Professional Documents

Culture Documents

Kohler Model13ERG

Uploaded by

WilliamBrown6Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kohler Model13ERG

Uploaded by

WilliamBrown6Copyright:

Available Formats

Model: 13ERG 60 Hz

Gasoline or LP

Commercial Mobile

Generator Set

Engine Features

D Port fuel injected (gasoline models)

D EPA certified

D CARB certified (requires CARB kit for gasoline

models)

D Electronic control module for optimizing fuel and

spark performance

D LP gas or gasoline fueled

D Four cylinder

D Four cycle

D Pistons have high silicon content for improved

durability and noise reduction

D Sintered powdered-metal exhaust valve seat

inserts for enhanced durability

D Poly V-belt harmonic balancer

D Electronic governing with frequency regulation of

±1.2% on gasoline models or ±0.75% on LP models

D Lifting eye

Generator Weights and Dimensions D Electric fuel lift pump (gasoline models)

Weight, kg (lbs.) D Fuel filter (gasoline models)

Dry 299 (660) D Water cooled, inline radiator cooling system

Length, mm (in.) 1111 (43.7)

Generator Features

Width, mm (in.) 528 (20.8) D Remote start 12-pin connector

Height, mm (in.) 691 (27.2) D Class H insulation

D Voltage regulation of ±1.5%

D

Generator Ratings RFI suppression

25_C (77_F) 25_C (77_F) ADC 2100 Advanced Digital Control

Model Series Voltage Hz Amps kW/kVA Ph

Features

13ERG 120/240 60 54.1* 13.0/13.0 1 D Designed for today’s most sophisticated electronics

* Denotes amps per terminal. D Easy to read alpha-numeric display

D Compact, integrally mounted control

RATINGS: Mobile continuous ratings per ISO 3046, ISO 8528-1, and Kohler ISO rating guideline

2.14. Obtain technical information bulletin (TIB-101) on ratings guidelines for complete ratings D Potted boards/sealed connectors for maximum

definitions. corrosion protection

Availability is subject to change without notice. Kohler Co. reserves the right to change the design or D SAE J1939 CANbus output

specifications without notice and without any obligation or liability whatsoever. Contact your local

Kohler generator distributor for availability.

D Remote monitoring of up to 13 fault conditions

D Membrane keypad for configuration and

adjustment

D Programmed crank cycle

G3-29 (13ERG) 7/08d

Application Data

Engine Lubrication

Engine Specifications 60 Hz Lubricating System 60 Hz

Type 4 cycle Type Pressure, eccentric bi-rotor

Cylinders, number 4 Oil capacity with filter, L (qts.) 3.5 (3.7)

Displacement, L (CID) 1.6 (98)

Bore and stroke, mm (in.) 79 (3.11) x 81.5 (3.21) Cooling

Compression ratio 9.4:1

Cooling System 60 Hz

Rated rpm 1800

Engine coolant capacity, L (qts.) 8.0 (8.4)

Max. power at rated rpm, HP 24.9 Heat rejected to cooling water at rated

Cylinder block material Cast iron kW, wet exhaust Btu/min. 1567

Cylinder head material Aluminum Engine water pump flow, Lpm (gpm) 37.9 (10.0)

Crankshaft material Cast iron Water pump type Centrifugal

Piston rings 2 compression/1 oil control Fan diameter, including blades, mm (in.) 390 (15.35)

Crankshaft bearings, type 5, replaceable inserts Fan, kW (HP) 1.2 (1.6)

Valve material Maximum air restriction on discharge

Intake . . . . . . . . . . . . . . . . . . . . . . . . Chrome/silicone steel side of radiator, in. Hg (in. H2O) 0.13 (0.50)

Exhaust . . . . . . . . . . . . . . . . . . . . . . Stellite F Operation Requirements

Piston material High silicon content Air Requirements 60 Hz

aluminum Engine combustion air requirements

Governor, type Electronic m3/min. (cfm) 1.13 (40)

Generator cooling air requirements

m3/min. (cfm) 5.9 (210)

Engine Electrical Radiator cooling air requirements

m3/min. (cfm) 85 (3000)

Engine Electrical System 60 Hz

Heat rejected to ambient air:

Ignition Electronic, distributorless Engine, kW (Btu/min.) . . . . . . . . . . 5.2 (294)

Starter motor . . . . . . . . . . . . . . . . . . Solenoid-actuated pinion Generator, kW (Btu/min,) . . . . . . . . 2.7 (153)

Spark plugs . . . . . . . . . . . . . . . . . . . Resistor-type RFI

suppression Exhaust

Battery voltage (DC) 12 Exhaust System 60 Hz

Battery charging alternator 70 amp Exhaust outlet size at hookup 1.5 in. NPT,

CARB: 2.0 in. ID pipe with

Battery recommendation (min.) 600 CCA @ --18_C (0_F)

catalyst

Exhaust flow @ rated kW, m3/min. (cfm) 3.7 (131)

Fuel Exhaust temp. @ rated kW, dry exhaust,

_C (_F) 649 (1200)

Fuel System 60 Hz

Max. allowable back pressure, kPa

Type LP gas or gasoline (in. Hg) 10.2 (3.0)

port fuel injected

Fuel pump (gasoline only) Electric Engine Features

Fuel pump, max. lift (gasoline only), D One-side serviceability of fuel system, lubrication system (with

m (ft.) 0.9 (3.0) remote oil filter kit), and air cleaner

LPG fuel supply pressure, in. H2O 7--11 D Low oil pressure cutout

D High water temperature cutout

Fuel Consumption 60 Hz D Vibromounts

Gasoline, Lph (gph) at % load D Disposable oil filter

100% 6.89 (1.82) D Fuel filter (gasoline models)

75% 5.75 (1.52)

D Oil drain petcock with extension hose

50% 4.24 (1.12)

25% 2.91 (0.77)

LP Gas, m3/hr. (cfh) at % load

100% 2.0 (74)

75% 1.6 (55)

50% 1.2 (43)

25% 0.9 (30)

G3-29 (13ERG) 7/08d

Application Data

ADC 2100 Control Features Generator Features

D Static excited, rotating field design permits power to be

obtained from stationary leads.

D Rotor and stator are vacuum impregnated and coated with

high-bond epoxy varnish. Varnish helps prevent corrosion in

high-humidity areas.

D Rotors are dynamically balanced to minimize vibration.

D Copper windings ensure minimal heat buildup. Insulation

meets NEMA standards for class H insulation.

D Directly connected to the engine, the generator has sealed

precision ball bearings with a precision-machined steel

sleeve in the end bracket (or end bearing tolerance ring) to

prevent shaft misalignment and extend bearing life.

D LED display: D Circuit breakers protect the generator from extreme

overload.

d Runtime hours

D Mounted on a rail-type tray.

d Crank cycle status

d Diagnostics/fault codes/data D Equipped with a four-lead reconnectable stator.

D Keypad:

d Secure access, password protected Accessories

d Voltage, gain, and speed adjustment

d Controller configuration (system voltage, phase, and Cooling System

frequency settings, battery voltage, and generator set - Block heater

model)

- Heat recovery fittings, wet

D Master control switch: run/off-reset/auto (engine start)

- Radiator guard

D Remote two-wire start/stop capability

D Potted electronics and sealed connections

D Voltage regulation ±1.5% Lubrication System

D Cyclic cranking: 15 seconds on, 15 seconds off - Remote oil filter kit

(3 cycles)

D Faults with shutdown:

Exhaust System

d High engine temperature

- Critical exhaust silencer

d Low oil pressure

d Overcrank safety - Flexible exhaust connector

d Overspeed - Catalyst (CARB) for gasoline models only

d Over/under voltage

d Over/under frequency Generator Set

d Auxiliary fault

- Line circuit breaker

D Faults with warning:

d Low battery voltage

d High battery voltage Controller Accessories

D Power requirements: - Sender kit—includes oil pressure sender

d 12 VDC with fuse protection - Remote digital gauge

d 200 mA @ 12 VDC

- Remote start/stop panel

- Remote wiring harness—12 in. (30 cm) pigtail

- Remote connection/extension wiring harness—

4.6 m (15 ft.) and 7.6 m (25 ft.) lengths

G3-29 (13ERG) 7/08d

KOHLER CO., Kohler, Wisconsin 53044 USA

Phone 920-565-3381, Fax 920-459-1646

For the nearest sales and service outlet in the

US and Canada, phone 1-800-544-2444

KohlerPower.com

GM63617-

Exhaust Catalyst

Assembly Drawing

ADV-6816-D

DISTRIBUTED BY:

NOTE: Dimensions in brackets are inch equivalents.

NOTE: This drawing is provided for reference only and is not

intended for installation planning. Contact your local

distributor for more detailed information.

E 2004, 2006, and 2008 by Kohler Co. All rights reserved.

G3-29 (13ERG) 7/08d

You might also like

- 28EOZD 60 Hz Marine Generator Set 1-Phase DieselDocument4 pages28EOZD 60 Hz Marine Generator Set 1-Phase DieselĐại DươngNo ratings yet

- Model: 11EKOZD 9efkozd: 60 HZ 50 HZ 1-Phase DieselDocument4 pagesModel: 11EKOZD 9efkozd: 60 HZ 50 HZ 1-Phase DieselEdgar MaldonadoNo ratings yet

- Model: 6EKOD 5efkod: 60 HZ 50 HZ 1-Phase DieselDocument4 pagesModel: 6EKOD 5efkod: 60 HZ 50 HZ 1-Phase Dieselyeng menNo ratings yet

- Model: 23EOZD 20efozd: 60 HZ 50 HZ 1-Phase DieselDocument4 pagesModel: 23EOZD 20efozd: 60 HZ 50 HZ 1-Phase DieselMaksym KlymenkoNo ratings yet

- Model: 15.5EOZD 13efozd: 60 HZ 50 HZ 1-Phase DieselDocument4 pagesModel: 15.5EOZD 13efozd: 60 HZ 50 HZ 1-Phase Dieselabduallah muhammadNo ratings yet

- 6EKOD SpecificationsDocument4 pages6EKOD SpecificationsEfrain FlorezNo ratings yet

- Model: 10EOZD 9efozd: 60 HZ 50 HZ 1-Phase DieselDocument4 pagesModel: 10EOZD 9efozd: 60 HZ 50 HZ 1-Phase DieselTeszt Sdj100% (1)

- Kohler 12.5EDocument4 pagesKohler 12.5EMike JacobsNo ratings yet

- Kohler 24 Specs SheetDocument4 pagesKohler 24 Specs Sheetabduallah muhammadNo ratings yet

- Model:: Residential GasDocument4 pagesModel:: Residential Gasapelectric100% (1)

- Manual Kohler 30RYGDocument4 pagesManual Kohler 30RYGjtamez2009No ratings yet

- Kohler 10REOD/REOZD Compact Diesel Generator SpecsDocument4 pagesKohler 10REOD/REOZD Compact Diesel Generator SpecsGalindez JoséNo ratings yet

- Kohler 35EFKOZD SpecificationsDocument4 pagesKohler 35EFKOZD SpecificationsKelvin YuenNo ratings yet

- Marine Generator Set Specs and FeaturesDocument4 pagesMarine Generator Set Specs and FeaturessebastianNo ratings yet

- Kohler 45RZ Generator Ratings and SpecificationsDocument4 pagesKohler 45RZ Generator Ratings and SpecificationsRebecca Winfrey100% (1)

- Kohler Marine 70efozd PDFDocument4 pagesKohler Marine 70efozd PDFĐại DươngNo ratings yet

- Kohler Home Generator Provides Reliable Power ProtectionDocument4 pagesKohler Home Generator Provides Reliable Power ProtectionAdmin BisnisNo ratings yet

- Models:: Multi-Fuel LP Vapor/Natural GasDocument4 pagesModels:: Multi-Fuel LP Vapor/Natural GasapelectricNo ratings yet

- Kohler 100efozcjDocument6 pagesKohler 100efozcjoppa FadlyNo ratings yet

- BLOWER 10-10DD 0.50 CCW CV at 1075RPMDocument3 pagesBLOWER 10-10DD 0.50 CCW CV at 1075RPMDiego RomeroNo ratings yet

- Model: 55EOZCJ (60 HZ) 45EFOZCJ (50 HZ) : 3-Phase DieselDocument4 pagesModel: 55EOZCJ (60 HZ) 45EFOZCJ (50 HZ) : 3-Phase DieselsebastianNo ratings yet

- Kohler 2000ROZD4 Spec SheetDocument4 pagesKohler 2000ROZD4 Spec SheetKhaled KamelNo ratings yet

- Kohler 60RZ Spec SheetDocument4 pagesKohler 60RZ Spec SheetRomanvi1980No ratings yet

- Kohler Generator g2166Document4 pagesKohler Generator g2166philipNo ratings yet

- Kohler Marine GensetDocument4 pagesKohler Marine GensetENG PTBBSNo ratings yet

- Kohler Moteur Johndeere 50EFOZDDocument4 pagesKohler Moteur Johndeere 50EFOZDzirra82No ratings yet

- Model: 500EOZCS (60 HZ) 450EFOZCS (50 HZ) : 3-Phase DieselDocument4 pagesModel: 500EOZCS (60 HZ) 450EFOZCS (50 HZ) : 3-Phase DieselPato DuhaldeNo ratings yet

- BLOWER 9-7DD 0.50 CCW CV at 1075RPMDocument3 pagesBLOWER 9-7DD 0.50 CCW CV at 1075RPMDiego RomeroNo ratings yet

- 40REOZT Towable Generator Sets Provide Reliable PowerDocument4 pages40REOZT Towable Generator Sets Provide Reliable Powerrendi valentinoNo ratings yet

- Kohler 80efozcjDocument4 pagesKohler 80efozcjoppa FadlyNo ratings yet

- 14resa (L) Spec Sheet 2019Document6 pages14resa (L) Spec Sheet 2019angelNo ratings yet

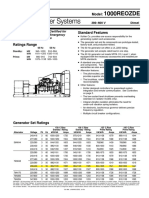

- 1000REOZDEDocument4 pages1000REOZDELanh TranNo ratings yet

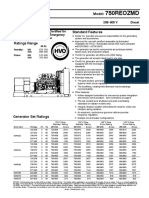

- Kholer Generator 750REOZMD Spec SheetDocument4 pagesKholer Generator 750REOZMD Spec SheetNicholas BrennanNo ratings yet

- Kohler 20resl 14resl SpecificationsDocument4 pagesKohler 20resl 14resl SpecificationsapelectricNo ratings yet

- G4-276 (7-18b) 48RCLB (KG6208) SpecDocument4 pagesG4-276 (7-18b) 48RCLB (KG6208) SpecService Brags & Hayes, Inc.No ratings yet

- Detroit Diesel Spectrum 600DS 4 Spec Sheet PDFDocument4 pagesDetroit Diesel Spectrum 600DS 4 Spec Sheet PDF6PMK IecaNo ratings yet

- 1500REOZDBDocument4 pages1500REOZDBRodrigoNo ratings yet

- Reozje: ModelDocument4 pagesReozje: ModelLuis LunarNo ratings yet

- Kohler 60RCLA Generator Specs and FeaturesDocument4 pagesKohler 60RCLA Generator Specs and FeaturesService Brags & Hayes, Inc.No ratings yet

- 20rca (L) Spec Sheet 2019Document4 pages20rca (L) Spec Sheet 2019angelNo ratings yet

- 50EFOZDJ Technical DataDocument4 pages50EFOZDJ Technical DataĐặng MinhNo ratings yet

- G5318 10reodbDocument4 pagesG5318 10reodbsakrgeorge2000No ratings yet

- Kohler 800rozmc SpecDocument4 pagesKohler 800rozmc Speclilama45-1No ratings yet

- Sgrutb08 e Sot DC01 El51 FD 0001 00Document7 pagesSgrutb08 e Sot DC01 El51 FD 0001 00vinicius leandroNo ratings yet

- Model 150ROZJ Generator Ratings and SpecificationsDocument4 pagesModel 150ROZJ Generator Ratings and Specificationsjuan_samaniego_60No ratings yet

- De1250 GCDocument4 pagesDe1250 GCgjgwrjf78cNo ratings yet

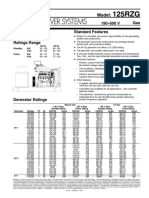

- Kohler 125rzg Spec SheetDocument4 pagesKohler 125rzg Spec SheetRomanvi1980No ratings yet

- JCB 214e Series 4 Backhoe Loader: F A S T - F A C T SDocument8 pagesJCB 214e Series 4 Backhoe Loader: F A S T - F A C T SFanatrailer FanatrailerNo ratings yet

- 20RES Spec Sheet g4172Document4 pages20RES Spec Sheet g4172apelectricNo ratings yet

- SS 11240728 1000028919 129Document12 pagesSS 11240728 1000028919 129Samir YahiaNo ratings yet

- 8resv (L) Spec Sheet 2019Document4 pages8resv (L) Spec Sheet 2019angelNo ratings yet

- Model KSS: Automatic Transfer Switches Standard Specific-Breaker RatedDocument8 pagesModel KSS: Automatic Transfer Switches Standard Specific-Breaker RatedIvan RamosNo ratings yet

- Kohler 50rozj Spec SheetDocument4 pagesKohler 50rozj Spec SheetRomanvi1980No ratings yet

- Koin 080T310Document4 pagesKoin 080T310PHAM THANH TUNo ratings yet

- Kohler 50 PDFDocument4 pagesKohler 50 PDFĐại DươngNo ratings yet

- Cat 3512C: Diesel Generator SetsDocument4 pagesCat 3512C: Diesel Generator SetsAndres FelipeNo ratings yet

- Planta CumminsDocument8 pagesPlanta CumminsHAROLD DAMIAN PEREA GUERRANo ratings yet

- Datasheet 10reozdcDocument4 pagesDatasheet 10reozdcWilliam AlvaradoNo ratings yet

- Gardening On The Contour Hg179 - 88Document8 pagesGardening On The Contour Hg179 - 88WilliamBrown6No ratings yet

- Kohler Model13ERGDocument4 pagesKohler Model13ERGWilliamBrown6No ratings yet

- Kohler Model7ERDocument4 pagesKohler Model7ERWilliamBrown6No ratings yet

- Kohler Model13ERGDocument4 pagesKohler Model13ERGWilliamBrown6No ratings yet

- Endangered Species Lesson PlanDocument5 pagesEndangered Species Lesson PlanIrena Stamenova100% (1)

- Composite Fish Culture PDFDocument2 pagesComposite Fish Culture PDFHanumant JagtapNo ratings yet

- Practice Test Answer Sheets AnswersDocument85 pagesPractice Test Answer Sheets AnswersDon't Make Me AngryNo ratings yet

- FP02BDocument3 pagesFP02BRazak JeyNo ratings yet

- Homemade Litmus Paper ExperimentDocument3 pagesHomemade Litmus Paper ExperimentEmmanuelle NazarenoNo ratings yet

- Filipino Street FoodsDocument5 pagesFilipino Street FoodsMs. 37o?sANo ratings yet

- Dum Aloo Recipe - How To Make Punjabi Dum Aloo, Restaurant StyleDocument14 pagesDum Aloo Recipe - How To Make Punjabi Dum Aloo, Restaurant Styleabhishek.mishrajiNo ratings yet

- sm2000 GBDocument4 pagessm2000 GBRikky ChaniagoNo ratings yet

- Environmental Pollution Control (ET ZC362 - WILP Course) : BITS PilaniDocument41 pagesEnvironmental Pollution Control (ET ZC362 - WILP Course) : BITS Pilanisa_arunkumarNo ratings yet

- Jurnal 10Document11 pagesJurnal 10Atika DelianaNo ratings yet

- Sterilization and DisinfectionDocument41 pagesSterilization and DisinfectionqiotenseiNo ratings yet

- Ficha Tecnica Sonometro Artisan SL2100PSDocument1 pageFicha Tecnica Sonometro Artisan SL2100PSJackson Steward Ríos SastoqueNo ratings yet

- Numerical Reasoning Practice Test Answers: de Roza Education and Research 2016Document2 pagesNumerical Reasoning Practice Test Answers: de Roza Education and Research 2016johnNo ratings yet

- Vote of Thanx For Grandparents Day at SchoolDocument1 pageVote of Thanx For Grandparents Day at SchoolkoolsurdieNo ratings yet

- Operation and Maintenance of Power PlantDocument31 pagesOperation and Maintenance of Power PlantAnkur Pathak100% (1)

- Shree Pa and Uranga Ash Tak AmDocument5 pagesShree Pa and Uranga Ash Tak AmDowlutrao GangaramNo ratings yet

- Tinnitus Causes and TreatmentDocument3 pagesTinnitus Causes and TreatmentTinnituscausesandtreatment Tinnituscausesandtreatment100% (1)

- ParaphrasingDocument20 pagesParaphrasingPlocios JannNo ratings yet

- Bio Brain Review Q S PDFDocument22 pagesBio Brain Review Q S PDFtehilashiftehNo ratings yet

- Assessment and Management of Patients With Biliary DisordersDocument33 pagesAssessment and Management of Patients With Biliary DisorderssarahkaydNo ratings yet

- November 2017 (v1) QP - Paper 4 CIE Chemistry IGCSEDocument16 pagesNovember 2017 (v1) QP - Paper 4 CIE Chemistry IGCSEGhulam Mehar Ali ShahNo ratings yet

- ASTM Liquid-in-Glass Thermometers: Standard Specification ForDocument64 pagesASTM Liquid-in-Glass Thermometers: Standard Specification ForAnonh AdikoNo ratings yet

- ONGC - Internship - Report Please Don't Edit Directly Make A Copy of This FileDocument65 pagesONGC - Internship - Report Please Don't Edit Directly Make A Copy of This File19024 Fenil PatelNo ratings yet

- American Institute of Timber Construction: AITC 405-2005Document8 pagesAmerican Institute of Timber Construction: AITC 405-2005jerchiNo ratings yet

- 17 Quarter 1 Module 17-ANAEROBICDocument20 pages17 Quarter 1 Module 17-ANAEROBICMah Jane DivinaNo ratings yet

- Benefits of HobbiesDocument6 pagesBenefits of HobbiesAdam YapNo ratings yet

- Radio WavesDocument17 pagesRadio WavesStuart Yong100% (1)

- Specimen - Case - Study - CP1 Paper 2 - 2019 - Final PDFDocument6 pagesSpecimen - Case - Study - CP1 Paper 2 - 2019 - Final PDFking hkhNo ratings yet

- CWU Psychiatry 1.1Document8 pagesCWU Psychiatry 1.1Codillia CheongNo ratings yet

- General Biology 1: Quarter 1 - Module - : Title: Cell CycleDocument27 pagesGeneral Biology 1: Quarter 1 - Module - : Title: Cell CycleRea A. Bilan0% (1)