Professional Documents

Culture Documents

Jenbacher Combustion Air Cooling

Uploaded by

Ali AbbasiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jenbacher Combustion Air Cooling

Uploaded by

Ali AbbasiCopyright:

Available Formats

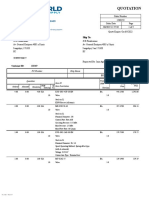

Project: Jenbacher Gas Engines Combustion Consultant:

Location: Pakistan Date: 2/10/11 9:52 AM

PRICE SUMMARY

Tag Model Location Qty

CHILLER HXWC-1 HXWC240-5PR(DBM) 1

CHILLER AFHX-5HR-1 AFHX 265-5HR(DBM) 1

AHU CS3-1 AHD1 FS 080 H M 1

91292 10-Feb-11 Page 1 of 10 SPEC ver. 7.0, 11440

Project: Jenbacher Gas Engines Consultant:

Location: Pakistan Date: 2/10/11 9:52 AM

Tag: CHILLER HXWC-1

PERFORMANCE SUMMARY

Location:

Screw Compressor Water Cooled Package Chiller

Model # HXWC240-5PR(DBM)

Quantity 1 Rating version HXWC16

Physical Specifications

Compressors (Qty) HX 1811(2) Shipping weight (lb) 12,092

Length (in) 171.00 Operating weight (lb) 13,062

Width (in) 58.63 Refrigerant R-134a

Height (in) 86.13 Approx. refrigerant charge (lb) 584

Conditions of service

Percent of full load 100% Unit power (kW) 146.61

Capacity (Tons) 209.42 Energy efficiency (EER) 17.14

NPLV (EER) 20.84

Evaporator Condenser

Model (Qty) X2R(1) Model (Qty) Z2R(1)

Number of passes 2 Number of passes 3

Fluid Water Fluid Water

Fluid flow rate (USgpm) 503.2 Fluid flow rate (USgpm) 628.3

Entering fluid temp. (°F) 54.0 Entering fluid temp. (°F) 90.0

Leaving fluid temp. (°F) 44.0 Leaving fluid temp. (°F) 99.6

Fouling factor (hr·ft·°F/Btu) 0.00010 Fouling factor (hr·ft·°F/Btu) 0.00050

Pressure drop (psi/ft w.g.) 5.1/11.7 Pressure drop (psi/ft w.g.) 17.3/40.0

Fluid freezing point (°F) 32.0 Fluid freezing point (°F) 32.0

Electrical characteristics

Unit power supply 400V/3ph/50Hz Unit min. circuit ampacity 277

Unit max. fuse size 400 Comp. rated load amps 123/123

Comp. locked rotor amps 745/745

Notes

- Certified in accordance with the AHRI Water-Chilling Packages - Meets ASHRAE 90.1-2007 chiller minimum efficiency

Using the Vapor Compression Cycle Certification Program, guidelines.

which is based on AHRI Standard-550/590-2003. - Refrigerant charge may vary. Unit nameplate will show final

factory charge.

NPLV Points

% Full load Tons Unit kW kw/Ton Cond. EFT Type

100% 209.42 146.61 0.700 90.0 Actual

75% 157.07 97.50 0.621 77.5 Actual

50% 104.71 55.01 0.525 65.0 Actual

25% 52.36 33.17 0.634 65.0 Actual

Sound Data

Total

Frequency (Hz) 63 125 250 500 1000 2000 4000 8000 dB(A)

Sound Pressure Level (free field) at 3.28 ft 66 64 69 67 78 75 70 57 81

*Sound Pressure Level (free field) ± 2 dB(A) Tolerance

Standard Equipment

Compressor

▪ HX horizontal screw ▪ Oil level Sight glass

▪ Cast iron housing ▪ One -1 year warranty

▪ Slide valve unloading ▪ Compressor liquid and vapour injection

▪ Suction shut off valve ▪ Star Delta Starter

▪ Discharge check valve ▪ External Oil separator for R134a unit

▪ Semi-hermetic compressors ▪ IP54 Terminal box

▪ Compressor oil sump heaters ▪ Integral lubrication system using pressure differential

▪ Relief valve if required

Evaporator/Condenser

▪ Vessels constructed in accordance to ASME CODES Sections ▪ drain and vent plugs

VIII Division I for unfired pressure vessels. ▪ Full pump down capacity in condenser

91292 10-Feb-11 Page 2 of 10 SPEC ver. 7.0, 11440

Project: Jenbacher Gas Engines Consultant:

Location: Pakistan Date: 2/10/11 9:52 AM

Tag: CHILLER HXWC-1

PERFORMANCE SUMMARY

Location:

▪ Flooded design for higher capacity and easy maintenance ▪ 1" thick PE foam closed cell evaporator insulation,thermal

▪ Cleanable integral fin copper tubes for easy serviceability conductivity 0.040W/m.K at 40°C (0.28Btu in/hr.ft2°F at 104°F.)

▪ One, two or three water passes available ▪ 1/2" thick PE foam closed cell suction line insulation/thermal

▪ Removable water heads conductivity 0.040W/m.K at 40°C (0.28Btu in/hr.ft2°F at 104°F)

▪ Victaulic groove water connections ▪ Carbon steel header, shell and tube sheet

▪ Relief valve(s), ѕ" FPT

Refrigerant Specialties

▪ Liquid level float control ▪ Charging and gauge connections

▪ Flash economizer usage to boost capacity ▪ High Pressure relief valves

▪ Sight glass with moisture indicator ▪ Refrigerant charge

▪ V. I. check valves on multiple compressor units ▪ Oil Charge

▪ Replaceable core filter drier ▪ Discharge check valves on multiple compressor units

Standard Electrical Components

▪ Compressor MCCB and contactors ▪ Single point power connection

▪ Compressor solid state overloads ▪ Control circuit transformer

▪ Low voltage/phase failure/phase reversal relay ▪ Current transformer

▪ On-off switch in the unit control circuit and each compressor

control circuit

Indicator lights Warranty and Testing

▪ Compressor overloads, ▪ High pressure, low ▪ Standard one year warranty on unit and on compressors

each compressor pressure, and freeze ▪ Factory run tested

▪ High motor temperature, ▪ Control power

each compressor

Code Compliance

▪ ASME std. B31.5 Refrigeration Piping code ▪ ASME Boiler and Pressure Vessel Code, Section VIII Division 1

▪ Units conform to NEC,NEMA and ASHRAE 15 safety code for "Unfired Pressure Vessels".

mechanical refrigeration ▪ Meets ASHRAE 90.1-2001 chiller minimum efficiency guidelines.

▪ Rated in accordance with AHRI 550/590 std. ▪ JKKP

▪ IEEE

Unit Protection Analog Readouts

▪ High and low pressures ▪ Evaporator and condenser refrigerant pressure

▪ High discharge temperature ▪ Compressor amps (each compressor)

▪ Freeze protection ▪ Water sensor: Evaporator leaving - Standard sensor to provide

▪ Low pressure differential temperature readout for water leaving the evaporator.

▪ Low oil level

▪ Compressor run error and over current

▪ Chilled water flow loss

▪ Compressor anti-recycle

▪ Sensor error

Controllers

▪ Vision 2020i Advanced microprocessor based DDC controller ▪ Oil level status

with 132x64 pixels DBG1 semi-graphic display panel with ▪ Fluid temperature reset value

menu driven software digital readout, pushbutton keyboard ▪ Water flow switch status

▪ Selection on English (Imperial) or metric display units ▪ External stop/start command status

▪ Remote monitoring via RS-485 port ▪ Identification of up to 99 most recent alarms with critical data

▪ Leaving chilled fluid temperature stamping

▪ Evaporator and condenser pressure ▪ OPTIONAL (BMS Communication option)

▪ Single phase amp draw, each compressor ▪ Optional Return water temperature sensor

▪ No. of compressor starts ▪ Optional Remote and stop signal

▪ Elapsed run time, each compressor

Digital Readouts Capacity control Setpoints

▪ Compressor contactor ▪ Elapsed compressor run ▪ Leaving water temperature ▪ Amp limit

status time ▪ Freeze up temperature ▪ Ramp up

▪ Flow switch status ▪ External enable/disable ▪ High and low pressure

▪ Oil level status status

▪ Number of compressor ▪ Liquid injection solenoid

starts state

Code Compliance (Standard Units)

▪ ASME std. B31.5 Refrigeration Piping code ▪ ASME Boiler and Pressure Vessel Code, Section VIII Division 1

▪ Units conform to NEC,NEMA and ASHRAE 15 safety code for "Unfired Pressure Vessels".

mechanical refrigeration ▪ Meets ASHRAE 90.1-2001 chiller minimum efficiency guidelines.

▪ Rated in accordance with AHRI 550/590 std. ▪ JKKP

▪ IEEE

Optional Equipment/Service Included

Factory Mounted Options Included

▪ Over and under voltage and phase protection relay (UVR2 or ▪ Condenser connection hand: Right

91292 10-Feb-11 Page 3 of 10 SPEC ver. 7.0, 11440

Project: Jenbacher Gas Engines Consultant:

Location: Pakistan Date: 2/10/11 9:52 AM

Tag: CHILLER HXWC-1

PERFORMANCE SUMMARY

Location:

UVR4) - protects against high and low incoming voltage ▪ Evaporator connection hand: Right

conditions as well as single phasing, phase reversal and phase ▪ Chilled water pump control (CWPC) - provides a contact closure

imbalance by opening the control circuit. It is an automatic reset for pump starting prior to starting of the chiller.

device, but the microcomputer can be set up for manual reset to ▪ Cooling tower fan staging (CTFS) - control provides up to three

prevent unwanted restarts. stage of output on fans based on condenser pressure.

▪ Soft starter with bypass contactors

Service Accessories (Shipped Loose)

▪ IEC panel (IEC) ▪ Spring isolators (SPG) - designed for 1" deflection, these

housed spring assemblies have a neoprene friction pad on the

bottom to help prevent the passage of noise and a spring locking

leveling bolt at the top. Neoprene inserts prevent contact

between the steel upper and lower housings. Suitable for more

critical applications than RIS isolators.

91292 10-Feb-11 Page 4 of 10 SPEC ver. 7.0, 11440

Project: Jenbacher Gas Engines Consultant:

Location: Pakistan Date: 2/10/11 9:52 AM

Tag: CHILLER AFHX-5HR-1

PERFORMANCE SUMMARY

Location:

Screw Compressor Air Cooled Package Chiller

Model # AFHX 265-5HR(DBM)

Quantity 1

Physical Specifications

Compressors (Qty) HX 1813(2) Shipping weight (lb) 25,125

Length (in) 381.00 Operating weight (lb) 25,628

Width (in) 88.00 Refrigerant R-134a

Height (in) 97.50 Approx. refrigerant charge (lb) 676

Conditions of service

Percent of full load 100% Compressor power (kW) 297.62

Capacity (Tons) 225.51 Total Fan Power (kW) 40.00

Unit power (kW) 337.62 Energy efficiency (EER) 8.02

NPLV (EER) 13.10

Evaporator

Models (Qty) J1R(2) Leaving fluid temp. (°F) 44.0

Fluid Water Fouling factor (hr·ft·°F/Btu) 0.00010

Fluid flow rate (USgpm) 541.8 Pressure drop (psi/ft w.g.) 3.8/8.8

Entering fluid temp. (°F) 54.0 Fluid freezing point (°F) 32.0

Condenser

Design ambient (°F) 122.0 Fan Motor Power (Qty) (kW) 2.5 (16)

Altitude (ft) 0 Fan size (Qty) (in) 35.43 (16)

Electrical characteristics

Unit power supply 400V/3ph/50Hz Unit rated load amps 458

Unit max. fuse size 600 Unit min. circuit ampacity 506

Comp. rated load amps 190/190

Notes

- Low ambient control to -20 °F (-28.9 °C) requires 50% - Refrigerant charge may vary. Unit nameplate will show final

minimum load, and a maximum 5 mph wind. factory charge.

- Outside the scope of AHRI Standard-550/590-2003.

NPLV Points

% Full load Tons Unit kW Comp. kW Fan kW EER Ambient Type

100% 225.51 337.62 297.62 40.00 8.02 122.0 Actual

75% 169.14 182.58 142.58 40.00 11.12 96.9 Actual

50% 112.76 89.35 69.35 20.00 15.14 71.8 Actual

25% 56.38 52.83 42.83 10.00 12.81 55.0 Actual

Sound Data

Total

Frequency (Hz) 63 125 250 500 1000 2000 4000 8000 dB(A)

Sound Pressure Level (free field) at 32.80 ft 53 51 57 57 65 62 57 48 68

*Sound Pressure Level (free field) ± 2 dB(A) Tolerance

Standard Equipment

Unit Construction

▪ Unit shall be constructed of heavy gauge G90 galvanized steel ▪ Bolted construction for easy semi knockdown at site in case

▪ All sheet metal parts are painted with oven baked epoxy / hoisting problem

polyester powder paint, sustaining 1000 hour salt spray test in ▪ Cobalt chromed boths and nuts for maximum corrosion

accordance with ASTM B1117 resistance

▪ Rigid Structural base to prevent unit deformation and damage ▪ Control panel IP54

during hoisting

Compressor

▪ HX horizontal screw ▪ Relief valve if required

▪ Cast iron housing ▪ Oil level Sight glass

▪ IP54 Terminal box ▪ One year warranty

▪ Slide valve unloading ▪ Compressor liquid and vapour injection

91292 10-Feb-11 Page 5 of 10 SPEC ver. 7.0, 11440

Project: Jenbacher Gas Engines Consultant:

Location: Pakistan Date: 2/10/11 9:52 AM

Tag: CHILLER AFHX-5HR-1

PERFORMANCE SUMMARY

Location:

▪ Suction shut off valve ▪ External Oil separator for R134a unit

▪ Discharge check valve ▪ Star Delta Starter

▪ Semi-hermetic compressors ▪ Oil separator

▪ Compressor oil sump heaters ▪ Integral lubrication system using pressure differential

Air Cooled condenser

▪ Inner ridged copper tubes ▪ Close blade tip clearance with the fan venturis to assure smooth,

▪ Aluminium fins quiet operation

▪ 450 psig test pressure for condenser coils ▪ 6 pole fan motor, IP55, class F insulation with class B

▪ Low noise direct driven propeller and axial fans temperature rise

▪ Galvanized steel tubesheet ▪ Fan cycling low ambient control down to 55°F, and reduce unit

power input at low ambient

Evaporator

▪ Flooded design for higher capacity and easy maintenance ▪ 150 psig on water side design pressure

▪ Cleanable integral fin copper tubes for easy serviceability ▪ drain and vent plugs

▪ Removable water heads ▪ relieve valve

▪ Optional Flanged water connection for quick installation and/or ▪ 1" thick PE foam closed cell evaporator insulation,thermal

service conductivity 0.040W/m.K at 40°C (0.28Btu in/hr.ft2°F at 104°F.)

▪ Full pump-down capacity in condenser, therefore, pump out unit ▪ 1/2" thick PE foam closed cell suction line insulation/thermal

not required conductivity 0.040W/m.K at 40°C (0.28Btu in/hr.ft2°F at 104°F)

▪ 300 psig on refrigerant side design pressure(For R22 & R407C) ▪ Carbon steel header, shell and tube sheet

▪ 200 psig on refrigerant side design pressure (For R134a)

Code Compliance Indicator lights

▪ ASME std. B31.5 Refrigeration Piping code ▪ Compressor overloads, ▪ High pressure, low

▪ Units conform to NEC,NEMA and ASHRAE 15 safety code for each compressor pressure, and freeze

mechanical refrigeration ▪ High motor temperature, ▪ Control power

▪ Rated in accordance with AHRI 550/590 std. each compressor

▪ Meets ASHRAE 90.1-2001 chiller minimum efficiency guidelines.

▪ IEEE

Refrigerant Specialties

▪ Liquid level float control ▪ Charging and gauge connections

▪ Flash economizer usage to boost capacity ▪ High Pressure relief valves

▪ Sight glass with moisture indicator ▪ Refrigerant charge

▪ liquid line solenoid ▪ Oil Charge

▪ Replaceable core filter drier ▪ Discharge check valves on multiple compressor units

Standard Electrical Components

▪ Compressor MCCB and contactors ▪ Fan control contactors

▪ Compressor solid state overloads ▪ Control circuit transformer

▪ Low voltage/phase failure/phase reversal relay ▪ Current transformer

▪ On-off switch in the unit control circuit and each compressor ▪ Optional Ambient temperature sensor

control circuit

Warranty and Testing Analog readouts

▪ Standard one year warranty on unit and on compressors ▪ Evaporator and condenser refrigerant pressure

▪ Factory run tested ▪ Compressor amps (each compressor)

▪ Water sensor: Evaporator leaving - Standard sensor to provide

temperature readout for water leaving the evaporator.

Controller

▪ Vision 2020i Advanced microprocessor based DDC controller ▪ Fluid temperature reset value

with 132x64 pixels DBG1 semi-graphic display panel with ▪ Water flow switch status

menu driven software digital readout, pushbutton keyboard ▪ External stop/start command status

▪ Selection on English (Imperial) or metric display units ▪ Condenser fan cycling

▪ Remote monitoring via RS-485 port ▪ Low ambient lockout

▪ Leaving chilled fluid temperature ▪ Identification of up to 99 most recent alarms with critical data

▪ Evaporator and condenser pressure stamping

▪ Single phase amp draw, each compressor ▪ OPTIONAL (BMS Communication option)

▪ No. of compressor starts ▪ Optional Ambient temperature sensor

▪ Elapsed run time, each compressor ▪ Optional Return water temperature sensor

▪ Oil level status ▪ Optional Remote and stop signal

Digital readouts Capacity control Setpoints

▪ Compressor contactor ▪ Elapsed compressor run ▪ Leaving water temperature ▪ Amp limit

status time ▪ Freeze up temperature ▪ Ramp up

▪ Flow switch status ▪ External enable/disable ▪ High and low pressure

▪ Oil level status status

▪ Number of compressor ▪ Liquid injection solenoid

starts state

Unit Protection

▪ High and low pressures

▪ High discharge temperature

91292 10-Feb-11 Page 6 of 10 SPEC ver. 7.0, 11440

Project: Jenbacher Gas Engines Consultant:

Location: Pakistan Date: 2/10/11 9:52 AM

Tag: CHILLER AFHX-5HR-1

PERFORMANCE SUMMARY

Location:

▪ Freeze protection

▪ Low pressure differential

▪ Low oil level

▪ Compressor run error and over current

▪ Power loss

▪ Chilled water flow loss

▪ High/Low System voltage

▪ Sensor error

▪ Compressor anti-recycle

Optional Equipment/Service Included

Factory Mounted Options Included Service

▪ Evaporator double layer insulation (INS2) - 1 1/2" Evaporator ▪ IEC panel (IEC)

insulation for ice build applications

▪ Over and under voltage and phase protection relay (UVR2 or

UVR4) - protects against high and low incoming voltage

conditions as well as single phasing, phase reversal and phase

imbalance by opening the control circuit. It is an automatic reset

device, but the microcomputer can be set up for manual reset to

prevent unwanted restarts.

▪ Soft starter with bypass contactors

▪ Touch screen display: 256 colors (CLR)

▪ Standard unit operates with fans cycling control for ambient

down to 45°F.

Accessories (Shipped Loose)

▪ Spring isolators (SPG) - designed for 1" deflection, these housed spring assemblies have a neoprene friction pad on the bottom to help

prevent the passage of noise and a spring locking leveling bolt at the top. Neoprene inserts prevent contact between the steel upper

and lower housings. Suitable for more critical applications than RIS isolators.

91292 10-Feb-11 Page 7 of 10 SPEC ver. 7.0, 11440

Project: Jenbacher Gas Engines Consultant:

Location: Pakistan Date: 2/10/11 9:52 AM

Tag: CHILLER AFHX-5HR-1

PERFORMANCE SUMMARY

Location:

91292 10-Feb-11 Page 8 of 10 SPEC ver. 7.0, 11440

Project: Jenbacher Gas Engines Consultant:

Location: Pakistan Date: 2/10/11 9:52 AM

Tag: AHU CS3-1

PERFORMANCE SUMMARY

Location:

CS3 Air Handler

Model # AHD1 FS 080 H M Quantity 1

Fan ratings version 3CS10 Insulation (entire unit) 2.5 # Polyurethane

Wall thickness 1" (25 mm)

A. Section 11 Angle filter section

Filter depth 2" (5.08 cm) Access panels One

Filter media 92% Arr. washable Panel hand Left

Pre-filter media N/A Liners Solid GI

Pressure drop (in w.g.) 0.12

B. Section 8 Long cooling coil section

Coil size Large Liners Solid GI

Drain pan Standard Pressure drop (in w.g.) 0.13

Refer coil performance as below.

C. Section 1 Horizontal draw-thru fan section SC

Fan type Forward curved (standard) External static @Actual (in w.g.) 0.50

Frame style SC Internal static @Actual (in w.g.) 0.45

Arrangement Horizontal front Total static @Actual (in w.g.) 0.95

Motor type TEFC Break power @Actual (HP) 3.58

Motor voltage 380V/3/50 Rotations per minute 638

Motor power (HP) 5.50 Altitude (ft) 0

Motor insulation class F Coldest dry bulb temp (°F) 70.0

Motor hand Left Access panels One

Drive Adjustable Liners Solid GI

Air flow (ft^3/min) 8,240 Pressure drop (in w.g.) 0.20

Internal isolation Spring (standard)

Supply Fan Sound Power(dB)

Frequency (Hz) 63 125 250 500 1k 2k 4k 8k Overall

At inlet 55 69 69 73 71 66 59 49 88

At discharge 55 69 69 73 71 66 59 49 88

Air Handler Coil

Coil Tag Model # Qty Location Footnotes

#1 A W H 1 B - 28T x 66 LH 1 Section B - Coil A N/A

Air properties Fluid properties Construction

Air flow (ft^3/min) 8,240 Fluid Water Type / tubes in face A (1/2" OD) /

Altitude (ft) 0 Fluid flow rate (USgpm) 53.0 28

Face velocity (ft/min) 514 Fluid velocity (ft/s) 6.3 Finned height (in) 35.0

Air pressure drop (in 0.13 Entering fluid temp. (°F) 44.0 Finned length (in) 66.0

w.g.) Leaving fluid temp. (°F) 54.0 Face area (ft^2) 16.0

Entering air DB / WB (°F) 120.0 / 90.0 Fluid pressure drop (ft 14.7 Rows / fin spacing 1 / 10

Leaving air DB / WB (°F) 101.3 / 83.6 w.g.) (fins/in)

Air properties measured Actual Number of feeds 14

at Casing construction Air handler

Supply connections 1@1

Coil (qty@in)

Return connections 1@1

Total capacity (MBH) 264.9 (qty@in)

Sensible capacity (MBH) 154.1 Connection type MPT

Fin material Standard

aluminium

91292 10-Feb-11 Page 9 of 10 SPEC ver. 7.0, 11440

Project: Jenbacher Gas Engines Consultant:

Location: Pakistan Date: 2/10/11 9:52 AM

Tag: AHU CS3-1

PERFORMANCE SUMMARY

Location:

91292 10-Feb-11 Page 10 of 10 SPEC ver. 7.0, 11440

You might also like

- Gas MixerDocument38 pagesGas Mixershahzad67% (3)

- ManualDocument4 pagesManualmuhammad arif67% (3)

- J624 G01 6300VDocument5 pagesJ624 G01 6300VJajap TanudjajaNo ratings yet

- GE Type 3 TECHNICAL SPECIFICATION OF THE CONTROLDocument24 pagesGE Type 3 TECHNICAL SPECIFICATION OF THE CONTROLSerg MarushkoNo ratings yet

- 1400-0100 enDocument3 pages1400-0100 enKopi BrisbaneNo ratings yet

- Fuel SystemDocument1 pageFuel SystemJamil Ahmed100% (1)

- Technical Specifiaction of Control SystemDocument34 pagesTechnical Specifiaction of Control SystemLidef SellenrofNo ratings yet

- 5 1 1 B J320C enDocument12 pages5 1 1 B J320C enAdnan Yousaf67% (3)

- J320V21 enDocument4 pagesJ320V21 enMartin KratkyNo ratings yet

- Extended DIA - Ne XT - AccessDocument2 pagesExtended DIA - Ne XT - Accesslaiquz zaman33% (3)

- Specific Trip Event 'Knocking Failure A3339Document4 pagesSpecific Trip Event 'Knocking Failure A3339msavoymaggi100% (3)

- GE Power & Water - Gas Engines: Grupos de Cogeneración Con Motor A Gas Jenbacher para España y Portugal (2013)Document1 pageGE Power & Water - Gas Engines: Grupos de Cogeneración Con Motor A Gas Jenbacher para España y Portugal (2013)bintoitoNo ratings yet

- Jenbacher Technical Diagram ComponentsDocument4 pagesJenbacher Technical Diagram ComponentsJamil Ahmed100% (2)

- Component OverviewDocument20 pagesComponent OverviewAndronic Cosmin0% (1)

- Boundary Conditions Engines Installation 1100-0110 enDocument19 pagesBoundary Conditions Engines Installation 1100-0110 enAndronic Cosmin50% (2)

- Jenbacher Engine DiagramsDocument6 pagesJenbacher Engine Diagramspalash11No ratings yet

- JMS 612 GS-N.L: Jenbacher Gas EnginesDocument4 pagesJMS 612 GS-N.L: Jenbacher Gas EngineshadNo ratings yet

- Jenbacher Start UpDocument3 pagesJenbacher Start UpJamil AhmedNo ratings yet

- Jenbacher 1.946kW Biogas Engine Module Technical SpecsDocument4 pagesJenbacher 1.946kW Biogas Engine Module Technical SpecsMartin KratkyNo ratings yet

- 320Document61 pages320Rashid Mahmood JaatNo ratings yet

- Jenbacher Type-6 EngineDocument24 pagesJenbacher Type-6 EngineAb Hannan chowdhury100% (1)

- Jenbacher: 1. Key To Module Diagrams and Technical Schema: - 1Document14 pagesJenbacher: 1. Key To Module Diagrams and Technical Schema: - 1Jamil Ahmed100% (1)

- Jenbacher: DocumentationDocument11 pagesJenbacher: DocumentationArîf100% (1)

- TS JGC320 D805 480V 35C 500NOx 01-Feb-18 PreliminaryDocument47 pagesTS JGC320 D805 480V 35C 500NOx 01-Feb-18 PreliminaryLUIS CARLOSNo ratings yet

- Jenbacher: 1. Ignition System: - 1Document2 pagesJenbacher: 1. Ignition System: - 1ArîfNo ratings yet

- Maint Inst GEJ320 PDFDocument175 pagesMaint Inst GEJ320 PDFengkos koswara100% (1)

- Jenbacher JMS 616 GS-N.L Natural Gas Module Technical SpecsDocument4 pagesJenbacher JMS 616 GS-N.L Natural Gas Module Technical Specsmxnoxn100% (1)

- ST-135 Steel Pistons, Cylinder Liners, Scraper Rings, Cylinder Head Gaskets PDFDocument5 pagesST-135 Steel Pistons, Cylinder Liners, Scraper Rings, Cylinder Head Gaskets PDFPopa MihaiNo ratings yet

- ST-124 New Gear Train PDFDocument21 pagesST-124 New Gear Train PDFPopa MihaiNo ratings yet

- Jenbacher: 5.1.1 DescriptionDocument12 pagesJenbacher: 5.1.1 DescriptionJamil Ahmed100% (1)

- Iil C249Document206 pagesIil C249Khalid RafiqNo ratings yet

- Jenbacher 1902-0228E Technical Instruction Screwing TorqueDocument6 pagesJenbacher 1902-0228E Technical Instruction Screwing TorqueArîf100% (2)

- Amjad Textile JH827 - 2196246 - 258Document279 pagesAmjad Textile JH827 - 2196246 - 258Shahzad AhmadNo ratings yet

- 1000-1109 - Index 17 GE Jenbacher Gas EnginesDocument14 pages1000-1109 - Index 17 GE Jenbacher Gas EnginesDavid PomaNo ratings yet

- GE - 200802 - Technical Specs Jenbacher Type 6 PDFDocument2 pagesGE - 200802 - Technical Specs Jenbacher Type 6 PDFsakthivelNo ratings yet

- J612V22 enDocument4 pagesJ612V22 enMartin Kratky100% (1)

- TS - JGS320-C81-Landfill - 1300m - 35C-Deg - 480V - Operadora-Ferrocarriles - V5-21 - Final PDFDocument43 pagesTS - JGS320-C81-Landfill - 1300m - 35C-Deg - 480V - Operadora-Ferrocarriles - V5-21 - Final PDFMarti H J100% (1)

- 1502 0068 en MORIS IgnitionDocument31 pages1502 0068 en MORIS Ignitionpalash1186% (22)

- Maintenance Program JenbacherDocument11 pagesMaintenance Program JenbacherHelder Pinto100% (1)

- Service Technician Instruction: Dia - Ne Xt4 HmiDocument7 pagesService Technician Instruction: Dia - Ne Xt4 HmiAhad Khalil100% (3)

- TBG616K PDFDocument4 pagesTBG616K PDFTyler GoodwinNo ratings yet

- Cylinder Head: Maintenance InstructionDocument12 pagesCylinder Head: Maintenance InstructionReny NapitupuluNo ratings yet

- Jenbacher: 1100-0110 Boundary Conditions For GE Jenbacher Gas EnginesDocument12 pagesJenbacher: 1100-0110 Boundary Conditions For GE Jenbacher Gas EnginesArîfNo ratings yet

- JGS 420 B05 - 1500 KW (Nox - 500)Document11 pagesJGS 420 B05 - 1500 KW (Nox - 500)Ibrahim Ahmed FarrukhNo ratings yet

- X20CM0985 1 Eng - V1.42Document72 pagesX20CM0985 1 Eng - V1.42rushaNo ratings yet

- CG 170-16K - Data Sheet PDFDocument1 pageCG 170-16K - Data Sheet PDFShah Newaz Kabir100% (1)

- SB 121Document4 pagesSB 121Plant Manager 50 MW GENo ratings yet

- Diane WinDocument15 pagesDiane Winimranbseee100% (2)

- Jenbacher JMS 620 GS-N.L 3.041kW Natural Gas Engine SpecsDocument4 pagesJenbacher JMS 620 GS-N.L 3.041kW Natural Gas Engine Specsdannymay9575% (4)

- Emissions Monitoring: Technical InstructionDocument16 pagesEmissions Monitoring: Technical InstructionJuly E. Maldonado M.No ratings yet

- JGS 320 GS-B.L: Technical Description GensetDocument11 pagesJGS 320 GS-B.L: Technical Description GensetAmir QayyumNo ratings yet

- GE Type 3 Technical Instructions 07-30-2012 - Isolated OperationDocument224 pagesGE Type 3 Technical Instructions 07-30-2012 - Isolated OperationSerg MarushkoNo ratings yet

- Jenbacher Gasm BHKW enDocument28 pagesJenbacher Gasm BHKW ensaniterm100% (1)

- Tag Model Location Qty: QN 21090714 Devine Mercy Hospital Bangladesh Daveen 9/30/21 2:18 PMDocument3 pagesTag Model Location Qty: QN 21090714 Devine Mercy Hospital Bangladesh Daveen 9/30/21 2:18 PMfakir mohammadNo ratings yet

- AVX-B & ACHX-B PerformanceDocument12 pagesAVX-B & ACHX-B PerformanceInzamam ShithilNo ratings yet

- ACHX-B Performance (Horizontal Compressor)Document3 pagesACHX-B Performance (Horizontal Compressor)Inzamam ShithilNo ratings yet

- AVX-B Performance (Vertical Compressor)Document4 pagesAVX-B Performance (Vertical Compressor)Inzamam ShithilNo ratings yet

- Acds120 Chiller SpecsDocument8 pagesAcds120 Chiller SpecsitovelaNo ratings yet

- 13-2-2020revised Screw chiller-1502KWDocument4 pages13-2-2020revised Screw chiller-1502KWthilina lakhithaNo ratings yet

- Air Cooled Screw Chiller Performance DatasheetDocument2 pagesAir Cooled Screw Chiller Performance DatasheetJuan Carlos Soto OrihuelaNo ratings yet

- Volvo FMX: Product Guide - Euro 3-5Document24 pagesVolvo FMX: Product Guide - Euro 3-5HiT Dayat100% (2)

- Smart is the most intelligent solution yet for urban drivingDocument8 pagesSmart is the most intelligent solution yet for urban drivingHenrique CorreiaNo ratings yet

- Loop Back DSP Audio AppDocument12 pagesLoop Back DSP Audio AppGytis BernotasNo ratings yet

- Refresher Day 3Document4 pagesRefresher Day 3Jevan A. CalaqueNo ratings yet

- Design Diesel-Photovoltaic Hybrid Power PlantDocument93 pagesDesign Diesel-Photovoltaic Hybrid Power PlantDaniel Okere100% (1)

- ASSAM - Uniform Zoning Regulation 2000Document35 pagesASSAM - Uniform Zoning Regulation 2000rajatesh1No ratings yet

- Assignment No1 Current and ElectricityDocument1 pageAssignment No1 Current and ElectricityshreyaNo ratings yet

- SHG 25 3000 SeriesDocument23 pagesSHG 25 3000 Seriesjpsingh75No ratings yet

- Details of Measurement: Total Qnty Nos. Length Breadth Height SN Description of Item Unit MEASUREMENT (In MTRS)Document6 pagesDetails of Measurement: Total Qnty Nos. Length Breadth Height SN Description of Item Unit MEASUREMENT (In MTRS)Biswajit SahooNo ratings yet

- The Autolisp TutorialsDocument285 pagesThe Autolisp Tutorialsmynareshk100% (7)

- DBMS Lab ExperimentsDocument45 pagesDBMS Lab ExperimentsMad Man100% (1)

- Monopoles and Electricity: Lawrence J. Wippler Little Falls, MN United StatesDocument9 pagesMonopoles and Electricity: Lawrence J. Wippler Little Falls, MN United Stateswaqar mohsinNo ratings yet

- Digital BandDocument93 pagesDigital BandTofel EmedNo ratings yet

- The Shell and Shell Scripting: Echo $SHELL - To See The Working Shell in SSHDocument12 pagesThe Shell and Shell Scripting: Echo $SHELL - To See The Working Shell in SSHThai PhuongNo ratings yet

- Low-Power Digital Signal Processor Architecture For Wireless Sensor NodesDocument9 pagesLow-Power Digital Signal Processor Architecture For Wireless Sensor NodesGayathri K MNo ratings yet

- Inventory Items DestinyDocument11 pagesInventory Items DestinyManish NautiyalNo ratings yet

- ISA SymbolsDocument2 pagesISA Symbolsmahesh009No ratings yet

- Cotización FM2Document2 pagesCotización FM2Anonymous 3o4Mwew0No ratings yet

- Philips Flat TV 15PF9936 - LeafletDocument2 pagesPhilips Flat TV 15PF9936 - LeafletVlad FlorescuNo ratings yet

- DRC800 Remote Control UserGuideDocument2 pagesDRC800 Remote Control UserGuideLuis MurilloNo ratings yet

- Verdi TCL TrainingDocument24 pagesVerdi TCL TrainingPratyush ShrotriyaNo ratings yet

- Foundation Practice Exam Questions 5Document11 pagesFoundation Practice Exam Questions 5Dr CoolzNo ratings yet

- PSC Unit 4 PPT - Part 3Document35 pagesPSC Unit 4 PPT - Part 3Rino VidNo ratings yet

- Temperature Sensors LM35Document92 pagesTemperature Sensors LM35Shaik Shahul0% (1)

- PHD Thesis BentzDocument320 pagesPHD Thesis Bentzcrusanu50% (2)

- Main Bearing Journal: Shutdown SIS Previous ScreenDocument3 pagesMain Bearing Journal: Shutdown SIS Previous Screenariy yuli styawanNo ratings yet

- Acer Aspire 4735z 4736z 4935z 4936z - COMPAL LA-5272P KALG1 - REV 0.1secDocument46 pagesAcer Aspire 4735z 4736z 4935z 4936z - COMPAL LA-5272P KALG1 - REV 0.1secIhsan Yusoff IhsanNo ratings yet

- TS1A-13A: Operation and Maintenance ManualDocument204 pagesTS1A-13A: Operation and Maintenance ManualJavier AponteNo ratings yet

- Aranya Housing Final To Be Submitted PDFDocument37 pagesAranya Housing Final To Be Submitted PDFsucheta100% (4)

- Brochure Ef SchoolDocument2 pagesBrochure Ef SchoolperulapiaNo ratings yet