Professional Documents

Culture Documents

Enclosure Design Basics

Uploaded by

kannanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Enclosure Design Basics

Uploaded by

kannanCopyright:

Available Formats

ENCLOSURE DESIGN BASICS

WWW.PROTOCASE.COM

© Protocase Inc. All rights reserved

Document edition – 1.2

Last updated: March, 2007

Toll free: 1-866-849-3911 (US & Canada only)

Tel: 1-902-567-3335

Fax: 1-902-567-3336

Email: info@protocase.com

Table of contents

Introduction ………………………………………………………………….. 3

Metal selection ………………………………………………………….. 3

Bending metal and bend radius ………………………………………….. 4

…….. Consequences ………………………………………………………….. 5

Self clinching fasteners ………………………………………………….. 6

Standard Stocked PEMs ………………………………………………….. 7

Welding ………………………………………………………………….. 8

Finishing ………………………………………………………………….. 8

…….. Powder coat color ………………………………………………….. 8

…….. Stocked powder coat colors ………………………………………….. 8

…….. Silk screen ………………………………………………………….. 9

…….. Silk screen samples ………………………………………….. 10

…….. Adding company logo’s, ventilation, and text as cutouts ………….. 11

…….. Cutout Samples ………………………………………………….. 11

Questions / comments ………………………………………………………….. 12

The enclosure design basics 2

Introduction

Whether you design your enclosure from scratch or make use of one of our simple

template based design, knowing the basics of enclosure design will make your work

easier.

Below you will find information on some of the basic concepts of enclosure and sheet

metal design. Looking for further information? Don’t hesitate to ask

tech@protocase.com. One of our technicians will be happy to answer your questions.

Please see the below menu for more information:

• Metal selection

• Bending metal and bend radius

o Consequences

• Self-clinching fasteners (PEM ®)

o Standard stocked PEM ®

• Welding

• Finishing

o Powder coating

o Silk-Screening

Metal selection

Major considerations for the metal selection are the types of metal and their thickness.

Protocase Inc. offers carbon steel and stainless steel as standard offerings. The table

below shows the standard sheet metal thickness:

Gage # Plain Steel Stainless Steel

11 0.120 in -

12 - -

14 0.075 in 0.078 in

16 0.060 in 0.063 in

18 0.048 in 0.050 in

20 0.036 in 0.038 in

22 0.030 in 0.031 in

24 0.024 in 0.025 in

Carbon steel is suitable for the majority of electronic applications, and shows long-term

durability in indoor applications when finished with powder coat.

Stainless steel should be used when corrosion resistance is an issue, or when that ´special

look´ of brushed stainless steel is desired. Stainless can be powder coated just like carbon

steel. It exhibits exceptional corrosion resistance whether bare or powder coated.

However, users should be aware that stainless steel could show surface corrosion when

contaminated with traces of carbon steel or other corrosion susceptible metals. If stainless

comes into contact with such metals (for example, if it is finished with a carbon steel wire

brush) then it must be 'passivated' to remove that contamination.

The enclosure design basics 3

Protocase Inc. has an in-house environmentally friendly citric-acid based passivation

process.

If a particularly corrosive environment is anticipated, please contact

tech@protocase.com.

Bending metal and bend radius

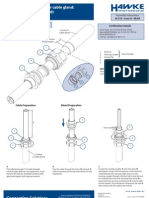

Sheet metal enclosures are fabricated by 'cold forming', where the metal is clamped and

bent in machines called 'press brakes'. As a result, metal typically cannot be formed into a

true 90 deg. corner, but rather, the corners are curved as per the figure below (FIG 1).

Different degrees of curvature can be achieved, and it is described by a parameter called

'bend radius' (see figure showing series of different bend radius FIG 1). Note that bend

radius is specified as the radius of the INSIDE surface of the bend.

FIG 1 (A)

FIG 1 (B)

The enclosure design basics 4

Consequences:

Sheet metal stretches during forming to some degree and the manufacturer must

consider this when fabricating the enclosure. It is a function of tooling, metal

thickness, bend radius, and metal composition. Metal composition varies somewhat

with even the best quality metal from the best suppliers and as a result, there is always

a certain tolerance on dimensions when bends are involved. Manufacturers will supply

standard tolerances on request.

Generally, cutouts should stay a minimum distance from bend radii in order to avoid

deformation and wrinkling of the enclosure during forming. See Fig 2 below. Strictly

speaking the cutout need only avoid being on the bend, but in practice, an exclusion

zone of 1/16" is suggested to allow for mfg tolerances.

FIG 2

Special consideration must be given to the intersection of two bend lines, i.e. a corner of

an enclosure. Specifically, extra material must be removed in order to prevent bends from

interfering with each other and is called a corner relief. See FIG 3 below. This is done

automatically in ProtoCase templates, but must be considered when designing enclosures

from scratch.

The enclosure design basics 5

FIG 3

Self-Clinching Fasteners

Self-Clinching fasteners are threaded nuts, studs, or standoffs that are mechanically

pressed into sheet metal to provide solid fastening points. Nuts can be used to accept

bolts, standoffs can be inserted for mounting circuit boards and studs can be used for

mounting connectors. See FIG 4 below. They are sometimes referred to by the most

common brand, called ´PEMS ®´, which is a trademark of Penn Engineering &

Manufacturing Corp (http://www.pemnet.com). They are a very useful item and solve a

lot of component mounting problems.

FIG 4 (A)

Protocase stocks a large assortment of self-clinching fasteners and will install for a very

reasonable cost.

The enclosure design basics 6

FIG 4 (B)

Standard Stocked PEMs ®

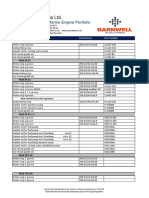

Stand Offs - Sizes Stocked

Thru Hole

4-40 x 1/4", 5/16", 3/8", 7/16", 1/2", 9/16"

6-32 x 1/4", 5/16", 3/8", 7/16", 1/2", 9/16"

8-32 x 1/4", 3/8", 1/2",

10-32 x 1/2"

M3 x 3mm, 4mm, 6mm, 8mm, 14mm

M4 x 6mm, 12mm

M5 x 12mm

Blind

4-40 x 5/16", 3/8", 7/16", 1/2", 9/16", 5/8",

11/16", 3/4"

6-32 x 5/16", 3/8", 7/16", 1/2", 9/16", 1"

8-32 x 5/16", 1/2"

10-32 x 3/8", 5/8"

Nuts - Size Stocked

2-56, 4-40, 6-32, 8-32, 10-32, 10-24, 1/4-20

M3, M4, M5, M6

Studs - Size Stocked

2-56 x 1/4", 1/2"

The enclosure design basics 7

4-40 x 1/4", 3/8", 1/2", 5/8", 3/4"

6-32 x 1/4", 3/8", 1/2", 5/8", 3/4"

8-32 x 1/4", 3/8", 1/2", 5/8", 3/4"

10-32 x 3/8", 1/2"

10-24 x 3/8", 1/2"

1/4-20 x 1/2", 1"

M3 x 8mm, 10mm, 12mm, 15mm, 18mm

M4 x 8mm, 10mm, 12mm, 15mm, 18mm

M5 x 12mm

M6 x 12mm

Welding

Depending on the user´s particular application, spot-welded enclosures or fully seam-

welded enclosures may be desirable. With many enclosure designs, such as our standard

U-shape (clam shell), no welding is required. One section of the enclosure contains small

flanges with self-clinching nuts and the other section of the enclosure is fastened using

mechanical fasteners such as machine screws or sheet metal screws.

However, in some cases welded flanges are desired. Spot welding would be used in cases

where disassembly is not required. Fully seam welded edges may also be a requirement,

especially if the application requires a more tightly sealed enclosure. Protocase offers

both spot-welded and fully seam-welded enclosures.

Finishing

Powder Coating

The standard finishing offered by Protocase is powder coating. This is now widely

recognized as the industry standard for painting metal, providing a high quality,

highly durable finish. Protocase offers a variety of standard stocked colors and

textures. There is no additional charge for using one of our standard stocked colors.

We can also provide fully custom colors for an additional fee (depends on the size

and the quantity of the parts). Lead times for fully custom colors vary and may affect

delivery. For more information please contact us.

Powder coat colors are identified by an RAL number. When specifying a fully custom

powder coat colors please provide us with the RAL number. Click here for RAL color

chart.

Stocked powder coat colors

Note: The color representations below may deviate from the actual color due to

variations in browser software, video cards, and monitors.

The enclosure design basics 8

White sandtex Storm white Almond Beige wheat

(textured) (smooth semi (wrinkle)

gloss)

Aero yellow ANSI 70 ANSI 61 Retro (smooth

(smooth (smooth semi (smooth semi semi gloss)

semigloss) gloss) gloss)

Graphite sandtex Black (smooth Black (smooth Black sandtex

semi gloss) matte)

RAL 6018 - RAL 6002 - RAL 6003 - RAL 5017 -

Yellow Green Leaf Green Olive Green Traffic Blue

RAL 5010 - Fire red RAL 3002 Safety Orange

Gentian Blue (smooth semi Textured

(Textured) gloss)

Stainless steel may be used bare without any finish. However, cut edges may have

imperfect aesthetics, such as slight roughness or slight discoloration, and

consideration should be given to 'molding' such edges by overlapping front panel

components or adjacent surfaces.

Carbon steel can be finished in other ways for special purposes. For example, white or

yellow zinc can be electroplated onto carbon steel to enhance corrosion resistance

(this is very durable when used in combination with certain powder coats.)

Silk Screening

Protocase completes the task of manufacturing fully finished, quality enclosures by

offering silk-screening, a process that provides required labeling for connectors,

switches, ports, etc., along with adding special graphics such a company logos,

product identifier graphics, etc.

The enclosure design basics 9

Our silk-screening process utilizes the latest in screen preparation technology, as well

as using durable epoxy based inks, ensuring a high resolution, quality finish.

Protocase stocks a variety of standard colors, but can provide custom colors upon

request.

The clarity of silkscreen can be greatly affected by the texture of powder coat used.

Generally for best results it is recommended you use a smooth finish. Silkscreen will

work on various textures and colors but each situation is unique. This may require

modifications to your silkscreen such as changing of fonts and thickening of fine

lines. For more information, please contact tech support at tech@protocase.com.

Images such as company logos must be provided electronically. Faxed images will

not provide sharp enough resolution for our process to replicate. If text-only screening

is required, simply provide information’s such as font type, font size, font color etc by

fax or e-mail. Our tech support team will be happy to produce the required text-only

screens.

Silk Screen samples

Traxi Technologies

X-Ray Imaging Solutions

The enclosure design basics 10

Stanford University

Adding company logo’s, ventilation, and text as cutouts

Protocase provides custom cutouts to mount connectors, displays, switches, etc.

There are very few limitations to the cutouts we can provide. For the most part, if

you can draw it, we can provide it.

Protocase offers clients the ability to be very creative with cutouts. In some cases we

can provide your company logo or name cut out in your enclosure.

We are also creative with ventilation cutouts. You no longer have to settle for

conventional straight-line ventilation cutouts.

Cutout Samples

Circular Ventilation Cutout Celtic Ventilation Cutout

Scion Logo Cutout Honda Logo Cutout

Traxi Technologies Logo Cutout EPIACENTER.com Name Cutout

The enclosure design basics 11

www.advancedglazings.com Cutout www.protocase.com Name Cutout

Questions / comments

If you still have questions or comments please do not hesitate to contact us at

tech@protocase.com or 1-866-849-3911 (toll free US & Canada).

The enclosure design basics 12

You might also like

- Mercedes Benz Kompressor Pulley Installation GuideDocument14 pagesMercedes Benz Kompressor Pulley Installation Guidekilofome05No ratings yet

- Orbit Completions Management Software GuideDocument29 pagesOrbit Completions Management Software GuideGeorge Van BommelNo ratings yet

- Mechanical Completion Certificate for Export PumpsDocument1 pageMechanical Completion Certificate for Export PumpsDeonNo ratings yet

- CATIA V5 QuestionsDocument10 pagesCATIA V5 Questionsvennesravan100% (1)

- Bit Wear PatternDocument11 pagesBit Wear PatternRezaNo ratings yet

- HMT Machine Tools Ltd. - Internship ReportDocument51 pagesHMT Machine Tools Ltd. - Internship ReportSwaroop Somanna33% (3)

- Method Statement For Exposed Conduits InstallationDocument24 pagesMethod Statement For Exposed Conduits InstallationNguyen Dang LongNo ratings yet

- Public Sector Panels of Consultants ListingDocument23 pagesPublic Sector Panels of Consultants ListingSteven NaungNo ratings yet

- Roxas Substation Pert-CpmDocument1 pageRoxas Substation Pert-CpmJohn Paul AlbanezNo ratings yet

- Assam Tea Corporation Limited: Request For Proposals (RFP)Document49 pagesAssam Tea Corporation Limited: Request For Proposals (RFP)Raghav PoddarNo ratings yet

- Senior Electrical Design Engineer CVDocument3 pagesSenior Electrical Design Engineer CVMohamedNo ratings yet

- 4-Technical Specs - LVDocument29 pages4-Technical Specs - LVtauqeer544gmailcomNo ratings yet

- Design of A Chemical Plant PDFDocument2 pagesDesign of A Chemical Plant PDFAdarsh SvNo ratings yet

- ABB Medium-Voltage Surge Arresters - Application Guidelines 1HC0075561 E2 AC (Read View) - 6edDocument60 pagesABB Medium-Voltage Surge Arresters - Application Guidelines 1HC0075561 E2 AC (Read View) - 6edAndré LuizNo ratings yet

- Types of Piping Drawings: Piping and Instrumentation DiagramDocument18 pagesTypes of Piping Drawings: Piping and Instrumentation Diagramakash dawareNo ratings yet

- Transformers, Dry Type, Air-Cooled, Low Voltage, SmallDocument2 pagesTransformers, Dry Type, Air-Cooled, Low Voltage, SmallHoneylyn IgnacioNo ratings yet

- Conduits PDFDocument12 pagesConduits PDFAnonymous PYEzEEVzNo ratings yet

- Electrical Engineering Technology - Higher National Diploma (HND)Document19 pagesElectrical Engineering Technology - Higher National Diploma (HND)Chibueze EzeokaforNo ratings yet

- Dokgoro K1785 Method StatementDocument6 pagesDokgoro K1785 Method StatementJackie van SchalkwykNo ratings yet

- Electrical ConduitDocument9 pagesElectrical ConduitAngling DharmaNo ratings yet

- VD V013 ZPM Pro 1507Document105 pagesVD V013 ZPM Pro 1507abdulNo ratings yet

- Installation & Termination of Wiring Devices Method Statement KSA ProjectDocument13 pagesInstallation & Termination of Wiring Devices Method Statement KSA ProjectehteshamNo ratings yet

- Digital Project DevelopmentDocument182 pagesDigital Project Developmentvasilsev100% (1)

- Cathodic Protection Cable Installation ProceduresDocument4 pagesCathodic Protection Cable Installation Proceduresarif rhNo ratings yet

- Elec Foreman CVDocument4 pagesElec Foreman CVhitanshu0% (1)

- Template (Electrical Works)Document10 pagesTemplate (Electrical Works)Anonymous Qu7LeENo ratings yet

- S-AAA-CAB-GEN (Rev.0-2011)Document35 pagesS-AAA-CAB-GEN (Rev.0-2011)Karuppu SamyNo ratings yet

- Tips in Estimating TOTAL LENGHT OF CABLES IN ELECTRICAL INSTALLATIONDocument2 pagesTips in Estimating TOTAL LENGHT OF CABLES IN ELECTRICAL INSTALLATIONcrescente galendezNo ratings yet

- Spec EarthingDocument10 pagesSpec EarthingDolyNo ratings yet

- HV SWITCHGEAR CONSTRUCTION AND DRAWING INDEXDocument28 pagesHV SWITCHGEAR CONSTRUCTION AND DRAWING INDEXmentong100% (2)

- PSK Checklist New Elec E01 - 18 HT CablingDocument1 pagePSK Checklist New Elec E01 - 18 HT CablingBAHARUDIN BURAHNo ratings yet

- Cable Tray Bill of MaterialDocument1 pageCable Tray Bill of MaterialVinay YadavNo ratings yet

- Sor HDB 2021Document137 pagesSor HDB 2021Lai Kok UeiNo ratings yet

- Assembly Instructions for 501/414 Exd IIC/Exe II ExtD Cable GlandDocument2 pagesAssembly Instructions for 501/414 Exd IIC/Exe II ExtD Cable GlandFoe AungNo ratings yet

- Technical Proposal: BKT Wellhead PlatformDocument43 pagesTechnical Proposal: BKT Wellhead PlatformMaina MathengeNo ratings yet

- Horizontal Directional Drilling (HDD) Pilot Bore Simulation PDFDocument14 pagesHorizontal Directional Drilling (HDD) Pilot Bore Simulation PDFMohd Khairul Azwan SirajudinNo ratings yet

- 1 ITB For Scour Protection at SLTS PROJECTDocument13 pages1 ITB For Scour Protection at SLTS PROJECTEng Muhammad Afzal AlmaniNo ratings yet

- Livening Up NotesDocument1 pageLivening Up NotesAceel FitchNo ratings yet

- Control Panel Space OptimizationDocument12 pagesControl Panel Space Optimizationyopy_yogieNo ratings yet

- Cable Tie Sae StandardDocument9 pagesCable Tie Sae StandardSandeep Goud ChatlaNo ratings yet

- Method Statement For Inst Cable LayingDocument24 pagesMethod Statement For Inst Cable LayingMallikarjun DevarapalliNo ratings yet

- Pipeline Leak Detection SystemDocument9 pagesPipeline Leak Detection SystemMohamad PizulNo ratings yet

- Electrical Engineer ResponsibilitiesDocument4 pagesElectrical Engineer ResponsibilitiesVenkata Suresh MandavaNo ratings yet

- Nicc802 Padmount Transformer BrochureDocument8 pagesNicc802 Padmount Transformer Brochureparas99No ratings yet

- E&I Tool Box ContentsDocument1 pageE&I Tool Box ContentsChandan RayNo ratings yet

- Electrical Design Engineering in Oil & GasDocument10 pagesElectrical Design Engineering in Oil & GasNaveen YallapuNo ratings yet

- 16126Document13 pages16126uddinnadeemNo ratings yet

- ChecklistDocument35 pagesChecklistShashi Kant Singh100% (1)

- SMDB Technical SpecificationsDocument55 pagesSMDB Technical SpecificationsAnsal KhanNo ratings yet

- Conduit and Cable ScheduleDocument1 pageConduit and Cable ScheduleFarhan SaadatNo ratings yet

- Haryana Vidyut Prasaran Nigam Limited: SPECIFICATION No. HGD/S-67/DGMS-171 (APRIL-2017)Document37 pagesHaryana Vidyut Prasaran Nigam Limited: SPECIFICATION No. HGD/S-67/DGMS-171 (APRIL-2017)samkarmakar2002No ratings yet

- Erection BOQ - SaranDocument339 pagesErection BOQ - SaranPrasanna kumar subudhiNo ratings yet

- 2011 40 Autumn Wiring Matters EarthingDocument8 pages2011 40 Autumn Wiring Matters EarthingsourcNo ratings yet

- RFQDocument4 pagesRFQPaul SigeiNo ratings yet

- Standar Operational Procedure (Electrical) : Pt. Krakatau PoscoDocument24 pagesStandar Operational Procedure (Electrical) : Pt. Krakatau Poscosefina mecNo ratings yet

- Opgc Owners Engineer - CPPDocument18 pagesOpgc Owners Engineer - CPPwas00266No ratings yet

- En B 373 Project 2012Document9 pagesEn B 373 Project 2012April IngramNo ratings yet

- Generator SWGRDocument16 pagesGenerator SWGRMiko QuijanoNo ratings yet

- Method Statement: Electrical and Instrument Cable InstallationDocument5 pagesMethod Statement: Electrical and Instrument Cable InstallationLeoj Saliw-an Palaoag100% (1)

- Typical Details For Metering Skid FoundationDocument1 pageTypical Details For Metering Skid FoundationSaravanan SelvamaniNo ratings yet

- Master Document for ME&I ProjectDocument18 pagesMaster Document for ME&I ProjectAbdullah AbdullahNo ratings yet

- Arcfix Arc StudDocument21 pagesArcfix Arc StudKiran Kumar KondapalliNo ratings yet

- Design For Manufacture (DFM) Tips For Die Cast PartsDocument5 pagesDesign For Manufacture (DFM) Tips For Die Cast PartsJimmy ManuelNo ratings yet

- Suruburi by S.C.RewlingsDocument8 pagesSuruburi by S.C.RewlingsMihnea OrzaNo ratings yet

- RAT Checklist Support Doc TemplateDocument6 pagesRAT Checklist Support Doc Template96chaitanya96No ratings yet

- Resume RamyaDocument2 pagesResume Ramya96chaitanya96No ratings yet

- Approved Vendor ListFINISHEDDocument11 pagesApproved Vendor ListFINISHED96chaitanya96No ratings yet

- 6 X 4.5 Thru All: PrognosysDocument1 page6 X 4.5 Thru All: Prognosys96chaitanya96No ratings yet

- Autocad Shortcut KeysDocument2 pagesAutocad Shortcut Keys96chaitanya96No ratings yet

- 6 X 4.5 Thru All: PrognosysDocument1 page6 X 4.5 Thru All: Prognosys96chaitanya96No ratings yet

- SheetMetal DesignDocument2 pagesSheetMetal Design96chaitanya96No ratings yet

- Fuselage Design ConsiderationDocument51 pagesFuselage Design ConsiderationNick5597No ratings yet

- Ecosyn - Imx: Direct Assembly Into Stainless SteelDocument8 pagesEcosyn - Imx: Direct Assembly Into Stainless SteelH JackNo ratings yet

- DAE BookDocument80 pagesDAE Bookultimate football soccer funNo ratings yet

- Auracem 400: Performance Enhancer For Blended and Portland CementsDocument2 pagesAuracem 400: Performance Enhancer For Blended and Portland CementsVenkata Raju KalidindiNo ratings yet

- Note 1Document9 pagesNote 1Dr. Aung Ko LattNo ratings yet

- Metric Coarse Threads: Carbon Steel Hand TapsDocument2 pagesMetric Coarse Threads: Carbon Steel Hand TapsRam SinghNo ratings yet

- 16-18 Deburring BladesDocument1 page16-18 Deburring BladesangelNo ratings yet

- WELDING GUIDELINES: COST-EFFECTIVE DESIGN TIPSDocument6 pagesWELDING GUIDELINES: COST-EFFECTIVE DESIGN TIPSsarath6725No ratings yet

- Service PantryDocument10 pagesService PantryCtHanifahNo ratings yet

- Micro Carbon ResidueDocument9 pagesMicro Carbon ResidueCaptainPatsNo ratings yet

- Enviroline 124 Eng A4 20191009Document4 pagesEnviroline 124 Eng A4 20191009lovedesuzaNo ratings yet

- Mcq-Ucmp - Unit Iv - Advanced Nano Finishing ProcessesDocument8 pagesMcq-Ucmp - Unit Iv - Advanced Nano Finishing ProcessesBollu SatyanarayanaNo ratings yet

- MAK Marine Engine Seals PortfolioDocument2 pagesMAK Marine Engine Seals PortfolioJavierNo ratings yet

- Fischer TropschDocument19 pagesFischer TropschConnor SailorNo ratings yet

- 13 PDFDocument14 pages13 PDFPedro SilvaNo ratings yet

- Pip Ctse1000-2018Document82 pagesPip Ctse1000-2018John BuntalesNo ratings yet

- Steel Structure 1Document15 pagesSteel Structure 1Febriono AdiNo ratings yet

- MigDocument6 pagesMigPensel KoNtotNo ratings yet

- Datasheet Sandvik Saf 2205 en PDFDocument12 pagesDatasheet Sandvik Saf 2205 en PDFYuriy NesterovNo ratings yet

- ABS DSS Engels Exp NieuweDocument6 pagesABS DSS Engels Exp Nieuwepaz_mmNo ratings yet

- Why Use Preheat and Post Weld Heat Treatments Brochure PDFDocument2 pagesWhy Use Preheat and Post Weld Heat Treatments Brochure PDFErick HoganNo ratings yet

- ZG35 CR 24 Ni 7 Si NDocument2 pagesZG35 CR 24 Ni 7 Si NP.K.V Choudhary0% (1)

- EN 44300 AlSi12 (Fe) (A)Document2 pagesEN 44300 AlSi12 (Fe) (A)wafi2131No ratings yet

- BTR Homes WTP Audit ReportDocument4 pagesBTR Homes WTP Audit ReportV Narasimha RajuNo ratings yet

- Multi Spindle Attacment in Drilling MachineDocument31 pagesMulti Spindle Attacment in Drilling MachineStartechnico Technocrats100% (1)

- PB Granshot Cold Work EngDocument16 pagesPB Granshot Cold Work EngkalaiNo ratings yet

- 716-50-001 - Flange Gate Valve - ANSIDocument2 pages716-50-001 - Flange Gate Valve - ANSIImtiyaz KhanNo ratings yet

- Metaceram 25010: Aluminum Oxide PowderDocument2 pagesMetaceram 25010: Aluminum Oxide PowderTob NisapakulNo ratings yet