the microcontroller

the GPS receiver are located on the main (the microcontroller pins are needed board. It is very sparsely populated, but

circuit board. The schematic diagram is for the SPI interface (J4); that is beneficial for the GPS receiver.

The boards are fitted in a Teko 011 case,

with the original aluminium front and

back panels replaced by acrylic sheets

covered with aluminium-coloured self-ad-

hesive film because the GPS receiver

needs access to the outside world. The

power source is a standard 5-V USB AC

line adapter.

Figure 6 gives an impression of the

author’s prototype.

Firmware

The firmware residing in the microcon-

troller, which performs all the functions

required for proper operation of the fre-

quency counter, is written in assembly

language because using a high-level lan-

guage would have a number of serious

disadvantages.

First of all, it would not be possible to

control the timing of the various functions

with sufficient accuracy, and secondly,

it would take up more memory space.

Figure 4. The display board with the input amplifier. And the software would run slower – also

66 September & October 2018 www.elektormagazine.com

Figure 5. The microcontroller board. Figure 6. The front and rear of the case.

and 7c). The Hold button freezes the

Never calibrate again reading on the display (Figure 7d). Note

that this only stops updating of the dis- a

play; the counter keeps on making

measurements.

The symbol at the left end of the bottom b

a significant consideration. In particu- row (Figures 7d and 7e) indicates that

lar, the multiplication and division oper- the VCTCXO is locked to the GPS signal.

ations that are necessary to calculate But even if this symbol is not shown,

c

the frequency shown on the display are accurate measurement is still assured

coded the way they need to be for this for a relatively long time. Once the fre-

application. Multiplying the content of quency counter has been locked to the

the 32-bit input counter by 10 and then GPS signal, the D/A converter settings d

dividing the result by the content of the are stored in the non-volatile memory of

second 32-bit counter takes less than the microcontroller as described in the

1 millisecond, including BCD conversion. article in the May/June issue. Each time e

All in all, the firmware in its present form the counter is powered up, these set-

occupies only 8% of the microcontroller tings are read from the memory and the

memory. The firmware and the PCB lay- converters are configured accordingly.

Figure 7. a: 0.1-s measurement window;

outs can be downloaded free of charge Of course, the frequency of the VCTCXO

b: 1-s measurement window;

from the project page for this article [2]. will gradually change over time — that c: 10-s measurement window;

is a normal ageing process. But as long d: oscillator locked, readout frozen;

Use as the oscillator is locked to the GPS e: oscillator locked, no input signal.

The frequency counter is easy to use. signal at more or less regular intervals,

The duration of the measurement window the latest calibration factors for the D/A

(the gate period during which pulses are converters are always stored in memory. @ www.elektor.com

counted) can be selected with the Time This way the accuracy of the frequency

ªGPS board

button. That determines the resolution of counter is guaranteed to be ±1 clock

www.elektor.com/gps-board-eb056

the measurement (see Figures 7a,b,c). pulse.

ªGPS antenna

The selected window time is indicated by 180343-02 www.elektor.com/trimble-gps-antenna

the number of dots in the bottom line of

ªPIC multiprogrammer

the display. Web Links www.elektor.com/pic-eb006

The small symbol at the left end of the

[1] www.elektormagazine.com/160595 ªTL866A universal programmer

top line appears for about 200 ms when

www.elektor.com/tl866a-programmer

a measurement has been completed [2] www.elektormagazine.com/

and the display is updated (Figures 7a 180343-01

www.elektormagazine.com September & October 2018 67

You might also like

- An 2098Document5 pagesAn 2098paiuiaNo ratings yet

- Frequency MeasurementDocument6 pagesFrequency MeasurementDarshan PatelNo ratings yet

- Exploring The Benefits of Frequency Counter Circuit Working and ApplicationsDocument11 pagesExploring The Benefits of Frequency Counter Circuit Working and ApplicationsjackNo ratings yet

- Admv 4640Document41 pagesAdmv 4640lp2nationzNo ratings yet

- MT1769 Full DocumentationDocument25 pagesMT1769 Full Documentationrain.kam86No ratings yet

- Digital Frequency and Time Measuring Instruments: BY Dr. K.V.Praveen Kumar Assistant Professor, Eed, SvnitDocument35 pagesDigital Frequency and Time Measuring Instruments: BY Dr. K.V.Praveen Kumar Assistant Professor, Eed, SvnitTushar SanwareyNo ratings yet

- A/D and D/A Converter FundamentalsDocument18 pagesA/D and D/A Converter FundamentalskarkeraNo ratings yet

- 30 MHZ 2 Channel 4 Trace Digital Readout Oscilloscope With oDocument2 pages30 MHZ 2 Channel 4 Trace Digital Readout Oscilloscope With oerdvkNo ratings yet

- Jitter-Wander Measurements GuideDocument30 pagesJitter-Wander Measurements GuidegercruNo ratings yet

- Digital Signal Processing SchemaDocument5 pagesDigital Signal Processing SchemaDragan IvanovNo ratings yet

- Evolution of Sinusoidal Encoder InterpolatorsDocument13 pagesEvolution of Sinusoidal Encoder InterpolatorsRaulFghiNo ratings yet

- Solid-State Optical Mouse Sensor With Quadrature Outputs: Version: 15 July 2004Document11 pagesSolid-State Optical Mouse Sensor With Quadrature Outputs: Version: 15 July 2004florinsslNo ratings yet

- Lecture7 MCU Timers - ADCDocument36 pagesLecture7 MCU Timers - ADCAKSHATA R CNo ratings yet

- Pic Tape Measure: Microcontrolled Ultrasonic Distance Calculator With Data Recording and Foreground MaskingDocument9 pagesPic Tape Measure: Microcontrolled Ultrasonic Distance Calculator With Data Recording and Foreground Maskingognen88No ratings yet

- Experiment SetupDocument7 pagesExperiment Setupalessandro8265No ratings yet

- IEEE JSSC: Low Noise Readout Circuit Detects Nanoampere SignalsDocument12 pagesIEEE JSSC: Low Noise Readout Circuit Detects Nanoampere Signalspasargad135106No ratings yet

- Mechatronics - 302050: Lecture Notes / PPT Unit IiiDocument29 pagesMechatronics - 302050: Lecture Notes / PPT Unit IiiRajesh GangwarNo ratings yet

- DC Lab ManualDocument24 pagesDC Lab Manualvidyae100% (2)

- Digital SignalsDocument45 pagesDigital SignalsDotNo ratings yet

- Sync 101: The Need For SynchronizationDocument11 pagesSync 101: The Need For SynchronizationMadhukar VarshneyNo ratings yet

- EC 2301 Digital Communication Unit I and II Question BankDocument63 pagesEC 2301 Digital Communication Unit I and II Question Bankgayathri nathNo ratings yet

- Elektor Electronics 1998-11Document54 pagesElektor Electronics 1998-11Adrian_Andrei_4433No ratings yet

- RPM IndicatorDocument39 pagesRPM IndicatorAnkur PatelNo ratings yet

- Train Speed Control F S KDocument54 pagesTrain Speed Control F S KDivya SantoshiNo ratings yet

- PSK Lab ManualDocument4 pagesPSK Lab ManualSakshi DewadeNo ratings yet

- Clap CounterDocument4 pagesClap CounterVivek jhaNo ratings yet

- Analog-Digital and Digital-Analog ConvertersDocument7 pagesAnalog-Digital and Digital-Analog Converterspepeluis666No ratings yet

- Inverters SpecsDocument11 pagesInverters SpecsbhuwaneshtakNo ratings yet

- 4 Time Based Measureme 2004 Analog Interfacing To Embedded MicroprocessorDocument16 pages4 Time Based Measureme 2004 Analog Interfacing To Embedded MicroprocessorDorianNo ratings yet

- GPS 10MHz StandardDocument8 pagesGPS 10MHz StandardBenjamin NaberNo ratings yet

- Digital Communications Lab: List of ExperimentsDocument50 pagesDigital Communications Lab: List of ExperimentsNeel SarkarNo ratings yet

- DC Manual FinalDocument42 pagesDC Manual FinalsrvsbondNo ratings yet

- The Digital Lock-In AmplifierDocument4 pagesThe Digital Lock-In AmplifierBob HwknsNo ratings yet

- Digital Communication Lab Manual For VI Semester B.Tech (Electronics Engineering)Document25 pagesDigital Communication Lab Manual For VI Semester B.Tech (Electronics Engineering)Nikolai RossanderNo ratings yet

- R8C25 DatasheetDocument59 pagesR8C25 DatasheetcoolhatNo ratings yet

- Frequency Display and VFO Stabilizer: Eliminates Frequency Drift in Home-Brew and Surplus' HF ReceiversDocument6 pagesFrequency Display and VFO Stabilizer: Eliminates Frequency Drift in Home-Brew and Surplus' HF ReceiversedosviracNo ratings yet

- r5f2021 Micro ControladorDocument73 pagesr5f2021 Micro Controladormauricio zamoraNo ratings yet

- CounterDocument11 pagesCounterDatpmNo ratings yet

- ICM7226 BL PLDocument19 pagesICM7226 BL PLMUHAMMAD SISWANTORONo ratings yet

- Clock Jitter Analyzed in The Time Domain, Part 2: by Thomas NeuDocument8 pagesClock Jitter Analyzed in The Time Domain, Part 2: by Thomas NeuMiraç Şamil YİĞİTNo ratings yet

- Lab3 - Laboratory For Experimental Computer ScienceDocument9 pagesLab3 - Laboratory For Experimental Computer ScienceGauthier G. LetellierNo ratings yet

- EDN Design Ideas 1999Document201 pagesEDN Design Ideas 1999chag1956100% (5)

- Measuring sensors and power consumption in wireless monitoring networkDocument4 pagesMeasuring sensors and power consumption in wireless monitoring networkAbhijeet KeerNo ratings yet

- Frequency GeneratorDocument10 pagesFrequency Generator6208050% (1)

- Experiment No. 1 Familiarization With Laboratory Instruments: Oscilloscope, Function Generator, Digital Multimeter, and DC Power SupplyDocument12 pagesExperiment No. 1 Familiarization With Laboratory Instruments: Oscilloscope, Function Generator, Digital Multimeter, and DC Power SupplyMukul ChandraNo ratings yet

- Amplifier DesignDocument9 pagesAmplifier Designian neymarNo ratings yet

- Real-Time Control and Signal Processing ExamplesDocument25 pagesReal-Time Control and Signal Processing ExamplesMano KaranNo ratings yet

- Implementation of PIC Based Digital Frequency CounterDocument4 pagesImplementation of PIC Based Digital Frequency CounterMichael DixonNo ratings yet

- One AND Gate and EX-OR Gate..Document3 pagesOne AND Gate and EX-OR Gate..Kashif SheikhNo ratings yet

- High Resolution Delta-Sigma Adcs: Slide 1Document64 pagesHigh Resolution Delta-Sigma Adcs: Slide 1Sarawut PhetsilpNo ratings yet

- Analog-To-digital Converter - Wikipedia, The Free EncyclopediaDocument6 pagesAnalog-To-digital Converter - Wikipedia, The Free EncyclopediaAziz SahatNo ratings yet

- A new design methodology for voltage-to-frequency converters circuitsDocument11 pagesA new design methodology for voltage-to-frequency converters circuitsGojko RatkovićNo ratings yet

- 3bx_iiiDocument37 pages3bx_iiiAntonio MarraNo ratings yet

- Very Accurate LC Meter Base..Document5 pagesVery Accurate LC Meter Base..Mahlet_Kiflu_T_4666100% (1)

- Radio Frequency Identification and Sensors: From RFID to Chipless RFIDFrom EverandRadio Frequency Identification and Sensors: From RFID to Chipless RFIDNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- bq24780S 1-To 4-Cell Hybrid Power Boost Mode Battery Charge Controller With Power and Processor Hot MonitoringDocument11 pagesbq24780S 1-To 4-Cell Hybrid Power Boost Mode Battery Charge Controller With Power and Processor Hot MonitoringEdovan soto lizcanoNo ratings yet

- Vestel 17MB63DDocument7 pagesVestel 17MB63DLuis RodriguezNo ratings yet

- Ipad W 3g PDFDocument111 pagesIpad W 3g PDFJavier Alberto Martínez Guadarrama100% (1)

- GND in Out: 12V 12V Led LedDocument1 pageGND in Out: 12V 12V Led LedLuis RodriguezNo ratings yet

- 05 Wiring DiagramDocument4 pages05 Wiring DiagramLuis RodriguezNo ratings yet

- J Runner UserGuideDocument38 pagesJ Runner UserGuideDaniel Diaz MartínezNo ratings yet

- USB 24xxx I2C E-Eprom Programmer Setup GuideDocument12 pagesUSB 24xxx I2C E-Eprom Programmer Setup GuideAnders HogreliusNo ratings yet

- Neón 18 16V Sohc C - 20 16V Sohc A - 20 16V Dohc y PDFDocument2 pagesNeón 18 16V Sohc C - 20 16V Sohc A - 20 16V Dohc y PDFLuis RodriguezNo ratings yet

- BOSE SoundDock 2004 - SoundDock 2008 Receptor Bluetooth SounddockDocument27 pagesBOSE SoundDock 2004 - SoundDock 2008 Receptor Bluetooth SounddockLuis Rodriguez50% (2)

- Crown 1400 CSL Service ManualDocument27 pagesCrown 1400 CSL Service Manualren_theoriginalpunks100% (2)

- TL866 DesignDocument12 pagesTL866 Designtemplpa100% (1)

- 1-No PCIE v2.8Document10 pages1-No PCIE v2.8Migeru SanNo ratings yet

- SUBJECT: The TV Displays A Black Bar, No Picture, or A Dark PictureDocument1 pageSUBJECT: The TV Displays A Black Bar, No Picture, or A Dark PictureLuis RodriguezNo ratings yet

- Guia de Refer en CIA para El Reemplazo de Transistores Peavey - VideosistemasDocument24 pagesGuia de Refer en CIA para El Reemplazo de Transistores Peavey - VideosistemasGloria Vela0% (1)

- 05 Wiring DiagramDocument7 pages05 Wiring DiagramLuis RodriguezNo ratings yet

- Datashet AutomotrizDocument152 pagesDatashet AutomotrizWilfredo Peñaloza100% (1)

- 1.SCH List: RF BB SchematicsDocument36 pages1.SCH List: RF BB SchematicsLuis RodriguezNo ratings yet

- Schematics-3116084tablet China Procesador A33Document60 pagesSchematics-3116084tablet China Procesador A33Luis RodriguezNo ratings yet

- TL866 DesignDocument12 pagesTL866 Designtemplpa100% (1)

- Service Bulletin Product: Led Bulletin NUMBER: ASC20140225001 Bulletin Date: 02/25/2014Document2 pagesService Bulletin Product: Led Bulletin NUMBER: ASC20140225001 Bulletin Date: 02/25/2014Luis RodriguezNo ratings yet

- Schematics-3116084tablet China Procesador A33Document8 pagesSchematics-3116084tablet China Procesador A33Luis Rodriguez100% (1)

- LED TV Service Bulletin Random Power CyclesDocument2 pagesLED TV Service Bulletin Random Power CyclesLuis RodriguezNo ratings yet

- LED TV powers ON automatically service bulletinDocument1 pageLED TV powers ON automatically service bulletinLuis RodriguezNo ratings yet

- PLC Handbook - FinaleDocument85 pagesPLC Handbook - FinalesaravanaNo ratings yet

- Bank StatementDocument23 pagesBank StatementKundan Kumar JaiswalNo ratings yet

- Infrared Spectroscopy of FAME in Biodiesel Following DIN 14078 PDFDocument2 pagesInfrared Spectroscopy of FAME in Biodiesel Following DIN 14078 PDFPedro AluaNo ratings yet

- CISSPDocument200 pagesCISSPkumarNo ratings yet

- Integrated Farming System: A ReviewDocument12 pagesIntegrated Farming System: A ReviewIndian Journal of Veterinary and Animal Sciences RNo ratings yet

- North Imenti Agents UpdatedDocument15 pagesNorth Imenti Agents UpdatedMuriira AntonyNo ratings yet

- IEEEDocument15 pagesIEEELaharish GuntukaNo ratings yet

- Defences of Illegality in England, Canada and the USDocument11 pagesDefences of Illegality in England, Canada and the USBetteDavisEyes00No ratings yet

- International Capital Structure and Cost of CapitalDocument20 pagesInternational Capital Structure and Cost of CapitalQuoc AnhNo ratings yet

- Politische StrategiesEnd 2012 de en FINALDocument405 pagesPolitische StrategiesEnd 2012 de en FINALFomeNo ratings yet

- TANG - Remedial Law Activity 4Document23 pagesTANG - Remedial Law Activity 4Nathaniel Niño TangNo ratings yet

- Nice - Folder - Bar - System - en Mbar HighlightedDocument16 pagesNice - Folder - Bar - System - en Mbar HighlightedSamastha Nair SamajamNo ratings yet

- The Piezoelectric EffectDocument10 pagesThe Piezoelectric EffectDmytro RakNo ratings yet

- A.No.360of19 14.07.21Document133 pagesA.No.360of19 14.07.21Bhupendra CharanNo ratings yet

- Grasshopper VB Scripting Primer IntroductionDocument28 pagesGrasshopper VB Scripting Primer Introductionfagus67No ratings yet

- Charles L. Mader - Numerical Modeling of The Deflagration-to-Detonation TransitionDocument21 pagesCharles L. Mader - Numerical Modeling of The Deflagration-to-Detonation TransitionSteemWheelNo ratings yet

- Barbara S. Hutchinson, Antoinette Paris-Greider Using The Agricultural, Environmental, and Food Literature Books in Library and Information Science 2002Document491 pagesBarbara S. Hutchinson, Antoinette Paris-Greider Using The Agricultural, Environmental, and Food Literature Books in Library and Information Science 2002Paramitha TikaNo ratings yet

- The Cucumber Book Behaviour-Driven Development For Testers and DevelopersDocument28 pagesThe Cucumber Book Behaviour-Driven Development For Testers and DevelopersGursharan AulakhNo ratings yet

- Eskom Tariff Book - 2018-19Document54 pagesEskom Tariff Book - 2018-19Sandro MasakiNo ratings yet

- Proceedings of The Third International Conference On Computational Intelligence and InformaticsDocument881 pagesProceedings of The Third International Conference On Computational Intelligence and InformaticsJanes DstNo ratings yet

- Guerrero vs. CA - DigestDocument2 pagesGuerrero vs. CA - DigestMarionnie SabadoNo ratings yet

- Module 1 The Nature of Strategic Management2Document8 pagesModule 1 The Nature of Strategic Management2Julienne LobchoyNo ratings yet

- Tutorial Question 4 TORTDocument2 pagesTutorial Question 4 TORTNBT OONo ratings yet

- AR15 Forging ReceiverDocument105 pagesAR15 Forging ReceiverNO2NWO100% (10)

- Calgary Police Employee Survey ResultsDocument118 pagesCalgary Police Employee Survey ResultsDarren KrauseNo ratings yet

- Jan 2012Document40 pagesJan 2012Daneshwer Verma100% (1)

- Excessive Heat: Current HazardsDocument14 pagesExcessive Heat: Current HazardsPeter MahonNo ratings yet

- Nonconventional Three Wheel Electric VehDocument7 pagesNonconventional Three Wheel Electric VehAbdelali AabadaNo ratings yet

- Energy and Memory Efficient Clone Detection in WSN AbstractDocument4 pagesEnergy and Memory Efficient Clone Detection in WSN AbstractBrightworld ProjectsNo ratings yet

- 72-76 kW 310SK/310SK TC Compact Track Loader SpecsDocument10 pages72-76 kW 310SK/310SK TC Compact Track Loader SpecsPerrote Caruso PerritoNo ratings yet

- Inflammability and Health Risks of Lubricant Oil 5W30 SNDocument9 pagesInflammability and Health Risks of Lubricant Oil 5W30 SNPerformance Lubricants, C.A.No ratings yet