Professional Documents

Culture Documents

Choice Choice Normal Module

Uploaded by

149933Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Choice Choice Normal Module

Uploaded by

149933Copyright:

Available Formats

Choice Choice

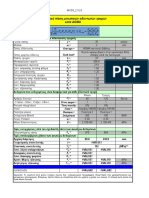

Normal Module INPUTS in Blue Cells

1 2

1 1.25 1 Normal module ( selected from table) mn 6

1.25 1.375 2 Nomuber of teeth on pinion gear Z1 17

1.5 1.75 3 Number of teeth on wheel gear Z2 90

2 2.25 4 Pressure Angle αn 20

Recommended 2.5 2.75

series as per 5 Helix angle β 13.75

IS:2535 Incase 3 3.5

of helical and 4 4.5

herring bone 6 Centre Distance a 335

gears these 5 5.5

moduks 6 6.5 7 Addendum correction factor (x = x1+x2)

represent the

"normal module" 8 7 for [x1 = x2 = 0] select ==> 1

X 3

As far as 10 9 for [x1 + x2 = 0] select ==> 2

possible choose

from Choice 1, 12 11 for [x1 + x2 ≠ 0 ] select ==> 3

module 6.5 16 14 Pinion

should be

avoided 20 18 1 Type Of Gear - HELICAL

25 22 2 Normal Module mn 6

32 28 3 Number of teeth z 17

40 36 4 Basic Rack - IS2535-78

50 45 5 Pressure Angle αn 20°

Tooth Depth 7 6 Helix Angle β 13° 45' "

Put the measured module 7 Direction of Helix - LH

value of tooth depth 3.11

= 8 Referance Dia d 105.009

9 Tip Dia of the Gear da 121.927

10 Radial run-out ↑ 0.053

11 Base Circle Dia db 98.333

12 Addendum modification coefficient x 0.467

13 Quality grade as per IS:3681-95 - 8

14 Centre Distance a 335.0

-

15 Chordal tooth thickness Sn 11.445

16 Chordal height h-a 8.718

17 Contant Chord S-c

10.122

-

18 Contant Height hc 6.617

Is there bearing on Pinion gear?

Yes -- 1 0 Is there any butting geometry on

No-- 0 the wheel? 2

Y => 1 , N => 2

- 40 40

- ! ! 70

- ! ! Butt pulsation/Perpendicularity = 0.1

Deg Min Sec

Do You want manual selection of X1 ?

13 45 Yes ==> 1 2

No ==> 2

0

Feedback from inputs Select condition from the list for calculation of X1

Pinion Tip Dia = 121.927 for equal sliding velocity select. ==> 1

Wheel Tip Dia = 571.131 for equal contact pressure (at i>2) select ==> 2 3

Center Distance = 332.746 for equal root stress select ==> 3

Wheel The Add Mod Coff X = 0.7902

HELICAL

6

90

IS2535-78

20°

13° 45' "

RH

555.932

571.1311

0.100

520.585

0.4667 0.3235 0.323

8

+/-0.125 335.0 +/-0.125

11.445 11.4507 11.451

8.7182 8.55692 8.557

10.122 9.56994

-0.09 -0.17

-0.17 -0.29

9.570

6.6165 5.85804 5.858

°

Drawing No.: PMM-3083 & PMM-3029

Details of Drawing : -

ref drawing no PMM-3083 & PMM-3029

Pinion Gear

1 Type of Gear HELICAL HELICAL

2 Normal Module mn 6 6

3 No. of Teeth z 17 90

4 Basic Rack - IS2535-78 IS2535-78

5 Pressure Angle a 20° 20°

6 Helix Angle b 13° 45' " 13° 45' "

7 Dirction Of Helix Angle - LH RH

8 Reference Diameter d 105.00935063958 555.931856327209

9 Base Circle Diameter db 98.332736019372 520.585073043734

10 Addendum Modification Cofficient x 0.467 0.323

11 Quality Grade as per IS:3681-95 - 8 8

+/-0.125 +/-0.125

12 Center Distance a

335.0 335.0

-0.09 -0.17

Tooth Thickness on Constant S -c

13 -0.17 -0.29

Chord

10.122 9.570

14 Constant Chord Height hc -

6.617 5.858

15 Tip Dia da 121.927 h9 571.131 h9

En 353 (Forged) En 353 (Forged)

16 Material

BS:970-55 BS:970-55

Notes For Pinion

1 Forging shall undergo a reduction of 4:1 (min.)

2 Forging shall be volume Hardened and tempered to 241-270 BHN.

Proof machined blank shall be ultrasonically tested as per BSPS:75022001395, to

3

Acceptance class - II.

Ovality and taper of surfaces f (brg & Coupling) surface shall not be more than half the

4

respective tolerances specified.

Skew and parallel shift of keyway shall not be more than 0.1 mm and 0.12 mm

5

respectively.

6 Gear teeth shall be hardened and tempered to Rc 58± 2 to a depth of 0.3 to 0.5 mm

The teeth to be cut by pre-hob cutter keeping allowance on thickness, hardened &

7

tempered to the value given and ground to get the requisit thickness as indicated.

8 Pinion shaft to be replaced strictly in pair alongwith its mating Gear.

Notes For Gear

1 Forging shall undergo a reduction of 4:1 (min.) and upset of 2.5:1 (max)

Rest of the points will be same as above

Rest of the points will be same as above

You might also like

- Spiral Bevel Gear Arcoid System ZFTKK 250-1Document2 pagesSpiral Bevel Gear Arcoid System ZFTKK 250-1er_winwibowoNo ratings yet

- GEAR CALCULATION CORRECTIONDocument9 pagesGEAR CALCULATION CORRECTIONmahendravsNo ratings yet

- Gear design and calculation parametersDocument2 pagesGear design and calculation parametersomprakashd4196No ratings yet

- Gear CorrectionDocument17 pagesGear CorrectionMurugesanNo ratings yet

- Gear CalculationDocument58 pagesGear CalculationSachin KubasadNo ratings yet

- Sprocket DesignDocument4 pagesSprocket DesignchethanNo ratings yet

- Agma Grade 5 Smpe Grade 10Document25 pagesAgma Grade 5 Smpe Grade 10er_winwibowoNo ratings yet

- UNIT-2 Design of Spur GearDocument56 pagesUNIT-2 Design of Spur GearMarthandeNo ratings yet

- Angrenaj Cilindric PDFDocument17 pagesAngrenaj Cilindric PDFDiana Maria CozmaNo ratings yet

- Rotork CatalogDocument12 pagesRotork CatalogKedar PatwardhanNo ratings yet

- Gearbox Design IitDocument25 pagesGearbox Design IitSrini VasanNo ratings yet

- Worm Gear PairDocument585 pagesWorm Gear Pairer_winwibowoNo ratings yet

- Spur Gear, Helical Gear Design Step Final1Document2 pagesSpur Gear, Helical Gear Design Step Final1Venkadesh ShanmugamNo ratings yet

- Spur Gear Design by IIT MadrasDocument28 pagesSpur Gear Design by IIT MadrasC.S.ABHILASHNo ratings yet

- AMRI ISORIA 16 Type Series Booklet DataDocument20 pagesAMRI ISORIA 16 Type Series Booklet Datarudiskw456No ratings yet

- Ball - Screw - Calculations - As Per THK and PmiDocument5 pagesBall - Screw - Calculations - As Per THK and PmiDharmeshPatelNo ratings yet

- Mdesign 2016 Gears Verzahnungen en PDFDocument86 pagesMdesign 2016 Gears Verzahnungen en PDFmgualdiNo ratings yet

- Iso Inch Thread With A Standard Unc-2A Tolerance: Relationship Between The TolerancesDocument1 pageIso Inch Thread With A Standard Unc-2A Tolerance: Relationship Between The TolerancesMiguelito MaxNo ratings yet

- Shaft Design - Overheads PDFDocument20 pagesShaft Design - Overheads PDFRyan BaleNo ratings yet

- Shafts and BearingsDocument43 pagesShafts and BearingsMario AndrewNo ratings yet

- Gear FormulaeDocument13 pagesGear Formulaeian_newNo ratings yet

- Bolt Selection - NT BOLT G9 V15Document8 pagesBolt Selection - NT BOLT G9 V15Choa Pei ShuangNo ratings yet

- Bearing CalculationDocument4 pagesBearing CalculationAnonymous lTQDM21No ratings yet

- Planetary Gearbox CalculationsDocument3 pagesPlanetary Gearbox CalculationsChinnuClansNo ratings yet

- Shaft Calculation Base PDFDocument27 pagesShaft Calculation Base PDFBarsanu AlexNo ratings yet

- Equations For The Design of Standard Sprocket TeethDocument4 pagesEquations For The Design of Standard Sprocket TeethvanjaurkeNo ratings yet

- 02 Mechanical BasicsDocument29 pages02 Mechanical BasicsVLADIMIR YOLVIS CHOQUEHUANCA GALINDONo ratings yet

- Helical Gear Calculation Using SoftwareDocument10 pagesHelical Gear Calculation Using SoftwareM036No ratings yet

- Worm Gear Formula-MasterDocument30 pagesWorm Gear Formula-Masterer_winwibowoNo ratings yet

- Involute Spline Strength CalculationsDocument1 pageInvolute Spline Strength CalculationsRjgandhi65No ratings yet

- Heat Exchanger Design OptimizationDocument26 pagesHeat Exchanger Design OptimizationEhsan MoemeniNo ratings yet

- The Importance of Profile Shift, Root Angle Correction and Cutter Head TiltDocument4 pagesThe Importance of Profile Shift, Root Angle Correction and Cutter Head TiltvijaykumarnNo ratings yet

- Σχεδιασμός σε επιφανειακή πίεση μετωπικών οδοντωτών τροχών κατά AGMADocument1 pageΣχεδιασμός σε επιφανειακή πίεση μετωπικών οδοντωτών τροχών κατά AGMAkstayroskNo ratings yet

- Pipe Data-ID-OD Thickness & WeightDocument4 pagesPipe Data-ID-OD Thickness & WeightsssmrsmNo ratings yet

- Shaft Torsion 1Document2 pagesShaft Torsion 1neelNo ratings yet

- Helical Gear Basic PDFDocument13 pagesHelical Gear Basic PDFCarlosQuelartNo ratings yet

- Straight Sided Serrations SpecificationsDocument2 pagesStraight Sided Serrations SpecificationsMarcel Dandaro100% (1)

- Bolt Calculation According To VDI 2230:2014: InputsDocument7 pagesBolt Calculation According To VDI 2230:2014: InputsSridhar TholasingamNo ratings yet

- Pressing Force Calculator UpdatedDocument25 pagesPressing Force Calculator Updatedanush_swaminathanNo ratings yet

- Worm Gea Pairs ReferenceDocument6 pagesWorm Gea Pairs Referenceer_winwibowoNo ratings yet

- Alwasy Step Ahead in TechnologyDocument6 pagesAlwasy Step Ahead in TechnologyDxFx100% (1)

- Spur Gear Calculations and FormulasDocument2 pagesSpur Gear Calculations and FormulasBilal Tayyab100% (2)

- Design Calculations for Worm & Worm Gear Endurance StrengthDocument9 pagesDesign Calculations for Worm & Worm Gear Endurance StrengthVenkateswaran venkateswaranNo ratings yet

- Cast Iron Grades PDFDocument1 pageCast Iron Grades PDFAnurag JainNo ratings yet

- ISO4156 Spline Design CalcsDocument10 pagesISO4156 Spline Design CalcsmaheshmbelgaviNo ratings yet

- Multi Hole CageDocument15 pagesMulti Hole CageEng-CalculationsNo ratings yet

- Gears and Gear TrainsDocument127 pagesGears and Gear TrainsVikki KotaNo ratings yet

- Conveyor ChainDocument51 pagesConveyor ChainRiksaNo ratings yet

- g1142 Us 0310 PDFDocument192 pagesg1142 Us 0310 PDFddNo ratings yet

- Worm and Worm Wheel NomenclatureDocument1 pageWorm and Worm Wheel NomenclaturemuhdqasimNo ratings yet

- It Should Be Less Than R /3 or 10mDocument5 pagesIt Should Be Less Than R /3 or 10mMawan BentzNo ratings yet

- Involute Spur Gear Geometry Calculations: Input DataDocument11 pagesInvolute Spur Gear Geometry Calculations: Input DataNILESH YADAVNo ratings yet

- Calculation of Gear DimensionsDocument22 pagesCalculation of Gear DimensionsdressfeetNo ratings yet

- Chap 7 - Worm DriveDocument33 pagesChap 7 - Worm DriveHuỳnh Nguyễn Thiên TânNo ratings yet

- Diseño de EjesDocument49 pagesDiseño de EjesMijhael Anatholi Romero MamaniNo ratings yet

- Bevel Gear Formula - MasterDocument191 pagesBevel Gear Formula - Masterer_winwibowo100% (1)

- Answer 1: Week 10Document2 pagesAnswer 1: Week 10api-441441400No ratings yet

- Acd Acr 13a en BroDocument2 pagesAcd Acr 13a en BroLe DuNo ratings yet

- UntitledDocument27 pagesUntitledDavid DjNo ratings yet

- Debre Birhan University: College of Enigneering Departmrt of Mechamnical EnigineerigDocument19 pagesDebre Birhan University: College of Enigneering Departmrt of Mechamnical EnigineerigDagmawi MenweyeletNo ratings yet

- Lista Preturi Linhai 300 2014 PDFDocument25 pagesLista Preturi Linhai 300 2014 PDFSimonaVătafuNo ratings yet

- Alternator PDFDocument4 pagesAlternator PDFebenazzouz100% (2)

- Vol0040 PDFDocument4 pagesVol0040 PDFFranciscoOliveiraNo ratings yet

- MCQ in Machine DesigngDocument15 pagesMCQ in Machine DesigngRobert V. AbrasaldoNo ratings yet

- Applied Strength of Materials - Robert L. Mott and Joseph A. Untener 6e SI 2018 SCF03Document2 pagesApplied Strength of Materials - Robert L. Mott and Joseph A. Untener 6e SI 2018 SCF03S M BNo ratings yet

- Staubli Knotting Machine (Warp Tying) - Machine Settings Assembling, Dismantling ProcedureDocument11 pagesStaubli Knotting Machine (Warp Tying) - Machine Settings Assembling, Dismantling ProcedureCourtney Harris67% (3)

- Semi ChampionDocument2 pagesSemi ChampionvmuthubharathNo ratings yet

- Starting SystemDocument21 pagesStarting Systemmkisa70No ratings yet

- Design of spur gears and epicyclic gear trainDocument3 pagesDesign of spur gears and epicyclic gear trainRakesh SinghNo ratings yet

- Mecamax Dok EsDocument4 pagesMecamax Dok EsValdir Anderson SilverioNo ratings yet

- Electric Forklift Truck Specs and FeaturesDocument6 pagesElectric Forklift Truck Specs and FeaturesMA TotalforkliftNo ratings yet

- Electro-Mechanical Power SteeringDocument34 pagesElectro-Mechanical Power SteeringSubhro Barua50% (2)

- Amit Borkar: Profile SummaryDocument3 pagesAmit Borkar: Profile SummaryJeevan K G HosamaneNo ratings yet

- Addinol Ecogear M Data SheetDocument1 pageAddinol Ecogear M Data SheetWahyu BtNo ratings yet

- Spare parts catalogue for axle 143157Document10 pagesSpare parts catalogue for axle 143157avant comercialNo ratings yet

- Turbo Docs P-01739 - PLN WKSKT - Serious Inspection STG PLTU Asam Asam Unit #1 - Rev-0 (1-Turbine)Document112 pagesTurbo Docs P-01739 - PLN WKSKT - Serious Inspection STG PLTU Asam Asam Unit #1 - Rev-0 (1-Turbine)Novi GaluhNo ratings yet

- Hecogear All Series CatalogDocument24 pagesHecogear All Series CatalogtvwrightchwNo ratings yet

- MK 9Document34 pagesMK 9api-242597694No ratings yet

- VOLVO EC220D NL EC220DNL EXCAVATOR Service Repair Manual PDFDocument22 pagesVOLVO EC220D NL EC220DNL EXCAVATOR Service Repair Manual PDFfjjsjekdmme100% (1)

- Bajaj Boxer BM 100 ES Spare Parts CatalogueDocument67 pagesBajaj Boxer BM 100 ES Spare Parts CatalogueEsteban Camilo Rodriguez BernalNo ratings yet

- Calcolo Capacita Iso 6336 PDFDocument7 pagesCalcolo Capacita Iso 6336 PDFmgualdiNo ratings yet

- WWW - Servorepair.ca: Scroll Down To View Your Document!Document21 pagesWWW - Servorepair.ca: Scroll Down To View Your Document!Pham LongNo ratings yet

- Pressed PDFDocument150 pagesPressed PDFAlojz MulecNo ratings yet

- He Ma End Us TriDocument57 pagesHe Ma End Us TriPratik PanchalNo ratings yet

- Different Kinds of MechanismsDocument31 pagesDifferent Kinds of Mechanismslockenload92% (13)

- MERITOR 160 161 and 164 Serie Drive Axle Parts Spb9250Document57 pagesMERITOR 160 161 and 164 Serie Drive Axle Parts Spb9250juango250455100% (2)

- Lista GeneralDocument262 pagesLista GeneralFelix Retamozo100% (1)

- Service Parts List: Transmission 8 821H-113 4264585Document53 pagesService Parts List: Transmission 8 821H-113 4264585Chester Dalitso MwanzaNo ratings yet

- DATA SHEET MULTIPHASE PUMP REV0 BornermanDocument5 pagesDATA SHEET MULTIPHASE PUMP REV0 BornermanJessika López100% (1)

- ASSIGNMENTS OF MD II New FormatDocument15 pagesASSIGNMENTS OF MD II New Formatsushant vermaNo ratings yet