Professional Documents

Culture Documents

Interlloy Grade 8620 Case Hardening Steel

Uploaded by

ajitchavan2150Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Interlloy Grade 8620 Case Hardening Steel

Uploaded by

ajitchavan2150Copyright:

Available Formats

Download a pdf version of this data sheet for printing and future reference.

(right click and select save to disk)

8620 Case Hardening Steel

8620 is a low nickel - chromium - molybdenum medium hardenability, case hardening (carburizing) steel, generally supplied

in the as rolled condition with a maximum brinell hardness of 280 (Rc30).

Characterised by good core strength and toughness in small to medium sections with case hardness up to Rc62 when

carburized, hardened and tempered.

8620 can also be used (uncarburised) as a high tensile steel, which when suitably hardened and tempered can be utilized

for various applications requiring good tensile strength and reasonable toughness.

Pre hardened and tempered (uncarburized) 8620 can be further surface hardened by nitriding but will not respond

satisfactorily to flame or induction hardening due to its low carbon content.

8620 (carburized) is used extensively by all industry sectors for light to medium stressed components and shafts requiring

high surface wear resistance with reasonable core strength and impact properties.

Typical uses are: Arbors, Bearings, Bushings, Cam Shafts, Differential Pinions, Guide Pins, King Pins, Pistons Pins, Splined

Shafts, Ratchets, Sleeves etc..

Colour Code Stocked Sizes Rounds 10mm to 260 mm Diameter

Bar Finish Peeled, Turned

Yellow or Hot Rolled

(Bar end)

Related Specifications

Australia AS 1444-1996-8620/8620H

Germany W.Nr 1.6523 DIN 21NiCrMo2

Great Britain BS970: PART 3: 1991 805 M20

BS970: 1955 - EN362

Japan JISG 4052 SNCM 220H

U.S.A. SAE 8620 AISI 8620

ASTM A29/A29M 1991 8620

UNS G86200

Chemical Composition Min. % Max. %

Carbon 0.17 0.23

Silicon 0.10 0.40

Manganese 0.60 0.95

Nickel 0.35 0.75

Chromium 0.35 0.75

Molybdenum 0.15 0.25

Phosphorous 0 0.04

Sulphur 0 0.04

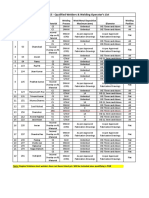

Typical Mechanical Properties For Core - Carburised and Oil Quenched at 840 o C.

Tensile Yield Elongation on Charpy Hardness

Section Strength Strength 5.65 Impact

Size Mpa Mpa % J HB Rc

mm

Min Max Min Min Min Min Max Min Max

11 980 1270 785 9 41 290 375 31 41

30 780 1080 590 10 41 235 320 23 35

63 690 930 490 11 205 275 16 29

Typical Mechanical Properties - As Rolled

Tensile Yield Elongation on Hardness

Strength Strength 5.65

Mpa Mpa % HB Rc

820 590 22 240 24

Typical Mechanical Properties - Water Quenched at 830 o C and Tempered as Indicated *

Tempering Tensile Yield Elongation on Izod Hardness

Temperature Strength Strength 5.65 Impact

oC Mpa Mpa % J HB Rc

205 1050 765 18 80 311 34

425 930 800 20 110 275 29

650 700 556 30 140 207 16

*Section Size 25 mm

Can be used in the Hardened and Tempered (uncarburised) condition for shock resisting shafts and parts with tensile

strengths up to 800 Mpa, plus reasonable toughness possible in sections up to 100 mm.

8620 is however generally used in the carburised condition with heat treatment details as follows.

Forging

Heat to 1150 o C and hold until temperature is uniform throughout the section. Soaking time at forging temperature should

be as short as possible to avoid heavy scaling and excessive grain growth. This will vary depending on furnace conditions

but 15 minutes per 25 mm of section may be used as a guide.

Do not forge below 850 o C.

Following completion of forging operation, work piece should be cooled as slowly as possible in sand or dry lime etc.

Note: Case hardening steels due to their low carbon content are less susceptible to cracking than medium or high carbon

steels, and may therefore be heated and cooled more rapidly.

Heat Treatment

Annealing

Heat to 820 o C - 850 o C, hold until temperature is uniform throughout the section and cool in furnace.

Carburizing

Pack, salt or gas carburize at 900 o C - 925 o C, holding for sufficient time to develop the required case depth and carbon

content, followed by a suitable hardening and tempering cycle to optimise case and core properties.

Hardening

Refer Refining & Hardening.

Nitriding

8620 suitably hardened and tempered (uncarburised) will respond to nitriding giving a surface hardness up to Rc 60.

Nitriding is carried out at 490 o C - 530 o C followed by slow cooling (no quench), reducing the problem of distortion.

During the initial heat treatment the tempering temperature employed should be higher than the nitriding temperature.

N.B. The relatively low nickel content in 8620 should not greatly influence the nitriding cycle.

Normalizing

Heat to 900 o C - 925 o C, hold until temperature is uniform throughout the section. Soak for 10 - 15 minutes and cool in

still air.

Refining & Hardening

Core Refine

Slow cool from carburizing temperature and re-heat to 840 o C - 870 o C, hold until temperature is uniform throughout the

section, quench as required in water, oil or air cool.

Case Hardening

Following core refining, re-heat to 780 o C - 820 o C, hold until temperature is uniform throughout the section, and quench

in oil.

Temper immediately while still hand warm.

Single Refine*

Direct Quench: Cool from carburizing temperature to 820 o C - 840 o C, hold until temperature is uniform throughout the

section. Quench in oil. Temper immediately while still hand warm.

Or: Cool from carburizing temperature to room temperature, re-heat to 820 o C - 840 o C and hold until

temperature is uniform throughout the section and quench in oil.

Temper immediately.

*Suitable for fine grained steels only.

Stress Relieving

Heat to 630 o C - 650 o C, hold until temperature is uniform throughout the section, soak for 1 hour per 25 mm section, and

cool in still air.

Tempering

Heat to 150 o C - 200 o C as required, hold until temperature is uniform throughout the section, soak for 1 - 2 hours per 25

mm of section, and cool in still air.

N.B.Tempering will improve the toughness of both case and core, with only a slight reduction in core strength and case

hardness. It will also reduce the susceptibility of the case to grinding cracks.

Notes on Heat Treatment

Heating temperatures, rate of heating, cooling and soaking times will vary due to factors such as work piece size/shape

also furnace type employed, quenching medium and work piece transfer facilities etc..

Please consult your heat treater for best results.

Machining

8620 in the as rolled as supplied condition, has very good machinability and all operations such as turning, drilling, milling

and tapping etc. can be carried out satisfactorily as per machine manufacturers recommendations for suitable tool type -

feeds and speeds.

Welding

8620 is readily weldable in the as rolled as supplied condition. Following welding, the work piece immediately upon cooling

to hand warm should be stress relieved at 630 o C - 650 o C if possible.

N.B. Welding in the carburized and heat treated condition is not recommended.

Welding Procedure

Welding of 8620 should always be carried out using low hydrogen electrodes - please consult your welding consumables

supplier.

Suggested pre-heat temperature

Section oC

40 mm 25

50 mm 40

75 mm 100

150 mm 150

Post Welding

Allow to cool in still air. Alternatively cover in sand or dry lime etc..

Interlloy believes the information provided is accurate and reliable. However no warranty of accuracy, completeness or

reliability is given, nor will any responsibility be taken for errors or omissions.

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- (17CrNiMo6) 4317 Case Hardening SteelDocument3 pages(17CrNiMo6) 4317 Case Hardening Steelazhar mohammedNo ratings yet

- 005-Interlloy Grade 4340 Hardened and Tempered BarDocument3 pages005-Interlloy Grade 4340 Hardened and Tempered BarDhruv MehtaNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- 420 Martensitic Stainless Steel BarDocument4 pages420 Martensitic Stainless Steel BarAHMED FATHINo ratings yet

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- 8620 Case Hardening Steel - Interlloy - Engineering Steels + AlloysDocument4 pages8620 Case Hardening Steel - Interlloy - Engineering Steels + Alloysankit7588No ratings yet

- Werkstoff 1.5217 (20MnV6)Document2 pagesWerkstoff 1.5217 (20MnV6)alextentwentyNo ratings yet

- 4140 High Tensile Steel PDFDocument3 pages4140 High Tensile Steel PDFFikri SiplhoNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- CaseHard AISI8620Document2 pagesCaseHard AISI8620Anonymous B3I6zYNhqdNo ratings yet

- Interlloy Grade 1045 Carbon Steel BarDocument3 pagesInterlloy Grade 1045 Carbon Steel BarPRASHANT KANTENo ratings yet

- 1022 Carbon Steel Bar PDFDocument3 pages1022 Carbon Steel Bar PDFjeyakumarNo ratings yet

- 20Mncr5: Steel GradeDocument4 pages20Mncr5: Steel GradeAhmad ShujaNo ratings yet

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6Jonas AnderssonNo ratings yet

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6Krzysztof WrzeszczNo ratings yet

- 90 MN CR V8Document1 page90 MN CR V8arunajay724No ratings yet

- Case Hardening Steel A Is I 8620Document2 pagesCase Hardening Steel A Is I 8620fahriNo ratings yet

- 20 MN CR 5Document2 pages20 MN CR 5sansmgNo ratings yet

- Case Hardening Alloy Steel Bar 6587Document3 pagesCase Hardening Alloy Steel Bar 6587CelsoNo ratings yet

- STAINLESS STEEL 431 / S43100/ 1.4057 SS 431: AvailabilityDocument3 pagesSTAINLESS STEEL 431 / S43100/ 1.4057 SS 431: Availabilitylir mNo ratings yet

- 16MnCr5 SpesifikasiDocument2 pages16MnCr5 SpesifikasibagusalienNo ratings yet

- kme_STOL76_C19010_enDocument1 pagekme_STOL76_C19010_enMattia Terri TerrandoNo ratings yet

- Quality 102Cr6: Lucefin GroupDocument1 pageQuality 102Cr6: Lucefin GroupPaulo ZechinNo ratings yet

- 16 Ni CR 11Document2 pages16 Ni CR 11ceca nikolicNo ratings yet

- 1045-Bright-Carbon-Steel-Bar (Les Différentes Traitements Thermiques, Recuit de Normalisation)Document3 pages1045-Bright-Carbon-Steel-Bar (Les Différentes Traitements Thermiques, Recuit de Normalisation)Mouna KallelNo ratings yet

- Quality 16Mncr5: Lucefin GroupDocument2 pagesQuality 16Mncr5: Lucefin GroupPrasadNo ratings yet

- 1816 Nicr 4Document2 pages1816 Nicr 4Rebekah WilsonNo ratings yet

- Jis C3771Document2 pagesJis C3771bkprodhNo ratings yet

- 42 CR Mo 4Document3 pages42 CR Mo 4lucasNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data Sheetreza amiriniaNo ratings yet

- Quality C10E: Lucefin GroupDocument3 pagesQuality C10E: Lucefin Grouptuananh638No ratings yet

- Quality C10E: Lucefin GroupDocument3 pagesQuality C10E: Lucefin Grouptuananh638No ratings yet

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6InaamNo ratings yet

- Technical Specifications for HS 10-4-3-10 High Speed SteelDocument1 pageTechnical Specifications for HS 10-4-3-10 High Speed Steelmarko9292No ratings yet

- AISI 440 Martensit PDFDocument4 pagesAISI 440 Martensit PDFJimmyVargasNo ratings yet

- 1.6523 - 20NiCrMo2-2 - SAE 8620 - 21NiCrMo2 - SS-2506 - SFS-506 - Datasheet - 1Document2 pages1.6523 - 20NiCrMo2-2 - SAE 8620 - 21NiCrMo2 - SS-2506 - SFS-506 - Datasheet - 1javadmohammadiNo ratings yet

- 708M40 Alloy Steel: Form of SupplyDocument3 pages708M40 Alloy Steel: Form of SupplyLUCIA MAÑAYNo ratings yet

- Tempering Conditions For 30CrNiMo8Document2 pagesTempering Conditions For 30CrNiMo8madyeNo ratings yet

- Material data sheet for steel grades SB-C45, 047 and Imatra 4MDocument2 pagesMaterial data sheet for steel grades SB-C45, 047 and Imatra 4Mabu asiyahNo ratings yet

- Datasheet Sandvik Saf 2205 en PDFDocument12 pagesDatasheet Sandvik Saf 2205 en PDFYuriy NesterovNo ratings yet

- CR Mo 4Document2 pagesCR Mo 4Mohsen ParpinchiNo ratings yet

- Sandvik 254 SMO Datasheet for Seamless Tube and PipeDocument9 pagesSandvik 254 SMO Datasheet for Seamless Tube and PipeReadersmoNo ratings yet

- 34crnimo6: Steel GradeDocument4 pages34crnimo6: Steel GradeAndrea FerrerNo ratings yet

- 41 CR 4Document2 pages41 CR 4Jhon ChitNo ratings yet

- Cusn8 Industrial RolledDocument4 pagesCusn8 Industrial RolledPrakash MakadiaNo ratings yet

- Datasheet Sandvik Saf 2507 en PDFDocument15 pagesDatasheet Sandvik Saf 2507 en PDFShesharam Chouhan100% (1)

- 1.7225 en PDFDocument2 pages1.7225 en PDFTheodoros AtheridisNo ratings yet

- 1 3243hs652513 PDFDocument1 page1 3243hs652513 PDFmarko9292No ratings yet

- ATA Heet: Marvac 250 VIM-VARDocument2 pagesATA Heet: Marvac 250 VIM-VARspibluNo ratings yet

- Join & Repair High-Carbon Steels with NiCr HLSDocument1 pageJoin & Repair High-Carbon Steels with NiCr HLSwalter091011No ratings yet

- 102 CR 6Document2 pages102 CR 6ceca nikolicNo ratings yet

- Quality 40nicrmov16 Ku: Lucefin GroupDocument1 pageQuality 40nicrmov16 Ku: Lucefin Groupkbwoniu123No ratings yet

- CASE HARDENING STEEL 8620Document3 pagesCASE HARDENING STEEL 8620kumarsathish2009No ratings yet

- 41 CR 4Document3 pages41 CR 4AHMED FATHINo ratings yet

- Fe-C Phase DiagramDocument34 pagesFe-C Phase DiagramYoung-long Choi100% (1)

- Designing an Activated Antiroll Tank System for Ship StabilizationDocument10 pagesDesigning an Activated Antiroll Tank System for Ship StabilizationkamnooNo ratings yet

- Crack DetectionDocument12 pagesCrack Detectionajitchavan2150No ratings yet

- 40% Offset Frontal Bumper Beam Crash Test Analysis of A Car With Ansys Ls-Dyna & Ls-PrepostDocument20 pages40% Offset Frontal Bumper Beam Crash Test Analysis of A Car With Ansys Ls-Dyna & Ls-Prepostajitchavan2150No ratings yet

- HammersDocument5 pagesHammersBenedictus Torres MoldesNo ratings yet

- Forg 1Document20 pagesForg 1danaandrei74No ratings yet

- DRILLING MACHINE SlidesDocument22 pagesDRILLING MACHINE SlidesNishchay pratapNo ratings yet

- FCAW Welder GuideDocument17 pagesFCAW Welder GuideMano HaranNo ratings yet

- Minimum Thread Engagement Formula and Calculation ISODocument2 pagesMinimum Thread Engagement Formula and Calculation ISOmohanjatinderNo ratings yet

- Study of factors affecting burr formation in sheet metal cuttingDocument7 pagesStudy of factors affecting burr formation in sheet metal cuttingniteshNo ratings yet

- Fasteners WeightDocument4 pagesFasteners Weightpbp2956No ratings yet

- Standard Pitch Diameter ChartDocument1 pageStandard Pitch Diameter ChartKiran PadalaNo ratings yet

- A Report On Industrial Visit at Nandratan Foundry Engineering Works-SarigamDocument8 pagesA Report On Industrial Visit at Nandratan Foundry Engineering Works-SarigamNiket SurawaseNo ratings yet

- Guide PostDocument1 pageGuide PostSeptian Tri NugrohoNo ratings yet

- ME2022 Manufacturing Engineering IDocument4 pagesME2022 Manufacturing Engineering IAmal SenevirathneNo ratings yet

- Gmaw WQTDocument23 pagesGmaw WQTDera LesmanaNo ratings yet

- XAR 400 (WB 703) EnglischDocument3 pagesXAR 400 (WB 703) Englischgheoda8926No ratings yet

- TLE-EIM Grade9 Module Quarter1 Week3and4Document11 pagesTLE-EIM Grade9 Module Quarter1 Week3and4Renzo zorillaNo ratings yet

- C55EDocument2 pagesC55EniranjanbmazireNo ratings yet

- Whose Lathe Essay ThesisDocument6 pagesWhose Lathe Essay ThesisBuyEssaysForCollegeBaltimore100% (2)

- How to Design Strippers in 15 Characters or LessDocument33 pagesHow to Design Strippers in 15 Characters or Lessmahdi sakhaeeNo ratings yet

- Adding and Altering: Surface FinishingDocument11 pagesAdding and Altering: Surface FinishingVijay Raj PuniaNo ratings yet

- Department of Civil Engineering S.Y. B.Tech Academic Year 2020 - 21 Sem - IIDocument22 pagesDepartment of Civil Engineering S.Y. B.Tech Academic Year 2020 - 21 Sem - IIswarup babalsureNo ratings yet

- AISI 4130 Alloy SteelDocument2 pagesAISI 4130 Alloy SteelKandeepanNo ratings yet

- Elding Rocedure Pecification: 7200-HDPE Butt WeldDocument2 pagesElding Rocedure Pecification: 7200-HDPE Butt Weldsamer8saifNo ratings yet

- Drill Press Safety Rules 6-15-09Document1 pageDrill Press Safety Rules 6-15-09Webindex BlogFunNo ratings yet

- 10 Types of Fasteners ExplainedDocument16 pages10 Types of Fasteners Explainedrecep1No ratings yet

- Gear Grinding Processing Developed for High-Precision Gear ManufacturingDocument6 pagesGear Grinding Processing Developed for High-Precision Gear ManufacturingvengadeshNo ratings yet

- 1255 - Qualified Welder ListDocument1 page1255 - Qualified Welder ListattaullaNo ratings yet

- Drill Size Chart For Number and Letter Gauges: Gauge Inch MM Gauge Inch MM Gauge Inch MMDocument3 pagesDrill Size Chart For Number and Letter Gauges: Gauge Inch MM Gauge Inch MM Gauge Inch MMMikeNo ratings yet

- Programming cycles for drilling, tapping and deep hole operationsDocument11 pagesProgramming cycles for drilling, tapping and deep hole operationsMirnes FejzicNo ratings yet

- Turning & Related OperationsDocument30 pagesTurning & Related OperationsIzi100% (6)

- Standard Operation Procedure (Cage Forming)Document7 pagesStandard Operation Procedure (Cage Forming)Mohd HaiqalNo ratings yet

- Bs 84 1956Document20 pagesBs 84 1956sunny guptaNo ratings yet