Professional Documents

Culture Documents

Seminar

Uploaded by

Saurav Kumar0 ratings0% found this document useful (0 votes)

66 views7 pagesAutomation can be de fined as technology concerned with the application mechanical, electronic and co mputer-based systems to operate and control production. The main advantage of automation is increased labor productivity at reduced labor cost. This paper deals w ith the data acquisition, program management and remote diagnosis of the system.

Original Description:

Original Title

seminar

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

TXT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAutomation can be de fined as technology concerned with the application mechanical, electronic and co mputer-based systems to operate and control production. The main advantage of automation is increased labor productivity at reduced labor cost. This paper deals w ith the data acquisition, program management and remote diagnosis of the system.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

66 views7 pagesSeminar

Uploaded by

Saurav KumarAutomation can be de fined as technology concerned with the application mechanical, electronic and co mputer-based systems to operate and control production. The main advantage of automation is increased labor productivity at reduced labor cost. This paper deals w ith the data acquisition, program management and remote diagnosis of the system.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

You are on page 1of 7

integration of information technology in machine tools

.doc integration of information technology in machine tools report.doc (Size: 1

.65 MB / Downloads: 165)

.doc integration of information technology in machine tools slide.doc (Size: 63

3 KB / Downloads: 108)

ABSTRACT

Today s buzzword IT has revolutionized every aspects of our day today working lives.

Automation of industries is one of its main contributions. Automation can be de

fined as technology concerned with the application mechanical, electronic and co

mputer-based systems to operate and control production. . The main advantage of

automation is increased labor productivity at reduced labor cost. The heart of m

achine tool is a CNC (Computerized Numerical Control) system, which coordinates

with the displays, PLC, drives system, and feed back systems. This paper deals w

ith the data acquisition, program management and remote diagnosis of the system

Numerical control is for of programmable automation in which the mechanical acti

ons of a mechanical tool or other equipment are controlled by a program containi

ng coded alphanumeric data. Computerized numerical control (CNC) is defined as a

n NC system who s MCU is based on a dedicated microcomputer rather than a hardwire

d controller.

Remote diagnosis or Tele service offers remote support for CNC systems, making i

t a cost-effective alternative to service calls. Lot of time can be saved by thi

s.

INTRODUCTION

Today s buzzword IT has revolutionized every aspects of our day today working lives.

Automation of industries is one of its main contributions. Automation can be de

fined as technology concerned with the application mechanical, electronic and co

mputer-based systems to operate and control production. Automated manufacturing

systems operate in the factory on the physical product. They perform operations

such as processing, assembly, inspection or material handling, in some cases acc

omplishing more than one of these operations in the same system. They are called

automated because they perform their operations with a reduced level of human i

ntervention. The main advantage ofautomation is increased labor productivity at

reduced labor cost.

An automated system consists of three basic elements:

1. Power to accomplish the process and operate the system

2. A program of instructions to direct the process and

3. A control system to actuate the instructions.

Here we are discussing about the developments in the software part, which contro

ls the entire process in machine tools.

The heart of machine tool is a CNC (Computerized Numerical Control) system, whic

h coordinates with the displays, PLC, drives system, and feed back systems. This

paper deals with thedata acquisition, program management and remote diagnosis o

f the system.

NC & CNC

Numerical control is for of programmable automation in which the mechanical acti

ons of a mechanical tool or other equipment are controlled by a program containi

ng coded alphanumeric data. The alphanumerical data represent the relative posit

ion between the work head and the work part as well as other instructions needed

to operate the machine. The concept for NC dates from the late 1940s and the fi

rst machine was developed in 1952 by US airforce.

Computerized numerical control (CNC) is defined as an NC system who s MCU is based

on a dedicated microcomputer rather than a hardwired controller. It includes ad

ditional features beyond what is feasible with conventional hardwired NC. It inc

ludes

Storage of more than one part program

Various forms of program input

Program editing at the machine tool

Fixed cycles and programming subroutines

Positioning features for setup and cutter length and size compensation

Communication interface and

Diagnostics

The CNC systems have processors for specific applications as the speed requireme

nts for the system is far greater here. The processors available in a CNC used t

o perform various tasks like communication, trigger, display, interpolation & ca

lculation functions, diagnosis, data exchange with PLC and other peripheries. Th

e new technology based personal computers has also made rapid development of new

manufacturing processes that enable achieving higher productivity and improved

job finish. Today several solutions are available for IT- integration from proce

ssing of job orders on as machine tool to vertical integration oat factory level

onto ERP systems like SAP and so on. The data available as a result may be used

in various activities vary ranging fromproduction planning to management inform

ation system.

Enterprise wide integration of factory data: The most recent progression in PC b

ased distributed control is enterprise wide integration of factory operations da

ta as depicted in the figure. It is according to the new philosophies of worker

empowerment, which assume fewer levels of company management and greater respons

ibilities for front line workers in sales, order scheduling andproduction.

fig.1. Enterprise Wide Management

Let us look at the different modules of information technology that can be integ

rated into machine tools. The very base of various modules is of handling a host

of data and a wide range of diagnostic functions.

MODULES IN MACHINE TOOLS

MODULE FOR PRODUCTION DATA MANAGEMENT

The module is available in two different variants i.e., WinBDE for machine data

management to carryout machine data acquisition and local evaluation and WinPDA

for central machine and production management to carry out central production ar

chiving and evaluation. WinPDA server is used as a data administrative unit for

the machine information, which is acquired and passed on by the WinBDE systems.

WinPDA server is responsible for all upload and download functions to SAP and Wi

nBDE. The WinPDA clients are the user interfaces for the WinPDA server. These cl

ients can be run on a standard Windows PC (Windows NT or Windows 2000) and are c

onnected to the server over Ethernet. Plant supervisors andproduction engineers

are the main users of WinPDA client. WinBDE is designed for the acquisition and

evaluation of machine data. The system acquires process information automaticall

y from a PLC s memory.

What WinBDE can do

Determination of the machine performance

Detailed disturbance analysis and diagnostics

Transparency at the machine due to graphical error diagnoses

Analysis of weak points

Function overview

A pilot study was conducted to assess Siemens MES solution s capabilities that incl

uded nine machines at one of their US facilities. The pilot included nine marria

ge machines in their assembly area. Three WinBDE terminals were used for data co

llection. The system automatically collects machine status conditions. Each marr

iage machine communicates digital process data via digital outputs to a Simatic

S7-ET200M. The Simatic S7-ET200M then communicates that information to a Simatic

S7 PLC (CPU 315-2DP) through a Profibus DP network connection. A WinCC station

was used to gather the process data from the PLC and pass the information to the

Open ShopFloor data acquisition program WinBDE through an OPC connection. Figur

e shows the system architecture.

Fig.2 WinBDE network

According to the result of the experiment, the customer could optimize their wor

k schedule by using the paperless order dispatching system. Work orders can now

be quickly assigned to a particular machine. The operators at the specified mach

ine can easily confirm the parts produced for the work order and when the order

is completed, it is automatically closed and the machine state is automatically

set to free. At this point area supervisor can assign a new work order to that m

achine. All this information is automatically sent to SAP. The customer has also

been able to track very precisely their machine utilization. Using the data, th

e customer can optimize their work schedules and improve machine utilization. Hi

storical data has proved to be extremely useful. While analyzing machine utiliza

tion and disturbance codes, the customer noticed some interesting patterns. Thes

e patterns showed some very regular disturbances. After further analysis, they d

iscovered that a small change in their maintenance schedule reduced and in some

cases eliminated the problem. This increased the machine utilization and reduced

maintenance costs.

What WinPDA can do

The main area of application for which WinPDA is de-signed is the dispatch and e

valuation of production and machine data (MDA/PDA). Using production data that i

s acquired either manually or automatically by means of PLCs, you always have an

up-to-date overview of the status of production orders, machine assignments, pe

rsonnel deployment, etc. This allows you to intervene appropriately to balance r

ates of utilization, to speed up order throughput and to significantly reduce in

ventory. Higher planning quality is achieved in a manufacturing requirements pla

nning system (MRP) due to the up-to-date data that is reported back by the onlin

e WinPDA system. If no information is reported back from the manufacturing proce

ss, planning options are very limited.

Function Overview

Fig3. WinPDA network

The core functions are production data acquisition and processing. This comprise

s all the interactive functions for processing order, workstation and personnel

data. Automatic machine data acquisition in addition to manual input dialogs ens

ures that process information is always up-to-date. WinPDA an Open System Enviro

nment User Interface. WinPDA is a client-server system that uses open internatio

nal standards based on Microsoft Windows with PC clients and network communicati

ons via a LAN to the data server running the Oracle relational database. WinPDA

is based on the Toolbox, which is a high-level development platform. The modular

open system structure ensures that you can integrate adaptations. Multi-stage s

ystem expansion options and the distribution of functions to different computers

allow the system to grow with your needs.

Main Data Acquisition Areas

Order or operation data (runtimes, piece counts, scrap,...)

Personnel data (working hours, reasons for absence, )

Machine and workstation data (utilization, availability, disturbances,...)

Acquiring Manual Production Events

Manual production events are entered at machines by the operators using the WinB

DE acquisition component. The system supports simple PDA terminals with displays

or user-friendly Windows terminals. The interactive functions available on the

WinBDE terminals include:

Dialogs for processing orders including quantity acquisition and reasons for int

erruptions or rejects

Dialogs for workstations with status acquisition (disturbance, maintenance)

Dialogs for personnel data

Acquiring Automatic Production Events

You can acquire and process events online via the PDA terminal's digital inputs:

Piece counts (good, scrap)

Down-time monitoring

Disturbances

WinPDA's user interface is designed with the same look and feel as Microsoft Win

dows. Users can modify overview tables, dialog windows, labels and even the lang

uage used. This makes possible easy adaptation to specific operating conditions

and individual requirements.

Dialogs for Production and Order Dispatch

The dialogs for production and order control are available on Windows clients. T

his allows you to use the PCs that are integrated in the WinPDA network as multi

functional operator control and monitoring stations. Dialogs for order control a

re available in the following form:

Order and operation overview

Maintain single order

Workstation overview

Maintain workstation

Display logbook

Personnel overview

Maintain personnel data

Maintain master data evaluations under Windows

The evaluations below are available as standard as stand-alone Windows programs:

Plant diagram Graphic display of the current workstation status (e.g. red = dist

urbed; green = production; etc.)

Representation in table form of currently pending reasons for disturbances/statu

s conditions

Shift profile Representation as a bar chart of the events of a completed shift f

or a selected workstation

Day profile- Representation as a bar chart of the events of the day for a select

ed workstation

Status profile Representation of the duration and frequency of individual status

conditions of a shift listed chronologically per workstation

Rate of utilization/availability

Representation of the rate of utilization/availability of a workstation over a s

electable period.

Works Calendar under Windows

The variations in working time models demand a flexible and convenient maintenan

ce function. WinPDA provides dialogs for setting up shift types and working time

models with appropriate works calendar structures.

Security Concept

To ensure a consistent data stock and to prevent unauthorized access to data, Wi

nPDA has available a comprehensive security concept. This includes:

Access and authorization functions

Disk mirroring (hardware option)

Transaction security

Un-interruptible power supplies

Interface to SAP R/3 Release 3.0

Today's MDA/PDA systems are only economically viable if you can integrate them a

t a low cost to other processes. A certified interface to SAP R/3 Release 3.0 is

available for this. The link modules offer functions for :

Accepting target data from the higher level system (E.g., order data).

Accepting master data from the higher level sys-tem (E.g. workstation data)

Processing the acquired actual data and reporting

It back the shopfloor controller or the MRP system

MODULE FOR NC PROGRAM MANAGEMENT

The important part of job shop manufacturing on machine tool is part program man

agement. The transfer of part programs was initially carried on punched tape by

a reader and further by floppy disks in recent years. Today the programs can be

transferred at a speed thousand times that of punched tape on industrial Etherne

t. Apart from transfer, the organization of part programs and handling plays an

important role in enhancing productivity and ensuring availability of desired pa

rt programs.

Functions of NC program management module

Scalable expansion system from small local DNC systems to DNC center archives wi

th DNC-NT 2000 server for entire plant.

NC program handling by means of DNC explorer.

Shop floor oriented NC program storage structure.

Data can be displayed, edited, printed, copied and pasted & deleted.

Functions and filters tailored to the requirements of the user.

Fast and simple analysis of optimized programs with the original programs.

Program transfer through operator action and direct loading of NC programs into

the CNC enabling fast transmission on Internet.

Simple and flexible interface through any NC program systems and data archives.

Online help system to assist the system operator.

Log book to record system messages.

ADVANTAGES

Cost reduction in NC data organization through simple handling of NC programs, t

ime-consuming process of handling punched tapes and floppy disks is eliminated.

Cost effective and safe electronic data acquiring.

Increased machine-operating time through short set up time by safe and fast NC d

ata transfer and provision of several NC programs.

Brings in transparency and convenience in handling and storage of part programs

even if several programs are available in the system.

No DNS terminals are required in latest CNC systems on one hand and conventional

CNC systems can be hooked on by dialog functions.

COMMUNICATION SOFTWARE- COMPUTER LINK

The software module provides for establishment of link between a master computer

to CNC system via ethernet network. The offers defined, open communication inte

rface to transfer the essential data of CNC control.

USER BENEFITS

Simple integration: The control can be simply integrated in a simple manner in u

ser s projects/ applications, using defined interfaces like ethernet/ TCP-IP.

Simple configuration: Data to be transferred to the PLC can be simply configured

.

Improved productivity: The module can be used as a tool to implement measures fo

r increased productivity.

Reduced cost: The use of standard hardware and software components reduces the c

ost of implementation, training, and maintenance.

DATA TRANSFER THAT CAN BE CARRIED OUT WITH COMPUTER LINK

NC programs

Tool data

Machine and operating data like operating modes, machine status and actual NC pr

ograms.

Machine messages like operator messages, operator interventions/ interruptions,

operating and fault messages.

Production dialog, configurable data transfer.

Data transfer with open architecture applications.

REMOTE DIAGNOSIS

Remote diagnosis or Tele service offers remote support for CNC systems, making i

t a cost-effective alternative to service calls.

HOW IT WORKS

The module consists of two subsets namely, Host and the Viewer , the host being instal

ed at the machine user end and the viewer at the machine manufacturers end (or on

the side of the service provider for the CNC system). The two, i.e. the host and t

he viewer are installed on the control at the machine end connected via a modem, w

hich in turn is linked to a telephone line through a modem. The host is installe

d on a PC at the other side and equipped with a modem to hook on a telephone lin

e.

The service or support requests are triggered by the Host and authorize the View

er with login password permitting access for exploration and support activities

on the CNC system remotely. The service provider on the viewer end confirms the

service request and initiates the remote diagnosis by calling the telephone numb

er.

The components of the remote diagnosis system are

TEAMS: Testability assessment and improvement (DFT), reliability analysis, Failu

re Modes, Effects and Criticality Analysis (FMECA) and pre-computed diagnostic t

est strategy generation in a variety of forms (e.g., SGML-based Interactive Elec

tronic Technical Manual);

TEAMS-RT: on-board diagnostics, health and usage monitoring systems;

TEAMATE: Portable Intelligent Maintenance Aids (PIMAs) with interactive electron

ic technical manuals and multi-media animation, dynamic TPSs for ATEs.

TEAMS-KB: Scheduled and unscheduled maintenance and diagnostics data collection,

Statistical data analysis and data mining for trend and anomaly detection/isola

tion.

FUNCTIONS OFFERED

Chat mode to enable the Host and the Viewer to understand the status of the machin

e via mail or voice call

Remote control mode to analyze the operator acti9ons and direct the operator actio

ns file transfer mode to automatically read out the important control files, to

transfer the corrected file or new software releases to the control side. This c

ompletes the process of diagnosis.

APPLICATION AREAS

With the machine tool manufacturer: useful for configuring and engineering, mach

ine testing and integration, start- up.

With the end users: setting up and controlling the machine tool, generating NC p

rograms, process visualization and monitoring, diagnostics and service, performa

nce enhancement and optimization.

ADVANTAGES FOR END USERS AND SERVICE PROVIDERS

Time advantage when service is required:

Help instead of travelling.

Better information transfer via chat mode.

Reduced machine down time.

Remote update/upgrade of software by file transfer mode.

Telephone/internet cost instead of travel cost.

Global support: wide applicability world wide, start up support, service support

and when machine re-equipping is required.

IN FUTURE,

Service providers can be reached around the clock via internet, by email or SMS

worldwide

Messages can be sent immediately after the fault occurs

At the service provider end , this information enables in faster in selection of

appropriate expert

CONCLUSION

The availability of PC technology and the control system architecture adapted fo

r the new changes has opened more and more opportunities for convergence of manu

facturing technology and information technology. With the advent of information

technology the entire process of running an entire plant, from generating and st

arting with the job orders, through production planning up and up to strategic p

lanning can be integrated. A new trend that has recently been put in is the web-

based support system. The users can post their needs and queries on the relevant

designated site to obtain the possible solutions and FAQ s and user documentation

. Several of the global automobile giants such as BMW AG, the Boeing company USA

etc and their likes are incorporating information technology into their plants

BIBLIOGRAPHY

1. Integration of information technology in machine tools ,

Mr. Virupakshappa HK, Industrial Automation, July 2003

2. Automation, Production Systems and Computer integrated Manufacturing, Mikell

p Groover, second edition, Pearson Education Asia.

3. http://www.siemens.it

4. http://www.sea.siemens.com

ACKNOWLEDGEMENT

I extend my sincere gratitude towards Prof . P.Sukumaran Head of Department for

giving us his invaluable knowledge and wonderful technical guidance

I express my thanks to Mr. Muhammed kutty our group tutor and also to our staff

advisor Ms. Biji Paul for their kind co-operation and guidance for preparing and

presenting this seminar.

I also thank all the other faculty members of AEI department and my friends for

their help and support.

CONTENTS

1. Introduction . . .... . 01

2. NC & CNC . .. . 02

3. Modules in machine tools . . .. .. 04

3.a. Module for production data management . . .. . 04

3.a.i. What Win BDE can do . . 04

3.a.ii. What Win PDA can do... . 06

3.b. Module for NC program management . .. . 11

3.c. Communication software-computer link . .. . 12

4. Remote diagnosis .. . .. 14

5. Conclusion ... . 17

6. Bibliography ... .. 18

Reference: http://www.seminarprojects.com/Thread-integration-of-information-tech

nology-in-machine-tools#ixzz0v5YABYUd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Comware CLI Commands in ProVisionDocument56 pagesComware CLI Commands in ProVisionjunediiiNo ratings yet

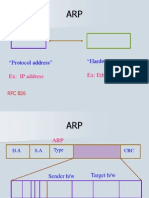

- Details of ARP and PPPDocument40 pagesDetails of ARP and PPPYogesh Palkar100% (1)

- MC-TRX Intro, HW Descr PDFDocument32 pagesMC-TRX Intro, HW Descr PDFady10arNo ratings yet

- VPN Comparison ChartDocument50 pagesVPN Comparison Chartchilkoti3793No ratings yet

- Discover Console Open IPTV - Requirements & Limitations v02 2017-03-29Document7 pagesDiscover Console Open IPTV - Requirements & Limitations v02 2017-03-29Camilo CuasesNo ratings yet

- Ee534 Lab13 (Duong - Le)Document9 pagesEe534 Lab13 (Duong - Le)Rock RáchNo ratings yet

- Cim 300 - Bacnet MS-TPDocument2 pagesCim 300 - Bacnet MS-TPBalasundaramSrinivasaRajkumarNo ratings yet

- Configuración de VTP, DTP y VLAN ExtendidasDocument5 pagesConfiguración de VTP, DTP y VLAN ExtendidasRuben Dario FernandesNo ratings yet

- Allen-Bradley: SLC500 Series (DF1)Document5 pagesAllen-Bradley: SLC500 Series (DF1)41930517No ratings yet

- Lab 10Document4 pagesLab 10M. Ahmad RazaNo ratings yet

- CommissioningReport FXCB+FXCB+FXCB 20200313Document56 pagesCommissioningReport FXCB+FXCB+FXCB 20200313Gustavo BessoneNo ratings yet

- 10 49Document45 pages10 49jarriaga.gonzalezNo ratings yet

- Template For Brochures: FL Switch Ep7400Document12 pagesTemplate For Brochures: FL Switch Ep7400Tio_louis32No ratings yet

- Glossary PDFDocument40 pagesGlossary PDFebg72900No ratings yet

- Dokumentaciya 2 Alcatel 1650 SMCDocument2 pagesDokumentaciya 2 Alcatel 1650 SMCBodeptrai NhatnhaNo ratings yet

- M-FTE-00001 V01 19.oct.2009Document55 pagesM-FTE-00001 V01 19.oct.2009nicoloh2002No ratings yet

- Chapter 1 - Information TheoryDocument55 pagesChapter 1 - Information TheoryBoruto69No ratings yet

- Meid-401-040315 CM Plan Uni Ground Subnetwork 401Document71 pagesMeid-401-040315 CM Plan Uni Ground Subnetwork 401aslamsatnaNo ratings yet

- BMX3420302Document3 pagesBMX3420302HafizNo ratings yet

- Channel Element Reference GuideDocument4 pagesChannel Element Reference GuideaimuganwaNo ratings yet

- Cornell Notes Sheet: 200-301 CCNADocument17 pagesCornell Notes Sheet: 200-301 CCNAjincamoNo ratings yet

- 3GPP TS 33.401Document176 pages3GPP TS 33.401nvilochanNo ratings yet

- Fiber Optic Network Optical Wavelength Transmission Bands & FOADocument174 pagesFiber Optic Network Optical Wavelength Transmission Bands & FOAMehdi RabbaniNo ratings yet

- Extreme NerworksDocument2 pagesExtreme NerworksJcmNo ratings yet

- Performance Analysis of Open Source Solutions Using WiresharkDocument7 pagesPerformance Analysis of Open Source Solutions Using Wiresharkapi-27373342No ratings yet

- CAPE Information Technology Unit One NotesDocument28 pagesCAPE Information Technology Unit One Notessmartkid167100% (8)

- Brocade Hitachi Data Systems QRGDocument4 pagesBrocade Hitachi Data Systems QRGJhovic ZuñigaNo ratings yet

- An Efficient Hardware-Based Human Body Communication Transceiver Architecture For WBANDocument8 pagesAn Efficient Hardware-Based Human Body Communication Transceiver Architecture For WBANMarisela RosalesNo ratings yet

- DRAGON-PTN With HiProvision Launch Presentation EXTERNAL 2018 Original 126776Document27 pagesDRAGON-PTN With HiProvision Launch Presentation EXTERNAL 2018 Original 126776ChintanPandyaNo ratings yet

- Practical 6 Aim - : Create A Basic MANET Implementation Simulation For Packet Animation and Packet TraceDocument3 pagesPractical 6 Aim - : Create A Basic MANET Implementation Simulation For Packet Animation and Packet TracePraveen MishraNo ratings yet