Professional Documents

Culture Documents

B201 98

Uploaded by

Ahmed HussienOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B201 98

Uploaded by

Ahmed HussienCopyright:

Available Formats

American Water Works Association

ANSI/AWWA B201-98

(Revision of ANSI/AWWA B201-92)

AWWA STANDARD

FOR

SODA ASH

Effective date: Aug. 1, 1998.

First edition approved by AWWA Board of Directors July 1, 1949.

This edition approved Jan. 25, 1998.

Approved by American National Standards Institute May 28, 1998.

AMERICAN WATER WORKS ASSOCIATION

6666 West Quincy Avenue, Denver, Colorado 80235

Copyright © 1998 American Water Works Association, All Rights Reserved.

AWWA Standard

This document is an American Water Works Association (AWWA) standard. It is not a specification.

AWWA standards describe minimum requirements and do not contain all of the engineering and

administrative information normally contained in specifications. The AWWA standards usually

contain options that must be evaluated by the user of the standard. Until each optional feature is

specified by the user, the product or service is not fully defined. AWWA publication of a standard

does not constitute endorsement of any product or product type, nor does AWWA test, certify, or

approve any product. The use of AWWA standards is entirely voluntary. AWWA standards are

intended to represent a consensus of the water supply industry that the product described will

provide satisfactory service. When AWWA revises or withdraws this standard, an official notice of

action will be placed on the first page of the classified advertising section of Journal AWWA. The

action becomes effective on the first day of the month following the month of Journal AWWA

publication of the official notice.

American National Standard

An American National Standard implies a consensus of those substantially concerned with its scope

and provisions. An American National Standard is intended as a guide to aid the manufacturer, the

consumer, and the general public. The existence of an American National Standard does not in any

respect preclude anyone, whether that person has approved the standard or not, from manufactur-

ing, marketing, purchasing, or using products, processes, or procedures not conforming to the

standard. American National Standards are subject to periodic review, and users are cautioned to

obtain the latest editions. Producers of goods made in conformity with an American National

Standard are encouraged to state on their own responsibility in advertising and promotional

materials or on tags or labels that the goods are produced in conformity with particular American

National Standards.

CAUTION NOTICE: The American National Standards Institute (ANSI) approval date on the front

cover of this standard indicates completion of the ANSI approval process. This American National

Standard may be revised or withdrawn at any time. ANSI procedures require that action be taken

to reaffirm, revise, or withdraw this standard no later than five years from the date of publication.

Purchasers of American National Standards may receive current information on all standards by

calling or writing the American National Standards Institute, 11 W. 42nd St., New York, NY 10036;

(212) 642-4900.

Copyright © 1998 by American Water Works Association

Printed in USA

ii

Copyright © 1998 American Water Works Association, All Rights Reserved.

Committee Personnel

The AWWA Standards Committee on Softening and Conditioning Chemicals,

which reviewed and approved this standard, had the following personnel at the time

of approval:

David A. Visintainer, Chair

Consumer Members

P.M. Callahan,* Council Liaison, Onondaga County Water Authority,

Syracuse, N.Y. (AWWA)

C.R. Dugan, Board of Water & Light, Lansing, Mich. (AWWA)

A.A. Khan, Pepsico, Arlington, Texas (AWWA)

G.C. Rosati, City of Mankato Public Utilities, Mankato, Minn. (AWWA)

A.T. Segars, Miami–Dade Water & Sewer Department, Hialeah, Fla. (AWWA)

J.C. Thurrott, City of Daytona Beach, Daytona Beach, Fla. (AWWA)

D.A. Visintainer, City of St. Louis Water Division, St. Louis, Mo. (AWWA)

General Interest Members

B.R. Elms,* Standards Engineer Liaison, AWWA, Denver, Colo. (AWWA)

A.R. Finney Jr., Clearwater, Fla. (AWWA)

H.E. Korab, Silver Spring, Md. (SSDT)

W.H. Plautz, Consoer Townsend Envirodyne Engineers Inc., Glenview, Ill. (AWWA)

M.T. Redman, National Soft Drink Association, Washington, D.C. (AWWA)

C.L. Truss Jr., Operator Training Committee of Ohio Inc., Springfield, Ohio (AWWA)

C.S. Wilder, Camp Dresser & McKee Inc., Atlanta, Ga. (AWWA)

Producer Members

H.L. Francis, National Lime Association, Arlington, Va. (NLA)

J.A. Gall, Dow Chemical USA, Midland, Mich. (AWWA)

W.B. Huebner, Wallace & Tiernan Inc., Belleville, N.J. (AWWA)

S.J. Schneider, Rhone-Poulenc Basic Chemical Company, Shelton, Conn. (AWWA)

J.M. Shepard, General Chemical Corporation, Claymont, Del. (AWWA)

* Liaison, nonvoting

iii

Copyright © 1998 American Water Works Association, All Rights Reserved.

This page intentionally blank.

Copyright © 1998 American Water Works Association, All Rights Reserved.

Contents

All AWWA standards follow the general format indicated subsequently. Some variations from this format may be

found in a particular standard.

SEC. PAGE SEC. PAGE

Foreword 2 References .......................................... 1

I Introduction........................................ vii 3 Definitions .......................................... 1

I.A Background......................................... vii

I.B History ................................................ vii 4 Requirements

I.C Acceptance .......................................... vii 4.1 Physical Requirements......................... 2

II Special Issues .................................... viii 4.2 Chemical Composition.......................... 2

III Use of This Standard........................... ix 4.3 Impurities.............................................. 2

III.A Purchaser Options and

5 Verification

Alternatives....................................... ix

5.1 Sampling ............................................... 2

III.B Modification to Standard..................... ix

5.2 Apparent Density ................................. 3

IV Major Revisions.................................... ix

5.3 Insoluble Matter ................................... 3

V Comments............................................. ix

5.4 Total Available Alkali .......................... 4

5.5 Rejection................................................ 4

Standard

1 General 6 Delivery

1.1 Scope ...................................................... 1 6.1 Marking................................................. 5

1.2 Purpose .................................................. 1 6.2 Packaging and Shipping ...................... 5

1.3 Application............................................. 1 6.3 Affidavit of Compliance........................ 5

Copyright © 1998 American Water Works Association, All Rights Reserved.

This page intentionally blank.

Copyright © 1998 American Water Works Association, All Rights Reserved.

Foreword

This foreword is for information only and is not a part of AWWA B201.

I. Introduction.

I.A. Background. Soda ash is the common name for the technical grades of

anhydrous sodium carbonate (Na 2CO3). Light and dense soda ash differ in physical

characteristics only, such as density (weight of unit volume), angle of repose, and size

and shape of particles. Light soda ash is a powder; dense soda ash is granular.

Soda ash is an anhydrous material having a sodium carbonate content of more

than 99 percent and a sodium oxide (Na2O) equivalent of more than 57.9 percent.

Sodium carbonate, although readily soluble in water, has the unusual characteristic

of attaining maximum solubility at 95.7°F (35.4°C). At this temperature, 100 parts of

water dissolve 49.7 parts of sodium carbonate. The solubility of sodium carbonate

decreases at temperatures above and below 95.7°F (35.4°C).

I.B. History. The first edition of this standard for soda ash was prepared

under the direction of the AWWA Water Purification Division. The standard was

approved by the Executive Committee of the Water Purification Division and by the

Water Works Practice Committee and received approval of the AWWA Board of

Directors on July 1, 1949. Additional reviews resulted in an edited copy that was

reaffirmed and approved as “Tentative” by the AWWA Board of Directors on Oct. 15,

1951. The initial document was made standard on May 15, 1953. This standard was

revised by the AWWA Standards Committee on Softening and Conditioning

Chemicals. Subsequent editions of AWWA B201 were approved on Jan. 26, 1959; Jan.

28, 1974; Jan. 28, 1980; June 14, 1987; and Jan. 26, 1992. This edition was approved

by the AWWA Board of Directors on Jan. 25, 1998.

I.C. Acceptance. In May 1985, the US Environmental Protection Agency

(USEPA) entered into a cooperative agreement with a consortium led by NSF

International (NSF) to develop voluntary third-party consensus standards and a

certification program for all direct and indirect drinking water additives. Other

members of the original consortium included the American Water Works Association

Research Foundation (AWWARF) and the Conference of State Health and Environ-

mental Managers (COSHEM). The American Water Works Association (AWWA) and

the Association of State Drinking Water Administrators (ASDWA) joined later.

In the United States, authority to regulate products for use in, or in contact

with, drinking water rests with individual states.* Local agencies may choose to

impose requirements more stringent than those required by the state. To evaluate

the health effects of products and drinking water additives from such products, state

and local agencies may use various references, including two standards developed

under the direction of NSF, ANSI†NSF‡ 60, Drinking Water Treatment Chemicals—

Health Effects, and ANSI/NSF 61, Drinking Water System Components—Health

Effects.

*Persons in Canada, Mexico, and non-North American countries should contact the

appropriate authority having jurisdiction.

†American National Standards Institute, 11 W. 42nd St., New York, NY 10036.

‡NSF International, 3475 Plymouth Rd., Ann Arbor, MI 48106.

vii

Copyright © 1998 American Water Works Association, All Rights Reserved.

Various certification organizations may be involved in certifying products in

accordance with ANSI/NSF 60 (61). Individual states or local agencies have authority

to accept or accredit certification organizations within their jurisdiction. Accredita-

tion of certification organizations may vary from jurisdiction to jurisdiction.

Appendix A, “Toxicology Review and Evaluation Procedures,” to ANSI/NSF 60

(61) does not stipulate a maximum allowable level (MAL) of a contaminant for

substances not regulated by a USEPA final maximum contaminant level (MCL). The

MALs of an unspecified list of “unregulated contaminants” are based on toxicity

testing guidelines (noncarcinogens) and risk characterization methodology (carcino-

gens). Use of Appendix A procedures may not always be identical, depending on the

certifier.

AWWA B201-98 addresses additives requirements in Sec. 4.3 of the standard.

The transfer of contaminants from chemicals to processed water or the residual solids

is becoming a problem of greater concern. The language in Sec. 4.3.2 is a

recommendation only for direct additives used in the treatment of potable water to be

certified by an accredited certification organization in accordance with ANSI/NSF

Standard 60, Drinking Water Treatment Chemicals—Health Effects. However, users

of the standard may opt to make this certification a requirement for the product.

Users of this standard should also consult the appropriate state or local agency

having jurisdiction in order to

1. Determine additives requirements, including applicable standards.

2. Determine the status of certifications by all parties offering to certify

products for contact with, or treatment of, drinking water.

3. Determine current information on product certification.

II. Special Issues. Soda ash is usually shipped in bulk or in 100-lb (45-kg)

multiwall paper bags, although it is also available in drums and barrels. The

material can be readily handled mechanically by screw or belt conveyors, bucket

elevators, or pneumatic systems. Soda ash should be stored in a dry, cool place with

minimal exposure to moisture and air. With prolonged storage, soda ash has a

tendency to lump and becomes difficult to handle and dissolve.

Soda ash is normally fed into water being treated by means of volumetric or

gravimetric mechanical feeders equipped with dissolving chambers. Less frequently,

solution feeding is used. The solution is prepared in tanks and fed by metering

pumps.

Soda ash can also be stored in a tank as a slurry with a concentrated 30-percent

solution being withdrawn from the upper portion of the tank for application to the

treatment process. This method requires much less storage space, because the dry

soda ash has a bulk density of 35 lb/ft3 (560 kg/m3). Monohydrate slurries have bulk

densities ranging from 83 lb/ft3 to 117 lb/ft3 (1,328 kg/m3 to 1,872 kg/m3). Dry soda

ash bulk densities range from 33 lb/ft3 to 68 lb/ft3 (560 kg/m3 to 1,088 kg/m3).

Soda ash is a relatively harmless chemical and, under normal conditions, has no

marked effects on skin, the respiratory system, or clothing. It is neither explosive nor

inflammable, and it is not classified as a dangerous substance.

Soda ash may produce a temporary irritation of the respiratory system, but the

symptoms will disappear once contact with soda ash is discontinued. Persons

handling soda ash should be equipped with goggles and dust respirators when

dustiness is prevalent. Eye irritation should be treated by flushing the affected eye

with tap water for 15 min or longer. Any condition of prolonged irritation should be

referred to a physician for treatment.

viii

Copyright © 1998 American Water Works Association, All Rights Reserved.

Individuals who are particularly sensitive to alkaline materials or who have a

preexisting skin disease may develop dermatitis when working with soda ash. It is

advisable to use a protective agent, such as an ointment or cream, to prevent this

condition. Normal skin irritations can be relieved by bathing the affected parts in a

5-percent boric acid solution.

Every effort should be made to avoid the simultaneous presence of soda ash and

lime dust. The combination of these chemicals in the presence of moisture or

perspiration will cause the formation of irritating caustic soda. Where both soda ash

and lime are used, workers exposed to one chemical should carefully wash it away

and remove its dust from clothing before working in the presence of the other

chemical.

Workers entering storage bins or silos containing soda ash should always wear

approved safety belts and connecting ropes to facilitate rescue in the event the soda

ash shifts or slides. In addition, workers should be in constant communication with

someone stationed outside the storage facility.

III. Use of This Standard. AWWA has no responsibility for the suitability

and compatibility of the provisions of this standard to any intended application by

any user. Accordingly, each user of this standard is responsible for determining that

the standard’s provisions are suitable for and compatible with that user’s intended

application.

III.A. Purchaser Options and Alternatives. The following items should be

covered in the purchaser’s specifications:

1. Standard used—that is, ANSI/AWWA B201, Standard for Soda Ash, of

latest revision.

2. Density required (Sec. 4.1.1).

3. Quantity required.

4. Form of shipment—bulk or package, type, and size (Sec. 6.2.1).

5. Basis of payment for cost of referee analysis (Sec. 5.5.1). NOTE: Previous

editions of this standard provided that this cost should be borne by the supplier if the

material is found not to meet the requirements of this standard and by the purchaser

if the material is found to comply with the standard’s requirements.

6. Affidavit of compliance, if required (Sec. 6.3).

III.B. Modification to Standard. Any modification to the provisions, defini-

tions, or terminology in this standard must be provided in the purchaser’s

specifications.

IV. Major Revisions. Major changes made to the standard in this revision

include the following:

1. The format has been changed to AWWA standard style.

2. The acceptance statement (Sec. I.C) has been revised to approved wording.

Section III.A, Purchaser’s Options and Alternatives, and Sec. 5.5.1 have been

revised to require the purchaser to specify the basis of payment for the referee

analysis if one is required.

V. Comments. If you have any comments or questions about this standard,

please call the AWWA Standards and Materials Development Department,

(303) 794-7711 ext. 6283, FAX (303) 795-1440, or write to the department at 6666 W.

Quincy Ave., Denver, CO 80235.

ix

Copyright © 1998 American Water Works Association, All Rights Reserved.

This page intentionally blank.

Copyright © 1998 American Water Works Association, All Rights Reserved.

American Water Works Association

ANSI/AWWA B201-98

(Revision of ANSI/AWWA B201-92)

AWWA STANDARD FOR

SODA ASH

SECTION 1: GENERAL

Sec. 1.1 Scope

This standard covers soda ash for use in the treatment of municipal and

industrial water supplies.

Sec. 1.2 Purpose

The purpose of this standard is to provide purchasers, manufacturers, and

suppliers with the minimum requirements for soda ash, including physical, chemical,

packaging, shipping, and testing requirements.

Sec. 1.3 Application

This standard can be referenced in specifications for purchasing and receiving

soda ash and can be used as a guide for testing the physical and chemical properties

of soda ash samples. The stipulations of this standard apply when this document has

been referenced and then only to soda ash used in water supply service.

SECTION 2: REFERENCES

This standard has no applicable information for this section.

SECTION 3: DEFINITIONS

The following definitions shall apply in this standard:

1. Manufacturer: The party that manufactures, fabricates, or produces

materials or products.

2. Purchaser: The person, company, or organization that purchases any

materials or work to be performed.

Copyright © 1998 American Water Works Association, All Rights Reserved.

2 AWWA B201-98

3. Soda ash: Soda ash is a commercial designation of anhydrous normal

sodium carbonate.

4. Supplier: The party that supplies material or services. A supplier may or

may not be the manufacturer.

SECTION 4: REQUIREMENTS

Sec. 4.1 Physical Requirements

The soda ash furnished shall be a dry, white powder containing no large lumps

or crystals. It shall be free-flowing and suitable for storage in closed, hoppered bins

and for feeding with a standard dry feeder.

4.1.1 Density. The apparent density of light soda ash shall range from 0.5 g/mL

to 0.9 g/mL or from 31.2 lb/ft3 to 56.2 lb/ft3 (500 kg/m 3 to 900 kg/m 3). The apparent

density of dense soda ash shall range from 0.9 g/mL to 1.1 g/mL or from 56.2 lb/ft 3 to

68.7 lb/ft3 (900 kg/m3 to 1,100 kg/m3).

Sec. 4.2 Chemical Composition

4.2.1 Quantity of sodium carbonate. The material, as delivered, shall contain

not less than 99 percent, by weight, of sodium carbonate (Na 2CO3), or a sodium oxide

(Na2O) equivalent of not less than 57.9 percent.

4.2.2 Insoluble matter. The insoluble matter shall not exceed 0.05 percent.

Sec. 4.3 Impurities

4.3.1 General. Soda ash supplied in accordance with this standard shall

contain no soluble material or organic substances in quantities capable of producing

deleterious or injurious effects on the health of those consuming a water that has

been treated properly with the soda ash.

4.3.2 Product certifications. Soda ash is a direct additive used in the treatment

of potable water. This material should be certified as suitable for contact with or

treatment of drinking water by an accredited certification organization in accordance

with ANSI*/NSF† Standard 60, Drinking Water Treatment Chemicals—Health

Effects. Evaluation shall be accomplished in accordance with requirements that are

no less restrictive than those listed in ANSI/NSF Standard 60. Certification shall be

accomplished by a certification organization accredited by the American National

Standards Institute.

SECTION 5: VERIFICATION

Sec. 5.1 Sampling

5.1.1 Sampling point. Samples shall be taken at the point of destination.

*American National Standards Institute, 11 W. 42nd St., New York, NY 10036.

†NSF International, 3475 Plymouth Rd., Ann Arbor, MI 48106.

Copyright © 1998 American Water Works Association, All Rights Reserved.

SODA ASH 3

5.1.2 Sampling precaution. To avoid exposed surface areas that might have

absorbed moisture and carbon dioxide, samples shall be taken from at least 12 in.

(300 mm) below the surface in bulk shipments and from the center portion of bagged

materials.

5.1.3 Sampling procedures.

5.1.3.1 If the soda ash is handled by conveyor or elevator, a mechanical

sampling arrangement may be used.

5.1.3.2 Soda ash may be sampled from carload shipments in bulk or from

packages by the use of a sampling tube at least 3⁄4 in. (20 mm) in diameter.

5.1.3.3 With packaged material, 5 percent of the packages shall be sampled.

No sample shall be taken from a broken package.

5.1.3.4 The gross sample, weighing at least 10 lb (5 kg), shall be mixed thoroughly

and divided to provide three 1-lb (0.5-kg) samples. Each sample shall be sealed in an

airtight, moisture-proof glass container labeled for identification with the label dated

and signed by the sampler.

5.1.3.5 Two samples shall be retained by the purchaser for not less than 30

days after the date of receipt of the shipment, for use by the supplier and the referee

laboratory if needed.

5.1.4 Preparation of sample. The sample shall be collected in accordance with

Sec. 5.1. The sample shall be quartered to approximately 100 g. After thorough

mixing, the sample shall be stored in an airtight container. Weighing of any portion

of the sample shall be done as rapidly as possible to avoid changes in moisture

content.

Sec. 5.2 Apparent Density

5.2.1 Procedure.

5.2.1.1 Pour, without packing, 30 g of the sample into a 100-mL graduated

cylinder and read the volume of the sample.

5.2.1.2 Calculation:

30 - = apparent density, grams per millilitre

------------------------------------ (Eq 1)

mL of sample

NOTE: Apparent density can also be determined by carefully filling (without

packing) and weighing a box or measure with a volume of exactly 1 ft3. The weight of

the filled measure, in pounds, minus the weight of the measure equals the apparent

density of the material, in pounds per cubic foot.

Sec. 5.3 Insoluble Matter

5.3.1 Procedure.

5.3.1.1 Add 10 g of the sample to approximately 200 mL of deionized distilled

water in a 400-mL beaker; bring to a boil and continue boiling for 10 min.

5.3.1.2 Filter through a weighed Gooch crucible, fitted with either a glass-wool

or glass-fiber filter medium; wash thoroughly; and dry at 100°C to 10°C. Cool, desiccate

to a constant weight, and weigh.

5.3.1.3 Calculation:

weight of insoluble residue

-------------------------------------------------------------------------- × 100 = percentage of insoluble matter (Eq 2)

weight of sample

Copyright © 1998 American Water Works Association, All Rights Reserved.

4 AWWA B201-98

Sec. 5.4 Total Available Alkali

5.4.1 Reagents.

a. 0.100N hydrochloric acid.

b. Methyl orange indicator.

c. Phenolphthalein indicator.

d. Silver nitrate indicator.

5.4.2 Procedure.

5.4.2.1 Weigh 1.325 g of the sample and transfer to a 500-mL glass-stoppered

volumetric flask partly filled with deionized distilled water. After the solution is

complete, add distilled water to make the total volume 500 mL and mix thoroughly.

5.4.2.2 Titrate 50 mL of the solution (Sec. 5.4.2.1) with 0.1N hydrochloric acid,

using phenolphthalein and methyl orange indicators. First, add the phenolphthalein

indicator and titrate until the pink color disappears. This will give the approximate

halfway point. Then, add the methyl orange indicator and continue the titration.

When most of the hydrochloric acid has been added, boil 2 min; cool thoroughly;

and complete the titration to the methyl orange end point. (This procedure will

remove most of the carbon dioxide and give a sharper end point.) As an alternative to

the phenolphthalein and methyl orange indicators, a pH meter may be used with the

titration end point at a pH of 4.4.

5.4.3 Calculation.

mL hydrochloric acid used × 4 = percent Na 2 CO 3 (Eq 3)

Multiply the percent Na2CO3 by 0.5849 to obtain the percent Na2O.

5.4.4 Correction. If an examination of the sample indicates less than 99 percent

sodium carbonate, the bicarbonate test may be applied according to Sec. 5.4.5 and the

sodium carbonate content of the material corrected as the results indicate.

5.4.5 Bicarbonate correction. Dissolve 8.4 g of the sample in 50 mL of carbon

dioxide-free distilled water and titrate with 1.0N sodium hydroxide until a drop of

the solution added to a drop of freshly prepared silver nitrate indicator on a spot

plate produces a dark color instantly.

5.4.6 Calculation.

mL 1.0N NaOH × 8.4

---------------------------------------------------------- = percentage NaHCO 3 (Eq 4)

weight of sample

Bicarbonate as percentage Na 2CO3 = percentage NaHCO3 × 0.6309

5.4.7 Total alkali. Total alkali as percentage Na2CO3 = percentage Na2CO3

(from Sec. 5.4.3) plus percentage NaHCO 3 expressed as Na2CO3 (from Sec. 5.4.6).

Sec. 5.5 Rejection

5.5.1 Notice of nonconformance. If the soda ash delivered does not meet the

requirements of this standard, a notice of nonconformance shall be provided by the

purchaser to the supplier within 10 working days after receipt of the shipment at the

point of destination. The results of the purchaser’s tests shall prevail unless the

supplier notifies the purchaser within five working days after receipt of the notice of

complaint that a retest is desired. On receipt of the request for a retest, the

purchaser shall forward to the supplier one of the sealed samples taken in accordance

with Sec. 5.1. In the event that the results obtained by the supplier on retesting do

not agree with the test results obtained by the purchaser, the other sealed sample

Copyright © 1998 American Water Works Association, All Rights Reserved.

SODA ASH 5

shall be forwarded, unopened, to a referee laboratory agreed on by both parties. The

results of the referee analysis shall be accepted as final. The cost of the referee

analysis shall be paid for as specified by the purchaser.

5.5.2 Removal of material. If the material does not meet the requirements of

this standard, the supplier shall remove the material from the purchaser’s premises

or adjust the price as agreed on by the supplier and purchaser.

SECTION 6: DELIVERY

Sec. 6.1 Marking*†

6.1.1 Required. Each shipment of material shall carry with it some means of

identification. Each unit package shall be legibly identified as light or dense soda

ash. Each unit package shall be marked with the net weight of the contents, the

name of the manufacturer, the brand name, if any, and other markings as required

by applicable laws and regulations. When shipped in bulk, this marking information

shall be provided according to applicable regulations.

6.1.2 Optional. At the option of the manufacturer, packages may also bear

the statement, “This material meets the requirements of AWWA B201, Standard for

Soda Ash,” provided that the requirements of this standard are met and the material

is not of different quality in separate agreement between the supplier and purchaser.

Sec. 6.2 Packaging and Shipping

Packaging and shipping of soda ash shall conform to all current local, state, and

federal regulations.†

6.2.1 Bulk containers. Soda ash shall be shipped properly in clean bulk contain-

ers; or in 100-, 150-, 200-, or 300-lb (45-, 68-, 91-, or 136-kg) bags; or in barrels of 275- or

300-lb (125- or 136-kg) net weight as required by the purchaser’s specifications.

6.2.2 Kraft bags. If bagged, soda ash shall be contained in multiwall kraft

bags, preferably constructed with a polyethylene moisture barrier to better protect

soda ash during storage.

6.2.3 Packaged weight. The net weight of packages shall not deviate from the

recorded weight by more than ±2.5 percent. If exception is taken to the weight of the

material received, acceptance or rejection shall be based on the weight of not less

than 10 percent of the packages received, selected at random from the shipment.

Sec. 6.3 Affidavit of Compliance

The purchaser may require an affidavit from the manufacturer or supplier

stating that the soda ash furnished according to the purchaser’s order complies with

all applicable requirements of this standard.

*Governmental packaging and marking references reflect US requirements. Users of ANSI/

AWWA B201 in Canada, Mexico, and non-North American countries should verify applicable

local and national regulatory requirements.

†Because of frequent changes in these regulations, all parties should remain informed of

possible revisions. Provisions of the purchaser’s specifications should not preclude compliance.

Copyright © 1998 American Water Works Association, All Rights Reserved.

1P-7.5M-42201-7/98-MG Printed on recycled paper.

Copyright © 1998 American Water Works Association, All Rights Reserved.

You might also like

- Awwa C110 PDFDocument64 pagesAwwa C110 PDFmerinofalNo ratings yet

- Installation, Testing, and Maintenance of Fire Hydrants: FieldDocument85 pagesInstallation, Testing, and Maintenance of Fire Hydrants: FieldCristiam MondragónNo ratings yet

- Ansi Awwa C520-2014 PDFDocument36 pagesAnsi Awwa C520-2014 PDFEslam Elsayed100% (1)

- AWWA Manuals of Water Supply Practices Library SetDocument23 pagesAWWA Manuals of Water Supply Practices Library Setalexmuchmure2158100% (1)

- Awwa C907-91-Word.Document24 pagesAwwa C907-91-Word.Jhon Gomez CastellanosNo ratings yet

- Ansi Awwa C517-16 PDFDocument36 pagesAnsi Awwa C517-16 PDFEslam ElsayedNo ratings yet

- AWWA C504 Butterfly ValvesDocument8 pagesAWWA C504 Butterfly ValvesAnderson SiqueiraNo ratings yet

- M03 PDFDocument166 pagesM03 PDFSubrata DebnathNo ratings yet

- Direct-Reading, Remoteaegistrkiion Meters: SystemsDocument16 pagesDirect-Reading, Remoteaegistrkiion Meters: SystemsJacques BlueqNo ratings yet

- BS en 00727-1995 (1999)Document12 pagesBS en 00727-1995 (1999)Institute of Marketing & Training ALGERIANo ratings yet

- 2020 Water Wastewater Standards ManualDocument739 pages2020 Water Wastewater Standards Manualbartsi1No ratings yet

- Pilot-Operated Control Valves: AWWA StandardDocument32 pagesPilot-Operated Control Valves: AWWA StandardAnnie De WildeNo ratings yet

- 7.4 PurchasingDocument3 pages7.4 PurchasingAhmed HussienNo ratings yet

- Awwa C219 BSTCDocument32 pagesAwwa C219 BSTCBoz Van DuynNo ratings yet

- C219-23 LookInsideDocument13 pagesC219-23 LookInsidemrdino2012No ratings yet

- Systematic Methods of Water Quality Parameters Analysis: Analytical MethodsFrom EverandSystematic Methods of Water Quality Parameters Analysis: Analytical MethodsNo ratings yet

- Awwa C600-99Document36 pagesAwwa C600-99Erdi Erdogan100% (1)

- AWWA Standards Presentation BrandedDocument22 pagesAWWA Standards Presentation BrandedHassan SleemNo ratings yet

- Flexible-Membrane-Lining and Floating-Cover Materials For Potable Water StorageDocument16 pagesFlexible-Membrane-Lining and Floating-Cover Materials For Potable Water StorageNanangNo ratings yet

- Tablet Disintegration Test and Basket Rack AssemblyDocument2 pagesTablet Disintegration Test and Basket Rack AssemblyPhoenix100% (1)

- Awwa C206-11 PDFDocument28 pagesAwwa C206-11 PDFRicardo B. GallegoNo ratings yet

- C105 99Document28 pagesC105 99Rached Ben AyedNo ratings yet

- F101 96Document24 pagesF101 96naser712No ratings yet

- New Appendix 1 Non Revenue Water and Large Water Meter Calibration. Johnson E 6 May 2016Document11 pagesNew Appendix 1 Non Revenue Water and Large Water Meter Calibration. Johnson E 6 May 2016engkj100% (1)

- Awwa C653-20-20210225141109Document20 pagesAwwa C653-20-20210225141109Jazent Anthony RamosNo ratings yet

- C151 - A21.51-17 - Ductile-Iron Pipe, Centrifugally CastDocument60 pagesC151 - A21.51-17 - Ductile-Iron Pipe, Centrifugally CastNelson MejiaNo ratings yet

- Awwa, M42-Re-TocDocument11 pagesAwwa, M42-Re-TocCristian Cornejo Catalán0% (1)

- Agru Catalogue PDFDocument505 pagesAgru Catalogue PDFAhmed HussienNo ratings yet

- Awwa C304 07 PDFDocument144 pagesAwwa C304 07 PDFDefi Nurul HidayahNo ratings yet

- Awwa C511Document20 pagesAwwa C511Jacques Blueq100% (1)

- Precoat Filter Media: Awwa StandardDocument20 pagesPrecoat Filter Media: Awwa StandardErdi ErdoganNo ratings yet

- Underground Service Line Valves and Fittings: Awwa StandardDocument28 pagesUnderground Service Line Valves and Fittings: Awwa StandardyvundeNo ratings yet

- C703-96 (Cold Water Meters - Fire Service Type)Document28 pagesC703-96 (Cold Water Meters - Fire Service Type)Seven CupsNo ratings yet

- C153 - A21.53 - Nov2019 - Ductile-Iron Compact FittingsDocument56 pagesC153 - A21.53 - Nov2019 - Ductile-Iron Compact FittingsNelson MejiaNo ratings yet

- Spring Steel 1Document17 pagesSpring Steel 1Manicharan100% (1)

- Awwa C213-15Document32 pagesAwwa C213-15Moito Carvalho100% (2)

- Awwa C502Document40 pagesAwwa C502Ðave MejiaNo ratings yet

- 4.2.3-4 Document and Record ControlDocument5 pages4.2.3-4 Document and Record ControlAhmed HussienNo ratings yet

- M58-2E - Internal Corrosion ControlDocument223 pagesM58-2E - Internal Corrosion ControlNelson MejiaNo ratings yet

- Astm C1103 3Document2 pagesAstm C1103 3Boz Van DuynNo ratings yet

- AWWA M11ed4Document16 pagesAWWA M11ed4авдей александр33% (3)

- Astm C25Document24 pagesAstm C25cynthia lecca rodriguezNo ratings yet

- AWWA ManualsDocument23 pagesAWWA Manualsopetaky86% (7)

- F102 96Document20 pagesF102 96chavico113No ratings yet

- Modelamiento AlcantarilladoDocument640 pagesModelamiento AlcantarilladoTyler HendersonNo ratings yet

- Norma Awwa C507-99 PDFDocument24 pagesNorma Awwa C507-99 PDFAnderson SiqueiraNo ratings yet

- Ansi Awwa c225-07Document28 pagesAnsi Awwa c225-07Harli M. HavilNo ratings yet

- Awwa C304-99Document120 pagesAwwa C304-99josegnunezNo ratings yet

- Awwa C509-23Document52 pagesAwwa C509-23Vijay KumarNo ratings yet

- (AWWA Standard F110-12) AWWA-Ultraviolet Disinfection Systems For Drinking Water - Effective Date, Aug. 1, 2012-American Water Works Association (2012)Document30 pages(AWWA Standard F110-12) AWWA-Ultraviolet Disinfection Systems For Drinking Water - Effective Date, Aug. 1, 2012-American Water Works Association (2012)Ujak KimiaNo ratings yet

- D104-17 - Automatically Controlled, Impressed-Current Cathodic Protection For The Interior of Steel Water StorageDocument36 pagesD104-17 - Automatically Controlled, Impressed-Current Cathodic Protection For The Interior of Steel Water StorageNelson MejiaNo ratings yet

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionFrom EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNo ratings yet

- CM TB Solutions C01Document3 pagesCM TB Solutions C01MahamIsmail86% (7)

- Ruchi Soya Project ReportDocument45 pagesRuchi Soya Project ReportAnkita Toshniwal75% (4)

- Self-Tapping Saddle Tees Foruse: PVC PipeDocument22 pagesSelf-Tapping Saddle Tees Foruse: PVC PipeJacques BlueqNo ratings yet

- Awwa b403-98Document24 pagesAwwa b403-98Armando PerezNo ratings yet

- Astm E119 PDFDocument24 pagesAstm E119 PDFRoly David Rodriguez Castro100% (3)

- QE341 Operations Manual 01 07 15 English PDFDocument226 pagesQE341 Operations Manual 01 07 15 English PDFghita60% (5)

- AWWA G200-15 - Distribution Systems Operation and ManagementDocument32 pagesAWWA G200-15 - Distribution Systems Operation and ManagementHồ Trung ThôngNo ratings yet

- WRF Meter Accuracy 2011Document344 pagesWRF Meter Accuracy 2011Jayakrishnan JkNo ratings yet

- Awwa C205 PDFDocument28 pagesAwwa C205 PDFPaolita Auza Balderrama100% (1)

- B301 99Document20 pagesB301 99Sanel Tucakovic100% (1)

- Polysulfone Design Guide PDFDocument80 pagesPolysulfone Design Guide PDFbilalaimsNo ratings yet

- Softwood and Hardwood in Dissolving PulpDocument126 pagesSoftwood and Hardwood in Dissolving PulpAlan KurniawanNo ratings yet

- ANSI - AWWA B304-13 - Liquid Oxygen For Ozone Generation For Water, Wastewater, and Reclaimed Water Sy (Z-Lib - Io) (1) 1Document28 pagesANSI - AWWA B304-13 - Liquid Oxygen For Ozone Generation For Water, Wastewater, and Reclaimed Water Sy (Z-Lib - Io) (1) 1Feyza KaragözNo ratings yet

- Recommended Standards Water 5Document159 pagesRecommended Standards Water 5nmulyonoNo ratings yet

- Water Supply Law Lao 2009Document25 pagesWater Supply Law Lao 2009Siharath PhoummixayNo ratings yet

- AWWA Manuals-ListDocument4 pagesAWWA Manuals-ListponjoveNo ratings yet

- Semester 1, 2019 Examination: School of Engineering & Applied TechnologyDocument8 pagesSemester 1, 2019 Examination: School of Engineering & Applied Technologyრაქსშ საჰაNo ratings yet

- Awwa C206Document74 pagesAwwa C206Jorge Navas VargasNo ratings yet

- As 3778.4.1-1991 Measurement of Water Flow in Open Channels Measurement Using Flow Gauging Structures - ThinDocument7 pagesAs 3778.4.1-1991 Measurement of Water Flow in Open Channels Measurement Using Flow Gauging Structures - ThinSAI Global - APACNo ratings yet

- GL XX Mobil DTE 20 SeriesDocument3 pagesGL XX Mobil DTE 20 SeriesdpomahNo ratings yet

- Burllus Dredger PicsDocument3 pagesBurllus Dredger PicsAhmed HussienNo ratings yet

- En 10204Document6 pagesEn 10204Ahmed HussienNo ratings yet

- Pressure Equipment - : Part 4: Establishment of Technical Delivery Conditions For Metallic MaterialsDocument48 pagesPressure Equipment - : Part 4: Establishment of Technical Delivery Conditions For Metallic MaterialsAhmed Hussien50% (2)

- 7.5.1C Control of Production & Service Provision (Fabrication)Document3 pages7.5.1C Control of Production & Service Provision (Fabrication)Ahmed HussienNo ratings yet

- Technical Offer: OrascomDocument28 pagesTechnical Offer: OrascomAhmed HussienNo ratings yet

- V2i3 Ijertv2is3311 PDFDocument8 pagesV2i3 Ijertv2is3311 PDFkinjalpatel12345No ratings yet

- 8.4 Data AnalysisDocument2 pages8.4 Data AnalysisAhmed HussienNo ratings yet

- 6.3 Maintenance PSC-WI-6.3Document2 pages6.3 Maintenance PSC-WI-6.3Ahmed HussienNo ratings yet

- Weld Neck Flange DN 800 Type 11 - en 1092-1 PN 6-RFDocument1 pageWeld Neck Flange DN 800 Type 11 - en 1092-1 PN 6-RFAhmed HussienNo ratings yet

- 6.2.2 Human ResourcesDocument3 pages6.2.2 Human ResourcesAhmed HussienNo ratings yet

- 8.5.2-3 Corrective and Preventive ActionDocument4 pages8.5.2-3 Corrective and Preventive ActionAhmed HussienNo ratings yet

- ST ST Pipe ALLOWABLE WORKING PRESSURE AT TEMPERATUREDocument1 pageST ST Pipe ALLOWABLE WORKING PRESSURE AT TEMPERATUREAhmed HussienNo ratings yet

- Orq SP 104 00 6001Document3 pagesOrq SP 104 00 6001Ahmed HussienNo ratings yet

- Pipe Stress Analysis Nozzel CommentDocument1 pagePipe Stress Analysis Nozzel CommentAhmed HussienNo ratings yet

- O R Q S P 1 0 4 0 0 6 0 0 0 0: Upgrade and Raising Capacity of Abu Rawash Wastewater Treatment Plant ProjectDocument3 pagesO R Q S P 1 0 4 0 0 6 0 0 0 0: Upgrade and Raising Capacity of Abu Rawash Wastewater Treatment Plant ProjectAhmed HussienNo ratings yet

- Orq SP 104 00 6003Document3 pagesOrq SP 104 00 6003Ahmed HussienNo ratings yet

- 435-Hdg-Flanges-02 Rev0Document1 page435-Hdg-Flanges-02 Rev0Ahmed HussienNo ratings yet

- Rainfall IntensityDocument1 pageRainfall IntensityAhmed HussienNo ratings yet

- DN1400 FlangeDocument1 pageDN1400 FlangeAhmed HussienNo ratings yet

- Road 7 Part 2-Road 7Document1 pageRoad 7 Part 2-Road 7Ahmed HussienNo ratings yet

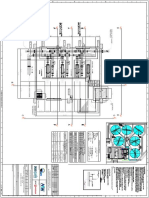

- DWG-04.11-ME-041 Pri - Sludge - Pump - Station 4 - 6 (r.6) PDFDocument5 pagesDWG-04.11-ME-041 Pri - Sludge - Pump - Station 4 - 6 (r.6) PDFAhmed HussienNo ratings yet

- DWG-04.11-ME-031 Pri - Sludge - Pump - Station2 (r.6) PDFDocument5 pagesDWG-04.11-ME-031 Pri - Sludge - Pump - Station2 (r.6) PDFAhmed HussienNo ratings yet

- DWG-04.11-ME-021 Pri - Sludge - Pump - Station1 (r.6) PDFDocument5 pagesDWG-04.11-ME-021 Pri - Sludge - Pump - Station1 (r.6) PDFAhmed HussienNo ratings yet

- DWG-04.11-ME-011 Pri - Sludge - Pump - Station 3 - 5 (r.6) PDFDocument5 pagesDWG-04.11-ME-011 Pri - Sludge - Pump - Station 3 - 5 (r.6) PDFAhmed HussienNo ratings yet

- B405 00Document25 pagesB405 00Ahmed HussienNo ratings yet

- Characterization and Reuse of Kiln Rollers Waste in The Manufacture of Ceramic Floor TilesDocument7 pagesCharacterization and Reuse of Kiln Rollers Waste in The Manufacture of Ceramic Floor Tilesmap vitcoNo ratings yet

- 2018-Areca Cathecu-Anopheles VagusDocument8 pages2018-Areca Cathecu-Anopheles VagusDwiNo ratings yet

- Determination of Tissue Equivalent Materials of A Physical 8-Year-Old Phantom For Use in Computed TomographyDocument8 pagesDetermination of Tissue Equivalent Materials of A Physical 8-Year-Old Phantom For Use in Computed TomographyInas Fathinah SaepudinNo ratings yet

- Manual Revised Spices Herbs 22 06 2021Document111 pagesManual Revised Spices Herbs 22 06 2021SUMAN KUMAR GHOSHNo ratings yet

- ABB CorrosionDocument8 pagesABB CorrosionForexFFNo ratings yet

- Disinfect water with UV lightDocument16 pagesDisinfect water with UV lightsleonNo ratings yet

- Total Solutions For Electrocatalysis Research: Discover The ECAT-packagesDocument2 pagesTotal Solutions For Electrocatalysis Research: Discover The ECAT-packagescipta irawanNo ratings yet

- Solar System GK Notes in PDFDocument7 pagesSolar System GK Notes in PDFPintu KumarNo ratings yet

- SCBA protects users from gases and vaporsDocument1 pageSCBA protects users from gases and vaporsdulichsinhthaiNo ratings yet

- Criteria air pollutants: Sources, health effects and control of particulate matterDocument8 pagesCriteria air pollutants: Sources, health effects and control of particulate matterSumaiya ImamNo ratings yet

- IADC/SPE 100824 Swell Packers: Enabling Openhole Intelligent and Multilateral Well Completions For Enhanced Oil RecoveryDocument8 pagesIADC/SPE 100824 Swell Packers: Enabling Openhole Intelligent and Multilateral Well Completions For Enhanced Oil RecoveryHadi KoraniNo ratings yet

- Fosroc Structuro W435: Constructive SolutionsDocument2 pagesFosroc Structuro W435: Constructive SolutionsVincent JavateNo ratings yet

- Cursor Tier 3 Series I PDFDocument216 pagesCursor Tier 3 Series I PDFDenis Hernandez100% (1)

- Lab 3 HysysDocument8 pagesLab 3 HysysZulhafizi Kamaruddin100% (2)

- NJ DEP Guidance on Process Hazard Analysis and Risk AssessmentDocument17 pagesNJ DEP Guidance on Process Hazard Analysis and Risk AssessmentaakashtrivediNo ratings yet

- Chemical Resistance Chart For AcrylicDocument2 pagesChemical Resistance Chart For AcrylicNasim KhanNo ratings yet

- ChemistryDocument188 pagesChemistrySamveg ClassesNo ratings yet

- Crack Control for Concrete Masonry VeneersDocument10 pagesCrack Control for Concrete Masonry VeneersAdam JonesNo ratings yet

- All Name Reactions of Chemistry Class 12th Cbse & IscDocument11 pagesAll Name Reactions of Chemistry Class 12th Cbse & IscAjit100% (1)

- Science: Revision Guide by MalaikaDocument7 pagesScience: Revision Guide by MalaikamalaikaNo ratings yet

- Effect of Herbal Tablet Prepared From Moringa Oleifera Leaves ExtractDocument7 pagesEffect of Herbal Tablet Prepared From Moringa Oleifera Leaves Extractsmail bendrissouNo ratings yet

- Solid Rivet - MS20470Document2 pagesSolid Rivet - MS20470Manoj ManoharanNo ratings yet

- Brochure Nuwind General Purpose CentrifugesDocument28 pagesBrochure Nuwind General Purpose CentrifugesMarco Antonio Lopez BalderasNo ratings yet