Professional Documents

Culture Documents

Fit A Bath and Wash Basin

Uploaded by

usamasheriff1Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fit A Bath and Wash Basin

Uploaded by

usamasheriff1Copyright:

Available Formats

FIT A BATH AND WASH

BASIN

A good knowledge of plumbing techniques and some

understanding of building construction would be an

advantage.

Be careful not to strain yourself whilst manoeuvring the

appliances. Ensure that all metal pipes and fittings are cross-

bonded with 6mm squared sheathed earthing wire.

Protective goggles, gloves and ear defenders may be needed

for some operations.

Changing your bath and washbasin gives you the ideal

opportunity to re-style your whole bathroom.

Plan your new installation thoroughly. If you only have one

bathroom in the house, the work must be carried out

efficiently to minimise the time that the amenities are

unavailable. If you have any concerns, ask professionals to

carry out the work. The methods described here refer to the

separate removal and installation of each fitting. However, in

practice it is more convenient to strip out the room first,

then carry out the new installation.

2 - Preparing the room

Clear the room of all storage units and fixtures, such as

towel rails and blinds. If the bath has a shower screen,

remove it. Take up carpeting, but leave sheet vinyl in place

until all the fittings have been removed. If you plan to install

new lighting or an extractor fan, make the alterations at this

stage.

The bath and basin are connected to the plumbing by water-

supply pipes and wastepipes. These pipes must be

disconnected before the fittings can be removed. First shut

off the hot and cold supply.

If your house has old lead pipes, make the most of this

opportunity and ask a plumber to replace them with copper

or plastic plumbing.

3 - Removing the old bath

Remove the bath panels to reveal the plumbing. Open the

taps to drain them, then disconnect the supply pipes. Place a

shallow bowl under the bath trap to catch the water, then

disconnect the wastepipe.

If the connectors cannot be unscrewed, saw through the

pipes. Also, cut through the old bath overflow.

If the bath has been sealed against the wall with flexible

sealant, cut through this with a craft knife. Pull the bath out

from the walls. If the bath has adjustable feet, it may help

to lower these first.

Unless a heavy cast-iron bath is worth salvaging, it is easier

to move it by first breaking it up into manageable pieces.

Cover the bath with an old blanket and strike it with a club

hammer. Protective goggles, gloves and ear defenders

should be worn during this operation.

Once the bath has been removed, extract the old overflow

pipe from the wall and repair the hole with mortar and

plaster. Also, remove old wall tiles and prepare the walls for

retiling.

When applying new wall tiles, measure out and cut a groove

in the plaster to inset the rim of the bath. This ensures a

good waterproof joint.

4 - Fitting the new bath

Before fixing a new bath or its panels, remove the protective

covering and check thoroughly for damage or colour faults. Any

claims made after the bath is fitted will not be accepted by the

manufacturer.

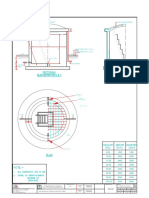

To add stiffness, most moulded plastic baths have a baseboard

bonded underneath and a wooden frame bonded beneath the

rim. A cradle kit is usually supplied for self assembly. Following

the manufacturer's instructions, fit the cradle legs to the frame

and baseboard. Also fit the centre support leg, if supplied (1).

Attach the wall-fixing brackets to the underside of the rim-

support frame. Fit hand grip(s) to the rim if supplied.

Set the bath upright and fit individual hot and cold taps or a

mixer-tap set. Attach flexible connecting pipes to the tap tails -

this allows for any misalignment when you connect up with the

supply pipes.

Fit the overflow outlet and waste

outlet into the bath. Connect

them with a combined waste-

and-overflow unit that

incorporates a deep-seal trap

(2).

Place the bath in the required position and adjust the screw feet

to set the height and level of the rim so that it can

accommodate the side panels.

When everything is in place, screw the brackets to the wall and

the feet to the floor. Connect the supply and wastepipes (see

below).

Fit the bath panels according to

the manufacturer's instructions

(3). Use a fine-toothed saw to

shape the panels around pipes or

to fit the skirting.

If you are constructing your own bath panel, make it easy to

remove, so that it provides simple access to plumbing and some

useful long-term storage.

Once the walls have been tiled

(4), waterproof the joint around

the rim of the bath with silicone

sealant.

After using an acrylic bath, clean it while it is still warm, using

soapy water. Then wipe it dry. Do not use organic solvents or

abrasive cleaners.

5 - Fitting a pedestal wash basin

Disconnect the supply pipes from the old taps, using a

cranked spanner to reach behind the basin. If this proves

difficult, cut the pipes at a convenient level for connecting

with the new flexible tap connectors.

Unscrew the old basin fixings and lift clear. Remove

supporting brackets from the wall or unscrew the pedestal

base from the floor.

Place the new basin on its pedestal base and position it

against the wall. Mark the fixing points on the wall and floor.

Drill and fit wall plugs on the

marks (5). Just drill pilot

holes for the screws when

fixing to a wooden floor.

Make any alterations to the 15mm (1/2in) supply pipes so

they will be neatly concealed by the pedestal. Fit miniature

in-line isolating valves for future servicing.

Fit new taps and a waste outlet in the basin. Check that the

tap spouts are correctly aligned. Do not over-tighten the

back nuts. Fit flexible connection pipes to the tap tails. Then

fit a 32mm (1.25in) waste trap to the waste outlet.

When fitting taps to a rim made from a thin material (such

as pressed steel), use a 'top-hat' spacer fitting placed under

the back nut (6).

Place the basin on its

pedestal and fix it in place

with brass screws. Connect

the trap to the existing 32mm

(1.25in) wastepipe. If a new

waste pipe is required in a

different position, drill a

clearance hole through the

wall with a masonry core

drill, and install a new pipe

run (see next section).

Connect the flexible tap connectors to the appropriate hot

and cold supplies. Follow the manufacturer's instructions, as

some taps require check valves to be fitted. Turn on the

water supply to test the installation.

Unless you are experienced with electrical installations, ask

an electrician to fit supplementary bonding to all metal

fittings and pipework.

6 - Supply pipes and wastepipes

Baths are fitted with 22mm (3/4in) taps and supply pipes;

basins with 12mm (1/2in) taps and pipes. Monobloc mixer

taps usually have 10mm (3/8in) tails, and a reducer is

needed when connecting them to standard pipework.

You can use copper supply pipes, connected with soldered or

compression joints, or plastic pipes that are usually

connected with push-fit joints. Adapter couplings are

available to join pipes of different materials and sizes.

Always follow tap manufacturers' instructions when

connecting supply pipes, as some tap installations require

check valves to be fitted.

Plastic pipe is used for wastes: 40mm (1.5in) pipe for baths;

32mm (1.25in) for washbasins; and 21mm (3/4in) for

overflows. Solvent-welded joints, push-fit connectors or

compression joints are used to join plastic wastepipes.

Unless you are connecting to

existing wastepipes, new

bath and basin wastes should

be connected to a soil-stack

with boss fittings (7).

If a trap cannot be removed

to provide access to the

wastepipe, include a rodding-

eye fitting so that any

blockages can be cleared (8).

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Plumbing Notes:: Plumbing Legend and SymbolsDocument1 pagePlumbing Notes:: Plumbing Legend and SymbolsRobee Ocampo100% (1)

- Mini Lathe Dismantling and Reassembly Guide PDFDocument18 pagesMini Lathe Dismantling and Reassembly Guide PDFkennkki100% (4)

- BakerDocument4 pagesBakerWilliam EvansNo ratings yet

- Fresh Vegetable Storage For HomeownersDocument2 pagesFresh Vegetable Storage For HomeownersSharad Bhutoria100% (1)

- Fresh Vegetable Storage For HomeownersDocument2 pagesFresh Vegetable Storage For HomeownersSharad Bhutoria100% (1)

- Torque Calculation For HT BoltsDocument2 pagesTorque Calculation For HT BoltsMadhava PadiyarNo ratings yet

- Каталог Shantui Sd16f EngDocument312 pagesКаталог Shantui Sd16f EngMax SashikhinNo ratings yet

- Dr. Bhojraj DwivediDocument13 pagesDr. Bhojraj Dwivedimohosinawolia29% (7)

- Dasa Lord TransitDocument10 pagesDasa Lord TransitSamar VaishampayanNo ratings yet

- Fox 8-20B V00R00 - Catalogo de PeçasDocument193 pagesFox 8-20B V00R00 - Catalogo de PeçasBritacet PedreiraNo ratings yet

- Improvised Explosive Device (IED) AwarenessDocument6 pagesImprovised Explosive Device (IED) AwarenessZefren Botilla100% (1)

- Format For Estimate of Distribution Transformers Part-ADocument6 pagesFormat For Estimate of Distribution Transformers Part-AKumuda SahuNo ratings yet

- Format For Estimate of Distribution Transformers Part-ADocument6 pagesFormat For Estimate of Distribution Transformers Part-AKumuda SahuNo ratings yet

- Earworm On Sweet CornDocument4 pagesEarworm On Sweet CornSharad BhutoriaNo ratings yet

- Exterior PaintingDocument4 pagesExterior PaintingApollyonNo ratings yet

- Flowers. Rose Care and PlantingDocument2 pagesFlowers. Rose Care and PlantingAlexandros PefanisNo ratings yet

- Fast Growing TreesDocument2 pagesFast Growing TreesFlorin IonescuNo ratings yet

- Evergreen Trees and ShrubsDocument4 pagesEvergreen Trees and ShrubsSanto Fransiscus AveriuesNo ratings yet

- Fertilizing Landscape Trees (SP548)Document4 pagesFertilizing Landscape Trees (SP548)dvskiwiNo ratings yet

- Earworm On Sweet CornDocument4 pagesEarworm On Sweet CornSharad BhutoriaNo ratings yet

- Western Electricity Supply Company of Orissa LimitedDocument1 pageWestern Electricity Supply Company of Orissa LimitedKumuda SahuNo ratings yet

- AstrologyDocument64 pagesAstrologyKumuda SahuNo ratings yet

- Uma Shambu HoraDocument10 pagesUma Shambu Horas1234tNo ratings yet

- Break Pressure Tank (Typical RCC Reservior)Document1 pageBreak Pressure Tank (Typical RCC Reservior)Madhu KurmiNo ratings yet

- S08 Diesel Power PackDocument115 pagesS08 Diesel Power PackPeetNo ratings yet

- Band Saw G5018WA: Features of Metal Band Sawing Machine From Hoton MachineryDocument1 pageBand Saw G5018WA: Features of Metal Band Sawing Machine From Hoton MachineryMantención FastpackNo ratings yet

- Cleanouts 2020Document17 pagesCleanouts 2020CliffordJamesSabiganNo ratings yet

- Metric Flat Washers Dimensions & Specs - AFT FastenersDocument1 pageMetric Flat Washers Dimensions & Specs - AFT FastenersMebin CherianNo ratings yet

- Eteeap: Gemini Criminology and Training CenterDocument4 pagesEteeap: Gemini Criminology and Training CenterHara kendall gonoNo ratings yet

- KM-2810 DP-110: Parts ListDocument47 pagesKM-2810 DP-110: Parts ListDuplicar Soluções GráficasNo ratings yet

- Change in Muzzle Velocity for Small Arms Due to Propellant Temperature VariationsDocument31 pagesChange in Muzzle Velocity for Small Arms Due to Propellant Temperature Variationsrick.mccort2766No ratings yet

- Alteryx ReferDocument16 pagesAlteryx ReferNitinKumarNo ratings yet

- Ethio Telecom HQ Building Fire Suppression ValvesDocument6 pagesEthio Telecom HQ Building Fire Suppression ValvesdiribaNo ratings yet

- Suport Sticle Vin PDFDocument5 pagesSuport Sticle Vin PDFLavinia LupulescuNo ratings yet

- SingerValve 106 PR UL Fire Valve Sheet Product PagesDocument2 pagesSingerValve 106 PR UL Fire Valve Sheet Product PagesAhlan kpNo ratings yet

- Troubleshooting - Dp50Document17 pagesTroubleshooting - Dp50Julinho Otiniano MauricioNo ratings yet

- M215 Va11 PDFDocument3 pagesM215 Va11 PDFPéter SpiegelbergerNo ratings yet

- CX900 GrinderDocument13 pagesCX900 GrindermarkantonybrownNo ratings yet

- Nivaka Office Furniture 2024Document31 pagesNivaka Office Furniture 2024miteshnagpal19No ratings yet

- Extracts of SS636Document2 pagesExtracts of SS636alvinchuanNo ratings yet

- US97821Document7 pagesUS97821ReggieNo ratings yet

- Two-Post Lift Model:210C 210CXDocument36 pagesTwo-Post Lift Model:210C 210CXventitapostNo ratings yet

- GBH 3 28 Dre Professional Manual 144832Document225 pagesGBH 3 28 Dre Professional Manual 144832Gomez GomezNo ratings yet

- 7.5m MMCD DavitDocument1 page7.5m MMCD Davitduda_sekaNo ratings yet

- Standard circlip dimensionsDocument1 pageStandard circlip dimensionsPrasad GhogareNo ratings yet

- Manual Mounting Type Dvc5010 Digital Valve Controllers On Fisher Type 657 667 Actuat en 141856Document6 pagesManual Mounting Type Dvc5010 Digital Valve Controllers On Fisher Type 657 667 Actuat en 141856hocine1No ratings yet