Professional Documents

Culture Documents

Safety Rules For Cylinders

Uploaded by

kvanps_kumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety Rules For Cylinders

Uploaded by

kvanps_kumarCopyright:

Available Formats

1. Unsecured cylinders.

Cylinders should always be secured with a strap or chain; groups of cylinders can be secured with a

single chain or gate. If a cylinder is being moved, received, or shipped, it should not be left unattended

- not even briefly.

2. Cylinders stored without cylinder caps.

Obviously the case when full, but even when empty, a cylinder should be stored with the valve

CLOSED, and the cylinder cap ON.

3. Cylinders stored with hardware attached.

Clearly, if the cylinder should be stored with the cylinder cap ON, all hardware must be removed first.

But we often see cylinders stored with external valves, hose, tubing, or regulators still attached. Even

if storage is temporary, the hardware should be removed; the valve closed; and the cylinder cap

installed.

4. Cylinder valve left open when gas is not in use.

If a cylinder is at point of use but not in current service, the cylinder valve should be closed. Closing

the discharge valve at the regulator is not sufficient.

5. Non-compatible gases stored together.

For example, flammable gases should not be stored with oxidizers. Flammables should be separated

from oxidizers by at least 20 feet, or a 1 hour fire wall.

6. Fire extinguishers not available when using flammable gas.

Gases used for brazing, welding, or burning - or any gas that is flammable, regardless of application -

should always be used with fire control devices at hand.

7. Safety shower, eyewash not available when using corrosive gas.

This is an obvious precaution, but one that is sometimes mistakenly ignored when gas is used briefly

and intermittently. Another concern is the working order and accessibility of the safety equipment.

8. Gas mask, breathing apparatus not available when using toxic gas.

See comments for item 7. Toxic, corrosive, or flammable gases should be handled in a hood or

outdoors. Such precautions do NOT replace the need for access to masks or breathing apparatus.

9. Empty and full cylinders stored together.

A compressed gas safety adage tells us that we should "treat every cylinder as if it were full." A

prevailing exception is when the cylinder is in storage. Empties should not be commingled with full

cylinders.

10. Failure to use basic personal protection.

This is probably the most common safety violation of all - but easily remedied, and not at all

excusable. Eye protection (glasses, goggles, or mask) should always be worn when working with

compressed gas. If moving cylinders, gloves and safety shoes should also be worn.

11. The eleventh rule.

The eleventh rule is never to ignore the obvious. We hope these ten points are helpful reminders for

the safe use of compressed gas.

Users of compressed gas should always familiarize themselves with the information

contained in the MSDS for the material being handled. MSDS should be kept on-site

and conveniently accessible. A link to online MSDS is provided at the top of this

email.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- CatalogoDocument56 pagesCatalogoMuhammad awaludin syahNo ratings yet

- Electrical Inspection ProceduresDocument21 pagesElectrical Inspection ProceduresbernardNo ratings yet

- Specialty HeatersDocument40 pagesSpecialty Heaterskvanps_kumarNo ratings yet

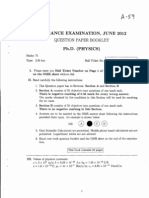

- Y-r ENTRANCE EXAMINATION QUESTION PAPERDocument20 pagesY-r ENTRANCE EXAMINATION QUESTION PAPERkvanps_kumar100% (1)

- Mci/P P L .: 4-V2-2210-GN-MAN-125003Document545 pagesMci/P P L .: 4-V2-2210-GN-MAN-125003Alvaro ArancibiaNo ratings yet

- Question Paper CBSE CLASS 12th Mathematics Sample Paper 2012-13-10Document21 pagesQuestion Paper CBSE CLASS 12th Mathematics Sample Paper 2012-13-10Vishu KukkarNo ratings yet

- Permanent MagnetDocument14 pagesPermanent Magnetkvanps_kumarNo ratings yet

- Maths XII - Chapter Wise Marks DistributionDocument7 pagesMaths XII - Chapter Wise Marks DistributionRishabh JainNo ratings yet

- PHD Physics EntranceDocument18 pagesPHD Physics Entrancekvanps_kumarNo ratings yet

- Quadrupole Mass Spectrometry: The Physics Behind Mass SeparationDocument16 pagesQuadrupole Mass Spectrometry: The Physics Behind Mass Separationkvanps_kumarNo ratings yet

- Maths XII - Chapter Wise Marks DistributionDocument7 pagesMaths XII - Chapter Wise Marks DistributionRishabh JainNo ratings yet

- 2012 General EnglishDocument7 pages2012 General Englishvenkat761No ratings yet

- Math 356 Abstract Algebra Midterm I (Due 5pm February 21st, 2003)Document7 pagesMath 356 Abstract Algebra Midterm I (Due 5pm February 21st, 2003)kvanps_kumarNo ratings yet

- Quadrupole Mass Spectrometry: The Physics Behind Mass SeparationDocument16 pagesQuadrupole Mass Spectrometry: The Physics Behind Mass Separationkvanps_kumarNo ratings yet

- PHD Physics EntranceDocument18 pagesPHD Physics Entrancekvanps_kumarNo ratings yet

- Technical SpecificationDocument20 pagesTechnical Specificationkvanps_kumarNo ratings yet

- Proposed admission qualifications and intake for postgraduate courses 2013-14Document11 pagesProposed admission qualifications and intake for postgraduate courses 2013-14kvanps_kumarNo ratings yet

- Quadrupole Mass Spectrometry: The Physics Behind Mass SeparationDocument16 pagesQuadrupole Mass Spectrometry: The Physics Behind Mass Separationkvanps_kumarNo ratings yet

- Magnet Guide & Tutorial: For More Information Please ContactDocument38 pagesMagnet Guide & Tutorial: For More Information Please ContactRiadh TarkhaniNo ratings yet

- IRCTC - Tatkal New RulesDocument3 pagesIRCTC - Tatkal New Ruleskvanps_kumarNo ratings yet

- Solving Process Problems at The Molecular Flux LevelDocument23 pagesSolving Process Problems at The Molecular Flux Levelkvanps_kumarNo ratings yet

- Why Are Trees ImportantDocument5 pagesWhy Are Trees Importantkvanps_kumarNo ratings yet

- Palanquin Bearers PoemDocument4 pagesPalanquin Bearers Poemkvanps_kumar100% (1)

- Examples of Image Analysis Using ImageJDocument2 pagesExamples of Image Analysis Using ImageJMarcela Morales GeddaNo ratings yet

- Broucher EditDocument2 pagesBroucher Editkvanps_kumarNo ratings yet

- The Main Door Opens As One Qualify The Joint CSIRDocument3 pagesThe Main Door Opens As One Qualify The Joint CSIRkvanps_kumarNo ratings yet

- Hydrogen Diffusion in MetalsDocument2 pagesHydrogen Diffusion in Metalskvanps_kumarNo ratings yet

- Ch. 28 Magnetic Field: Text: Fundamentals of Physics (8 Ed.) by Halliday, Resnick, WalkerDocument27 pagesCh. 28 Magnetic Field: Text: Fundamentals of Physics (8 Ed.) by Halliday, Resnick, Walkerkvanps_kumarNo ratings yet

- School Supply Listing Sy 2023-24Document1 pageSchool Supply Listing Sy 2023-24api-242315971No ratings yet

- ) Perational Vlaintena, Nce Manual: I UGRK SeriesDocument22 pages) Perational Vlaintena, Nce Manual: I UGRK Seriessharan kommiNo ratings yet

- KNX td002 - en PDocument184 pagesKNX td002 - en PNelsonNo ratings yet

- Band-It Tool Specifications: Item Minimum SpecificationDocument1 pageBand-It Tool Specifications: Item Minimum SpecificationikchikovaNo ratings yet

- Serelo Sunglasses Brochure 09 E-MailDocument17 pagesSerelo Sunglasses Brochure 09 E-MailSam Abuel100% (2)

- Manual de Instalación Estructura de LastreDocument8 pagesManual de Instalación Estructura de LastreFabian GarretaNo ratings yet

- Casio CD-311s SMDocument52 pagesCasio CD-311s SMClaudio Hector ArrosaNo ratings yet

- Appendix BDocument23 pagesAppendix BAngel Borbon GabaldonNo ratings yet

- The Tool MakerDocument4 pagesThe Tool MakerRitesh YadavNo ratings yet

- Input, Output Devices - AssignmentDocument16 pagesInput, Output Devices - AssignmentZacardious DhanrajNo ratings yet

- JP L250C7C OmDocument30 pagesJP L250C7C OmEdduis ArrietaNo ratings yet

- ATX Power Supply Pinout TablesDocument4 pagesATX Power Supply Pinout TablesElectrical EEENo ratings yet

- Mlks10haricipanoDocument3 pagesMlks10haricipanoNour BenNo ratings yet

- Listado de SuminsitrosDocument1 pageListado de SuminsitrosArbey GonzalezNo ratings yet

- 688 Level Switch For Pressure Vessels Up To 2000 Psig: SeriesDocument2 pages688 Level Switch For Pressure Vessels Up To 2000 Psig: SeriesDante Cabrera GuzmanNo ratings yet

- Research Work #4 (PEC)Document25 pagesResearch Work #4 (PEC)Tin VillalbaNo ratings yet

- Juki MS-26Document11 pagesJuki MS-26Richard AquinoNo ratings yet

- ANSI Device Numbers 2022Document7 pagesANSI Device Numbers 2022ajitkalel1986No ratings yet

- What is a compass or circular planeDocument3 pagesWhat is a compass or circular planeedeoliveiralima4185No ratings yet

- Universal Bugomatic Bro 03 21Document4 pagesUniversal Bugomatic Bro 03 21Victor PATIÑONo ratings yet

- Rfc35N Nmea Compass: Installation and CalibrationDocument12 pagesRfc35N Nmea Compass: Installation and CalibrationmakenodimaNo ratings yet

- 3 Pole ATS White Paper - ToPPPDocument4 pages3 Pole ATS White Paper - ToPPPAdhyartha KerafNo ratings yet

- Skid Steer Loader Master Part ManualDocument39 pagesSkid Steer Loader Master Part Manualkeno73No ratings yet

- UNITED Y8PCugjDocument2 pagesUNITED Y8PCugjFadhilNo ratings yet

- MTL901 ESD Link (ATEX) : Instruction ManualDocument24 pagesMTL901 ESD Link (ATEX) : Instruction ManualAndy Kong KingNo ratings yet

- Abubakar Design and Construction of LampDocument7 pagesAbubakar Design and Construction of LampBatiyaNo ratings yet

- Manual Montaje Mural Su-Pw2 Sony TVDocument32 pagesManual Montaje Mural Su-Pw2 Sony TVQuinoGallardoGomezNo ratings yet