Professional Documents

Culture Documents

Shamu 1 PDF

Uploaded by

Danial DarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shamu 1 PDF

Uploaded by

Danial DarCopyright:

Available Formats

Journal of Software Engineering and Applications, 2012, 5, 364-366

http://dx.doi.org/10.4236/jsea.2012.55042 Published Online May 2012 (http://www.SciRP.org/journal/jsea)

Flex Sensor Based Robotic Arm Controller Using Micro

Controller

Abidhusain Syed1, Zamrrud Taj H. Agasbal2, Thimmannagouday Melligeri 1, Bheemesh Gudur1

1

Department of Electronics and Communication, BLDEA College of Engg Bijapur-3, India; 2Department of Electronics and Com-

munication, KBN College of Engg Gulbarga-4, India.

Email: abidsyed4u@gmail.com

Received September 6th, 2011; revised March 10th, 2012; accepted April 3rd, 2012

ABSTRACT

Sensor plays an important role in robotics. Sensors are used to determine the current state of the system. Robotic appli-

cations demand sensors with high degrees of repeatability, precision, and reliability. Flex sensor is such a device, which

accomplish the above task with great degree of accuracy. The pick and place operation of the robotics arm can be effi-

ciently controlled using micro controller programming. This designed work is an educational based concept as robotic

control is an exciting and high challenge research work in recent year.

Keywords: Flexsensors; ADC; Data Glove (DG); Micro Contoller; Position Control; DOF (Degree of Freedom)

1. Introduction troller and micro controller used. Section 4 shows the flow

of action in the presented work. Section 5 discusses results.

The ever increasing population trend of the new millen-

Finally Section 6 discusses about conclusion and future

nium expects new technical innovation to meet the new work.

challenges being faced by human beings. The integration

of medical science and engineering has made the task 2. Related Work

like complicated surgery by robotic arm simpler. To

capture the motion of human limbs, sensors can be used. An interesting description of inertial sensors and some

Some companies have designed units, which can inte- innovative application of sensors have been discussed in

grate accelerometers, gyroscopes, magnetometers and [1]. [2] gives an examination of the impact of individual

can be attached to human limbs. These units can be worn sensor on the performance of a navigation system. [5]

for video game character modelling [1], virtual reality gives the design of a controller intended for teleoperation,

[2,3], activity recognition [4]. A sensor is a device that which is capable of controlling an anthropomorphic ro-

can measure some attribute of motion, being one of the botic arm through a LAN or via the Internet. [6] provides

three primitives of robotics (besides planning and con- a review of relevant mobile robot positioning technolo-

trol), sensing plays an important role in robotic para- gies like Odometry, Inertial Navigation, Magnetic Com-

digms. Robotic arm manipulators can have different con- passes, GPS Model Matching etc. Pick and place opera-

figurations and kinematic constraints. Few of these con- tion by controlling the speed and position using FPGA

straints can be effectively mapped from the human arm and sensor circuitry has been discussed in [7-8]. But the

important contribution of present work is that any human

domain to the robot’s restricted joint space. In this paper

arm moments can be mapped onto the robotic arm with

a general method of mapping human motions to the ro-

good precision. Further the flexibility of micro controller

botic arm domain has been demonstrated. The arm mo-

programming makes the task easier. Finally [9] discusses

ment is reciprocated almost exactly by the robotic arm.

the robotic arm function using MATLAB simulink.

Data capture is achieved with the special motion capture

sensor called “Shape Tape” that is worn by the human

3. Flex Sensor Based Robotic Arm Using

operator. Any human arm (or even leg, neck or spine)

Micro Controller

moment can be mapped on to any of the robotic arm ma-

nipulator. Below is the outline of this paper. The block diagram consist of three important parts:The

Section 2 describes related work, which gives a detail wearable data glove controller, Processing unit and the

discussion about the various works that are taking place servo controlled robotic arm as shown in Figure 1. The

in this field. Section 3 describes the data hand glove con- DG has been designed with two flex sensors, signal con-

Copyright © 2012 SciRes. JSEA

Flex Sensor Based Robotic Arm Controller Using Micro Controller 365

Servo Motor 1

(Gripper)

Flex Sensor 1

(Finger

movement) Servo Motor 2

Power

(Wrist)

Supply

Flex Sensor 2 Servo Motor 3 & 4

(Wrist (Elbow)

movement)

Analog to Digital

Microcontroller

Converter

(P89v51RD2)

(ADC0809)

Stepper Motor

(Base)

Accelerometer

(ADXL 335)

(Elbow Processing Stepper Motor Driver

movement) (ULN2803AG)

Gesture & Posture Robotic Arm

Figure 1. Flex sensor based robotic arm using micro controller.

ditioning circuit and 3-axis accelerometer. Processing

unit consists of micro controller (P89V51RD2), analog to

digital converter (ADC0809), stepper motor driver (ULN

2803AG). At other side a 3 degree of freedom robotic

arm is built using 4 servomotors and one stepper motor.

Experimental set-up is shown in Figure 2.

Flex Sensors

Flex sensors are analog resistors. These resistors work as

variable analog voltage divider. Inside the flex sensor are

carbon resistive elements with thin flexible substrate.

More carbon means less resistance. When the substrate is

bent the sensor produces resistance output relative to the

bend radius. The flex sensor achieves great form-factor

on a thin flexible substrate. When the substrate is bent,

the sensor produces a resistance output correlated to the

Figure 2. Experimental set-up.

bend radius as shown in Figure 3. Smaller the radius,

higher will be the resistance value [2].

The impedance buffer in the circuit is a single sided FLEX SENSOR OFFERS VARIABLE RESISTANCE READINGS

operational amplifier used with these sensors as shown in AT REST

NOMINAL

Figure 4. Since low bias current of the op amp reduces RESISTANCE

VALUE

error due to source impedance of the flex sensor as volt-

age divider. The variation in deflection or bending of flex

sensor results in variation of resistance itself. The signal 45° BEND

conditioning circuit is used to read these resistance INCRESED

RESISTANCE

changes and it is given to ADC. VALUE

90° BEND

ADC converts these values into equivalent digital values. RESISTANCE

VALUE

Micro controller: The micro controller is responsible FURTUER

for controlling the action of robotic arm. It receives input INCREASED

variation of flex sensor through ADC, which is given in

form of proportional current variation to motors attached

to robotic arm. The design engineer can choose to run the Figure 3. Flex sensor bend proportional to varying degree

application with the conventional 80C51 clock rate (12 of resistance.

Copyright © 2012 SciRes. JSEA

366 Flex Sensor Based Robotic Arm Controller Using Micro Controller

BASIC FLEX SENSOR CIRCUIT: 80

default value

Scale: Along x-aixs 1 cm = 15 degrees

VIN 70 Along y-aixs 1 cm = 10 volts

Flex sensor output in volts

60

50

R1 VOUT 40

R2 Flex sensor output

VOLTAGE 30

DIVIDER 20

IMPEDNCE R1

VOUT VIN

10

BUFFER R1 R 2 0

1 2 3 4 5 6 7 8 9 10 11 12 13

Figure 4. Flex sensor basic circuit. Deflection in the sensor(degress)

Figure 5. Deflection in the sensor V/S flex sensor output.

clocks per machine cycle) or select the X2 mode (six

clocks per machine cycle) to achieve twice the through-

put at the same clock frequency [8]. 120

Scale: Along x-aixs 1 cm = 10 degrees

Along y-aixs 1 cm = 20 volts

Accelerometer output in volts

100

4. Flow of Action for the Robotic Arm

80

Read values of the sensor; z-axis

60

Micro controller processes the sensor values; x-axis

Send values from microcontoller to servomotors; 40 y-axis

Pick up the objects; 20

Place at the required position; 0

Bring arm at original position. –60 –50 –40 –30 –20 –10 0 10 20 30 40 50 60

Deflection of accelerometer in 3-axis

5. Results and Discussion Figure 6. Deflection of accelerometer in 3 axis V/S acceler-

ometer output.

5.1. Flex Sensor Output Variation

Figure 5 shows the variation of volt with respect to The robotic arm can be fitted with wheel and more sen-

variation in deflection of flex sensor. Initially the flex sors to equip the device with more flexible movements of

sensor is at default position, a constant value of 73 de- the robotic arm.

gree. The value decreases as we start bending the flex

sensor. This particular change in flex sensor value is used

REFERENCES

to rotate servo motors.

[1] R. Slyper and J. Hodgins, “Action Capture with Accel-

5.2. Accelerometer Output Variation erometers,” Euro Graphics/A CMSIG GRAPHS Sympo-

sium on Computer Animation, 2008.

Figure 6 shows the changes due to tilt of accelerometer [2] E. Foxl and L. Naimark, “Vis-Tracker: A Wearable Vi-

in forward/backward(X axis), left/right (Y axis) and sion-Inertial Self-Tracker,” IEEE Virtual Reality Confer-

up/down (Z axis) direction. Accelerometer converts the ence, 22-26 March 2003, Los Angeles.

deflections into equivalent voltage variation. ADC con- [3] M. Gross and D. James, “Eurographics/ACM SIGGRAPH

verts these analog voltage values into equivalent digital Symposium on Computer Animation,” Smart Objects Con-

ference SOC ’03, Grenoble, 2003.

values. When there are positive deflections, motor rotates

in clockwise direction and in counter-clockwise direction [4] L. Bio and S. Intille, “Activity Recognition from User-An-

notated Acceleration Data,” Pervasive Computing, Vol. 3001,

for negative values. 2004, pp. 1-17. doi:10.1007/978-3-540-24646-6_1

[5] D. Fontaine, D. David and Y. Caritu, “Sourceless Human

6. Conclusion and Future Work Body Motion Capture,” Smart Objects Conference (SOC

2003), Grenoble, 2003.

The paper discussed a hardware and software co design

of robotic arm controller using four servomotors em- [6] J. Bernstein, H. R. Everett, L. Feng, and D. Wehe, “Mo-

bile Robot Positioning Sensors & Techniques,” Journal

ploying micro controller. Micro controller programming of Robotic Systems, Special Issue on Mobile Robots, Vol.

can be done with an ease to suit the requirements. Unlike 14, No. 4, pp. 231-249.

[7] which employ FPGA based control. Micro controller [7] U. D. Meshram and R. Harkare, “FPGA Based Five Axis

based programs can be flexibly modified to suit the nec- Robot Arm Controller,” International Journal of Electron-

essary drive control of the serve motor. ics Engineering, Vol. 2, No. 1, 2010, pp. 209-211.

Researcher can work for wireless control of the robotic [8] http://en.wikipedia.org/wiki/80c51

arm by employing some wireless application protocol. [9] C. Edwards and E. Smith, “Design of Simulink-Based 2-

Then the robotic arm can be more efficiently employed. DOF Robot Arm Control Workstation,” 31 October 2006.

Copyright © 2012 SciRes. JSEA

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- EC302Document27 pagesEC302api-3853441No ratings yet

- Electrical Work Safety GuidelineDocument13 pagesElectrical Work Safety GuidelineMogodan GabrielNo ratings yet

- Trinity Relay ModuleDocument2 pagesTrinity Relay ModuleSushil RajputNo ratings yet

- User Manual TV Power Demoboard TEA8818DB1440: TEA8818 + TEA1995 130W 13V and 90V Power SupplyDocument29 pagesUser Manual TV Power Demoboard TEA8818DB1440: TEA8818 + TEA1995 130W 13V and 90V Power SupplyCube7 Geronimo50% (2)

- ZMD400xT Technical DataDocument8 pagesZMD400xT Technical DataChu ToànNo ratings yet

- Panasonic TC 20kl03a 29kl03a mx5zbDocument48 pagesPanasonic TC 20kl03a 29kl03a mx5zbAriel SantosNo ratings yet

- Chapter OneDocument35 pagesChapter OneMamush MesheshaNo ratings yet

- A1512 Panasonic SemiconductorDocument2 pagesA1512 Panasonic SemiconductorbrneiNo ratings yet

- Understanding the Electromagnetic SpectrumDocument3 pagesUnderstanding the Electromagnetic SpectrumHelen Grace Llemos Cabalag100% (1)

- Manual Jem-10 PDFDocument126 pagesManual Jem-10 PDFcesNo ratings yet

- Meralco StandardsDocument28 pagesMeralco StandardsBenj Alvarez Capistrano100% (2)

- How To Use Quantum Numbers To Describe AnDocument11 pagesHow To Use Quantum Numbers To Describe AnAntonio Exal ColladoNo ratings yet

- Megger mft1741Document4 pagesMegger mft1741Clarear Soluções em EletricidadeNo ratings yet

- R100 R 2 eDocument82 pagesR100 R 2 edesc82No ratings yet

- Numerical Modeling of A UHF Rfid TagDocument5 pagesNumerical Modeling of A UHF Rfid TagRahim KarimNo ratings yet

- NTE7165 Integrated Circuit DMOS Audio Amplifier, 100W, For Self Powered LoudspeakersDocument3 pagesNTE7165 Integrated Circuit DMOS Audio Amplifier, 100W, For Self Powered LoudspeakersdaneloNo ratings yet

- Computer Power System AnalysisDocument155 pagesComputer Power System AnalysisSamir ElabasiryNo ratings yet

- CNCmakers-EP100 B QuickGuide-EN - EP100Document14 pagesCNCmakers-EP100 B QuickGuide-EN - EP100Angelica PeñarandaNo ratings yet

- S 7 MicrowaveDocument96 pagesS 7 MicrowaveViji VinodanNo ratings yet

- Aic23 DatasheetDocument44 pagesAic23 DatasheetBalacescu ClaudiuNo ratings yet

- Arc 151i A33 and Arc 201i A33 Spare Parts ListDocument8 pagesArc 151i A33 and Arc 201i A33 Spare Parts ListGurkan ÇetinkayaNo ratings yet

- D4 Endeavor (E)Document8 pagesD4 Endeavor (E)HJKB1975No ratings yet

- Modal Impact Hammers: IecexDocument4 pagesModal Impact Hammers: Iecexsathish K KumarNo ratings yet

- 500 Thiết bị điện Mi17Document92 pages500 Thiết bị điện Mi17Duy Khanh NguyễnNo ratings yet

- Practical Report TransformerDocument3 pagesPractical Report TransformerJesus MachaconNo ratings yet

- MAX500 Frequency Inverter Catalog V218Document8 pagesMAX500 Frequency Inverter Catalog V218luis castiblancoNo ratings yet

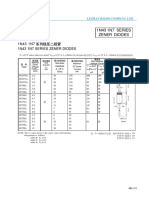

- 1N43 1N7 1N43 1N7 Series Zener DiodesDocument2 pages1N43 1N7 1N43 1N7 Series Zener DiodesAllan Souza SantanaNo ratings yet

- Telecommunications Engineering: Engineering Studies - HSC Course, Stage 6Document158 pagesTelecommunications Engineering: Engineering Studies - HSC Course, Stage 6Johnny MarshNo ratings yet

- KuMax HIGH EFFICIENCY POLY MODULE CS3U-375|380|385|390|395PDocument2 pagesKuMax HIGH EFFICIENCY POLY MODULE CS3U-375|380|385|390|395PAlak RenukuntlaNo ratings yet

- Harris Cathode-Follower (Source-Follower) OscillatorsDocument2 pagesHarris Cathode-Follower (Source-Follower) OscillatorsJhorman Y'susNo ratings yet