Professional Documents

Culture Documents

COLORADO DOT SOIL DRILLING SAFETY

Uploaded by

fajee_faridOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

COLORADO DOT SOIL DRILLING SAFETY

Uploaded by

fajee_faridCopyright:

Available Formats

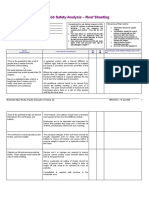

COLORADO DEPARTMENT OF TRANSPORTATION

JOB SAFETY ANALYSIS

Activity Name: Soft Soil Investigations (Auger drilling) Activity Number:

Activity Description & Purpose: Soil drilling using augers, Drilling using Hollow Stem Augers (HSA) or 4" solid augers is an in situ testing method used to determine the

geotechnical engineering properties of soils and delineating soil stratigraphy.

Date Prepared: 04/01/2009 PPE Required

Typical Equipment Typical Crew Size: Typical Material Safety Boots, Hardhat,

Reflectorized Vest, Safety

Description Class Code Description Class Code

P/U 4X4 3 to 11 n/a n/a

Glasses, Dust Mask, Hearing

10

Drill Rig 942 Protection, Appropriate

Drill/Truck Mounted 945 Gloves

Trailer - Lowboy 606 (Crew sizes may vary due to different site

(If Night Drilling)

conditions such as on road, off road

Light Plant 913

(If Traffic Control is needed) drilling, winter conditions, summer

Arrow Board/VMB 902-903 conditions, day time or night time drilling.

Sequence of Job Tasks Potential Hazards Safe Job Procedures Never

1) Preplan N/A Orientation - Safety Meetings - Tailgate Talks. Develop Traffic Control Plan and discuss it with everyone involved. Use unsafe equipment

Notify the Traffic Management Center and Public Relations, Utilize Uniformed Law Enforcement when available.

2) Underground and Overhead Buried power, gas & water Insure UNCC clearance and non-member utillities are

Utillities lines, fibre optics, overhead contacted and cleared

lines

2) Pretrip Tripping, Falling, Pinching, Always perform equipment inspections before and after operations (pre and post) Lift with your back, no loose clothing

Crushing, Burns, Lifting,

Bending, Pulling, Twisting

3) Loading Equipment Backing truck or equipment If using ATV Drill Rig...Use a spotter, Do a walk around, Proper loading/ unloading of equipment, Secure loads, Load equipment without a spotter,

into objects/ people or off the Display appropriate warning signs, Wear appropriate PPE- if using Truck mounted drill rig - be sure all transported Travel with unsecured loads

side of a trailer, Unsecured equipment and tools are properly secured.

loads, Tripping, Falling,

Pinching, Crushing, Moving

Parts, Burns, Lifting, Bending,

Pulling, Twisting

4) Traffic Control Setup Tripping, Falling, Pinching, Follow your traffic control plan (MHT) and insure the plan is on location. Mark all overhead obstructions with cones, Set up traffic control without an

Crushing, Moving Parts, signs, or flags. Always use attenenuator trucks when available and TEST your plan and insure it is working approved plan, lift with your back

Burns, Lifting, Bending, properly.

Pulling, Twisting, Backing

equipment into objects/

people, Traffic

Worn/faded/dirty traffic control Use clean and legible traffic control devices

devices

Getting struck by traffic or Use identified escape routes in your traffic control plan – always have a set of eyes watching traffic Never turn your back to oncoming

equipment traffic

Signs blowing over Use sandbags

5)Perform Task Tripping, Falling, Pinching, Use trained personnel to operate equipment, Follow all procedures outlined in the Driller Safety Handbook. Operate unsafe equipment, Work in an

Crushing, Moving parts, unsafe/ negligent manner

Flying debris, Noise, Dust,

Backing truck/ equipment into

objects/ people, Overhead &

Buried Utillities/ bridges/

signs/ obstructions, Weather -

lightning/ heat/ Hazardous

Materials

6) Traffic control removal Tripping, Falling, Pinching, Remove signs and other safety devices in accordance with Methods of Handling Traffic. Always use attenenuator Take your eyes off traffic

Crushing, Moving Parts, trucks when available, notify the traffic management center and public relations when work is completed, utilize law

Burns, Lifting, Bending, enforcement when available, wear appropriate PPE

Pulling, Twisting, Backing

equipment into objects/

people, Traffic

7)Unloading equipment Backing truck or equipment Use a spotter, Do a walk around, Proper unloading of equipment, Wear appropriate PPE Unload equipment without a spotter,

into objects/ people, Lift with your back

Unsecured loads, Tripping,

Falling, Pinching, Crushing,

Moving Parts, Burns, Lifting,

Bending, Pulling, Twisting

8) Post Trip Tripping, Falling, Pinching, Always perform equipment inspections before and after operations (pre and post)

Crushing, Burns, Lifting,

Bending, Pulling, Twisting

Notes and Specifications Instructions Other Related Resources

Regional MHT

Driller Safety Handbook

MMS Manual

MUTCD

PD 80.1, Personal Protective Equipment

M & S Standards

Lane Closure Strategy Book

Distribution: CDOT Form 1370 May 2006

CDOT Safety Manual Page 1 of 1

You might also like

- Jsa ExcavatorDocument1 pageJsa Excavatorbladeliger22No ratings yet

- JSA Sample 1 Changing A TireDocument3 pagesJSA Sample 1 Changing A Tiree smith100% (1)

- A1 GE JSA Installation PDFDocument7 pagesA1 GE JSA Installation PDFCao Huu TungNo ratings yet

- Job Site Safety ChecklistDocument4 pagesJob Site Safety Checklistတိုး ေဝ ေအာင္No ratings yet

- JSA Crack Injection at Scruber Basin Unit 3Document6 pagesJSA Crack Injection at Scruber Basin Unit 3MarhendraNo ratings yet

- JSA FormDocument4 pagesJSA Formpharhuntrun100% (2)

- Rocky Mountain Safety ProceduresDocument5 pagesRocky Mountain Safety ProceduresSAMUEL POBRENo ratings yet

- Job Safety Analysis WorksheetDocument14 pagesJob Safety Analysis WorksheetCherry Betonio100% (2)

- Example Risk Assessment For Outdoor EventsDocument6 pagesExample Risk Assessment For Outdoor EventsAnonymous 5YMOxVQNo ratings yet

- JSA For Offshore SafetyDocument69 pagesJSA For Offshore SafetyGaluh Pramudipto50% (2)

- Life-Saving Appliances Including LSA Code 2017Document8 pagesLife-Saving Appliances Including LSA Code 2017fajee_faridNo ratings yet

- Column Lifting & Erection JSADocument7 pagesColumn Lifting & Erection JSAAli Mohsin100% (3)

- Shipsure V2.0 FAQDocument13 pagesShipsure V2.0 FAQNik DerNo ratings yet

- Jsa For Alignment of Vessel and DrumDocument3 pagesJsa For Alignment of Vessel and DrumMohammed MinhajNo ratings yet

- 15.tube Bundle Puller.Document3 pages15.tube Bundle Puller.Mohammad Fazal Khan100% (1)

- JSA For Welding GrindingDocument7 pagesJSA For Welding GrindingBabar78% (9)

- Job Safety AnalysisDocument2 pagesJob Safety AnalysisAris RNNo ratings yet

- Job Safety Analysis (JSA) : DefinitionDocument5 pagesJob Safety Analysis (JSA) : DefinitionMesut MahmutogluNo ratings yet

- Safety Check For Chemical Cleaning Operation: SI. No. Description Status Ok / Not Ok RemarksDocument1 pageSafety Check For Chemical Cleaning Operation: SI. No. Description Status Ok / Not Ok RemarksRísês ÃfrözNo ratings yet

- Risk AssesmentDocument2 pagesRisk Assesmentsabu1995No ratings yet

- PCRA Construction Risk AssessmentDocument6 pagesPCRA Construction Risk AssessmenttommyNo ratings yet

- Hand SafetyDocument59 pagesHand SafetybenonNo ratings yet

- Job Safety Analysis TemplateDocument9 pagesJob Safety Analysis Templatecathodic protection100% (1)

- Pentens PU-300 Grouting Product Data SheetDocument2 pagesPentens PU-300 Grouting Product Data SheetS EfendiNo ratings yet

- Window CleaningDocument1 pageWindow CleaningSanthoshKumarNo ratings yet

- LOTO ChecklistDocument3 pagesLOTO ChecklistPutri UnaNo ratings yet

- Petrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.013Document5 pagesPetrochina International Jabung Ltd. Job Safety Analysis: Hse-Icg/Pcj-3075-Ca/Jsa.013Yosua SitumorangNo ratings yet

- Hot Work PermitDocument1 pageHot Work PermitKlyneRamirezNo ratings yet

- 30682417-Forklift Safety ChecklistDocument2 pages30682417-Forklift Safety ChecklistWaqas GujjarNo ratings yet

- SP-091-C CNC Router SOPDocument1 pageSP-091-C CNC Router SOPBorislav VulićNo ratings yet

- SCISSOR LIFT SAFETYDocument7 pagesSCISSOR LIFT SAFETYnatuan74No ratings yet

- Guidelines Ensure Access for AllDocument32 pagesGuidelines Ensure Access for AllrenuNo ratings yet

- Peer Review Form TemplateDocument1 pagePeer Review Form TemplateBagus KridhaNo ratings yet

- MSDS - Asada Threading Oiil Red - ENDocument7 pagesMSDS - Asada Threading Oiil Red - ENnghiaNo ratings yet

- Standard Operating Procedures of Hand and Power Tool SafetyDocument3 pagesStandard Operating Procedures of Hand and Power Tool Safetysingenaadam100% (1)

- LCC DOCS-11568884-V1-HS-PRO-013 Working in On Over or Adjacent To WaterDocument13 pagesLCC DOCS-11568884-V1-HS-PRO-013 Working in On Over or Adjacent To WaterabogadieNo ratings yet

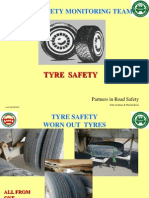

- LMV Tyre SafetyDocument19 pagesLMV Tyre SafetykarvadNo ratings yet

- Mhs12-Boliers and Pressures VesselDocument29 pagesMhs12-Boliers and Pressures VesselWidya BungaNo ratings yet

- Root Cause Analysis Example Near Miss Asphalt Drop FULLDocument9 pagesRoot Cause Analysis Example Near Miss Asphalt Drop FULLnayakya100% (1)

- Checklist Site and Security Fencing SchoolsDocument2 pagesChecklist Site and Security Fencing Schoolsakshay aryaNo ratings yet

- JHA BlastingDocument2 pagesJHA BlastingNevin RoldonNo ratings yet

- Surface Blasting Safety Procedures ManualDocument21 pagesSurface Blasting Safety Procedures ManualRajanbabu100% (1)

- Job Safety Analysis: Cooling Tower OperationDocument2 pagesJob Safety Analysis: Cooling Tower OperationVi VekNo ratings yet

- Ocp BatchingDocument1 pageOcp BatchingAarya Mishra TiwariNo ratings yet

- Appendix A-Job Safety Analysis FormDocument3 pagesAppendix A-Job Safety Analysis Formjiks_i4uNo ratings yet

- JSA Circular Saw OperationDocument1 pageJSA Circular Saw OperationNira100% (1)

- JsaDocument10 pagesJsaTanzeel LiaqatNo ratings yet

- Asian Paints - Prem Gloss EnamelDocument1 pageAsian Paints - Prem Gloss EnamelwilliumstNo ratings yet

- Confined Space OperationDocument138 pagesConfined Space OperationAhmad MensaNo ratings yet

- Attendance List TBTDocument2 pagesAttendance List TBTGunawanNo ratings yet

- Safe Work Procedure: Overhead CraneDocument2 pagesSafe Work Procedure: Overhead CraneNos GoteNo ratings yet

- Critical housekeeping risksDocument5 pagesCritical housekeeping risksZegera MgendiNo ratings yet

- JSA Excavation PDFDocument6 pagesJSA Excavation PDFmohamedamine.zemouriNo ratings yet

- Material Handling Check SheetDocument3 pagesMaterial Handling Check SheetJulius Mark CerrudoNo ratings yet

- Hot Work PermitDocument2 pagesHot Work PermitRex UrbiztondoNo ratings yet

- Management of ChangeDocument85 pagesManagement of ChangeHerik renaldoNo ratings yet

- Excavaten Work PermitDocument1 pageExcavaten Work Permitasem sawalmehNo ratings yet

- Basic 5S Audit ChecklistDocument1 pageBasic 5S Audit Checklistbasha1900No ratings yet

- Check List For ScaffoldingDocument3 pagesCheck List For ScaffoldingyakuzaQ100% (1)

- 3216 JSA Roof PlumbingDocument14 pages3216 JSA Roof Plumbingmalimsaidi_160040895100% (2)

- KRA 1.4 Plant and EquipmentDocument13 pagesKRA 1.4 Plant and EquipmentSubburajMechNo ratings yet

- Majeestech JSP for Scaffolding and Working at HeightDocument3 pagesMajeestech JSP for Scaffolding and Working at HeightkrishnakumarNo ratings yet

- Traffic MG T Plan TempDocument4 pagesTraffic MG T Plan TempLeoven Jef Suzara LorinNo ratings yet

- Driving On SiteDocument15 pagesDriving On SitejhoniNo ratings yet

- MJSA-Hard Rock Coring Final (8-3-09)Document1 pageMJSA-Hard Rock Coring Final (8-3-09)Bogdan-Gabriel SchiopuNo ratings yet

- Rig Move-JsaDocument1 pageRig Move-JsasNo ratings yet

- MRAPs: Main Resistant Ambush Protected VehiclesFrom EverandMRAPs: Main Resistant Ambush Protected VehiclesRating: 5 out of 5 stars5/5 (1)

- Win Saf 42Document5 pagesWin Saf 42fajee_faridNo ratings yet

- No. 90 Ship Structure Access Manual No. 90: (Cont) (Oct 2005) (Rev.1 Apr 2019)Document18 pagesNo. 90 Ship Structure Access Manual No. 90: (Cont) (Oct 2005) (Rev.1 Apr 2019)fajee_faridNo ratings yet

- اطلاعات عمومی دریاییDocument15 pagesاطلاعات عمومی دریاییfajee_faridNo ratings yet

- Dynamic UKC BookletDocument19 pagesDynamic UKC BookletOllivier AmaruNo ratings yet

- Recovery of Persons From The WaterDocument5 pagesRecovery of Persons From The Waternidhink18No ratings yet

- Onboard Routine Maintenance Check Sheet: February 2009Document34 pagesOnboard Routine Maintenance Check Sheet: February 2009Jhae Ang Ngub100% (3)

- Merchant ships and maritime terminologyDocument252 pagesMerchant ships and maritime terminologyfajee_faridNo ratings yet

- فهرست گواهینامه ها و مدارک مورد نیاز کشتیDocument10 pagesفهرست گواهینامه ها و مدارک مورد نیاز کشتیfajee_faridNo ratings yet

- طرح جامع انواع خدمات و سیستمها در کمک به دریانوردیDocument652 pagesطرح جامع انواع خدمات و سیستمها در کمک به دریانوردیfajee_faridNo ratings yet

- Engineering and Design of Military PortsDocument146 pagesEngineering and Design of Military Portsdyc123No ratings yet

- Ship Risk Review 2017 v4 2Document35 pagesShip Risk Review 2017 v4 2fajee_faridNo ratings yet

- Dynamic UKC BookletDocument19 pagesDynamic UKC BookletOllivier AmaruNo ratings yet

- 417 Grbic Culin BielicDocument9 pages417 Grbic Culin Bielicfajee_faridNo ratings yet

- MEPC.124 (53vvccf. Bvv6) PDFDocument10 pagesMEPC.124 (53vvccf. Bvv6) PDFbehzad parsiNo ratings yet

- Imo Guide For Cold Water Survival MSC 1 Circ 1185 Rev 1Document14 pagesImo Guide For Cold Water Survival MSC 1 Circ 1185 Rev 1fajee_faridNo ratings yet

- ETA Procedure & StrengthDocument23 pagesETA Procedure & StrengthPratap SahuNo ratings yet

- Sample Emergency ResponseDocument22 pagesSample Emergency Responsefajee_faridNo ratings yet

- Ocean Tow GuidelinesDocument18 pagesOcean Tow GuidelinesRoger AddyNo ratings yet

- GUIDELINES-No.37Guidelines For Towage at Sea, 2012 (Full Permission)Document45 pagesGUIDELINES-No.37Guidelines For Towage at Sea, 2012 (Full Permission)NMHaNo ratings yet

- Guidelines For The Development of Plans and Procedures For Recovery of Persons From The WaterDocument4 pagesGuidelines For The Development of Plans and Procedures For Recovery of Persons From The Watersailorgeorge1No ratings yet

- Ocean Tow GuidelinesDocument35 pagesOcean Tow Guidelinesfajee_faridNo ratings yet

- AR 1.28 Emergency Towing Procedures On ShipsDocument7 pagesAR 1.28 Emergency Towing Procedures On Shipsfajee_faridNo ratings yet

- RESOLUTION MEPC.220 (63) Guidelines For The Development of Garbage Management PlansDocument5 pagesRESOLUTION MEPC.220 (63) Guidelines For The Development of Garbage Management Plansfajee_faridNo ratings yet

- The ISM Code Implementation and Its Effects On Maritime Claims PDFDocument101 pagesThe ISM Code Implementation and Its Effects On Maritime Claims PDFfajee_faridNo ratings yet

- Checklist For Maintenance and Inspection of Safety EquipmentDocument4 pagesChecklist For Maintenance and Inspection of Safety Equipmentfajee_faridNo ratings yet

- Drills and Training On Board Ship in Maritime TransportDocument6 pagesDrills and Training On Board Ship in Maritime Transportfajee_faridNo ratings yet

- Checklist For Maintenance and Inspection of Safety Equipment PDFDocument12 pagesChecklist For Maintenance and Inspection of Safety Equipment PDFBobo Mason100% (5)

- 017.JSA - SHE.IV.2013 (Sack Out Water Accumulation of MW)Document3 pages017.JSA - SHE.IV.2013 (Sack Out Water Accumulation of MW)siswanto sugengNo ratings yet

- New Microsoft Word DocumentDocument5 pagesNew Microsoft Word DocumentniyasNo ratings yet

- Diesel Generator Operation JSADocument1 pageDiesel Generator Operation JSANoe Aranel100% (1)

- Job Safety Analysis: Shankar Raman Dhanushkodi Professor in Chemical EngineeringDocument15 pagesJob Safety Analysis: Shankar Raman Dhanushkodi Professor in Chemical EngineeringAMOL RASTOGI 19BCM0012No ratings yet

- JSA Scaffolding Erection and Dismentling New 2021Document5 pagesJSA Scaffolding Erection and Dismentling New 2021Captain ChickenNo ratings yet

- Fuel Transfer Safety AnalysisDocument2 pagesFuel Transfer Safety AnalysisIlya BordonosovNo ratings yet

- Electrical Safety ProcedureDocument33 pagesElectrical Safety ProcedurePraful E. Pawar100% (1)

- Jsa Grinding Welding Gas CuttingDocument3 pagesJsa Grinding Welding Gas CuttingRyanNo ratings yet

- Guidance Note For Drop Zone Management Within The VESI - February 2016Document7 pagesGuidance Note For Drop Zone Management Within The VESI - February 2016Tigor GurningNo ratings yet

- JOB SAFETY ANALYSIS FOR WORKOVER OPERATIONSDocument5 pagesJOB SAFETY ANALYSIS FOR WORKOVER OPERATIONSAshok SureshNo ratings yet

- Release Sheet: BGC Steel Site Safety ManualDocument94 pagesRelease Sheet: BGC Steel Site Safety Manualjacobpm2010No ratings yet

- Hand Out Maintenance Course For EngineersDocument109 pagesHand Out Maintenance Course For EngineersGauravNo ratings yet

- Petrofac: Job Safety Analysis / Risk AssessmentDocument7 pagesPetrofac: Job Safety Analysis / Risk AssessmentazerNo ratings yet

- Jsa Insulation WorkDocument19 pagesJsa Insulation WorkM M PRADHAN100% (2)

- She Strategy DocumentDocument30 pagesShe Strategy DocumentEarnest A. Bartlett100% (2)

- 01.work Instruction For Operation of Belt Conveyor-UpdatedDocument6 pages01.work Instruction For Operation of Belt Conveyor-UpdatedRahul VermaNo ratings yet

- Jsa-004 Pressure WasherDocument4 pagesJsa-004 Pressure WasherDamien MonizeNo ratings yet

- Gas Cutting JsaDocument4 pagesGas Cutting JsaMohammed Minhaj100% (1)

- Job Safety Analysis Sheet: Activity Potential Hazard Likely Causes Control MeasureDocument2 pagesJob Safety Analysis Sheet: Activity Potential Hazard Likely Causes Control MeasureM Waqas HabibNo ratings yet

- Roof Sheeting SafetyDocument6 pagesRoof Sheeting SafetyMomo XxxxNo ratings yet

- 4 2 Hirarc Compatibility ModeDocument56 pages4 2 Hirarc Compatibility ModeImzara AmeaNo ratings yet

- Hazard IdentificationDocument13 pagesHazard IdentificationmohammedNo ratings yet

- Job Safety Analysis Worksheet: JGC Penthouse Extension BLDGDocument2 pagesJob Safety Analysis Worksheet: JGC Penthouse Extension BLDGCherry BetonioNo ratings yet

- JSA GI Earthstrip at PTAO&M Building 05Document5 pagesJSA GI Earthstrip at PTAO&M Building 05Saiyad RiyazaliNo ratings yet