Professional Documents

Culture Documents

Applying Harmonic Filters Effectively

Uploaded by

Mostafa ElSayedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Applying Harmonic Filters Effectively

Uploaded by

Mostafa ElSayedCopyright:

Available Formats

Applying Low Voltage Harmonic Filters, Revisited

By: Brian Prokuda, P.E.

Keweenaw Power Systems, Howell, MI

Introduction frequencies (stages) to meet the project goals. If the

Many industrial facilities, big and small, are applying system is weak (a large impedance) than a less

harmonic filters due to problems occurring within their aggressive, single stage filter may be used. Information

facility or because the utility is requiring them to prevent required to determine the system impedance are the three

other customer problems. Harmonic filters are not a phase fault MVA of the utility distribution connection

piece of equipment that may be purchased “Off the and the kVA and percent impedance of the step down

Shelf”, and the customer can become discouraged as transformers. A one-line diagram or sketch of the power

conflicting recommendations are presented during the system helps when multiple transformers are involved,

quotation process. When the decision to purchase and see Figure 1.

install filters has been made, the information presented

here will help the manufacturer and the customer enjoy a

pleasant relationship. It is critical to understand what 4160 V 480 V

30 MVA

you are purchasing and why one unit may be so much X/R=12.0

1000 kVA

5.5%Imp. 1000 HP

less expensive than another. There are several types of Plant Load

DC Drive

filters available for various goals, but the most common 200 kVA

0.85 dPF

Step 1 Step 2 Step 14

is the shunt connected series notch filter. This is the

50 kVAr 50 kVAr 50 kVAr

harmonic filter discussed in this paper.

What Information Needs to be Provided? Figure 1 - One-Line Diagram

There is nothing mystical about harmonic filters. The

concept is to create a lower impedance path, as compared The utilization voltage is necessary to size the capacitors.

to that of the source, for currents at frequencies other Low voltage capacitors are commonly available in the

than 60 Hz. As a minimum, the filter manufacture U.S. with 240V, 480V, 600V, and 1000V ratings, off

requires the source impedance, utilization voltage, load shore capacitors may be found at other ratings. Series

power information, and harmonic summaries at each load notch harmonic filters consist of a reactor in series with a

condition. capacitor. The series reactor will create a slightly higher

voltage on the capacitor than that of the line. If the

Before we discuss each of these independently, the goals harmonic current that the filter needs to absorb is large,

of the installation must be determined. These will this voltage could become excessive and require the use

typically fall into one or more of the following: 1) of a higher voltage capacitor.

Power Factor Correction to avoid utility demand charges,

2) Release of Capacity to unload system transformers Harmonic data is the most critical information to be

and cables, 3) IEEE-519 Compliance , 4) A Plant provided. So much so that manufacturers may choose to

Operation Problem . Number four is included because visit the facility to take their own measurements once the

quite often a plant manager will have a POP and order a project has been awarded. As a minimum, it is important

harmonic filter to meet the 519 limits. After the filter is to take snap-shots of the harmonic spectra in all of the

installed, the limits may be met, but the POP has not plant operation configurations. Ideally, the harmonic

been resolved because it is caused by some other power spectra will be trended over several plant cycles (day,

quality problem such as neutral to ground voltages, week, month, etc.) To assure that the largest load has

transients, or notching. Knowing what the project goals been measured and to help with reactive power

are up front will help get the most cost effective and requirements, it is a good idea to include the past 12

appropriate solution installed initially. months of utility bills. If possible, a snap-shot

measurement with minimal plant load will help

System impedance is important because it will determine determine the amount of utility distortion that the filter

how big, how many stages, and how aggressive the filter may need to absorb.

or filters must be tuned. If the source is stiff (a small

impedance) than the filters need to be more aggressively

tuned and may require to be tuned at multiple

At some point, it must be decided who will be collecting a good place to start in the search for such a person.

the information. If the facility only has one or two Keep in mind that some manufacturers will provide this

transformers and a few variable speed drives, plant service for a fee that all or part of may be applied to the

personnel should be able to provide sufficient purchase of their equipment. Often times this will lead to

information. If the facility is more sophisticated than the smoothest solutions. Figure 2 offers one format for

this, it is wise to work with someone who is the data collection process.

knowledgeable in power quality. The utility company is

Filter Application Guideline Sheet

Goal of Harmonic Filter Application: (Choose All That Apply)

Power Factor Correction

Release of Capacity

IEEE-519 Compliance

Plant Operation Problem (Explain)

Other (Explain)

System Information:

Fault MVA at the Primary of the Transformer

Transformer kVA

Transformer % Impedance

Transformer Primary & Secondary Voltages

Transformer Connection (Include Grounding)

How Many Transformers Feed Plant Loads

Are the Transformers Connected to Plant or Utility Distribution

Are their Capacitors on the Line or Load Side of the Transformer

Load Information:

Horse Power or kVA of Harmonic Loads

Horse Power of Motor Loads

kVA of all Other Loads

Peak Load kVA and dPF

Average Load kVA and dPF

Minimum Load kVA and dPF

Harmonic Summary:

Voltage (Volts or %Fund.) Current (Amperes)

Harmonic Peak Average Minimum Peak Average Minimum Harmonic

1 1

2 2

3 3

4 4

5 5

7 7

9 9

11 11

13 13

17 17

19 19

%THD %THD

Application Information:

Indoor / Outdoor Application

Enviromental and Electrical Classification Considerations

Circuit Length from Filter to System Connection

Dimensional Restrictions

Maximum / Minimum Ambient Temperatures

Required System Protection

Customer Information:

Company Name Phone

Contact Person Fax

Date Initiated Date Required

Form Created 4/95

Figure 2 - Filter Application Guideline Sheet

Where should the Filters be Located?

There are three choices when deciding where to apply Application of harmonic filters near the load side of the

harmonic filters: At the Load, At the transformer, or on transformer, refer to Figure 1, will typically prove to

the Primary Distribution. From application to provide the best performance to cost ratio. The largest

application the correct choice will differ. Below the impedance in the circuit is the transformer, so losses

pros and cons of each are discussed. and system capacity are improved the greatest by

shunting current away from it. This approach also rides

Lets start with the later. At first glance the distribution the middle of the road for reliability and maintenance.

connection is an attractive location for filters. The filter There is a unit for each transformer so that the facility is

cost per kVAr will be less, the voltage is higher so the not relying on one or two filters as with medium voltage

currents will be smaller, and there may be multiple applications. On the other hand, there are a reasonable

transformers feeding the facility that can be corrected number of systems to maintain unlike the many units

from one location. The down side is that protective with motor switched applications. The primary

devices will be more expensive, the cost of automatic advantage of this is that automatic switched systems are

switching is very expensive, and if the distribution is economically feasible to maintain unity power factor at

owned and operated by the utility there is little control each transformer. This of course minimizes the kVA

over neighbors harmonics overloading your filter. For that the transformer must supply to the load.

facilities with relatively constant load and that maintain

their own distribution, this may be a cost effective Should they be Fixed or Automatic?

solution. Like deciding where the filters should be located,

whether or not they should be fixed or switched

Motor switched capacitors are still quite common, a depends on the application. If an automatic switched

specific piece of equipment can run at unity system is going to be used, it most likely will be applied

displacement power factor and reduce feeder size and at the load side of the distribution transformer. The

voltage drop concerns. Many people have shied away primary reasons to use an automatic system is to release

from this practice because it can be a maintenance the maximum capacity from the supply system and to

nightmare and can set up multiple parallel resonance’s avoid excessive capacitance on the line during lightly

throughout a facility amplifying harmonics. If these loaded conditions. The two main drawbacks are: if the

motor switched capacitors are configured as harmonic installation and protection cost are not incorporated as

filters, an additional concern arises, OVERLOAD. Just part of other types of installations, then the per kVAr

like the distribution filter being applied to a utility cost of a low voltage automatic system will be larger

feeder, the filter may be undersized to handle harmonic than any other installation and second there is a concern

currents absorbed by neighboring loads. In this case a about over loading the filter system under lightly loaded

filter installed and sized for a specific harmonic load conditions. The later will be discussed further in the

may need to absorb harmonics from other nonlinear component section, but can often be overcome by

loads that do not have filters on the same motor control incorporating a fixed bank filter in conjunction with the

center. This practice is highly discouraged for loads automatic filter.

less than 100 kVA to keep the filter from becoming too

low of an impedance and should only be installed with a How Big do they need to be?

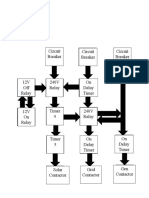

line reactor (choke) as shown in Figure 3. Sizing of harmonic filters can be accomplished by

various methods: rules of thumb, hand calculations,

computer simulations, etc. The bottom line is that one

4160 V 480 V must determine how much harmonic current each filter

30 MVA

X/R=12.0

1000 kVA Line Reactor to

section will absorb. Once this is done, harmonic filter

Block Outside

5.5%Imp. 500 HP

DC Drive

Harmonics components may be designed with appropriate margins

Plant Load

200 kVA

0.85 dPF

for overload. As a rule of thumb, a 480V 100kVAr

filter tuned to the 4.7th harmonic should be applied for

50 kVAr

Harmonic 100 HP

Filter DC Drive

every 80Arms of 5th harmonic produced by the load.

For instance, if the load of a facility produced 400Arms

of 5th harmonic current it should be expected that a

500kVAr filter would be required. This should be used

Figure 3 - Application of Filters at Individual Loads only as a starting point and it may be possible to design

a smaller filter to handle the same current. This rule of

thumb is only provided so that a conservative estimate

can be made. It is recommended that a more

comprehensive analysis be done for all applications.

For a one or two transformer facility, hand calculations

or a simple spreadsheet analysis should suffice. For a

larger facility with multiple transformers, a program

such as the Electrotek Concepts SuperHarmtm harmonic

analysis software should be used.

Filter System and Component Selection

Capacitors

The capacitors should comply with the requirements of

IEEE Std 18-1992 for allowable overload limits:

110% of rated rms voltage

120% of rated peak voltage

180% of rated rms current

135% of rated reactive power

Request from the filter manufacturer what the expected

values for each of the criteria are for capacitors in your

filter system. This information will be used later as a

base for the verification process. Figure 4 - Filter with Multiple Capacitors per Step

A controversial topic is whether to use dry or oil filled When large fixed banks are constructed it is necessary

capacitors. For harmonic applications, specify oil to gang capacitors together with a single reactor, see

filled. This is becoming difficult as more and more Figure 4. This practice should be avoided unless

capacitors from Europe are being used in the United necessary. For low voltage systems, capacitor cells are

States and these are primarily of dry construction. available up to 200 kVAr, so only fixed filters larger

Capacitors are constructed of a foil conductor laminated than this would require multiple cells. Below this size

to either a polymer dielectric or kraft paper with a should utilize one cell with one reactor. This way if a

polymer dielectric between layers. These layers are problem occurs with a cell (bad connection, failure,

then rolled to form a cylinder. Several of these clearing of protective device, etc.) the filter will be out

cylinders are connected in parallel for each phase and of service instead of detuning. The danger in detuning

then a three-phase configuration before being placed in is that the filter tuning frequency will increase and go

a metal or polymer case. The polymer dielectric traps above the nominal frequency. As this occurs, the filters

heat between the layers. With the increased losses corresponding parallel resonance approaches the

induced by large harmonic currents, an effective means nominal tuning point, amplifying current at that

to release heat from inner layers must be used. In what frequency instead of absorbing it, see Figure 5.

is known as a soggy film (kraft paper) capacitor, the

kraft paper will wick oil between layers helping to Often times capacitors with a larger rms voltage rating

conduct heat from within the capacitor. This is not than the line voltage are used. This is because a slight

possible with a Metalized Polypropylene constructed voltage rise occurs across the filter reactor creating a

capacitor because no material that will wick oil exists. higher voltage at the capacitor than that of the power

In addition to this, the ends are often covered with system. The price of doing this is that the available

metalized “End Spray” which creates a barrier between reactive power per cell is reduced by the square of the

the ends of each layer prohibiting oil from passing. voltages. For instance, 600V capacitors applied to a

Even though oil can’t get between the layers, it is felt 480V system will only yield 64% of the nameplate

that it is still beneficial to have oil which surrounds each reactive power (kVAr). Typically if capacitors meeting

roll and is able to get heat to a preferably metal shell, or the IEEE Std 18 are used, than 480V capacitors may be

one that can conduct the heat to the ambient air. No applied to a 480V system with moderate harmonic duty.

official comparison test have been published, but It is important that the filter manufacturer knows what

several filter systems with degraded dry capacitors have the peak system rms voltage recorded for the facility

been witnessed and no oil filled capacitors in was and that they calculate the voltage rise of the

comparable or worse harmonic applications have been system with capacitors on-line to assure that derated

found. capacitors will not be required. As the tuned frequency

once the epoxy is applied and baked the only way to

adjust inductance is to replace the reactor. To assure

Current Seen by Transformer

proper tuning, the manufacturer should do an

900

800

inductance measurement at rated current near the tuned

700 frequency for each phase of each reactor.

600

500

400 Switching Devices

300 When applying automatic systems below 1000V, it is

200

100

typical that a mechanical switching device (contactor)

0 will be used. These need to be rated for capacitor

4

5

switching and have a voltage rating in excess of the line

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

5.1

5.2

5.3

5.4

Filter Tuning

voltage. Figure 6 shows the voltage across the contacts

of a contactor as it opens. The line reactor dampens the

Figure 5 - Transformer Current vs. Filter Tuning transient as it propagates to the power system, but the

switching device contacts will see a substantial voltage.

of a filter is decreased, voltage rise will increase at the In theory, this voltage can approach two times the

fundamental frequency. So the voltage at a capacitor in system peak voltage. Internal discharge resistors of low

a filter tuned to the 4.2nd harmonic will be higher than voltage capacitors along with proper switching delays,

that of a filter tuned to the 4.7th harmonic. Therefore at least one minute, minimize the closing transient

this is of greater concern with lower order filters. which in theory could approach three times peak. If

switching transients are of great concern, than costly

Reactors solid state switching devices with zero crossing

Up to 5kV applications, reactors typically are iron core detectors may be justified.

dry type. This is due to control of the magnetic field

and compactness as compared to an air core reactor.

There is no standard that exist to address harmonic

reactors, but most manufacturers use ANSI/IEEE

C57.12.01 (General Requirements for Dry-type

Distribution and Power Transformers) as a guideline.

For low voltage applications, reactors typically are not

given a BIL test. The insulation should have as a

minimum a low frequency voltage test, (Hi-Pot) on each

phase to ground. This test is typically on the order of

10 times the rms voltage rating. ANSI/IEEE C57.12.01

suggest 4kV on 480V systems. If a similar field test is

to be performed, consult with the filter manufacturer on

the values to expect and the procedure to be used. Figure 6 - Voltage Across Filter Switching Device

Single phase vs. three phase reactors is a decision not to Protection

be taken lightly. Fine-tuning of a harmonic reactor is Capacitors that have a UL rating will have internal

done by adjusting the air gap. With a three-phase expansion links to avoid case rupture. As an additional

reactor the fringing characteristics are different for the precaution it is recommended that all three phases of

center leg than they are for the outer legs, which will capacitor cells be fused. Ideally, these fuses will be

affect the flux density and inductance of that phase. located in front of the switching device, reactors as well

This is a tough physical characteristic to overcome, as the capacitor to provide short circuit protection of the

being all three gaps are usually the same for a three- entire filter section without effecting adjacent sections.

phase core. There are techniques that allow three-phase The National Electric Code requires 135% over-current

reactors to be tuned reasonably balanced, but it takes protection for capacitors, but this value will approach

additional care to do and there are manufacturers that 180% for filters.

do not realize this. By using a distributed gap, instead

of a single gap as with an E-I lamination, this effect can The primary cause of reactor failure is the over heating

be minimized. On the other hand, with single-phase of the insulation system. Reactors of this type typically

reactors each phase may be individually tuned and have a 200oC insulation system, although it is possible

adjusted. Understand that with low voltage reactors, that they have a 150, 185, 200 or 220oC rating. If the

hot spot of the winding is operated near these ratings, not enough turns on the reactor to allow the use of

UL reports the life expectancy to be at 20,000 hours multiple taps and while a manufacture can hold

(2.3 years). Thermal aging data shows that for every tolerances within a 5% span most will not guarantee

10oC below the maximum rating that an insulating shorter than 10%. This means that a tolerance needs to

system is operated, the life expectancy doubles. For be selected that is going to optimize the tuning

example, if a 200oC insulation system is used in a frequency and that there is little hope for field

harmonic reactor designed for 115oC average adjustment. Based on the capacitor tolerances, it is

temperature rise in a 40oC ambient the life expectancy clear that reactor tolerances should be +0% to -10%

would be 160,000 hours, or just over 18 years. The hot realizing that the manufacture will target -5%.

spot will be approximately 15oC higher than the average

temperature. [200oC – (40oC + 115oC + 15oC) = 30oC, The effect of tolerances will now be demonstrated:

30oC/10oC=3 so the life expectancy doubles three times. 1

At least one phase of a filter cell should have f tuned = f nominal •

temperature cutout protection imbedded near the hot (1 + t r )(1 + t c )

spot that will take that section off line when the hot spot f tuned Actual Tuned Frequency

temperature approaches 1800C. Recognize that the hot

spot temperature will be significantly higher than any f nominal Specified Tuned Frequency

spot on the surface of the reactor. When applying filters tr Reactor Tolerance (pu)

at voltages above 1000V, embedded temperature

cutouts may not be possible due to the degradation of tc Capacitor Tolerance (pu)

BIL rating. Lets say that a filter is specified to be tuned to the 4.7th

harmonic. Using the above equation tuning point

Filter detuning protection is a great feature that is not ranges have been calculated. In both cases the capacitor

very common due to the competitiveness of the filter tolerance are -0 / +15 with expected to be +8%. First

business. As the end user of a harmonic filter, it is we will look at the range with a + / - 2.5% tolerance

money well invested to specify detuning protection. If with expected to be 0%. This results in a range from

multiple capacitors are grouped with a single reactor, as the 4.33rd to the 4.76th and an expected value of

discussed previously, it is essential to require detuning 4.52nd. Next we use the +0 / -10% with expected to be

protection, to prevent parallel resonance amplification. -5%. This results in a range from the 4.38th to the

4.95th and an expected value of 4.64th harmonic.

Component Tolerances

It is often assumed that a harmonic filter is precisely Another concern in low voltage applications is the

tuned to the specified frequency. Just like cutting a feeder inductance from the filter unit to where it is

piece of wood, filters are usually tuned near the connected to the power system. Reactors for these

intended mark. What makes the difference between systems will be on the order of 100’s of µH. It is not

vendors that assemble reactors with capacitors from one unusual for long cable inductance’s to be a few µH

who builds harmonic filters is tolerance management. If which will significantly affect the filters tuning

a capacitor is built to IEEE-18, 1992 then it will have -0 frequency as seen by the power system.

/ +15% of the nameplate capacitance. From

observation it is rare to find low voltage capacitors with When determining what frequency your harmonic filters

less than +4% and more than +10% capacitance with need to be, do not forget to figure out the tolerances

the majority being near +8%. The key is that a filter including the feeder cable inductance. Being the

vendor has very little control over the tolerance of manufacturer has more control over the reactor

capacitors because they are produced in mass tolerance than that of the capacitors, it is recommended

production. that a range of acceptable tuning points for the assembly

be provided instead of tolerances for individual

On the other hand, the tuning reactors can be adjusted components. If tuning is critical, advise the filter

in their pre-epoxy bake to control the tuning point. No vendor so that components with tighter constraints are

standard presently exist for filter reactors, although utilized and prepare to pay a premium.

ANSI C57.16 is often referenced. Between consultants

and manufactures there is little common ground on what Selecting a Qualified Vender

these tolerances ought to be. C57.16 suggest -3% to The key here is to use common sense. Even though it is

+7% and others say +/- 2.5%. When talking about low important to use vendors that are involved in national

voltage filters there are two facts: typically there are standards committees and other power quality working

groups, over the telephone any company can seem to be taken when the Sample System, shown in Figure 7, had

an expert. Make sure they take the time to explain their the drive operating at 500 kVA and 500 kVAr of

approach to filter application, this business is as much harmonic filter was connected.

about educating the customer as it is about building

quality equipment. Request a customer list with

references to contact. Specifically ask if there are Power

Analyzer

Voltage Probe C

projects that had difficulties and to speak to a contact at

Voltage Probe A

Current Probe A

Current Probe C

Voltage Probe B

Current Probe B

one of those facilities. If a vendor says that all of there

jobs have gone off without a hitch, they are either lying

4160 V 480 V

or haven’t been building filters for very long. It is more 30 MVA

X/R=12.0

important to know how the vendor reacts when an 1000 kVA

5.5%Imp. 1000 HP

DC Drive

occasional project goes sour than to hear about the long

list of successful applications. Finally, ask about

warranties on individual components, the complete Plant Load

200 kVA

0.85 dPF

system, and performance. Step 1 Step 2 Step 14

50 kVAr 50 kVAr 50 kVAr

What to Expect when the Filters Arrive?

Low voltage filter systems cost between $50 and $75

per kVAr with special applications approaching $100 Figure 7 - Meter Setup for Filter Performance

per kVAr. For example, a 600 kVAr fully automatic Measurement

system will be on the order of $35,000. Don’t be too

disappointed when a gray box with some other gray Table 1 shows that of the 138 A of 5th harmonic current

boxes and copper coils wrapped around an iron core being injected into the system, the filter shunts away

shows up at your facility. Think of it on the lines of a 130 A, leaving 8 A to the utility power system. For this

transformer at five times the cost: It is a lot of money simple example, the phase angles have been omitted. If

for a gray box that sits there and hums, but the plant can utility voltage distortion were present, it is possible that

operate a lot better with it. Also keep in mind that in the filter would shunt all of the drives 5th harmonic

many parts of the country the reduction of utility current and sink harmonic current from the utility

demand charges will provide a less than two-year system. This is why paying attention to phase angles

payback. and looking at the three points shown in Figure 1 is

important.

Measurement of Filters for Verification Table 1 - Measured Currents

Once a harmonic filter is installed, it is important to Transformer Filter Load

verify its performance and the magnitude of critical Harmonic Probe A (Amps) Probe B (Amps) Probe C (Amps)

5 8 130 138

parameters of the individual components. Verifying the 7 22 43 65

performance of the filter assures that it is doing what the 11 12 16 28

13 9 12 21

manufacturer said it would, along with providing

valuable information to improve computer simulations. Parameter Rated Measured

Measurement of critical parameters are important to Wye Equiv. Cap. Range (uF) 575 - 633 610

assure that the filter rating is not exceeded. In addition, Peak Voltage (Vpk) 800 692

this gives a bench mark for evaluating the filters Current (Arms) 108 64

Reactive Power (kVAr) 68 56

condition as it remains in service. RMS Voltage (Vrms) 528 500

Inductance (uH) 498 - 553 524

Figure 7 shows the meter setup for measuring the 5th Harmonic Current (Arms) 45 13

harmonic filters performance. The diagram shows the 7th Harmonic Current (Arms) 10 5

11th Harmonic Current (Arms) 5 2

ideal situation where one current transformer (CT) is 13th Harmonic Current (Arms) 5 2

used to measure the load, one for the filter, and one CT Total Current (Arms) 80 64

for the transformer. Space restraints and load Harmonic Filter Tuned Harmonic 4.48 - 4.95 4.69

connection points may make this connection more Figure 8 - Sample Filter Verification Table

difficult. It is important to use a meter that will sample

all of the transducer channels simultaneously (or near To create a benchmark for comparison of future test,

simultaneously) and that all the probes be connected to critical parameters should be recorded. Figure 8 shows

a common phase so that a correlation between the three typical measurement results from such a test. The filter

currents may be made. The values in Table 1 were manufacture needs to provide the information shown in

the rated column. The measured values are obtained The IEEE-519 allows utilities to operate with 5% Vthd

using the following technique. and 3% distortion at any one frequency. These values

should be assumed regardless of what short term

monitoring show. This also shows the importance of

Current Probe A

temperature protection. If the problem does arise, it is

Voltage Probe A best to meet with the utility and manufacturer to discuss

utility system changes that have occurred that may have

caused the increase in distortion. It will require the

Analyzer

Current Probe B

Power

Voltage Probe B cooperation of all three parties to determine the best

Current Probe C

solution to rectify the problem. This may incorporate

Voltage Probe C utility system changes, modification of the filter system,

and/or additional filtering at neighboring facilities.

Conclusions

Application of harmonic filters is a sizable investment

for any facility. It is worth investigating harmonic filter

vendors for their technical capability and rapport with

Figure 9 - Meter Setup for Capacitor Limit past customers. The importance of talking with a

Measurement customer that had a difficult installation can not be

emphasized enough. If it is a small installation, make

sure the chosen vendor takes time to educate you to a

To find the capacitor parameters, the meter setup is as point where you feel comfortable. For larger

in Figure 9. It is important that the voltage probes be installations an independent consultant may be

connected at the terminals of the capacitor. The power preferred, utilities and filter manufacturers are a good

analyzer will display the values of Peak Voltage, source to refer someone. A systems approach should be

Current, Reactive Power, and RMS Voltage. These taken as opposed to applying a filter for a single piece

values are recorded and compared with the rated values of equipment. After the filter is installed, take

provided by the manufacturer. verification measurements to assure compliance with

the specification and to have a base case measurement

to compare to the filters performance in years to come.

What to do when Things go Wrong?

Here is where talking to the manufacturers other

customers ahead of time pays off. While most filter

applications are done without any problems, there are a

small number that do occur. Most common with low

voltage applications are tuning out of tolerance and

filter overload leading to premature failure.

Tuning out of tolerance may or may not be critical

depending on the goals of the project. If the filter is out

of tolerance and forces tuning above the harmonic

frequency injecting current into the system, i.e. a 5th

filter tuned to the 5.2nd, the system needs to be

modified to avoid amplification due to parallel

resonance. On the other hand, if tuning is lower than

anticipated, performance compared to the project goals

need to be assessed to determine the action taken.

More serious is a filter that is over loaded. It is more

common then preferred to see a filter be applied based

on measured utility distortion, say one or two percent,

then six months later the reactors burn up or nuisance

trip due to overheating protection. The utility

distribution is active with system reconfiguration and

new customers and loads being connected continuously.

References Brian Prokuda, P.E. Presently performs power quality

[1] E. Reid and K. Puskarich, “Harmonic Filter investigations, trouble shooting of power and control

Application Criteria”, Presented at a 1994 systems and failure analysis. He holds both

IEEE/PES Winter Power Meeting Panel Session, Professional Engineering and Electrical Journeyman’s

New York, NY. licenses in the State of Michigan and a BSEE and

MSEPE from Michigan Technological University and

[2] R. Dwyer, “Specifying Harmonic Filters for Rensselaer Polytechnic Institute respectively. Currently

Industrial Applications”, EPRI/Electrotek Harmflo Brian is a member of the IEEE Capacitor Subcommittee

Users Group Technical Notes, Spring 1995. and Harmonics Committee. As a member of the

Harmonics Committee, Brian is co-writing several

[3] IEEE Std 18-1992, IEEE Standard for Shunt Power sections dealing with capacitor and filter installations

Capacitors for the IEEE-519A, Harmonic Controls Application

[4] IEEE Std 1036-1992, IEEE Guide for Application Guide. Prior experience included two years of

of Shunt Power Capacitors designing and constructing harmonic filters for Var

[5] ANSI/IEEE Std 59-1992, IEEE Recommended Controls, Brian headed up the data collection for the

Practices and Requirements for Harmonic Control EPRI Distribution Power Quality project that was

in Electrical Power Systems. performed by Electrotek Concepts, Inc. and designed

process control and drive systems for the Dow

[6] ANSI/IEEE Std C57.12.01-1989, IEEE Standard Chemical Company.

General Requirements for Dry-Type Distribution

and Power Transformers Including Those With

Solid Cast and/or Resin-Encapsulated Windings.

Biography

You might also like

- Passive Tuned Harmonic FiltersDocument4 pagesPassive Tuned Harmonic FiltersRajendra Prasad Shukla100% (1)

- Schaffner An Filter Solutions For Motor Drives ApplicationsDocument28 pagesSchaffner An Filter Solutions For Motor Drives Applicationssykimk8921No ratings yet

- 3 PhaseDocument9 pages3 PhasekarlosNo ratings yet

- Cap & Fuse Failure Analysis 04Document12 pagesCap & Fuse Failure Analysis 04GMCaselNo ratings yet

- Do Capacitor Switching Transients Still Cause ProblemsDocument5 pagesDo Capacitor Switching Transients Still Cause Problemsaris09yekofNo ratings yet

- A Quantitative Comparison of Central Inverters and String Inverters in Utility Scale Solar Systems in North AmericaDocument11 pagesA Quantitative Comparison of Central Inverters and String Inverters in Utility Scale Solar Systems in North AmericaykuscuNo ratings yet

- IEEE519 Guide ToshibaDocument3 pagesIEEE519 Guide ToshibaVanshika MasandNo ratings yet

- POWER DEVICES IMPLEMENTATION & ANALYSIS ON ETAP by Abhilash ReddyDocument26 pagesPOWER DEVICES IMPLEMENTATION & ANALYSIS ON ETAP by Abhilash ReddyAbhilash ReddyNo ratings yet

- Hazardous Gas Detecting Rescue Robot in Coal MinesDocument49 pagesHazardous Gas Detecting Rescue Robot in Coal MinesAakash DindigulNo ratings yet

- Circuit Breaker Sizing IEEE Areva Oct 09Document20 pagesCircuit Breaker Sizing IEEE Areva Oct 09George GeorgeNo ratings yet

- Consulting - Specifying Engineer - Power Factor Correction Capacitors - Part 2Document6 pagesConsulting - Specifying Engineer - Power Factor Correction Capacitors - Part 2Schalter ElectricNo ratings yet

- Energy Efficiency Technical Guide: How To Select and Maintain Contactors For Capacitor Banks?Document16 pagesEnergy Efficiency Technical Guide: How To Select and Maintain Contactors For Capacitor Banks?SorinDanielMoisaNo ratings yet

- Project PlanDocument12 pagesProject Plan1deakz4lu7geNo ratings yet

- Design of Class-A Chopper For Minimizing Load Voltage RippleDocument5 pagesDesign of Class-A Chopper For Minimizing Load Voltage Rippleyemane gebremichalNo ratings yet

- 1-MHz Self-Driven ZVS Full-Bridge Converter For 48-V Power Pod and DC-DC BrickDocument10 pages1-MHz Self-Driven ZVS Full-Bridge Converter For 48-V Power Pod and DC-DC Brick李漢祥No ratings yet

- Transformer Basics Chapter 4Document4 pagesTransformer Basics Chapter 4Fahad AlamNo ratings yet

- Selection of Passive FiltersDocument3 pagesSelection of Passive FiltersTyler SamsonNo ratings yet

- Power FactorDocument3 pagesPower FactorravisriramulNo ratings yet

- Sine Wave Inverter With PICDocument50 pagesSine Wave Inverter With PICmtrapkNo ratings yet

- Impact of APFC Panel at LT Side of TransDocument6 pagesImpact of APFC Panel at LT Side of TransRitaban R. BanerjeeNo ratings yet

- Solving Power Quality Issues and Equipment Failures in a Non-Ferrous Metal IndustryDocument14 pagesSolving Power Quality Issues and Equipment Failures in a Non-Ferrous Metal Industrydan_geplNo ratings yet

- TRM 1099 Leading Power Factors To Generators and UPS EquipmentDocument4 pagesTRM 1099 Leading Power Factors To Generators and UPS EquipmentQuyet Thang TranNo ratings yet

- Current Transformer, Potential Transformer, LTCT, Low Tension CT, Combined CTPT Unit, Metering Unit, Metering Cubicle, Resin Cast CT, Cast Resin CT, Cast Resin PT, RVT, Residual Voltatge TransformerDocument12 pagesCurrent Transformer, Potential Transformer, LTCT, Low Tension CT, Combined CTPT Unit, Metering Unit, Metering Cubicle, Resin Cast CT, Cast Resin CT, Cast Resin PT, RVT, Residual Voltatge TransformerSharafatNo ratings yet

- A Series Tuned Harmonic FilterDocument59 pagesA Series Tuned Harmonic Filterajitkalel1986No ratings yet

- AC Auxillary SystemDocument51 pagesAC Auxillary Systemmugilee.psNo ratings yet

- Optimize solar power switching with an automated transfer switchDocument7 pagesOptimize solar power switching with an automated transfer switchMaxwellNo ratings yet

- Harmonics MitigationDocument8 pagesHarmonics MitigationbkNo ratings yet

- Medium-Voltage High-Speed Source-Transfer Switching Systems A New Tool To Solve Power Quality ProDocument6 pagesMedium-Voltage High-Speed Source-Transfer Switching Systems A New Tool To Solve Power Quality Proue06037No ratings yet

- 852 Fa40Document10 pages852 Fa40M. T.No ratings yet

- Estimated Available Fault Current Calculator: Project NameDocument15 pagesEstimated Available Fault Current Calculator: Project NameCH AsiaNo ratings yet

- Quote CT PT Isolator VCB AB Switch Drop Out Fuse Set TPMO SMC LT Distribution Box HT PanelDocument11 pagesQuote CT PT Isolator VCB AB Switch Drop Out Fuse Set TPMO SMC LT Distribution Box HT PanelSharafatNo ratings yet

- Optimizer2008 - 2 Calculo de PararrayosDocument278 pagesOptimizer2008 - 2 Calculo de PararrayosshfedericoNo ratings yet

- apfc-panelDocument7 pagesapfc-panelChander MohanNo ratings yet

- Digital Potentiometers in RF Power Amplifier AppsDocument4 pagesDigital Potentiometers in RF Power Amplifier AppserdemsecenNo ratings yet

- A Guide To Supply Harmonics and Other Low Frequency Disturbances Iss2x 0704 0002 02x PDFDocument32 pagesA Guide To Supply Harmonics and Other Low Frequency Disturbances Iss2x 0704 0002 02x PDFRichie ChicolNo ratings yet

- Transformador PrincipalDocument20 pagesTransformador PrincipalCarmen Diaz FloresNo ratings yet

- Optimum Location and Size of Capacitor Bank in Distribution SystemDocument10 pagesOptimum Location and Size of Capacitor Bank in Distribution SystemsurajNo ratings yet

- Power Quality Improvement in Transmission Line Using DPFCDocument7 pagesPower Quality Improvement in Transmission Line Using DPFCVIVA-TECH IJRINo ratings yet

- PWM Drive Filter Inductor Influence On Transient Immunity PAPERDocument7 pagesPWM Drive Filter Inductor Influence On Transient Immunity PAPERpatrickNo ratings yet

- Active Harmonic FilterDocument8 pagesActive Harmonic FilterKanai BanerjeeNo ratings yet

- EO6ADocument35 pagesEO6Amspd2003No ratings yet

- Impact of Utility Switched Capacitor On Customer Systems - Part 2 - Adjustable Speed Drive ConcernsDocument6 pagesImpact of Utility Switched Capacitor On Customer Systems - Part 2 - Adjustable Speed Drive ConcernsMadhusudhan SrinivasanNo ratings yet

- Etap Calculo CCDocument22 pagesEtap Calculo CChikary2.032No ratings yet

- 489Document52 pages489jovce.doneski215No ratings yet

- Voltage Quality Improvement Using DVRDocument3 pagesVoltage Quality Improvement Using DVRSeid EndrisNo ratings yet

- Chapter 08 - AC ElementsDocument349 pagesChapter 08 - AC Elementsyanuartw7No ratings yet

- Calculating Short-Circuit Current - IAEI MagazineDocument13 pagesCalculating Short-Circuit Current - IAEI MagazineMohamedAhmedFawzy100% (1)

- Modeling Transmission and Distribution Systems Using PSS AdeptDocument8 pagesModeling Transmission and Distribution Systems Using PSS Adeptlinkin_slayerNo ratings yet

- User's Manual of Construction: Power Grid Corporation of India LimitedDocument59 pagesUser's Manual of Construction: Power Grid Corporation of India Limitedparamgagan100% (1)

- Choosing Resistor vs Reactor Neutral GroundingDocument8 pagesChoosing Resistor vs Reactor Neutral GroundingRaod2No ratings yet

- Co_ordination_of_Overcurrent_Relay_for_ChemistryDocument4 pagesCo_ordination_of_Overcurrent_Relay_for_ChemistryChú cún sa mạcNo ratings yet

- Protection Relay SettingsDocument3 pagesProtection Relay SettingssmsbondNo ratings yet

- Various Subsystems in Substation and Their Functions: SL No. System FunctionsDocument11 pagesVarious Subsystems in Substation and Their Functions: SL No. System FunctionsMuhammad Asif IqbalNo ratings yet

- Kamarudin B.khalidDocument7 pagesKamarudin B.khalidMidhun U KNo ratings yet

- Designing Harmonics Filters For Adjustable Speed DrivesDocument6 pagesDesigning Harmonics Filters For Adjustable Speed DrivesRolando AvalosNo ratings yet

- ANPC-5L Technology Applied To Medium Voltage Variable Speed Drives ApplicationsDocument8 pagesANPC-5L Technology Applied To Medium Voltage Variable Speed Drives ApplicationsRen Hong GiangNo ratings yet

- AC Auxiliary Systems in Power SubstDocument16 pagesAC Auxiliary Systems in Power SubstNepoliyanNo ratings yet

- Automated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsFrom EverandAutomated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsNo ratings yet

- GelHandbookPart1 PDFDocument22 pagesGelHandbookPart1 PDFMario StrašniNo ratings yet

- TCI, LLC Store Catalog 1571031284Document2 pagesTCI, LLC Store Catalog 1571031284Mostafa ElSayedNo ratings yet

- Epcos DatasheetDocument5 pagesEpcos DatasheetMostafa ElSayedNo ratings yet

- 400V Capacitor Bank - SpecDocument10 pages400V Capacitor Bank - SpecGianc87No ratings yet

- Detuning ReactorsDocument1 pageDetuning ReactorsMostafa ElSayedNo ratings yet

- Led Site Lighting Performance SpecificationDocument21 pagesLed Site Lighting Performance SpecificationMostafa ElSayedNo ratings yet

- LD5760-DS-02 LeadtrendDocument20 pagesLD5760-DS-02 Leadtrendvahid hoseinpourNo ratings yet

- Bty Charger 5.6KWDocument12 pagesBty Charger 5.6KWPankaj TiwariNo ratings yet

- PracticeDocument4 pagesPracticedeyn suello33% (3)

- FireFinder XLS Card Cage Model CC-5Document2 pagesFireFinder XLS Card Cage Model CC-5Mazenabs AbsNo ratings yet

- 5 KW Two-Channel Interleaved CCM PFC EVAL Board InfineonDocument41 pages5 KW Two-Channel Interleaved CCM PFC EVAL Board InfineonshrikrisNo ratings yet

- Digital load cell for trucks, hoppers and electronic weighingDocument2 pagesDigital load cell for trucks, hoppers and electronic weighingPravin NirukheNo ratings yet

- OEE Boiler Panel Bill of MaterialsDocument2 pagesOEE Boiler Panel Bill of MaterialsVikas YadavNo ratings yet

- PowerRelays Selection GuideDocument24 pagesPowerRelays Selection GuidearturobatallasNo ratings yet

- Installation Manual: International Power Machines'Document46 pagesInstallation Manual: International Power Machines'haNo ratings yet

- Ma - VD4-WHD (En) - 1VCD601411 - Ba 414-074Document28 pagesMa - VD4-WHD (En) - 1VCD601411 - Ba 414-074EFranNo ratings yet

- Inverex Nitrox 6kW Hybrid Inverter Datasheet SpecificationsDocument2 pagesInverex Nitrox 6kW Hybrid Inverter Datasheet Specifications1saad116No ratings yet

- Allen Bradley 100 C43ZJ10Document1 pageAllen Bradley 100 C43ZJ10Diana Cristina PereaNo ratings yet

- Reglaj Protecții Transformatoare MittalDocument23 pagesReglaj Protecții Transformatoare MittalFlorin CristiNo ratings yet

- Hoffman 5F1Document4 pagesHoffman 5F1samuel tassiniNo ratings yet

- Hybrid Switched-Inductor Converters For High Step-Up ConversionDocument11 pagesHybrid Switched-Inductor Converters For High Step-Up ConversionRahim SamanbakhshNo ratings yet

- Tds-Orion Led Bay LightDocument1 pageTds-Orion Led Bay LightAjayNo ratings yet

- Generation of Impulse CurrentsDocument9 pagesGeneration of Impulse CurrentsSaufiNo ratings yet

- An 4140Document11 pagesAn 4140ommidbeNo ratings yet

- For All Your Requirements: Essential EquipmentDocument32 pagesFor All Your Requirements: Essential EquipmentMuhammed Talha QureshiNo ratings yet

- X012 Designation Code For Power Cables PDFDocument1 pageX012 Designation Code For Power Cables PDFSunil SinghNo ratings yet

- Fehlercodes ListeDocument5 pagesFehlercodes ListefdashhanaNo ratings yet

- WindingDocument61 pagesWindinganoopingle9100% (2)

- Assignment 1 Machine and DrivesDocument2 pagesAssignment 1 Machine and DrivesChawyang CheahNo ratings yet

- Easy To Build CNC Mill Stepper Motor and Driver CiDocument11 pagesEasy To Build CNC Mill Stepper Motor and Driver Cipcstuffs100% (6)

- 03 TechnicalDocument33 pages03 Technicalban-mrw CompaniesNo ratings yet

- Controlling Railway Crossing Simulation with Hall SensorDocument5 pagesControlling Railway Crossing Simulation with Hall SensorDENI DENI ALFIYANSYAHNo ratings yet

- SPB Acienda Electrical Plans - For TenderDocument20 pagesSPB Acienda Electrical Plans - For TenderRyan DizonNo ratings yet

- Retrofit Additional BatteryDocument3 pagesRetrofit Additional BatteryAnonymous F4tPbieYEGNo ratings yet

- Subminiature DIL relays 2A featuresDocument2 pagesSubminiature DIL relays 2A featuresTony RodriguezNo ratings yet

- Component R2 R26 R33 R62Document1 pageComponent R2 R26 R33 R62rodruren01No ratings yet