Professional Documents

Culture Documents

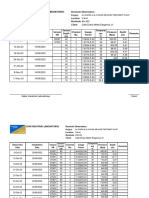

Tests To Establish Concrete Pumpability Jl74-19

Uploaded by

saiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tests To Establish Concrete Pumpability Jl74-19

Uploaded by

saiCopyright:

Available Formats

TITLE NO.

74-19

Tests to Establish Concrete Pumpability

By ROGER D. BROWNE and PHILLIP B. BAMFORTH

This paper describes test methods developed for tion was available concerning the proportioning

examining the pumping characteristics of concrete and testing of concrete mixes for pumping.

which have aided the range of studies undertaken Over the last 8 years a number of investigations

on pumped concrete over the last 8 years.

Details are given of the basic state of the con- were carried out into the basic mechanisms of

crete in the pipeline, from which is established the concrete pumping both theoretically and by ob-

importance of impermeability of the material in servation in the laboratory and on site pipelines.3.4

minimizing pipe blockage. A practical test method It was during these investigations that test meth-

for this property, simulating the pressurized state

of concrete in a pipeline, is described, together with

ods for pumpability were considered.

test results from pumping trials on a number of This paper briefly summarizes the understand-

concrete mixes. ing developed of the basic state of concrete in a

Viscometric methods are also briefly mentioned pipeline and the mechanics of concrete pumping

in relation to the laboratory measurement of flow

in relation to the following three test methods

resistance.

The void meter test is described and its value for measuring the pumpability of fresh concrete:

as a mix proportioning tool is considered in rela- 1. The pressure bleed test to measure the in-

tion to the optimization of cement contents. ternal resistance of concrete to "dewatering;" this

Finally, the details and results from instrumen- was found to be a major cause of blockages.

tation of pipelines to observe pumping pressure

variations are presented and conclusions are given 2. The voids measurement of the total aggre-

related to pump performance and concrete charac- gates as an aid to mix proportioning of pumpable

teristics. concretes.

Keywords: concretes; field tests; fresh concretes; mix pro-

portioning; permeability; pumped concrete; pumping; pumps;

test equipment; tests; voids; water; water-cement ratio; work- ACI member Roger D. Browne, is a char-

ability. tered civil engineer and head of the Re-

search Laboratories of Taylor Woodrow

Construction Ltd., Southall, England. He

• IN RECENT YEARS CONCRETE PUMPING systems received his PhD in the field of high altitude

aerial photography and his diploma in

have been increasingly used in an attempt to in- photogrammetry at University College, Lon-

crease the speed of construction. This has been don, in 1959. Since that time, he has in-

vestigated many aspects of concrete tech-

particularly influenced by the development of nology in relation to the development of concrete pressure

mobile and truck mounted pumps fitted with tele- vessels for nuclear power stations and offshore structures,

as well as more conventional constructions.

scopic booms, which provide a completely inde- Dr. Browne has coauthored publications on the long term

pendent and flexible means of concrete placement. properties of concrete at normal and elevated temperatures,

resin concretes, high pressure water jet cutting of concrete,

Although concrete has been pumped success- large concrete placements, admixtures, strength in situ, and

fully for many years, variations in aggregates, marine durability of concrete.

hatching, and mixing can still make it difficult to Phillip B. Bamforth is at present a research

guarantee completely trouble-free concrete on engineer with Taylor Woodrow Construction

Ltd., Southall. England. He received his BSc

every occasion. The blocking of concrete in a pipe, in civil engineering from Leeds University in

therefore, may still present problems due to the 1970 and since that time has been involved

in the investigation of various aspects of

disturbance that such a condition can cause to concrete technology including pumping,

smooth and efficient site operation. early age behavior of mass placements, and

creep in relation to prestressed concrete

At the start of the present investigation in 1967, pressure vessels. He has coauthored publications on the

it was found that although various workers, such performance of concrete pressure vessels and effect of

cement replacement materials on the early age behavior of

as Ede 1 and Weber,~ had examined the behavior of Ia rge placements.

concrete in the pipeline, little practical informa-

ACI JOURNAL I MAY 1977 193

the lubricating layer to zero at the pipe wall as

shown in Fig. 1.

FLOW RESISTANCE

Degree of saturation

The resistance to the flow of concrete in a pipe-

line is thought to be a combination of hydraulic

shearing of the lubricating layer and friction of the

solid particles in contact with the pipe wall. The

extent to which frictional resistance is effective,

however, depends greatly on the state of satura-

tion of the concrete.

LUBRICATING LAVER When concrete is in a saturated state (i.e., when

there is sufficient water in the mix to overfill the

voids of the dry materials) the magnitude of fric-

tional resistance is negligible compared with that

VELOCITY found when the concrete is in an unsaturated state.

PROFILE This effect was clearly shown by Ede 1 who

measured the flow resistance of a single concrete

with a varying water-cement ratio; the results are

PLUG

presented in Fig. 2. It will be seen that, as the

water-cement ratio and hence the workability was

Fig. 1-Piug flow reduced, the flow resistance increased and there

was a critical level of water-cement ratio, in this

3. The measurement of concrete pressure in a case 0.45, below which the frictional resistance in-

pipeline to give information on the efficiency of creased dramatically.

the pump and also the performance and pumping The sudden increase in flow resistance may be

characteristics of the concrete. attributed to the change from the saturated to

Much of the material in this paper is based on the unsaturated condition.

an investigation carried out for the Construction The pressure distribution down a pipeline for

Industry Research and Information Association, the saturated and unsaturated states may be ex-

and it is given here with CIRIA's permission. pressed as follows:

STATE OF CONCRETE IN THE PIPELINE

Saturated (hydraulic) flow 1•2-Under saturated

conditions the pressure loss in the pipeline has

Development been observed to be linear,l· 2 and the pressure at

Although direct observation of the internal be- any point in the line can be defined by the simple

havior of concrete while flowing under pressure expression:

through a pipeline has proved impossible, the

theoretical and experimental studies undertaken p =p 0 _ 4Rx

D (1)

on the pressurized state of fresh concrete and

measurements made of pressures at the pump and where

the pipe wall, together with observations of the P pressure in the pipeline at a distance x

state of the concrete at the end of the line, have from the pump (under saturated con-

provided the following understanding of the state ditions, axial = radial pressure)

of concrete in a pipeline. Pn pressure at the pump end of the line

(i.e., when x = 0)

Plug flow D internal pipe diameter

Concrete flows in a pipeline in the form of a R = flow resistance/unit area of pipe

plug separated from the pipe by a lubricating

layer of water, cement, and fine sand particles. The derivation of Eq. (1) is included in Appendix

The plug consists of aggregate, sand, and cement A.

particles separated by a continuous water layer The flow resistance has been shown to be made

which is hydraulically linked to the lubricating up of two separate components, the adhesion re-

layer. The velocity is constant across the width of sistance A, which exists even when the concrete is

the plug, i.e., there is no relative velocity between stationary, and a factor related to the velocity V

the aggregate particles, and drops rapidly across of flow in the pipeline and is given by the equation

194 ACI JOURNAL I MAY 1977

R=A+KV• (2) permeability to the flow of its own mix water, and

also that this property is maintained.

where K and n are constants for a particular con-

crete and are related to the mix proportions and

Flow velocity

workability.

The term R was introduced by the authors to As described earlier, the resistance to flow in

overcome the problems of defining values of A, the hydraulic state is also affected by the concrete

K, and n and is generally defined in relation to velocity through the pipeline and to a lesser extent

the concrete velocity as described later. by the concrete workability. Results of site tests

Unsaturated (fractional) state 1-When concrete indicated an approximately linear Newtonian re-

is pumped in an unsaturated state, the pressure lationship between flow resistance and concrete

loss down the line is no longer linear, but has velocity as shown in Fig. 3. The results are plotted

been found to follow a more complex exponential to show concrete transport velocity V 1 against

relationship. The development of the general 3001r---------,----------.--------~

equation describing unsaturated flow is given in

the appendix. N

E

Under conditions of frictional flow the resistance ~

01

R is related to the radial pressure P,. in the con- .X

crete by the equation ""0

I '200

><

R =A+ f!Pr (3)

UJ

u

where z Unsaturated Saturated

<( Concrete Concrete

A = adhesion resistance (R =A when Pr = 0) I-

~

f! = coefficient of friction between the con- If) 100

UJ

a:

crete and the pipe wall

~

The general term for flow resistance, however, 0

-'

IJ_

cannot be used in this case. Not only is the value

of R related directly to the radial pressure, but

also the relationship between the axial and radial o.Jo Q.40 o.so o.so

pressure varies with a change in pump pressure. WATER/CEMENT RATIO (by wt.)

The various factors, therefore, have to be consid-

ered separately. Fig. 2-Effect of water-cement ratio on flow resistance

for a given mix (Reference I) (I kgf/ em~ = 14.22 psi)

Distance pumpable

The theoretical relationships for saturated and -+- T.W.C. Data.

After EDE (Ref. 1 )

unsaturated flow may be used to demonstrate that &-----e After WEBER (Ref. 2)

a change in the state of the concrete can have a After ALEKSEEV(Ref 5)

dramatic effect on the length of pipeline through

which the concrete may be pumped.

Consider, for example, the maximum distance /

that saturated apd unsaturated concrete may be >

1--

u

/

pumped through a 10 em (4 in.) diameter pipeline

for a given pump pressure of 35 kgf/cm~ (500 psi).

0

_J

UJ

I

From the calculations included in the appendix

>

UJ

!/

it can be seen that for saturated flow the con- 1-

UJ

crete may be pumped through a distance of 250 m 0:

u

(820 ft) while in an unsaturated condition, this z

0

value is reduced to a mere 1.1 m (3.6 ft). This u

means that, if for any reason, more than 1.1 m of

concrete anywhere in the pipline became unsat-

urated, the pump pressure would be exceeded by

the pressure required to move the concrete, caus-

2 3

ing blocking.

Thus it can be seen that blockages may be FLOW RESISTANCE (x10-Jkgjcm 2 )

caused by "dewatering" of· the concrete over a

Fig. 3-Relationship between flow resistance and concrete

relatively short length of line. To avoid such oc- velocity (I kgf/cm~ = 14.22 psi: I em= 0.39 in.; I mm

currences it is essential that the concrete has a low = 0.039 in.)

ACI JOURNAL I MAY 1977 195

Part·iclc Migration of Taylor ·woodrow data presented in Fig. 3, were

Mix Water

obtained by measuring the pressure drop down

a pipeline and converting the results to flow re-

sistance using the equation:

R _ (P1- P2) D

- L 4 (5)

where P1 and P2 are pressures· at two positions

along a pipe of internal diameter D, at a distance

High Frictional Resistance L apart.

Results obtained by Weber2 in a similar manner

Fig. 4--Dewatering of concrete in a pipeline using a laboratory piston rig, by Alekseev5 using

a rotary viscometer, and by Ede using a sliding

compression apparatus,! have also been included

in Fig. 3 for comparison with results obtained by

the authors. It will be seen that although in each

case different methods were used the results are

Dou blc Acting for practical purposes comparable.

Hydraulic Cylinder

The relationship obtained shows that:

1. The flow resistance can be reduced by using

higher slump concretes.

Calibrated 2. For a maximum pump pressure the maximum

Measuring Rod ---11

concrete velocity or pump output is limited by the

flow resistance/velocity relationship.

Top Cop

Summary

The above theoretical concepts have provided

a base for not only developing the dewatering

test described in the following section, but have

also enabled assessment of the value of various

parameters which affect the pumping process,

e.g., admixtures. There may be little value in

using a workability aid to improve the pumpability

of a mix which shows dewatering characteristics.

'o' Ring Bleed

Top The dewatering performance of a pumping mix

t

is not, however, the only factor for defining its

Measuring suitability. Even certain saturated mixes can re-

Bose Cylinder sult in a high flow resistance with too great a

50 Mesh Gauze demand for pumping pressure and can induce

Gauze Retainin severe pump and pipeline wear. Such mixes tend

Plate. to have a high proportion of fine material in the

form of either fine sand or a high cement content.

Fig. 5-Pressure bleed test apparatus (I mm = 0.039 in.) Thus to measure the pumpability of a concrete

mix, two parameters should be measured: (a) the

flow resistance R. The value of V 1 has been de-

permeability or dewatering characteristics, and

fined as follows:

(b) the flow resistance.

s In the United Kingdom for the range of con-

Vt=T cretes and concreting materials generally used, the

where flow resistance values appear not to require high

S = stroke length of the pump pumping pressures. With the more commonly

T = time for a single pressure stroke

occurring coarser aggregates, dewatering is more

likely to be a problem. This has meant that greater

If the piston and pipeline diameters (D 1 and D 2

emphasis has been attached to the development of

respectively) are not equal, however, the velocity

a means of measuring the dewatering characteris-

of flow in the line must be corrected for the

tics than to flow resistance.

change in cross section as follows:

However, it is considered that where necessary,

D1 ) 2

S the use of viscometric methods to measure the

Vt = ( D;- --ry- (4) shear resistance of the boundary layer paste would

196 ACI JOURNAL I MAY 1977

be suitable. The authors feel that to obtain the

most realistic measurement the test should be

carried out if possible under pressure, to simulate

more closely the pressure state existing in a pipe-

line.

PRESSURE BLEED TEST

Background

It has been shown previously that to pump con-

crete through any appreciable distance, the con-

crete must be in a consistently saturated state.

However, certain concretes (especially those with

low fines contents), even though they are intro-

duced into the pump in a saturated state, are

rapidly transformed into the unsaturated state by Fig. 6-Pressure bleed test in operation

"dewatering" under the severe pressure gradients

which exist in the pipeline, particularly at tapers The top cap is then locked on and, with the

and bends, and blockages occur a:s shown in Fig. 4. bleed tap closed, the concrete is subjected to a

To avoid dewatering, therefore, the concrete pressure of 35 kgf/cm 2 (500 psi). The bleed tap is

itself must offer internal resistance to the flow then opened and the quantity of water emitted is

of mix water while under pressure. The pressure measured at specific time intervals while main-

bleed test is a static test designed to simulate the taining the pressure on the concrete.

state of concrete under pressure in a pipeline, in

which the dewatering characteristics of concrete Interpretation of results

can be measured. A sample of concrete is com- A concrete which dewaters quickly under pres-

pressed in a section of pipeline and the mix water sure will be prone to blocking in a pipeline; the

allowed to drain out under a sustained pressure. rate of dewatering is measured by the pressure

bleed test. The water emitted is measured against

Apparatus

time, some typical results being illustrated in Fig.

The bleed test apparatus is illustrated in Fig. 5 7 for pumpable and nonpumpable concretes. The

and 6, and consists essentially of a 12.5 em (5 in.) volume of water emitted in the first 10 sec is

diameter cylinder with a detachable top cap and designated V 10 and the total volume emitted in the

base. The top cap houses a piston which runs on first 140 sec is designated v140· It has been found

two rubber "0" rings and is attached to the in practice that for concretes of any slump, the

plunger of a double acting hydraulic jack. The jack volume of water emitted after the first 140 sec is

is screwed into the top of the piston housing and small and the test is not continued beyond this

hence a force can be applied to the piston through time. The water remaining in the concrete after

the top cap. The jack is operated from a hand this time exists in the voids between the com-

pump with a four-way valve, allowing the piston pressed particles. Under laboratory conditions

to be moved in two directions. The travel of the

piston enables the rapid removal of the compressed

concrete plug after the test. WATER EMITTED

The base has a bleed hole drilled into the side 120

and a tap has been inserted. The inside of the PUM~ABLE-

bleed hole is covered by a 50 mesh wire gauze 6 100 r\\

to prevent blockages in the tap.

Procedure

Having locked on the base plate, the cylinder is

filled with concrete to a level about 1.5 em (0.6

..

~

c:

0

u

0 4

0

>

5

..,

~

E 60

.:!

80

v10

!

j~l7

4

·'/7

v

~

---

~ ~-+ --- ~·-

BORDERLINE p. s

NON-PUMPABLE

in.) from the top of the cylinder. This is equivalent

~3

;;e 40

. ~1

-

to a sample volume of approximately 1700 cm3

(109 cu in.). The concrete is placed in two equal 20

VA

[t i

layers each of which is lightly tamped to insure ~

that the cylinder is filled. It is not necessary to 0

0 20 40 60 80 100 120 140

fully compact the concrete as this state may not in

TIME (seconds)

fact occur when concrete is fed into a pump cylin-

der. Fig. 7-Typical bleed test results (I cm3 = 0.0593 in. 3 )

ACJ JOURNAL/ MAY 1977 197

where the initial water content of the mix is For use with a wider range of materials, further

known, the residual water can be used as a calibration tests may be necessary.

measure of the compressed void content of the

solid particle system. VOID MEASUREMENT

A concrete which is prone to dewatering will Background

emit water quickly during the first 10 sec and

hence the value of v1411- VIO should be small; The permeability of fresh concrete is a major

larger values of V1411 - V 10 therefore indicate the factor in defining its pumpability; the pressure

more pumpable concretes, i.e., those which retain bleed test is a practical method for measuring

the interparticle water more efficiently. this property indirectly. Further, the permeability

From the tests undertaken using concrete with is related to the porosity of the concrete, i.e., the

20 mm aggregate, minimum permissible values of void content of the solid particle system, and if

VHo- vlO were quantified for different levels of this can be minimized the proneness to dewater-

workability according to the relationship shown ing will also be reduced.

in Fig. 8.

Thus, from the limited tests carried out so far, Apparatus

it would appear feasible to determine whether or An apparatus for measuring the voids content

not a concrete may be prone to blocking in a of dry materials with continuous voids was de-

pipeline, by adopting the following procedure: veloped by Kempster, 6 and is illustrated in Fig. 9.

1. Measure V 10 and Vt4o· The method is based on measuring the head of

2. Calculate V14n - V10. water which can be supported by a partial vacuum

3. Measure the slump of the concrete. created within the aggregate.

4. For the measured slump, read off the mini-

mum acceptable value of V14 n - V10 from Fig. 8. Procedure

If the measured value of V 140 - V 111 is greater The material to be examined is placed into the

than the minimum acceptable value then the sample jar in four equal layers up to a level 3.5

concrete should pump successfully. em (1.5 in.) below the top of the jar. Each layer

If Vl4o- V10 is less than the minimum value, is hand compacted using a weight supplied with

then modification of the mix will be necessary. the apparatus which also acts as a spacer used to

It should be noted, however, that the pressure determine when the jar has been filled to the

bleed test is not designed in its present form to required level. The airtight lid is then screwed

indicate the magnitude of flow resistance of con- down on top of the jar with the tap open.

crete in either the saturated or unsaturated state. With the reservoir in Position 1, the water level

in the measuring tube is brought to a predeter-

mined level by adjusting the water level in the

• Pumpablc

<t Border! inc

15 o Non-pumpablc --+Gh*-''~<-"""'~

RESERVOIR

POSITION 2.

0 50 100 150

WATER EMITTED (V 140 -V 10 >ccm 3 )

Fig. a-Interpretation of bleed test results (I em = 0.39

in.; I cm3 = 0.0593 in.3 ) Fig. 9-Void measuring apparatus (Reference 6)

198 ACI JOURNAL I MAY 1977

reservoir. The tap is closed and the apparatus is

now set up as shown in Fig. 9.

To measure the voids in the sample, the res-

ervoir is lowered to Position 2, creating a pressure

head in the measuring tube. The water level is

allowed to settle to an equilibrium position, the ..

E

head of water in the measuring tube being sup- :I

0

ported by the partial vacuum created in the >

sample. The head which can be sustained is in- .:.<

:I

versely related to the volume of air in the sealed .Q

system and the void content of the sample can be

read directly from the previously calibrated scale.

-0

~

Some typical values of void content for com- 1-

bined aggregate sand and cement are illustrated z

11.1

in Fig. 10. 1-

z

0 0

Application u

CEMENT("/. by wt.of total solids)

As well as measuring the void content of the c

combined solids including cement, it is also useful 0

>

to measure the voids within the aggregate system

alone. By combining the aggregates in such a way

as to produce a minimum voids content, it follows

that to fill these voids a minimum cement content

will be required to produce a concrete which is

sufficiently impermeable for pumping.

Fig. 10 shows the typical effect of varying the

sand content on the voids in the combined aggre-

gate and also the increase in the voids of the total SAND ("/.by wt of total aggregate)

solid particle system when the cement content is Fig. I0-Typical values of void content

increased above an optimum value.

The void meter has been found to be a useful 3No.25mm DIA.STEEL

RESTRAINING BARS

tool for the assessment of aggregates for pump LUMINIUM SHEETING

mixes, and can 'also be used to measure the effec- STEEL

tiveness of alternative void filling materials such COLLAR

as fine sand or cement substitutes, such as pul-

verized fuel ash or ground granulated blast fur-

nace slag.

IN-LINE PRESSURE MEASUREMENT

With the rapid increase in the use of pumps in

recent years, the necessity has arisen for advanced VERMICULITE

THERMAL

methods of mix proportioning and also a higher INSULATION

degree of control over both ready-mixed and site- -4 PAIRS OF ACTIVE ELECTRICAL

RESISTANCE STRAIN GAUGES

hatched concrete. AT 90° INTERVALS (HOOP AND

0 POWER SUPPLY

AND STF\AIN REC.ORDER.

LONGITUDINAL DIRECTION).

Technique

Fig. 11-Details of instrumented pipeline (I mm = 0.039

A method has been developed whi~h may be in.)

used in the laboratory or on site to record in-

directly the pressure of concrete in a pipeline and A strip ~hart pen recorder was used to monitor

thus give an indication of both the pumpability the results, allowing adjustment of the chart speed

and variability of concrete while being pumped. and enabling instantaneous observation of the

The method consists of measuring the line pressure data.

continuously by the strain developed in the short A typical pressure trace is illustrated in Fig. 12,

section of calibrated pipeline. The results are re- showing results obtained using a chart speed of

corded in terms of the voltage change from a 1 mm/sec (0.04 in./ sec). The advantage of having

bridge of electrical resistance strain gages mounted a continuous record of pipeline pressure is that the

on a reduced section of the pipe wall. A section of variability of the concrete may be observed

strain gaged pipe is illustrated in Fig. 11. throughout a pumping operation and immediate

ACI JOURNAL I MAY 1977 199

N, 6 Chart Speed= lmm/scc.

E

.z 5

....tJI

UJ 4

a:

::::1

Vl

Vl 3

UJ

a:

D.

UJ 2

1-

UJ

a:

u

z I !

0

u

0

0 2 3

TIME (Minutes)

Fig. 12-Continuous pressure trace (I kgf I em~ = 14.22 psi; I mm = 0.039 in.)

action taken in the event of a tendency towards time" is taken up by the valve change time Tv,

a high pipeline pressure. and also the time taken for the piston to hit the

The recorder, when operated at a faster rate concrete, Tp. The latter part of the dead time Tp

(10 mm/sec) (0.4 in./ sec), provides a range of is related to the design of the cylinder inlet valve

more detailed information including pipeline (i.e., the filling efficiency of the cylinder), and

pressures, concrete velocity, and the efficiency of also the workability of the concrete.

the pump, which may be quantified and ulti- The filling efficiency can be defined by that pro-

mately used in the design of pumpable concretes portion of a piston stroke during which the piston

and improved pumping systems. is in contact with the concrete.

The time for a single piston stroke is (T c/2) -

Analysis of traces Tv; thus the filling efficiency can be defined by

The majority of work carried out in this field the equation:

has been mainly concerned with determination of

pipeline pressures.~ However, from a more detailed

analysis of the pressure traces it will be seen that

Efficiency= [ 1 - (Tc/ 2~P _ T, JX 100 percent

(6)

further useful information may be obtained related

particularly to concrete workability and also the For a particular pump, the value of TP will be

efficiency of the pumping system. A typical pres- directly related to the workability of the concrete,

sure trace obtained using the increased chart being defined by its ability to flow into the pump

speed is illustrated in Fig. 13. cylinder. This is illustrated more clearly in Fig.

The peak pressure P]J occurs when the piston 14. Thus by continuous recording of the pressure

hits the concrete in the cylinder and is the impact traces the variability of the concrete workability

and initial pressure required to move the concrete. may be indirectly observed.

The constant velocity pressure Pcu is the pressure A knowledge of the concrete velocity during

required to keep the concrete in motion. the pressure pulse is of value in investigating

During one cycle (i.e., the time taken for both pumping problems and the influence of, for ex-

pistons to complete one stroke), some of the time ample, admixtures on pumping performance.

is ineffective in moving the concrete. This "dead The transport velocity of concrete in the pipe-

_PEAURESSU~__(pp}_ _ _ line can be estimated using the following equation:

Concrete velocity V 1 = ( ~: ) ~ ( (Tc/ 2 ~ _Tv )

(7)

MEAN MINIMUM where

_,PRESSURE(f.d_.

ATMOSPHERIC

D1 piston diameter

D2 pipeline diameter

s length of piston stroke

T,/2 = half cycle time (i.e., the time for one

piston stroke)

Fig. 13-Analysis of a pressure pulse Tv valve change time

200 ACI JOURNAL I MAY 1977

INCREASING WORKABILITY

j I

r - -r

.

I Tp

I

I I

i) POOR WORKABILITY ii)MEDIUM WORKABILITY iii)GOOD WORKABILITY

LOW FILLING EFFICIENCY INCREASED FILLING EFFICIENCY HIGH FILLING EFFICIENCY

LOW THROUGHPUT AVERAGE THROUGHPUT HIGH THROUGHPUT

HIGH FLOW RESISTANCE REDUCED FLOW RES I STANCE LOW FLOW RESISTANCE

Fig. 14-Effect of concrete workability on pumpability and pump efficiency

The value of (To/2) - T, is in fact the value T pumping system has been established which pro-

given in Eq. 4. vides at least a qualitative basis for understanding

Thus it can be seen that by close observation of problems in pumping.

the shape and dimensions of the pressure traces, 2. The pressure bleed test apparatus has been

information not only on pumping pressures but found to be a satisfactory laboratory and site

also the flow properties of the concrete and ef- method for measuring indirectly the permeability

ficiency of the pump may be obtained. of concrete for pumping and, as regards this fac-

tor, provides a method for controlling pump mixes

Application on site.

A number of tests have been carried out using 3. The void measuring apparatus may be used

strain-gaged pipelines. The original flow re- in the proportioning of economic pumpable con-

sistance/concrete velocity relationship illustrated cretes to minimize the cement requirement by ob-

in Fig. 3 was determined using this method and a taining a minimum voids content in the combined

series of pressure traces and associated values of aggregates.

throughput are illustrated in Fig. 15. 4. Recording of in-line pressure/time traces

Further tests have been carried out to measure provides a method for measuring the effectiveness

the effectiveness of additives and modifications to of different types of pumps and improvements to

the pumping system designed to reduce the pump- the pumping process, as well as observing varia-

ing pressure requirements. tions in materials and mix proportions.

The most recent series of tests has been carried 5. By use of the basic theory outlined, and the

out to measure the variability of site-mixed con- test methods described, pump, pipeline, and con-

crete. A strain-gaged pipe was inserted into a

fixed pipeline on site and readings taken on 2 0

three occasions for periods of up to 4 hr. A set

of traces showing the variation in workability is

shown in Fig. 14.

The strain-gaged pipeline has been found to be IIJ

a: 15

a useful tool in the assessment of the factors :::1

1/)

affecting the pumpability of concrete. Further- 1/)

IIJ

more, having overcome the major problems of in- a:

a..

strumentation the results can be used confidently

IIJ

to quantify the effectiveness of various methods of .....

IIJ

improving the pumpability of concrete by vari- a:

u

ation in mix proportions or ·the use of admix- z 5

0

tures. It is also useful as an instrument for quality u

control by continuous recording of pipeline pres-

sures and to assess t'he operating performance of

different types of pumps.

0 2 3 4

CONCLUSIONS Tf ME (Seconds)

1. A model for relating the state of concrete in

Fig .. IS..:_Pressure pulses for concrete placed at varying

the pipeline to the concrete mix components and rates (I kgf I em~ = 14.22 psi; I cu m = 35.3 cu ft)

ACI JOURNAL I MAY 1977 201

.SAWJY/r£n ! IIYfJe!Jouc JfLOt...J

Fig. A-1-Saturated (hydraulic) flow Fig. A-2-Unsaturated (friction) flow

crete mix performance may be quantitatively es- Taylor Woodrow Research Laboratories, Southall, 1970,

tablished, particularly on site, which hitherto has 50 pp.

not been a practical proposition. 4. Loadwick, F., "Some Factors Affecting the Flow of

Concrete Through Pipelines," Proceedings, First Inter-

national Conference on Hydraulic Transport of Solids

ACKNOWLEDGMENTS in Pipes (Sept. 1970), (The British Hydromechanics

Research Association), Bedford, England, Paper D1, pp.

The authors wish to thank the directors of Taylor Dl-32.

Woodrow Construction Ltd., Southall, England, for al-

lowing the paper to be produced and permitting the 5. Alekseev, S. N., "On the Calculation of Resistance

inclusion of company information, and to the Construc- in Pipes of Concrete Pumps," Mekhanizatziya Stroi-

tion Industry Research and Information Association who tel'stva (Moscow), V. 9, No. 1, Jan. 1952, pp. 8-13 (in

partly financed the initial research program. The au- Russian). Translated as Library Communication No. 450,

thors are also indebted to the former and current per- Building Research Station, Garston-Watford, Apr. 1963.

sonnel in the Materials Laboratory of Taylor Woodrow 6. Kempster, E., "Measuring Void Content," Contract

Construction Ltd. for their contribution to the experi- Journal (Surrey), V. 229, Mar. 27, 1969, pp. 409-410.

mental, laboratory, and site work, and assistance in the

theoretical studies. In particular they would like to

express their appreciation of the efforts of Mr. A. APPENDIX

Flateau, Dr. J. Parkinson, and Mr. F. Loadwick, who

were directly involved in the project during their em-

Saturated or hydraulic flow

ployment in the laboratory. Consider an element of pipe of length d,, and diameter

D, as shown in Fig. A-1. The forces producing a con-

stant velocity V will be the pressure force opposed by

REFERENCES

the resistance to flow. The flow resistance R for hy-

1. Ede, A. N., "The Resistance of Concrete Pumped draulic flow is a function of the fluid properties and

Through Pipelines," Magazine of Concrete Research its velocity. Thus for a constant velocity, the flow re-

(London), V. 9, No. 27, Nov. 1957, pp. 129-140. sistance is constant with respect to pressure and length

2. Weber, Robert, Transport of Concrete by Pipeline of pipe for a particular fluid.

(Rohrforderung von Beton), Beton-Vertrage GmbH, Equating forces across the element for constant ve-

Dusseldorf, 1963. Translated as C&CA Library Trans- locity (i.e., constant volume flow rate):

lation No. 61.129, Cement and Concrete Association, .

London, 1968, 88 pp. D

p.,.T-

2

( dP

P +dx dx

).,.D2

- 4- = R ..Ddx

3. Browne, R. D., and Loadwick, F., "Mechanics of

Pumping Concrete," Research Report No. 014J/70/1450, (A-1)

202 ACI JOURNAL I MAY 1977

dP TrD:! Now dx is small and second order quantities may be

. ·.RTrDdx =- dx dx 4 ignored thus:

. D dP D dP

.. R = - - - - - - = A + ILkP

4 dx 4 dx

Separating the variables and integrating over a length

Integrating over a length of pipeline x from the pump, of pipeline, x from the pump,

R

0

! "' -

dx- - D

-

4 Po

!P dP

:. Rx = - -D4 (P- P.) .". _1_[ log, (A

ILk

+

ILkP)

(A+ ~LkP.)

J= _ !.:__

D (A-6)

Rearranging,

4Rx =e

P=P.-D (A-2)

Re-arranging,

4~tkX A ( 4~tkX )

Unsaturated or friction flow P = P.e - D -- 1- e - D

ILk (A-7)

If the flow resistance is in some way dependent on

The maximum distance pumpable can be obtained by

the pressure in the concrete then the system is said to be

considering the distance x along the pipeline at which

in a friction state, and the element of pipe considered

the axial pressure P becomes zero.

is now as shown in Fig. A-2.

Now the total flow resistance is made up of two Thus, for saturated flow, when P = 0,

components: the frictional resistance RF, which is pro-

DP.

portional to the radial concrete pressure, and an ad- Xm.or =4R

hesive stress A, which is independent of concrete pres- (A-8)

sure. Consider, first, the component R,.. If the coefficient and for unsaturated flow, when P = 0,

of friction is IL and the radial pressure is PR, then

(A-3) Xma:z: == (A-9)

But Edel has shown that the radial pressure under un-

saturated conditions is not equal to the axial pressure Example

P, the ratio PR/P being given by the constant k. Thus

Eq. (A3) becomes For the example described previously, P. 35 kgf/ =

m2 (500 psi) and D =

10 em (4 in.). Typical values of

(A-4) the flow resistance parameters are as follows:

Saturated flow: R = 3.5 x 10-3 kgf/m2 (0.05 psi)

Consider now the adhesive stress A. Edel has expressed

a need for such a parameter since there is appreciable Unsaturated flow: t

frictional resistance in the pipeline even when the pres-

sure at the outlet is zero. Thus the total resistance to

A = 65 x lQ-3 kgf/m2 (0.92 psi)

flow can be expressed in the form J.l. = 0.38

k = 0.25

R=A+J.tkP (A-5)

Substituting values into Eq. (A-8) for saturated flow:

The average resistance over a pipe length dx is given by: (10 X lQ-2) X 35

Xmaz =

4 X ( 3.5 X 10 3 ) = 250m (820ft)

Substituting values into Eq. (A-9) for unsaturated

flow:

RAv = A + ILk ( P + -dx

dP -dx)

2 X., •., =- [

(10 X lQ-2)

4 X 0.38 X 0.25

J

Equating forces for constant flow velocity

loge

[

65 X lQ-3

(35 X 0.38 X 0.25) X (65 X 10-3 )

J

Tr ~T p _ ( p + :: dx) J = 1.1 m (3.6 ft)

= TrDdx [A + ILk ( p + :: ~x ) J In this particular example, therefore, a change in the

state of the concrete over a 1.1 m length of line from

the saturated to the unsaturated state would immedi-

dP ately result in a blockage, the pressure requirement ex-

D2 [ (

:. - dx dx '~~"T= TrDdx A+ ILk P + dP dx ) ]

dx 2 ceeding the capacity of the pump.

D dP

- - - =A+ILk

( dP dx)

P+ -- Received Dec. 3. 1975, and reviewed under l·nstitute publication

4dx dx2 policies.

ACI JOURNAL I MAY 1977 203

You might also like

- Influence of Fiber Type and Fiber Orientation On Cracking and Permeability of Reinforced Concrete Under Tensile Loading 2017 Cement and Concrete ReseaDocument12 pagesInfluence of Fiber Type and Fiber Orientation On Cracking and Permeability of Reinforced Concrete Under Tensile Loading 2017 Cement and Concrete ReseaKaio OliveiraNo ratings yet

- Abrams LawDocument2 pagesAbrams LawShazwanShahNo ratings yet

- Pumpability of ConcreteDocument10 pagesPumpability of Concretevikram kumarNo ratings yet

- Bingham Model For Pumpable ConcreteDocument11 pagesBingham Model For Pumpable ConcreteYogendra SINGH PATELNo ratings yet

- Modelling the tensile behavior of plain concrete under flexural loadingDocument7 pagesModelling the tensile behavior of plain concrete under flexural loadingAhmad MensaNo ratings yet

- 4634 PDFDocument7 pages4634 PDFMuthu KumarNo ratings yet

- Fresh Cement Concrete BanfillDocument70 pagesFresh Cement Concrete BanfillBatepola BacNo ratings yet

- Shrinkage TestDocument12 pagesShrinkage TestAlsonChinNo ratings yet

- NDT On Concrete Pull Off Test: by Subhodeep Neogi Sai Prakash VaddiDocument12 pagesNDT On Concrete Pull Off Test: by Subhodeep Neogi Sai Prakash VaddiManish Mittal100% (1)

- The Effect of Excess Water in ConcreteDocument2 pagesThe Effect of Excess Water in ConcreteKevin NacalabanNo ratings yet

- Monitoring Methods of Concrete From Early Age Strength Gain of Concrete A ReviewDocument8 pagesMonitoring Methods of Concrete From Early Age Strength Gain of Concrete A ReviewAmit Sharma IPS AcademyNo ratings yet

- 2012 - Compressive Strength of Concrete After Early LoadingDocument7 pages2012 - Compressive Strength of Concrete After Early LoadingafuhcivNo ratings yet

- Energy TestDocument19 pagesEnergy TestDataNo ratings yet

- C1582C1582M-Aditivos Inhibidores de CorrosionDocument10 pagesC1582C1582M-Aditivos Inhibidores de CorrosionAnthony López HuamanNo ratings yet

- TENSAR Cement StabilizationDocument72 pagesTENSAR Cement StabilizationHenrry L. Gonzales Fernández100% (1)

- ConcreteSoc Drugo Izdanje2004Document118 pagesConcreteSoc Drugo Izdanje2004Rusovic RejhanNo ratings yet

- Field CompactionDocument5 pagesField CompactionG-ann DatarioNo ratings yet

- Aashto T307Document27 pagesAashto T307Viviana CruzNo ratings yet

- Evaluating Structural Buildup at Rest of Self-Consolidating Concrete Using Workability TestsDocument10 pagesEvaluating Structural Buildup at Rest of Self-Consolidating Concrete Using Workability TestsHuaman Chavez Jesus AngelNo ratings yet

- Grout Pumps & System PDFDocument13 pagesGrout Pumps & System PDFImran AlamNo ratings yet

- TheStability of A Laminated Voussoir Beam PDFDocument17 pagesTheStability of A Laminated Voussoir Beam PDFDaniel SantanaNo ratings yet

- Indian Codal Provisions For Shotcrete - Appraisal and RecommendationsDocument11 pagesIndian Codal Provisions For Shotcrete - Appraisal and Recommendationssharathr22No ratings yet

- Rock BoltDocument5 pagesRock BoltMuhammad Noufal AchyarNo ratings yet

- SM Triaxial Compression Test 1978 PDFDocument5 pagesSM Triaxial Compression Test 1978 PDFNicolás Silva0% (1)

- Testing Concrete: BS 1881: Part 116: 1983Document8 pagesTesting Concrete: BS 1881: Part 116: 1983Muhammad AmmarNo ratings yet

- Bond Strength of Cement Grouted GFRP Anchor BoltsDocument11 pagesBond Strength of Cement Grouted GFRP Anchor Boltssstelang456No ratings yet

- 04 - TDS Meyco FlowcableDocument3 pages04 - TDS Meyco FlowcablebossbobNo ratings yet

- ACI 207.2R-95 Effect of Restraint, Volume Change, and Reinforcement On Cracking of Mass ConcreteDocument26 pagesACI 207.2R-95 Effect of Restraint, Volume Change, and Reinforcement On Cracking of Mass ConcreteAltin CeroNo ratings yet

- Repair of Damage With Exposed Steel ReinforcementDocument4 pagesRepair of Damage With Exposed Steel ReinforcementMohamed NkNo ratings yet

- Peter Day - Geotechnical Engineers and The Construction RegulationsDocument6 pagesPeter Day - Geotechnical Engineers and The Construction RegulationsBobNo ratings yet

- Performance Criteria For Tremie Concrete in Deep FoundationDocument42 pagesPerformance Criteria For Tremie Concrete in Deep FoundationYoshua YangNo ratings yet

- Inclined Micropile - 05 Damavandinejad MonfaredDocument8 pagesInclined Micropile - 05 Damavandinejad MonfaredJpver1000No ratings yet

- Nondestructive Evaluation of Wood-Based Flexural Members Using Transverse VibrationDocument8 pagesNondestructive Evaluation of Wood-Based Flexural Members Using Transverse Vibrationasma hamzaNo ratings yet

- Delayed Ettringite Formation in ConcreteDocument1 pageDelayed Ettringite Formation in ConcretemakhsmyNo ratings yet

- TDS - IPNet SystemDocument2 pagesTDS - IPNet SystemRadha KrishnanNo ratings yet

- Rilem Ii.4Document4 pagesRilem Ii.4manil_5No ratings yet

- Determination of Water-Cement Ratio of HardenedDocument6 pagesDetermination of Water-Cement Ratio of HardenedMárcio AlvesNo ratings yet

- Generalized Maxwell ModelDocument10 pagesGeneralized Maxwell Modelsalkan_rahmanovic810No ratings yet

- Technical Report TR 5 Conc Mix DesignDocument18 pagesTechnical Report TR 5 Conc Mix DesignSunil ReddyNo ratings yet

- Astm D7380 - 15Document3 pagesAstm D7380 - 15guyii86No ratings yet

- Hyper CreteDocument2 pagesHyper CretedjgiumixNo ratings yet

- TDS - Flowcable 50Document2 pagesTDS - Flowcable 50Venkata RaoNo ratings yet

- Ultra High Strength Concrete1Document34 pagesUltra High Strength Concrete1rangarajNo ratings yet

- Construction and Building Materials: Min Wu, Björn Johannesson, Mette GeikerDocument13 pagesConstruction and Building Materials: Min Wu, Björn Johannesson, Mette GeikerKaryne FerreiraNo ratings yet

- Introduction To Shell TheoryDocument45 pagesIntroduction To Shell TheorySurendraBhatta100% (1)

- Astm C1196Document6 pagesAstm C1196Lorenzo GambassiNo ratings yet

- High Performance ConcreteDocument27 pagesHigh Performance ConcretePratik MandlikNo ratings yet

- 238.2T 14 PDFDocument6 pages238.2T 14 PDFJoão Carlos Protz ProtzNo ratings yet

- Injection: Solutions For Underground ConstructionDocument12 pagesInjection: Solutions For Underground ConstructionDevinder SokhiNo ratings yet

- Concrete Mix Design Methods, Verification StudyDocument26 pagesConcrete Mix Design Methods, Verification StudyAhmed M AminNo ratings yet

- ASTM-C 512 (Creep of Concrete Test)Document5 pagesASTM-C 512 (Creep of Concrete Test)Evgeny PankovNo ratings yet

- Polypropylene Fibre Reinforced ShotcreteDocument11 pagesPolypropylene Fibre Reinforced Shotcreteabhineet srivastava100% (2)

- Specification For Shotcrete (ACI 506.2-95) : Reported by ACI Committee 506Document8 pagesSpecification For Shotcrete (ACI 506.2-95) : Reported by ACI Committee 506santiago hernandezNo ratings yet

- Ccanz tm35 PDFDocument246 pagesCcanz tm35 PDFcristiano68071No ratings yet

- Micropile Design DwgsDocument1 pageMicropile Design DwgsPrakash Singh RawalNo ratings yet

- Flow of Hydraulic Cement Mortar: Standard Test Method ForDocument2 pagesFlow of Hydraulic Cement Mortar: Standard Test Method ForINARQ1979No ratings yet

- Effect of Aggregate Gradations on Porous Friction Course Mix PropertiesDocument13 pagesEffect of Aggregate Gradations on Porous Friction Course Mix PropertiesBen Mur MarNo ratings yet

- Testing and Moddeling Creep of Cracked Macro SyntheticDocument12 pagesTesting and Moddeling Creep of Cracked Macro SyntheticsaiNo ratings yet

- Ggbs in Cement Paste and MortarDocument6 pagesGgbs in Cement Paste and MortarsaiNo ratings yet

- Strain Hardening HPFRCDocument10 pagesStrain Hardening HPFRCsaiNo ratings yet

- Toughness Based Analysis and Design of Fiber Reinforced Concrete BarsbyDocument222 pagesToughness Based Analysis and Design of Fiber Reinforced Concrete BarsbysaiNo ratings yet

- State of The Art On Prediction of PumpingDocument11 pagesState of The Art On Prediction of PumpingsaiNo ratings yet

- Attack On Plain and Blended Cements Exposed To Aggressive Sulfate Environments 2002 Cement and Concrete CompositesDocument12 pagesAttack On Plain and Blended Cements Exposed To Aggressive Sulfate Environments 2002 Cement and Concrete CompositessaiNo ratings yet

- DR Tian Sing NG, BOSFA Fibres For Crack Control PDFDocument68 pagesDR Tian Sing NG, BOSFA Fibres For Crack Control PDFsaiNo ratings yet

- Use of Macro Plastic Fibres in ConcreteDocument9 pagesUse of Macro Plastic Fibres in Concretemichael jayNo ratings yet

- Cracking Behaviour of FRC Slabs With Traditional ReinforcementDocument19 pagesCracking Behaviour of FRC Slabs With Traditional ReinforcementsaiNo ratings yet

- Effect of Coarse Aggregate Size On PumpingDocument8 pagesEffect of Coarse Aggregate Size On PumpingsaiNo ratings yet

- Attack On Plain and Blended Cements Exposed To Aggressive Sulfate Environments 2002 Cement and Concrete CompositesDocument12 pagesAttack On Plain and Blended Cements Exposed To Aggressive Sulfate Environments 2002 Cement and Concrete CompositessaiNo ratings yet

- 269 PDFDocument5 pages269 PDFsaiNo ratings yet

- Lubrication Layer Properties During Concrete PumpingDocument10 pagesLubrication Layer Properties During Concrete PumpingsaiNo ratings yet

- Designing Rock Support for RockburstsDocument13 pagesDesigning Rock Support for RockburstsDaniel ZabalaNo ratings yet

- Bothma - Structural - FRS - Slabs - 2013 PDFDocument156 pagesBothma - Structural - FRS - Slabs - 2013 PDFsaiNo ratings yet

- Dimensions: S60-PA-5 S60-PA-2Document2 pagesDimensions: S60-PA-5 S60-PA-2saiNo ratings yet

- Altimeter - Test ReportDocument2 pagesAltimeter - Test ReportSani IhsanNo ratings yet

- Mata Pelajaran Tingkatan TajukDocument15 pagesMata Pelajaran Tingkatan TajukmalaomarNo ratings yet

- Manual: Good Practices For The Feed IndustryDocument106 pagesManual: Good Practices For The Feed Industryadrizootecnista100% (4)

- 15Document10 pages15Tuan Nguyen ManhNo ratings yet

- Numerical Problem With Solution For Engg MeasurementDocument31 pagesNumerical Problem With Solution For Engg Measurementssanthosh073100% (5)

- Manual Grimm enDocument95 pagesManual Grimm enJonatan Enriquez50% (2)

- Paper Friction Johan91a PDFDocument9 pagesPaper Friction Johan91a PDFYessieNo ratings yet

- A Text Book of Physics (C.R. Dasgupta) (Z-Library)Document760 pagesA Text Book of Physics (C.R. Dasgupta) (Z-Library)toffee9soumavaNo ratings yet

- FM Assignment 5Document4 pagesFM Assignment 5JadeJadeTrevibulNo ratings yet

- Wave Equation in FluidsDocument48 pagesWave Equation in FluidssetakNo ratings yet

- What Is HCDPDocument5 pagesWhat Is HCDPfumerojr5164100% (1)

- Sewage Pumping HandbookDocument12 pagesSewage Pumping Handbookmfhaleem@pgesco.comNo ratings yet

- Mod CHSDocument2 pagesMod CHSAndree VargasNo ratings yet

- Take HOME PROBLEMSDocument4 pagesTake HOME PROBLEMSFontanilla Mark AnthonyNo ratings yet

- C1277-15 Standard Specification For Shielded Couplings Joining Hubless Cast Iron Soil Pipe and Fittings PDFDocument9 pagesC1277-15 Standard Specification For Shielded Couplings Joining Hubless Cast Iron Soil Pipe and Fittings PDFCarlos Guillermo Somoza AlvarengaNo ratings yet

- Minivap Vpxpert: Operation Manual Of2Document63 pagesMinivap Vpxpert: Operation Manual Of2Erick Jhonhatan LimonNo ratings yet

- Software To Calculate Pressures in Cylindrical Metal Silos: Lí Cia Carvalho Coelho and Carlito Calil JúniorDocument5 pagesSoftware To Calculate Pressures in Cylindrical Metal Silos: Lí Cia Carvalho Coelho and Carlito Calil JúniorffyuNo ratings yet

- Hyd& PneumaticsDocument18 pagesHyd& PneumaticssathishNo ratings yet

- M.engineering - Piping SystemsDocument55 pagesM.engineering - Piping SystemsKordalhs KyriakosNo ratings yet

- Introduction To PumpsDocument9 pagesIntroduction To PumpsJaydeep TrivediNo ratings yet

- Uplit Pressures Final Report PDFDocument30 pagesUplit Pressures Final Report PDFMekete DessieNo ratings yet

- HSP Science Form 5Document35 pagesHSP Science Form 5Rafizal ShafieeNo ratings yet

- Process DesignDocument46 pagesProcess Designdevya123No ratings yet

- Pipeline Failure Investigation ReportDocument21 pagesPipeline Failure Investigation ReportBozeman Daily ChronicleNo ratings yet

- Water Table Observation - 12 MarchDocument5 pagesWater Table Observation - 12 Marchrupeshkumar642mdsNo ratings yet

- Soluforce Catalogue PDFDocument32 pagesSoluforce Catalogue PDFsureshisisis100% (1)

- The Motivational Power of Science Discrepant EventsDocument8 pagesThe Motivational Power of Science Discrepant EventsJennifer Owens100% (1)

- Ultrasonic flowmeters for flexible measurementDocument39 pagesUltrasonic flowmeters for flexible measurementkatakliztmaNo ratings yet

- Foam Chamber: Model: NF-FC SeriesDocument6 pagesFoam Chamber: Model: NF-FC SeriesJESUS HUAMANINo ratings yet

- Iptc 13784 MS PDocument9 pagesIptc 13784 MS PSergio Flores100% (1)