Professional Documents

Culture Documents

50 BMG Plans

Uploaded by

Dana Dunn100%(25)100% found this document useful (25 votes)

4K views44 pagesUse centerdrill to start holes to keep more accurate. Drills can walk over. Use sharp taps and use tap fluid / oil. Clean bore before shooting. Use only good quality ammo from someone you can trust. When testing, inspect for loose bolts or cracks in reciever. Also if Firing Pin is too long, it can punch hole in primer. Meaning you will get a hard kick.

Original Description:

Original Title

50 bmg plans

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentUse centerdrill to start holes to keep more accurate. Drills can walk over. Use sharp taps and use tap fluid / oil. Clean bore before shooting. Use only good quality ammo from someone you can trust. When testing, inspect for loose bolts or cracks in reciever. Also if Firing Pin is too long, it can punch hole in primer. Meaning you will get a hard kick.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF or read online from Scribd

100%(25)100% found this document useful (25 votes)

4K views44 pages50 BMG Plans

Uploaded by

Dana DunnUse centerdrill to start holes to keep more accurate. Drills can walk over. Use sharp taps and use tap fluid / oil. Clean bore before shooting. Use only good quality ammo from someone you can trust. When testing, inspect for loose bolts or cracks in reciever. Also if Firing Pin is too long, it can punch hole in primer. Meaning you will get a hard kick.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 44

WOD'USQI]ODA4 FL FMAM

SWa_OS te

[Dasa

SU]d Ady YEq0D OG S,UYOr

USEFUL INFORMATION

* Use centerdrill to start holes to keep more accurate. Drills can walk over.

* Use sharp taps and use tap fluid / oil. Blow out all tapped holes, leaving

no oil, or shaving

* All fasteners required removable loc-tite.

* Torque bolts to proper torque.

* Clean bore before shooting,

* When welding muzzle brake, dont use water to cool.

* Check muzzle brake setscrews before shooting. Never shoot without it.

* Use only good quality ammo from someone you can trust.

* When testing, inspect for loose bolts or cracks in reciever.

* Also if Firing Pin is too long, it can punch hole in primer.

If this happen, the muzzle brake is not as effective. Meaning you will

get a hard kick.

Keep in mind, if ‘a hole is punched in primer, the force from the shell

will try to force out firing pin thru the back of firing block. So make it sure

to install hammer stop.

Blue loc-tite the 10-32 screws on hammer stop. This is important part.

Don't use any hot Roll, mild steel for any parts. Don't drop reciever or hit

with hammer / punch.

AR-15 stock is optional. If you want to cut $40.00 off to your budget,

just use the 1" o.d. aluminum rod. And add butt plate and recoil pad. Paint

1" o.d. aluminum black, you can add stock later.

* Review Photos on floppy before beginning to make parts.

Usefull Information ~

When buying ak-47 parts, buy the import, china stuff, some ak-47

parts are being made in the U.S. The only trouble, is they are harden,

and are tough to drill, and tapping is out of the question. The trigger,

you can weld a .125 pin, in place ,of an 8-32 setscrew. The pin length

would be about .375 long. Its function, is to retain the trigger spring.

Without it, the spring would fall out.

Use only good quality fasteners, such as screws, and bolts. Use blue

removable loc-tite, on all fasteners. Check all fasteners before shooting,

Fasteners could crack, or become loose, check them.

When making parts on firing block page, follow plans exactly. Drill

the .157" hole first, to a depth of .860°. If you drill, the .077" hole

first, it may drift, from it correct location. And always use center

rill, and edge finder. The firing pin can be turned down on a lathe,

just use proper material. To save time, I used an AR-15 firing pin,

and went from there.

All parts should be properly made, and installed properly, before

test firing, or shooting. Use 100 yards of fishing line, to test. Sit

the rifle, on the ground, tie on your line, and load. I recommend

that you be atleast 100 yards away, when firing. Loose parts may

fly off with great force. I hope, you have tighten all your fasteners,

so this should not happen. Parts such as barrel clamp, hammer

stop, muzzle brake, and handle, should always be on rifle, when

shooting.

Always check bore before fring, it should be clean of dirt, grease

or anything, even cleaning solvents. Do this with rifle unloaded.

When loading, cock hammer completely, completely, is when the

trigger catches the hammer. This is the safe way, to cock hammer.

Ifyou hold it, you may let go, and rifle could fire. Cock the hammer

and then insert the round. Make sure to mill small flats, on hammer

cocking shaft, so setscrews will hold. Use removable loc-tite.

Usefull Information

Always lock firing block, when firing. Clearance for firing block

is .003", front, or back. Top, or bottom is .005". Use feeler gauge.

To check, insert completed firing block, into receiver slot, and dont

lock down, when checking clearance. This is not a shooting test, it

is to check the clearance, of firing block, and receiver slot.

Barrel clamp, should be mounted straight. This clamp will keep barrel

from screwing in or out. This will keep the head space, where it was

set. The barrel clamp will help support, the barrel. Another plus of the

barrel clamp, is that it will make rifle more rigid.

When making muzzle brake, have welded, by certified welder. And

use good quality material. After welding, dont cool with water, this

could cause cracking. Drill the .562" hole in proper location, and

only when it has cooled. After drill, deburr hole, and check alinment

to barrel. Use wooden dowel rod, to check, clearence of hole. Re-

move dowel after test, is complete.

Bi-pod beight, on plans are for a range of 300 yards or so. You may

need to make higher, or lower. A different design may be used, just

be sure, it will hold up.

Alumnium base is 3.0"wide. And the slot for the trigger, can be half

the size. The plans call for a one inch, but a .6" could be used. The

trigger, must pivot freely.

Ifyou start with the reciever, I suggest trying this...

Cut two pieces of 1.5 x 3.0.x 5.1 mild steel, cold finish, or other proper steels

such as; 4140.41.40 is three times stronger, but will cost more and add

machining time. I used mild steel. Cut material with cold cutting saw, not

friction. Friction sawing tends to heat edges, and can dull tools. Even when

you make your muzzle brake don't dip into water to cool it. Don't forget to

wear safety glasses even when tapping, they can break too.

After ma&i#is cut and deburred, mill to lenght (5.00) for both pieces. Check

for Squareness. Length on plates can vary plus or minus .050" without

trouble. Just make both plates the same.

Let get milling with 3/4” rougher endiill. Mill out clearance for firing block,

and shell loading area. I did it in 4 or 5 passes, the faster you move this

metal the more it will warp. Try to keep it cool as possible. Lused flood type

coolant, but mist will work. The slot is where the most will occur cause of

its depth. After you had rough plates in, use .5 or .625 endmill to get in

tolerance. Use slower feeds to get smooth surface, milling marks can start

cracks.

Mill clearance for hammer in bottom plate. Only the bottom plate. Hammer

cant touch sides, must pivot freely.

Face both plates on the sides that make contact, when bolted together. They

must be flat. If you have access to precision grinder, then use it that will be

the best.

Next step, will be drilling for the top plate. Drill clearance holes for 3/8 allen

bolt, And then, counter bore the same 3 holes that was just drilled. Dowel

pinning is done after torque together. Now for the bottom plate, drill the 3

tapped 3/8-16 hole @ 1.0 deep. On the bottom of the bottom plate drill the

mounting holes in proper location. Two are 3/8-16 and two are 5/16-18.

Tap all holes straight, make sure to remove all burrs and lub.from tapped

holes.

Now its time to bolt together. I used blue loc-tite and torqued several times,

at different settings. Try to keep flat, like torque of a cylinder head. Be sure

to fit firing block, it must move freely. Clearance is on firing block drawing.

As far as torque of bolts, torque to proper torque for that size of bolt. With

feeler gauge, check clearance of firing block.

Next dowel pinning, use .250 pins. I used two and place them in location,

where there was plenty metal around the pins for support, and not by the slot

for the firing block. 1 didn't drill holes anywhere near the slot, not even for

scope mounts.

Next, barrel threads, drill, bore and tap threads into bolted together reciever.

Making sure its straight, use indicator. Drawings are for BMG hd ground

barrel. Other barrels may have problem with head spacing. I used 17/16-8

tpi. I bought tap, and shared the cost with friend. If'you rethread the barrel

“mankcessiee sure that itis not too thin. I would keep the threads that are already on

‘barrel. A four jaw lathe can be used to thread the reciever.

A 8-32 tap hole is needed on the bottom of the reciever, location is on prints.

This hole is for setscrew, that holds spring for trigger.

‘ 1

‘SUB| OUT JEqNED OS SUUOT

SO}B|q Jeneooy

[_—a

“s8eU72Yy UIE}GO 0) ‘papeau S| }EyM AjuO eAOWEY

ey ‘sere\d Ujog aoe} ‘9z]8 OF Buy Jey

“preys jim eBediem ‘seye{d ay) UO

WW NOK sy “Tey seed Bute)

seye Ares Aew'g-y Jo S8euyOIUL

1 S| sseUOIUL “Y

“soyeid Jo ‘ssouyo14) B}e0!pUN (WM CY

“exey umoys ‘eyeid puey IYBIY

fs pene oy

de

|

9

* v/a

Te

ov

| : |

i via 2 | 6

eh

| fhe

|

“e104 UMOYS ‘e;e/d pueY 87

‘G@aLS399NS SI snidva

/881 % ‘LINDOd NI ‘Cad a3N

LON 3aV SY3NAOD JavNds

‘3N3SH LNNOW VIM SaWWYvH

‘yaav SIHL NAHL TWIIW

[gat

aLVid wOZ70g

NGAIZIIS

ove

"YF BOHR HE

og 6018 91.9

4

‘peeny ou Buunpa anja nis do

Jopabcy usysey oq yen ‘seek JeWeoe! NOG

ono

8

| S 9

oS) €)

of

i

ee

wri Ol

‘AyUO azojd dol

"UaA|aDaU JO 4dPUSD OZ

SDUVUVA)D UOPDOUZXS UOZ’ZJO ]0ZEW YW fY STON

‘pou {OCT

42IM4 Ser

J-O }a81S 00}

4OZDOU}X"

68108

wos saqyoodyy MWA

supid OH

20qHPD OS sUyOr

*oIua GLE" WNUWNY

RUNOW YOZD0UEXZ

nus

SLE

ayzo}d doz

NAYy Uaaleday

c€-0 o0s'0

rar — 43

eiaq sonjaooy

‘BUBid OUI JEGIED 0S 8,UUOr

L

ean —s

o

sa

r waAIsOa4 -asey sjunow doyg 490g Buu

‘sueid opr JOqNED 0g S.UyOr i

“ONDIOVHO ISISTY TIM ONV 'HLONZMLS GOW TIM,

107§ YOO78 ONIUId 40 SHANHOS SNIGVY “LON

Tors oo|g Buyt+

“eave souReao JeWUWe|

10H pepBasU jeLle§

“a19H S]UNOW WeUS uueH

“ajay syunow JopenXy

‘yoq ualje whut ¢ epes6 esr

r 7 ¥ z — T 7

Id

ONTAI4

©

= 10

©

dOls

YAWNVH

w09"s2q 1) 0K AMAA

suDjg URL

sq 05 SUYOr

&

MOO TE

ONTAT 4

sueid a17Y 19qHTeD 06 SYUOr

fi

iu

“aley qouy baie 60

deep .g @ ze-0l de 8 I

Magwoug

g0'0

diy snipoy

‘P'0,82E' 7] ‘po'cs 0

seo

—| 002

La

colt Lt

jr O1E'T

si-av WOYs 3aVW

NId ONISI4

asia

sz00~_ [© ry

Ma4IS PLY 2015 yous 60

eE-Ol YO¥S AUIS'D

yaays

SS'TXg'xGo"

dOLS aaWWVH

*A\MO)S YZOQ UN]

aaym Bujpuju6 uemo)

0} aypuLy Suuny puLy vauzo sv

«pu0y AQ pazozou aq uvd uid Bujyj4

"ZO)J S| WOLZO0q auNs arnoW

‘Buo) Ssaysu! € UO Z 8845 PIIW ash

8S'0-+-—

sro

4h. z ot

82'0 J

‘aunyx|Z BujMoyjo¥ ayy arou

vapul6 uojsjdaud © Bujsn ¥T

xe dn payoss

a ZWD

80'0

dja snipoy

'p'0,82€" '‘po'cza’

s2'o

ect

ST-av WOYs F04W

NId ONIAI4

‘sa0eid Om,

AO'EXSL' LX") WNUIUINIY :IBUSIEN

aero wep aed oF ‘AnuoN dweps yenu duet jeueEg

“Ulu ,g00" ‘JeIoWEIP fee UBL JeyeWIS aq snl E10,

“JeI@UIEIP [0UEq JO} 9/0} ‘S810

eee EE

| sn. ast

SUBId @bY JEGIIED OS B,LYOL

TINGTORTY .0'€ X w/e “TEUEVEN

3u3H SLNNOW STONVH ANNO

“SU3H SLNNOW SIGN

M3lIA dol

“3U3H SLNNON NOLS.

'343H SLNNOW GOd/8 “3M3H SLNNOW GO 4a99I8L

4 “SeaH SLNNOW el

i wa j

“aUSH SINNOW dWYTO 134 1s

Pe» 4 4 es

SUH SLNNOW anzoa_—_|

(jeuondo )

a =a

i

Low oral

200g wnauunry

“pemolie 8} ‘pou Ja66u} Jo LONE IOI ON

‘SUBId Obie 2eGTED 0G LUO “wonisod ut ‘pod 86613 400) 1M SIU,

“9joy ewes ey) JO ‘pus Yoee UI

B1-O1/ SMavOS|ES UD|IB OM) [/29SU]

NUTTY ,0'e x pre BUI ‘doap .¢'® at-9/S

“2J04 .Gz" aun 40 SPU YyO dEL, .

cova sem

he T a =a

. tf ° i .

“seBpe do} Jayweus M3IA adis

4

1 7 { f-

| “T L +. — +

TTA] 3 ede s'6eq o6@sej0y om. ‘PY ozez-.00sz" @ Wway

Fee

ied oi

‘sueid eure JeqNed 0 S,uuOr Ld

| eo

MaWNWH Lv *

“uonedo| Jedoud U!"9joy .9eZ° BABY [Wm JOWWEH

"3OVd LX3N ‘S3LON 33S a

“uoje99| sadaud Ut '3}oy . 962" eneY IIIM JeBBU }

“r.ozgz-.002' WY3Y

‘Buds 166. Ujeyer [Im MaLDSIOS.

“Buo],g @mesos jos 26-8

MODIFING PARTS

The AR-47 Trigger : the pivot hole in it is 6mm. Drill it out to .25 id tha

both sides. Next grind or belt sand off 1 ear if you like

this will make for smoother trigger.

A 8-32 thread hole located in rear, this will hold in trigger spring. Lock-tite

in with removable, trigger is now finish. Trigger is mounted in Rail.

The trigger shaft is 2.215” long, 1 used 1/4" stainless steel, mild steel is fine.

A348 tap hole is put in center. A allen screw is loc-tited here. Note this

serew keeps the trigger in the right location, in the unfired position. The

spring pushes the trigger up, and this allen screw (3-48) stops the upward

movement.

The 5/16" setscrews, 2 of them in the aluminum base pushes against the

trigger rod, holds it in place and stop it from rotating.

Really tighten the 5/16 setscrew tight with loc-tite. If the Rod, rotate while

Joaded the gun should not fire. It just will not cock the hammer. This is

really easy to understand the trigger system.

‘SUBld Sule JEqIED OS §,UUOr

YROOINL Le

tuys ten xg ui

WM wasoeee au “unoe# 0 30 97 Bu,

8 Bmeiosoe ze # neu "Buran Jou

“pamowe s1 pox JoB6u,

JO UOREIOY ON "UOHEIO! Aue “syeUIWIO

04 ‘aoe d uy pex0) oq srs "pory 3986.1,

‘UIeL, Ul ‘@pIs YRS BUC “eed UI pod 19B6N

uy

yeseq wnuwnty uw yuno i

“poy JaB611), Uo ‘Ajeay) jonid smu JeBBU

“uogisod

pauyun ‘pauisep ui 1eB66u1 daoy tm ‘Buds

‘Buo} ,gz' mains peay valle ‘ar-€ Nes)

wonwe

see

181g SSEILIEIS “1EUEIEW

dou uz99/uL

Ou

poy sewweH

1

2.

az

fog

Ieeg ssolueis eUReW

[POU JOUIWBY UO JAAS] JO.

pus eysoddo ‘Je1109 490} ‘p't Sz"

sleysu! ‘pou JewWey Uleyes djey OL

“JeAIE084 JO OPIS Yo ‘Jene| yn soeds

WA Siu. “J0A1000 Jo Opis PUB 18AE7

usemjed Je}jojeoeds ,2" EISUL

“JOWWEY Ul SMEIDS1OS

YoVew oF ‘pos JOMWEY UO $YBy IIA

‘JOAIST94 Ul Aju OAId ISN pou)

‘Invindani

°

[

oy

‘poy sBuRUEH EIUCD IVA

‘smes0eye8 B104Mr ‘POY JOLUIEH UO 224 I

-pageds fijenbe sejoy om,

UnuJWINIY .0'L XG" > EYE},

POY JEWWEH 40) J8A87

woo aqyoanyy MM

suid ay

Jeqyod os Suyor

70S" OF NMP “CUg) B]04 FOAL

“dae .0E0 S¥°1J TIN wauWoY UL

suouosqas 4240s oF joys waUUDY UO

OU ONa a4, aU 30 APO

jou Ogu “S3}04 ee-OF OMe dod ¥ Nive

“sausuy 9S2 0} 3104 3OAIG WHQ TT

“a}0u4

paddoz sauuoH Lye

2-01

“yu0do

saavGap 06 ‘Sa}oy

paddo; 2E-0T OM,

SUD\q S)sly YEqog OG s,UYOr

MODIFING HAMMER

Make sure not to bu¥ American made they're to hard to drill. Get Import.

Hammer comes with 6mm hole, drill out to .25 i.d. to fit your .25" rod.

er Rod, which is 4.10" oal,)drill and tap (2) 10-32 holes thru to the .25

hole, this will let you lock the hammer to the hammer rod. Mill small flats,

so that the setscrew in the hammer will help lock hammer to shaft. The

hammer rod is just cut to lenght, and flats for setscrews. The hammer will

need to be milled to fit in the slot of the reciever. Make sure the hammer

spring is correctly installed, it will only work one way. The hammer will

only work one way. Most people install the hammer wrong. The ears on

hammer are away from hitting fimg pin. Use pictures for reference.

THE BARREL

The lenght of mine is 32". I suggest no shorter, the shorter it is the higher the

pressure will get. It will come 45" oal. and 26 pounds. I turn all the o.d.s.

off, and I measured 1.562" at barrel clamp area. The rest of the barrel, I tum

down to 1.5" od, Using carbide endmill, mill 2 flats near reciever end not to

deep, just touse wrench to tighten. Loc-tite-blue-on barrel threads.

“The barrel lenght I used is 32”.36" is the longest that you want to go. After

36" the barrel starts adding drag. Barrel clamp should be straight. It should

also be tight to barre! od. T bored .002" to small, to insure a positive fit.

Muzzle brake should always be on rifle when shooting. This will reduce

recoil. Also it will reduce stress to the recieyer. The muzzle brake has 3

setscrews that will lock down on the barrel 2.150" from end. I suggest that

you cut a small groove around the od. of barrel, 2.150 from end, and not the

thread end. Muzzle brake will go on, not thread end. Hope you already

know this.

Aline muzzle brake horizontal straight and lock the (3) setscrews tight with

loc-tite. Make sure .562 id hole in muzzle brake is in proper location. To

check use .510" od wood dowel pin. The wood should not touch muzzle

brake.

mk ———

[LEC]

a

une 7

“enoouB epim T

SUB Ole JEqIIED OS S.UUOr Ole: sip sew Wm sMaDEIOS ' i

“pus Siu s]UNOW 9yB1g 9/ZZNY

“JeyOWEIP O9G"t 0} UMOP

SJe}OWEIP {a1eq LUNAYBIEM BWOS BAQWAL OL

“spunod 9z inoge syBjem jeuieq sriduns ¥

“Speouy) [AUER “YOVeW JsnW aJog/spBaltA

Jenjeoey ‘pasn aq ABW ‘S/e}eWEIP PEI) 1NNO)

"pepeesiy eq Apeauye Im

“pasequeyp eq Apeauje |IWM sjaueg sryding QWa

r T ¥ r —————

i ,

BUILDING MUZZLE BRAKE (M.B.)

Bore out a piece of 2.25 diameter rod. I used some thick wall tubing, that

was thick enough to obtain my dimensions. The M.B. bore should only be

002" difference, than the barrel diameter. I put the same dimension on

drawings. I did this, to reduce mistakes, of builders.

Once the rod has been bored, face to Jength, both ends. Drill 3 holes 5/16-

18, 120 degrees apart. 5/16-18 setscrews will go here. They will lock

muzzle brake to end of barrel. The setscrews will lock in the groove on

barrel, The 1.462 0.4. groove.

‘Next mill two flats on 2.25 rod, .125" deep and 1.00" back 180 degrees

apart. Between the two flats should measure 2.0. This flat is very

important. It will hold 1/4” x 4.0 x 4.5 plates (CRS) square, and will allow

better welding. Dont make M.B. without milling flats.

The two 1/4" x ARamstoold Roll steel plate can be cut on band saw, and

belt sand to dimensions. Clean metal plates / rod clean before welding. Do

all machine work before welding, except for bullet hole .562 ,. Tack weld

parts in proper location first. After welding, let air cool, dont dip in water to

cool, and dont drop. This could cause cracks to start.

After M.B. is cool, drill the .562" hole in proper location. A lathe or mill

can be used. I used Lathe. If you use mill indicate a 1.562 od rod vertical in

the mill vise, slide M.B. on vertical rod. Tighten setscrews lightly and

evenly. Now you can drill on mill the .562 id hole. After drilling install on

barrel and check for clearance of the .562 id hole.

John's 50 Caliber

Rifle Plans

www fiftycaliber.com

1

a ee

>

oyesg oz

‘SUBId OLN JOQYeD Og S,UYOr “ae

‘810q UA “sa}UG Ul oq ISN BfoY SILL “942 JO

ue Uy ejoy ,zZ9S" up ‘eunjeedie} wood Ss] eye1G LOYAA

1009 0} J8)2M 98N JOU OG ‘1009 4/8 364 ‘BUIP|OM JayY

a

“@Joq gny Jo sejUeo @ "pi ,09¢" tO»

seedings Set —t

~s

wsossseqyeohyyy mane

‘supjd ut

seqyed 0S 44°F

‘mauds yD0f UOROAa}a JOS. S|

Siu) ‘4azua> ul daap Ta €1-,2/1 404

3 Mup ‘aypuvy ayz JO ‘WORZ0q 24} UT

"as00)

Bujuoraq vo Guyx304 wo4s aypuey daar

TWH sia ‘uid aMop © OJ S| ,06T BUL

‘djaB uy Apoaue aj04 doy ma42S ZE-0T ©

Jog S| ajoy Bupsixa SyL "woxz0q 440

gz'a du6 uj aoy aoueseer> 4102" 4p

duB uy Kay wnyo yunow of “dvb 3i3s0\d

uy Kowhay Apoasyo s} avayl ‘dly6 313S0\d

yI-u Aougog uo s3unow fay gos’ whujwniy

aypucy}

= fe sco

ax unuumy 227

oosx2cr"

nau

2e-01

poy unujuniy .S2'T

mara dol

00

daap

2060"

Wi

daap

2€-0I—}-0—

(

swe |

SLBBI-.91/S:

vvo—| |

daap,sa

éToe.

nau

02-.6/1:

“sit

GUBig aUY JEqIIED OS UUOr

ANMOW 310018

all

‘@SBQ “WIN|e O} JUNOW III 3UNOWY ¥O01S

O'EX.S LE wWNUIWUNTY “JELETEA

14 sea

NIG

eroewt

woe eros

Te L

=i ume] er

| Fa

cut

Pou x20

SUBid OUle JEQIED OS S,UUOL see

SPOS SL-NY UMM pesn aq o1

10°} Poy TERUTINTY jeuerew

deed ce @ ‘wioe-vihy

deed .0°) ® ih €1-2/1-

———-t

Lal barn

MINOW 4201S,

‘SUBld OUI J8qIIeD OS S,UUOr

“$3903 duWvHS Tv 3AOWSY

wnujwnty 1909 ‘evereW

POW A|AIS SL-wW JO] Jedepe OOIS

SLN

e704 sion

“Bu0] 0° ® e-Z/1 maxoses ualIe UD

“wpOue} (e104 ,¢'6 ® pow wnulwniy 0°} ‘Pepesu sjEVeIEW JNO

ad T —————.—_—— —— + T

4

001"

TET se

yoo

mauosTpy

daap ,0TBET-.2/1

qunow

pod-ig

poadyy10

el-2/1

ua

863)

yovray

\

\

powwnyo

I

SIN

wnulwnyy so

Uljag 1]0J4a}. 0,

"maurs

apununay)

pyuony uweh6iul

SU0|d ajsly veqneog Az4!4

HEAD SPACING

To do, the falling block, barrel, and reciever will be used.

(Fring)

With the reciever threaded, screw barrel in. Use falling block, without firing

pin for safety. Screw in barrel until it is almost completely in. Now put live

Round in chamber / barrel, slide in falling block. Bullet must measure 5.430.

Thave got some a little smaller by .010*, They will still work. As the falling

block slides in, it will push Round in to its Final depth. The Radius on the

front edge of the falling block will do this.

‘You want the falling block to be slightly resistance not so tight you have to

force in. Try with a few more Rounds. I can push my falling block thra with

my fingers, but it will not fall out on its own.

When test fire use 100 yards of fishing line. Remain 100 away. Shot one

time and inspect everything screws, bolts for cracks, etc. You can set rifle on

the ground, and have good back stop. Shoot again, inspect after every shot.

Thave check mine, before and after each shot. After testing, when regular

shooting I still will check before I shot. And wear ear protection always

during testing and shooting of your fifty caliber, and I suggest to wear safety

glasses.

Afier shooting check for checks around the firing pin,slot in reciever. Cracks

usually start in a comer, other than just on a flat surface. I would test with

about 10 rounds and on 3 differerit days, dont paint until you are finish test

firing. Paint may hide any cracks. I suggest you use check list, on index

card, and dont have lots of people around. They may influence your

judgement, but I would take someone.

Remember I just sold you the plans, I dont accept and personal property

damage.

Make sure all the bolts are tight, dont over look checking any, like the bi-pod

On the firing block check it for cracks. Also, check spring and firing pin. Its

hammer stop tight. Does firing pin floats freely.

John's 50 Caliber

Rifle Plans.

wor fftycaliber.com

Or

ASIA

a3AIgo3a

‘Bap 06 ASIA Uf Yarjaday az0304 4D

‘auyu) $a3.0)d saajasau daay 03

vanjazeu ul ag pynoys sujd jeKoq Spt

31g YDuEdM

Sd01g THN

‘sayaq owas

aINPa4 0} ‘ASIA Ul PUOOgp4od adv)\q

“ARUBNS Uar4B|z aq AWUO Pinoys asiA

“3S8¥a WANIWNTVY NO LON

“as|A ul auop aq pinous Gusedsooay 29ST 199 06 L

sudid arid aang Aas14

ASSEMBLY-

Receiver:

Insert hammer and spring in the reciever and push in the hammer shaft.

Fasten the hammer knob and brass spacer on next, and lock the set screws

tight, with removable lock tite. On the opposite end of the shaft install nylon

or brass washer and loc-collar. This shaft now should not come out of

reciever.

Install Bipod on base and handle. They will keep the base up and steady, so

parts can be add easier. Now insall he trigger and spaces in base and add

the 3-48 allen screw in trigger shaft.

Screw the barrel into the reciever, attach it to the base. Install trigger spring.

Fasten the allen bolts tight with removable loc-tite. Make sure the reciever is

straight.

Next, install the barrel clamp with removable loc-tite to base. Clamp must be

tight on the barrel od.

‘Try cocking hammer with rifle unloaded of coarse. I suggest not to dry fire,

just hold hammer, and see if it releases proper. Dry firing will cause

setscrew in hammer to release. If they slip when cocking the rifle could fire,

so make sure its no play here between the hammer and shaft. Try trigger,

several times and make adjustments. You may hay vate trigger shaft to

Ifyou have questions, please contact me via e-mail.

Material List (50 caliber rile) John's $0 Caliber

3/4 23° x20.38 inches aluminum plate 6061-16 basertal Rifle Plons

1-5-%game3" x10.3* (mill two pes. From this 5.00 long) receiver ‘www fiftycaliber.com

Tod. aluminum rod 16"long bi-pod legs & stock rod

40d9" long hammer pivot shaft and trigger sbaft

1250d aluminum rod 4.0lang handle

1.753q38.0x2 pes barel clamp

1x26 mild ste! cold finish filling block

12x1.0x 1.38 aluminum fat — lever fr hammer shaft

25x40 fat mild steel cold finish muzzle rake

2.25 odx 2.75 longrod mild stel cold finish muzzle brake

25x5%20 flat mild or stainless hammer stop

Purchased Parts

‘Ak-47 hammer spring &: trigger ( get cheap hammer,not American made)

‘American hammers are too hard. Cant drill for set screws

‘Ar-15 fring pin & stock assembly

lock collar may want to use 2 collars are .5 o.d. x.25 id. x28 thick

‘with 10-32 ap hole tara side, These can be made.

3 bronze o oillite bushing for hammer shaft 375 0.4.25 i..x25 or 38 thick

‘Allen screws and bolts. to assemble, the list will follow on another page.

Suppliers

‘Taw ine. Vemoia Oregon 1-503-429-5001 Web :/members.aol.com/tnwoorp

Miscproducts htm! barrels and ammo

Classic Arms inc. Indian trail NC, 1-800-383-8011 Ak-47 parts

Iwanhoes Warchouse oulet 1-508-667-5181 wew.ivanhoeoutletcom Ak-47 parts

Fulton Armory 180-878-9485 ar-15 pans -

(Oyster Bay N.Y. 1-516-922-1376 may get more barrels,

Ammo

AAA yworw.asg-ammo com 402-334-3389

‘Thunderbird Cartridge Co. www.qpg.comvutcci. 1-800-535-ammo

BOLT LIST; FIFTY CALIBER RIFLE PLANS

Bolt Type :

Allen

Allen

Allen

Flathead Scre

Setscrews

(or althread)

Brass Nut

Allen Screw

Dowel! Pins

Size:

375 x1.0

375 X 1.75

312 x10

375 x 1.0

-312 x 875

312 x10

375 x2.0

312.x 1.0

10/32 x.5

8/32 x 3/8

8/32 x 1/2

10/32 x 1/4

10/32 x 3/8

5/1618 x 3/8

12-13 x 1.0

1/4-20

3-48 x .25 long

25x10

187 1.0

Nw 8

aN

bn

For:

Receiver

Barrel Clamp

Bi-pod

Bi-pod Leg

Stock Mount

Firing Block

‘Hammer Knob

Retain Trigger Spr.

Hammer

Hammer

Retain Trigger Shit

Stock & Bi-pod

Spacers

Trigger Shaft

Reveiver

Stock & Handle

2 ¥ © 1

uunulwnty Iv : SIeveyeN

AISWASSY FTONVH

gh

SUBId SUI J8qIIED 0S 8,UYOr

fei Ile ty —

4

ae a

ae | /

uaAOSy

‘BUC OUTH FEqIED 05 S.0UOT

HHS |

fist

at

eer log.

a if *

=r

MaIA Scis

Mai -dOL

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Keeping Beaks Trimmed and FunctionalDocument6 pagesKeeping Beaks Trimmed and FunctionalDana DunnNo ratings yet

- Dornier 335 Fuselage and TemplatesDocument1 pageDornier 335 Fuselage and TemplatesDana DunnNo ratings yet

- Dornier 335 Wing and TemplatesDocument1 pageDornier 335 Wing and TemplatesDana DunnNo ratings yet

- P2 Jungmeister Wing and TemplatesDocument1 pageP2 Jungmeister Wing and TemplatesDana DunnNo ratings yet

- P1 Jungmeister Fuselage and TemplatesDocument1 pageP1 Jungmeister Fuselage and TemplatesDana DunnNo ratings yet

- AG Parts List and PrintsDocument30 pagesAG Parts List and PrintsDana DunnNo ratings yet

- AF TexanSSManual2017Document16 pagesAF TexanSSManual2017Dana DunnNo ratings yet

- Classic & Modern Wheels Made in EnglandDocument8 pagesClassic & Modern Wheels Made in EnglandDana DunnNo ratings yet

- C4 Tire Reference Guide-ADocument2 pagesC4 Tire Reference Guide-ADana DunnNo ratings yet

- Bluebird GliderDocument1 pageBluebird GliderDana DunnNo ratings yet

- Major Swine BreedsDocument1 pageMajor Swine BreedsDana Dunn100% (1)

- Fairchild A-10 ThunderboltDocument2 pagesFairchild A-10 ThunderboltDana DunnNo ratings yet

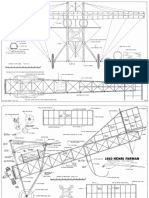

- 1910 Henri Farman 47inDocument3 pages1910 Henri Farman 47inDana DunnNo ratings yet

- Mcsorley 400Document49 pagesMcsorley 400GermanHundNo ratings yet