Professional Documents

Culture Documents

Build A Colonial-Style Storage Shed - Popular Mechanics

Uploaded by

rockhard4wd9696Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Build A Colonial-Style Storage Shed - Popular Mechanics

Uploaded by

rockhard4wd9696Copyright:

Available Formats

http://www.popularmechanics.

com/home/improvement/1276231

Build A Colonial-Style Storage Shed

A Colonial-style storage shed that anyone can build.

BY JOESPH TRUINI

Intro: Tools and Materials

Homeowners complain about having too

much storage space about as often as they

do about having an overabundance of cash.

It just doesn't happen.

Nearly every home, regardless of its size, has

a shortage of accessible storage space. Need

proof? Take a peek into the average garage

and you'll likely find it crammed full of

bicycles, lumber, garden tools, trash cans,

outdoor power equipment, sports gear and

car-care supplies.

An occasional spring-cleaning can help you

reorganize and reclaim some space, but it's

only a matter of time before the clutter

returns. What you really need is more space,

and one of the best ways to find it is to create

it by building a backyard storage shed.

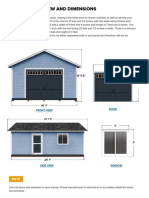

At 10 x 16 ft., this handsome garden shed is

large enough for most backyard needs. We've added an interior partition so it serves double duty

as a storage shed and an all-weather children's playroom. Double doors on the side and gable

end make it easy to access the space.

We built the Colonial-style garden shed shown here from a set of mail-order building plans. The 10

x 16-ft. outbuilding has easy-to-install plywood siding, three large windows and two pairs of doors.

The entire building could be used for storage, but we decided to divide the interior space into two

separate areas: a 4 x 10-ft. tool-storage area and a 10 x 12-ft. children's playroom.

It's hard to say exactly how much it will cost you to build this shed. Lumber prices fluctuate almost

daily and vary widely from one region of the country to another, but figure on spending between

$1600 and $2000. Before starting construction, take your plans to your local building department

and apply for a building permit.

Click on link for high-resolution version of the plans. (Illustration by Eugene Thompson)

Step 1: Starting At The Bottom

The shed we built rests on a foundation

made up of 12 solid-concrete blocks. The 4 x

8 x 16-in. blocks are arranged in three rows

spaced 59 in. apart. These blocks are

typically set directly on the ground, but we put

down a 4-in. bed of gravel first because our

site occasionally receives groundwater. The

gravel will keep the soil beneath the shed

from eroding or becoming soggy.

After laying out the 12 blocks, use a straight 2

x 4 and a 4-ft. level to ensure that all the

blocks are level. Shim up any low blocks with

strips of asphalt roofing, cedar shingles or 2-

in.-thick concrete patio block. Next, form each

front and rear band joist by nailing a 2 x 6 to

a 2 x 8 mudsill. Set the mudsills on top of the

blocks running across the front and rear of

the shed. Cut a third 2 x 8 mudsill to fit along

the tops of the center row of foundation

blocks.

Step 2: Starting At The Bottom

Cut all the 2 x 6 floor joists to length and set

them between the two band joists and on top

of the mudsills. These floor-frame parts are

cut from pressure-treated lumber.

Step 3: Starting At The Bottom

Space the joists 16 in. on center and secure

them with 16d galvanized nails. Before nailing

down the plywood floor, secure the floor

frame with four steel-cabled ground anchors,

which are code-required in some areas. Bolt

one anchor to each corner of the frame and

drive the holddown spikes deep into the

ground.

Step 4: Starting At The Bottom

For the shed floor, we used 3/4-in. tongue-

and-groove ACX plywood. Tongue-and-

groove joints create a rigid floor that doesn't

bounce or sag. Secure the plywood with 8d

galvanized nails.

Step 5: Framing The Roof Trusses

Each truss is made up of two 2 x 4 rafters

and one 2 x 4 ceiling joist. The three boards

are joined together with 1/2-in. plywood

gussets. To speed up the assembly process,

build all the trusses on the shed floor before

erecting the walls. Start by cutting all the

rafters to length with a 40° angle at one end

of each. Cut 2 x 4s to 10 ft. long for the

bottom chords of the trusses. Also, cut all of

the plywood gussets.

Make a template on the shed floor for

assembling the trusses. Begin by laying out

the parts for one truss. Align the bottom

chord with the edge of the plywood floor.

Then cut four 24-in.-long 2 x 4s. Lay two

alongside each rafter and screw them to the

plywood floor. Now use these short boards

as stopblocks for laying out and assembling

each truss. Fasten plywood gussets to each

side of every truss with carpenter's glue and

1-in. roofing nails and set the trusses aside.

Step 6: Building The Walls

Cut all the 2 x 4 parts for the end wall and lay

them out on the shed floor. Space the studs

24 in. on center and secure them with 16d

nails. Then cut the plywood siding to size and

nail it to the wall framing with 6d galvanized

nails.

Step 7: Building The Walls

Carefully raise the end wall into position.

Note how the plywood siding hangs down to

cover the floor framing.

Step 8: Building The Walls

With the wall in position, secure it by

screwing down through the bottom 2 x 4 plate

and into the floor framing. Frame and erect

the rear wall, followed by the front wall. Then,

install the interior partition. If you're including

a playroom, as we did, cover the partition

side that faces that room with plywood, and

screw it in place. Then install the final wall.

Step 9: Setting The Roof Trusses

Start the roof by installing the end trusses.

Note that the plywood siding is nailed on

before the truss is raised. Secure these with

3-in. deck screws driven into the top wall

plate. A central 2 x 4 chord stiffens the

sheathing.

Step 10: Setting The Roof Trusses

Then, install the remaining roof trusses. Set

one truss over every wall stud and fasten it

by driving 3-in. deck screws up through the

top wall plate.

Step 11: Setting The Roof Trusses

Cover the trusses with 1/2-in. CDX plywood,

then nail on the asphalt roof shingles.Eight

bundles are needed to complete this roof.

Step 12: Finishing Touches

Install perforated hardboard to the partition

wall in the tool-storage area. Fasten it with 1-

1/4-in. screws.

Step 13: Finishing Touches

Make the 5-ft.-long transom window from a

wooden frame and a single piece of glass.

Install it over the end doors.

Step 14: Finishing Touches

Next, build the doors from 1 x 6 tongue-and-

groove cedar boards and battens cut from 1x

stock. Attach the battens with 1-1/2-in.

screws, and hang the doors with heavy-duty

strap hinges.

Step 15: Finishing Touches

For the windows, we used wooden barn

sash, which tilt in for ventilation. The 2 x 3-ft.

windows are available at most lumberyards

for about $60 apiece. Install a barrel bolt at

the top of each sash so they can be locked

shut.

The textured plywood siding we installed

came with a factory-applied coat of primer.

We finished it with two coats of barn-red

acrylic latex paint. If you would prefer to stain

your shed, be sure to buy unprimed plywood

siding.

Step 16: Shed Plans By Mail

Want more information on building this

versatile storage shed? A set of detailed

building plans is available from Better Barns,

126 Main St. S., Bethlehem, CT 06751;

www.betterbarns.com.

The 2 x 3-ft. plans sheet (Plan No. 2009,

$29.95) is printed on both sides and includes

24 detailed illustrations and a materials list. In

addition, Better Barns can supply hardware,

such as the hinges and latch we used, and

other shed options.

http://www.popularmechanics.com/home/improvement/1276231

You might also like

- Free 12 X 8 Shed Plan: Click Here To Download 12,000 Shed PlansDocument24 pagesFree 12 X 8 Shed Plan: Click Here To Download 12,000 Shed PlansRamón Baró100% (1)

- Shed 10x16 PlansDocument8 pagesShed 10x16 PlansLory Dena Heath100% (1)

- Build a 12x12 Storage ShedDocument11 pagesBuild a 12x12 Storage ShedkenNo ratings yet

- 8x10 Lean To Shed 2022-09-04Document29 pages8x10 Lean To Shed 2022-09-04Steven 659No ratings yet

- A Complete Guide To Building Your Own Deck PDFDocument16 pagesA Complete Guide To Building Your Own Deck PDFremowood100% (1)

- A Complete Guide To Building Your Own Deck PDFDocument16 pagesA Complete Guide To Building Your Own Deck PDFr1greenNo ratings yet

- Diy - Woodwork - Plans - Shed Framing PDFDocument0 pagesDiy - Woodwork - Plans - Shed Framing PDFSignora LofaroNo ratings yet

- Installation Guide: 1) Foundation PreparationDocument7 pagesInstallation Guide: 1) Foundation PreparationdarkchechoNo ratings yet

- Gabions Install GuideDocument2 pagesGabions Install GuideTele2 Phone2100% (1)

- Roofing Application Standard No 111Document14 pagesRoofing Application Standard No 111nmblobNo ratings yet

- Gable Shed Building GuideDocument61 pagesGable Shed Building GuideBach Xuan NguyenNo ratings yet

- Ten Tips For Great StuccoDocument6 pagesTen Tips For Great StuccoAdityaNo ratings yet

- Sears Kit House ReportDocument108 pagesSears Kit House ReportDLM7No ratings yet

- MinimumStandards - (Ext Wall Framing)Document14 pagesMinimumStandards - (Ext Wall Framing)Samia H. BhuiyanNo ratings yet

- Historic American Timber Joinery: Roof Joinery Excluding TrussesDocument10 pagesHistoric American Timber Joinery: Roof Joinery Excluding TrussesCristian Morar-BolbaNo ratings yet

- Deck Design Guide for One and Two Family HomesDocument22 pagesDeck Design Guide for One and Two Family HomesChristopher Laliberte0% (1)

- Legacy Postand Beam Digital Catalog 2022Document39 pagesLegacy Postand Beam Digital Catalog 2022Jorge SouzaNo ratings yet

- David de Lossy/Photodisc/Getty ImagesDocument15 pagesDavid de Lossy/Photodisc/Getty ImagesasiasiNo ratings yet

- Boral Installation MasonryGuideDocument25 pagesBoral Installation MasonryGuidem0172No ratings yet

- Pole Building Construction PDFDocument78 pagesPole Building Construction PDFjoebaffaNo ratings yet

- Engineered Wood Construction Guide PDFDocument72 pagesEngineered Wood Construction Guide PDFneo_may_sing100% (1)

- Residential Inspection ChecklistDocument12 pagesResidential Inspection ChecklistthescubataterNo ratings yet

- Foldable Stool Reverse Engineering The Tallon StooDocument37 pagesFoldable Stool Reverse Engineering The Tallon StooEnrique CoronelNo ratings yet

- Master The Basics of Drywall: Cutting Drywall: The Family HandymanDocument11 pagesMaster The Basics of Drywall: Cutting Drywall: The Family Handymanbwatkins6No ratings yet

- Basic Overview and Dimensions: Front View DoorDocument6 pagesBasic Overview and Dimensions: Front View DooraditzuNo ratings yet

- Topic1 4 Structural Supporting 104Document31 pagesTopic1 4 Structural Supporting 104Baldaniya Bhakti100% (1)

- Wall and CeilingDocument16 pagesWall and CeilingAbhishek JaniNo ratings yet

- Framing WallsDocument6 pagesFraming WallsLen SNo ratings yet

- Specification & Construction of Custom Stile & Rail Doors: A Division of Amherst Woodworking & Supply, IncDocument31 pagesSpecification & Construction of Custom Stile & Rail Doors: A Division of Amherst Woodworking & Supply, Incrcmmaz100% (1)

- 71 - Cam-Lever Quick ReleaseDocument2 pages71 - Cam-Lever Quick ReleaseGsmHelpNo ratings yet

- How To Turn Your Shed Into A Workshop - A Free Guide From WaltonsDocument18 pagesHow To Turn Your Shed Into A Workshop - A Free Guide From WaltonsWaltons Garden Buildings100% (2)

- Roofing ShinglesDocument10 pagesRoofing Shinglescertainteed 98No ratings yet

- III. Sill Floor JointsDocument8 pagesIII. Sill Floor JointsCristian Morar-BolbaNo ratings yet

- How To Build A Shed With A Slanted Roof Step-by-Step GuideDocument39 pagesHow To Build A Shed With A Slanted Roof Step-by-Step GuideFederico BarberisNo ratings yet

- Lowes Deck Design ForDocument13 pagesLowes Deck Design ForCarmen C BejaranNo ratings yet

- WRCLA Installing SidingDocument16 pagesWRCLA Installing SidingITLHAPNNo ratings yet

- Canadian Wood Frame House Construction PDFDocument378 pagesCanadian Wood Frame House Construction PDFmsenerNo ratings yet

- Cord Wood MasonryDocument3 pagesCord Wood MasonryJason DiGiulioNo ratings yet

- RoofingCOP v3 2018-11-01Document472 pagesRoofingCOP v3 2018-11-01sattar12345No ratings yet

- Apa - A535Document24 pagesApa - A535Patrice AudetNo ratings yet

- Installing A Pre-Hung DoorDocument3 pagesInstalling A Pre-Hung DoorEng_20140% (1)

- Everything you need to know about skillion roofsDocument2 pagesEverything you need to know about skillion roofsTeodoro Miguel Carlos IsraelNo ratings yet

- 150 Cordwood CabinDocument4 pages150 Cordwood CabinEmmanuel BarbiniNo ratings yet

- Ten Rules For Finish CarpentryDocument12 pagesTen Rules For Finish Carpentryjosvelasco100% (1)

- Graphic Roof Framing Method Without TablesDocument7 pagesGraphic Roof Framing Method Without TablesMarius Camy PingaNo ratings yet

- Build a Backyard Treehouse with Zip Line, Trap Door and Sliding DoorDocument174 pagesBuild a Backyard Treehouse with Zip Line, Trap Door and Sliding DoorMoises Martins RochaNo ratings yet

- Residential Floor Framing System Product Technical ManualDocument32 pagesResidential Floor Framing System Product Technical Manualsamsurendran_mech4020100% (1)

- Wood Deck PlansDocument12 pagesWood Deck PlansLindsay Coleman100% (1)

- Brick Foundation & Brick Wall Defects & FailuresDocument9 pagesBrick Foundation & Brick Wall Defects & FailuresHHTNo ratings yet

- Patio Cover Structural Drawings: Sheet Number Sheet ContentsDocument10 pagesPatio Cover Structural Drawings: Sheet Number Sheet ContentsZaher ShuhaiberNo ratings yet

- Floor Truss GuideDocument4 pagesFloor Truss GuideSamia H. BhuiyanNo ratings yet

- Chainsaw Mill Build Use Tips N TricksDocument34 pagesChainsaw Mill Build Use Tips N TricksRosangela Rafaele Dos SantosNo ratings yet

- Foundation Repair Secrets: Learn How to Protect Yourself and Save ThousandsFrom EverandFoundation Repair Secrets: Learn How to Protect Yourself and Save ThousandsNo ratings yet

- Wood Shop A - Z: A collection of simple woodworking projects and craftsFrom EverandWood Shop A - Z: A collection of simple woodworking projects and craftsNo ratings yet

- Installing a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersFrom EverandInstalling a Garage Door and Opener- Special Bundle: Cake Decorating for BeginnersNo ratings yet

- Steel Square - Use Of The Scales, Roof Framing, Illustrative Problems And Other UsesFrom EverandSteel Square - Use Of The Scales, Roof Framing, Illustrative Problems And Other UsesNo ratings yet

- Woodwork Joints: How They Are Set Out, How Made and Where UsedFrom EverandWoodwork Joints: How They Are Set Out, How Made and Where UsedNo ratings yet

- Build Your Own Sheds & Outdoor Projects Manual, Fifth Edition: Over 200 Plans InsideFrom EverandBuild Your Own Sheds & Outdoor Projects Manual, Fifth Edition: Over 200 Plans InsideRating: 5 out of 5 stars5/5 (1)

- Interthane 990SG: Protective CoatingsDocument4 pagesInterthane 990SG: Protective CoatingsajuhaseenNo ratings yet

- Nanotechnology Applied To Chemical Soil Stabilization: Procedia EngineeringDocument8 pagesNanotechnology Applied To Chemical Soil Stabilization: Procedia EngineeringAravindNo ratings yet

- An Absorption Refrigeration System Used For Exploiting Mid-Low Temperature Geothermal ResourceDocument4 pagesAn Absorption Refrigeration System Used For Exploiting Mid-Low Temperature Geothermal ResourcehelderfsnNo ratings yet

- Wheel Centering Stand - For Home Use Stojalo Za Centriranje Koles, Za Domačo UporaboDocument5 pagesWheel Centering Stand - For Home Use Stojalo Za Centriranje Koles, Za Domačo UporaboDeta Alvian AnggonoNo ratings yet

- Evolution of Information Systems PDFDocument2 pagesEvolution of Information Systems PDFRobert50% (2)

- Small Scoop Spare PartsDocument10 pagesSmall Scoop Spare PartsMartinNo ratings yet

- Hospital Wastewater Treatment Plant ComponentsDocument2 pagesHospital Wastewater Treatment Plant ComponentsRina D RakhmaNo ratings yet

- Catalogue - New QPF PDFDocument32 pagesCatalogue - New QPF PDFShaiju EbrahimNo ratings yet

- Midea MSV1 07 09 12HRN1 CRN1Document37 pagesMidea MSV1 07 09 12HRN1 CRN1Giselma ZéoNo ratings yet

- Valvula Solenoide VMLDocument8 pagesValvula Solenoide VMLRené Rocha MolinaNo ratings yet

- Cylinder Head Valve & Cylinder Piston MotoDocument23 pagesCylinder Head Valve & Cylinder Piston MotoDeysi CardenasNo ratings yet

- SantoshDocument27 pagesSantoshVishwarajNo ratings yet

- Model Airplane News 1955-02Document61 pagesModel Airplane News 1955-02Thomas KirschNo ratings yet

- Concrete Technology Lecture Notes Cement Aggregates AdmixturesDocument5 pagesConcrete Technology Lecture Notes Cement Aggregates AdmixturesawasarevinayakNo ratings yet

- For Flash Flotation and Flash Roughing: SkimairDocument2 pagesFor Flash Flotation and Flash Roughing: SkimairQuicayCerroNo ratings yet

- Atlas CopcoDocument5 pagesAtlas Copcogiapy0000No ratings yet

- The Weight of Graeco Bactrian KalchusDocument4 pagesThe Weight of Graeco Bactrian KalchusSajad AmiriNo ratings yet

- TimetableDocument42 pagesTimetableTrevor T MuchabaiwaNo ratings yet

- Ficha Tecnica Luminaria Led Vt3 Vt2Document1 pageFicha Tecnica Luminaria Led Vt3 Vt2neymarronNo ratings yet

- 2012-2013 Fund - All EntryDocument96 pages2012-2013 Fund - All EntrypupbankuraNo ratings yet

- PT14 Engine Monitor 1Document2 pagesPT14 Engine Monitor 1BJ DixNo ratings yet

- Speed Limit Chapter 1Document21 pagesSpeed Limit Chapter 1kalu chimdiNo ratings yet

- Earthing TheoryDocument3 pagesEarthing TheoryM.Venkata RameshNo ratings yet

- Sony Klv-32v400a klv-32v400b Chassis Eg1l 987299403 Rev.3Document80 pagesSony Klv-32v400a klv-32v400b Chassis Eg1l 987299403 Rev.3بوند بوندNo ratings yet

- May 2011 IssueDocument102 pagesMay 2011 IssuePumper MagazineNo ratings yet

- Iso 8894-2Document15 pagesIso 8894-2LaudirNo ratings yet

- Leaf-Shaped Pavilion in ForestDocument3 pagesLeaf-Shaped Pavilion in ForesthopeNo ratings yet

- Factors Affecting Walkability in Intramuros SurveyDocument1 pageFactors Affecting Walkability in Intramuros SurveyacidusdragonNo ratings yet

- VSMC Compressor Unit Installation Operation Maintenance Manual 35391vc Rev 0 en Us 1580320 PDFDocument156 pagesVSMC Compressor Unit Installation Operation Maintenance Manual 35391vc Rev 0 en Us 1580320 PDFSEFRIGUA NH3No ratings yet

- Selected Topics in Embedded Systems: SeminarDocument13 pagesSelected Topics in Embedded Systems: Seminarstephen562001No ratings yet