Professional Documents

Culture Documents

Sulzer Spec Trays

Uploaded by

andy19791Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sulzer Spec Trays

Uploaded by

andy19791Copyright:

Available Formats

Sulzer Standard Specification for

Fractionation Trays

Sulzer Chemtech Ltd

Table of Content

1 General..........................................................................................................................................2

1.1 Scope ............................................................................................................................................2

1.2 References ....................................................................................................................................2

2 Materials ........................................................................................................................................2

2.1 Specifications ................................................................................................................................2

2.2 Comparison Table ASTM – DIN...................................................................................................4

2.3 Gaskets .........................................................................................................................................5

2.4 Material properties.........................................................................................................................5

2.5 Tray hardware ...............................................................................................................................5

3 Mechanical design.........................................................................................................................5

3.1 Loads and stresses .......................................................................................................................5

3.2 Allowable deflection.......................................................................................................................6

3.3 Minimum thickness ........................................................................................................................6

3.4 Corrosion allowance ......................................................................................................................6

3.5 Depth of tray structural members ..................................................................................................7

3.6 Support ring sizes..........................................................................................................................7

3.7 Gaskets .........................................................................................................................................8

3.8 Bubble caps and valves ................................................................................................................8

3.9 Chimney trays & draw-off sumps ..................................................................................................8

3.10 Multi-Pass trays .............................................................................................................................9

3.11 Drainholes and Ventholes .............................................................................................................9

3.12 Bolt size and spacing.....................................................................................................................9

3.13 Thermal expansion ........................................................................................................................9

3.14 Column manhole .........................................................................................................................10

3.15 Tray supports...............................................................................................................................10

3.16 Tolerances...................................................................................................................................10

3.17 Maximum weight..........................................................................................................................10

3.18 Heavy duty trays..........................................................................................................................10

4 Tray fabrication............................................................................................................................11

4.1 Tolerances...................................................................................................................................11

4.2 Welding........................................................................................................................................11

4.3 Sieve and valve hole punching....................................................................................................11

4.4 Surface finishing ..........................................................................................................................11

5 Shop Inspection and testing ........................................................................................................12

5.1 Shop inspection - trial assembly..................................................................................................12

5.2 Leakage test ................................................................................................................................12

5.3 PMI Examination (when applicable) ............................................................................................12

5.4 NDE Examination (when applicable)...........................................................................................12

6 Marking and shipping ..................................................................................................................13

6.1 Part marking ................................................................................................................................13

6.2 Standard packaging.....................................................................................................................13

6.3 Shipping.......................................................................................................................................13

7 Tray installation ...........................................................................................................................13

7.1 Tray manway(s)...........................................................................................................................13

7.2 Standard connection....................................................................................................................14

7.3 Tolerances...................................................................................................................................14

7.4 Spares for erection ......................................................................................................................14

8 Documents ..................................................................................................................................15

Revision: Rev 2.0 April 2008 Document: Sulzer_Spec_Trays.doc Page 1 of 18

Sulzer Standard Specification for

Fractionation Trays

Sulzer Chemtech Ltd

1 General

1.1 Scope

This specification covers the mechanical design, fabrication, inspection, testing, installa-

tion, handling, storage, shipping and packaging of trays.

1.2 References

American Society for Testing and Materials (ASTM) Material Specifications.

American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code.

ASME Section IX, Qualification Standard for Welding and Brazing Procedures, Welders,

Brazers and Welding and Brazing Operators.

DIN (Deutsche Industrie Norm) German Industry Norm for Material Specifications.

2 Materials

2.1 Specifications

The following ASTM standard material specifications apply.

The reference shall be taken to mean the latest edition of the code.

ASTM A36 Carbon Structural Steel

ASTM A167 Stainless and Heat-Resisting Chromium-Nickel Steel Plate, Sheet,

and Strip

ASTM A176 Stainless and Heat-Resisting Chromium Steel Plate, Sheet, and

Strip

ASTM A193 Alloy-Steel and Stainless Steel Bolting Materials for High-

Temperature Service

ASTM A194 Carbon and Alloy Steel Nuts for Bolts for High-Pressure and High-

Temperature Service

ASTM A240 Stainless and Heat-Resisting Chromium and Chromium-Nickel

Steel Plate, Sheet, and Strip for Fusion-Welded Unfired Pressure

Vessel

ASTM A276 Stainless and Heat-Resisting Steel Bars and Shapes

ASTM A283 Low and Intermediate Strength Carbon Steel Plates

ASTM A285 Pressure Vessel Plates, Carbon Steel, Low-and Intermediate-

Tensile Strength

ASTM A307 Carbon Steel Bolts and Studs, 60,000 psi Tensile

ASTM A322 Steel Bars, Alloy, Standard Grades

ASTM A479 Stainless Steel Bars and Shapes for Use in Boilers and Other

Pressure Vessels

ASTM A515 Pressure Vessel Plates, Carbon Steel for Intermediate and High

Temperature Services

ASTM A516 Pressure Vessel Plates, Carbon Steel for Moderate and Lower

Revision: Rev 2.0 April 2008 Document: Sulzer_Spec_Trays.doc Page 2 of 18

Sulzer Standard Specification for

Fractionation Trays

Sulzer Chemtech Ltd

Temperature Services

ASTM A563 Carbon and Alloy Steel Nuts

ASTM A675 Steel Bars, Carbon, Hot-Wrought Special Quality, Mechanical

Properties

ASTM B127 Nickel-Copper Alloy Plate, Sheet and Strip

ASTM B164 Nickel-Copper Alloy Rod, Bar, and Wire

ASTM B265 Titanium and Titanium Alloy Strip, Sheet and Plate

ASTM B348 Titanium and Titanium Alloy Bars

DIN 17100 Steel for General Structural Purposes

DIN 17155 Plate and Strip of Steels for elevated temperatures

DIN 17440 Stainless steels, plates, hot rolled strip, wire rods, drawn wire, bars

and forgings

DIN 17750 Plates, strips and sheets of wrought nickel and nickel alloys

DIN 17743 Wrought nickel alloys with copper

Revision: Rev 2.0 April 2008 Document: Sulzer_Spec_Trays.doc Page 3 of 18

Sulzer Standard Specification for

Fractionation Trays

Sulzer Chemtech Ltd

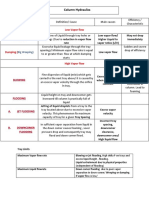

2.2 Comparison Table ASTM – DIN

ASTM Type DIN Raw material number

A-36 C-Steel 17100 1.0044

A-167 304 17440 1.4301

A-167 304L 17440 1.4306

A-167 316 17440 1.4401

A-167 316L 17440 1.4404

A-167 321 17440 1.4541

A-167 347 17440 1.455

A-176 405 17440 1.4002

A-176 410 17440 1.4006

A-176 410S 17440 1.4000

A-193 Grade B 6 17440 1.4000

A-193 Grade B 7 17200 / 17240 1.7225 / 1.7258

A-193 Grade B 7M 17200 1.7225

A-193 Grade B 8 17440 1.4301

A-193 Grade B 8C 17440 1.4550

A-193 Grade B 8M 17440 1.4401

A-193 Grade B 8T 17440 1.4541

A-193 Grade B 16 17240 1.7711

A-194 Grade 2H 17240 1.1181

A-194 Grade 4 17240 1.7258

A-194 Grade 6 17440 1.4000

A-194 Grade 6F - -

A-194 Grade 8 17440 1.4301

A-194 Grade 8M 17440 1.4401

A-240 410S 17440 1.4000

A-240 410 17440 1.4006

A-240 405 17440 1.4002

A-240 430 17440 1.4016

A-240 304 17440 1.4301

A-240 304L 17440 1.4306

A-240 316 17440 1.4401 1.4436

A-240 316L 17440 1.4404 1.4435

A-240 316Ti 17440 1.4571

A-240 317 17440 1.4449

A-240 317L 17440 1.4438

A-240 321 17440 1.4541

A-240 347 17440 1.4550

A-276 304 17440 1.4301

A-276 304L 17440 1.4306

A-276 316 17440 1.4401

A-276 316L 17440 1.4404

A-276 317L 17440 -

A-276 321 17440 1.4541

A-276 347 17440 1.4550

A-283 Grade C 17100 1.0036

A-285 Grade C 17155 1.0425

A-515 Grade 55 17155 1.0425

A-515 Grade 60 17155 1.0435

A-515 Grade 65 17155 1.0445

A-515 Grade 70 17155 1.0485

A-516 Grade 55 17155 1.0426

A-516 Grade 60 17155 1.0436

A-516 Grade 65 17155 1.0436

Revision: Rev 2.0 April 2008 Document: Sulzer_Spec_Trays.doc Page 4 of 18

Sulzer Standard Specification for

Fractionation Trays

Sulzer Chemtech Ltd

ASTM Type DIN Raw material number

A-516 Grade 70 17155 1.0843

B-164 Monel 400 17743 2.4360

SB-265 Titanium gr1

SB-265 Titanium gr2

B-425 Incoloy 825 17750 2.4858

B-574 Hastelloy C-276 17750 2.4819

S31803 Ferritic/Austenitic DUPLEX 1.4462

2.3 Gaskets

Gaskets are tape or braided rope fabricated from asbestos-free material suitable for the

processing environment. Minimum thickness of gasket tape shall be 1.5 mm (1/16”).

Gasket material shall be used for internal flange connections and Bubble Cap gaskets (if

applicable).

The gasket material needs to be specified by the customer.

List of typical gasket material:

• PTFE

• Fiberglas

• Graphite

• Aramid

• Teflon

2.4 Material properties

The material properties shall be according to ASME Boiler & Pressure Vessel Code, Sec-

tion II, Part D.

2.5 Tray hardware

Tray hardware for carbon steel trays shall be either 410 or 304 stainless steel.

The valves for carbon steel trays shall be of 410S stainless steel.

To avoid galling, it is possible to use 304 grade material for nuts when bolting is 410 grade

material.

3 Mechanical design

3.1 Loads and stresses

Tray assemblies shall be mechanically designed using a corroded thickness to support

their own weight plus the following design loads at the design temperature.

Revision: Rev 2.0 April 2008 Document: Sulzer_Spec_Trays.doc Page 5 of 18

Sulzer Standard Specification for

Fractionation Trays

Sulzer Chemtech Ltd

Active area:

A design load of 1000 N/m² (21 lb/ft²) or the head of water twice the outlet weir height,

whichever is the greater.

Inlet area (panels under downcomer):

A design load of 3000 N/m² (64 lb/ft²) or the head of water half the tray spacing, whichever

is the greater.

Draw-off sumps and Chimney trays:

A design load of head of water equal to the riser height of the chimney tray.

Tray assemblies shall be capable of supporting their own weight plus a concentrated load

of 1350 N (300 lbs.) located at any trusses on the tray at ambient temperature. The maxi-

mum allowable stress permitted under this condition is at ambient temperature.

Heavy-duty trays will be designed based on a uniform load of 6900 N/m² (1psi). Under

these conditions trays are not designed for deflection and the maximum stress permitted

under this condition is 90% of the yield stress at design temperature.

Baffle trays, shed decks and disc and donut trays will be designed for a design load of

7000 N/m² (146 lb/ft²).

3.2 Allowable deflection

The deflection of tray assemblies under the loads as given in section 3.1 shall be limited

to 1/900 of the internal column diameter. For all other equipment only stress conditions

must be followed.

An initial camber may be made in the principal support members of the assemblies to re-

duce the deflection due to the dead load.

3.3 Minimum thickness

Minimum thickness for trays including corrosion allowance shall be:

Tray component Carbon Steel Stainless Steel

Valves NA 1.5 mm (16 Ga)

Bubble Caps 3.5 mm (10 Ga) 1.5 mm (16 Ga)

Tray decks, Downcomers,

3.5 mm (10 Ga) 2 mm (14 Ga)

Weirs, Integral beams

Major Trusses and beams 4.5 mm (8 Ga) 3 mm (12 Ga)

3.4 Corrosion allowance

The total corrosion allowance for carbon steel trays shall be 1.5 mm (1/16”).

This means 0.75 mm (1/32”) per exposed side.

No corrosion allowance required for stainless steel trays.

Revision: Rev 2.0 April 2008 Document: Sulzer_Spec_Trays.doc Page 6 of 18

Sulzer Standard Specification for

Fractionation Trays

Sulzer Chemtech Ltd

3.5 Depth of tray structural members

The depth of integral trusses parallel to the liquid flow shall not exceed 30% of the tray

spacing.

The depth of integral trusses perpendicular to the liquid flow shall not exceed 20% of the

tray spacing.

Major support beams will be oriented parallel to the direction of liquid flow.

Support members are to be located on the underside of the tray floor except for open-type

(lattice) trusses supporting two trays.

Support beams shall not restrict the flow of vapor between tray passes.

The beam shall occupy not more than 50% of the vertical area between the trays meas-

ured along the flow path.

3.6 Support ring sizes

Recommended support ring sizes for new vessels equipped with trays.

I.D. Column Support ring width Support ring thickness

Stainless steel Carbon steel

/ mm / mm / mm / mm

------ to 800 40 8 5 + 2 x SCA

(See note 1)

801 to 2500 50 8 5 + 2 x SCA

(See note 1)

2501 to 3500 60 8 5 + 2 x SCA

(See note 1)

3501 to 5000 75 8 5 + 2 x SCA

(See note 1)

5001 to 7000 85 8 5 + 2 x SCA

(See note 1)

7001 to 9000 90 8 5 + 2 x SCA

(See note 1)

Above 9001 Individual design

I.D. Column Support ring width Support ring thickness

Stainless steel Carbon steel

/ in / in / in / in

---- to 42 1 1/2 1/4 1/4 + 2 x SCA

(See note 1)

43 to 100 2 1/4 1/4 + 2 x SCA

(See note 1)

101 to 125 2 1/2 1/4 1/4 + 2 x SCA

(See note 1)

126 to 180 2 1/2 1/4 1/4 + 2 x SCA

(See note 1)

Revision: Rev 2.0 April 2008 Document: Sulzer_Spec_Trays.doc Page 7 of 18

Sulzer Standard Specification for

Fractionation Trays

Sulzer Chemtech Ltd

I.D. Column Support ring width Support ring thickness

Stainless steel Carbon steel

/ in / in / in / in

181 to 210 3 3/8 3/8 + 2 x SCA

(See note 1)

211 to 230 3 1/2 3/8 3/8 + 2 x SCA

(See note 1)

231 to 400 3 1/2 1/2 1/2 + 2 x SCA

(See note 1)

Above 401 Individual design

Note 1:

For carbon steel, two times the vessel corrosion allowance (SCA) have to be added to the

thickness.

3.7 Gaskets

The seams of bubble cap trays will be provided with gaskets.

Valve and sieve trays are not supplied with gaskets.

Chimney trays and total draw-off sumps are normally seal welded. In services where a

small amount of leakage is not detrimental to the process gasketing is permitted. If leak-

age is critical see section 3.9.

3.8 Bubble caps and valves

Bubble caps are 3” and 4” standard FRI bubble cap design or 6” slotted cap design, see

Fig. 2 and Fig. 3 (pages 17 and 18).

Movable valves shall be supplied with dimples or other projections to provide a clearance

between the valve and the tray deck when the valve is in the closed position.

Tabs are used to prevent valves from sticking to the tray deck.

Round valve holes will not be equipped with an anti-rotation feature.

3.9 Chimney trays & draw-off sumps

Chimney trays and draw-off sumps can be bolted and gasketed design in services where

a small amount of leakage is acceptable for the process.

Chimney trays and draw-off sumps should be seal welded in services where leakage is

deemed detrimental to process operation. Welded chimney trays and draw-off sumps will

have the minimum number of sections to minimize potential for leakage.

Partial draw-off trays with overflow provision can be equipped with bolted downcomer de-

sign located below the tray deck.

Revision: Rev 2.0 April 2008 Document: Sulzer_Spec_Trays.doc Page 8 of 18

Sulzer Standard Specification for

Fractionation Trays

Sulzer Chemtech Ltd

Chimney tray hats will be designed with ‘V’ hats to focus liquid drainage on the small face

of the chimney (hat support).

Chimney trays in services where minimum leakage through hats is desired will be de-

signed with inverted U-hat or flat caps that completely seal and cover the risers.

Chimney tray risers are specified with approximately 15% riser area for vessels equipped

with trays.

3.10 Multi-Pass trays

4-pass and 6-pass trays are normally designed based on equal flow path length.

Picket Fence type outlet weirs and clearances are used to balance the 3-pass, 4-pass and

6-pass tray designs.

No vapor equalizers are supplied in the intermediate and center downcomers of 3-pass,

4-pass and 6-pass trays.

3.11 Drainholes and Ventholes

Bottom tray seal pans are equipped with a single 10 mm (⅜") drain hole.

Liquid tight chimney trays and draw-off sumps are not equipped with drainholes.

One drainhole is required in each tray recessed seal pan.

One drainhole is required in each distributor pipe where process fluid does not discharge

vertically downward.

One venthole is required for each distributor pipe, except for spray nozzle distributor

where ventholes are not required.

3.12 Bolt size and spacing

All bolting for trays shall be a minimum of 10 mm (3/8") diameter.

Tray clamp spacing shall not exceed 180 mm (7") around the tray perimeter of the active

area and around the perimeter of the inlet area. Bolt and/or clamp spacing shall not ex-

ceed 150 mm (6") along downcomer clamping bars.

Bolt spacing on truss seams shall not exceed 180 mm (7”) spacing.

Manway clamp spacing shall not exceed 250mm (10”). Each side of the manway shall be

connected to the tray deck with at least two manway clamps.

Clamping shall be used except where bolting is necessary for load supporting capabilities.

Bolt and clamp spacings are not applicable for heavy duty trays.

3.13 Thermal expansion

Slotted holes with sufficient clearance for thermal expansion shall be used where support

beams are bolted to welded-in supports.

Revision: Rev 2.0 April 2008 Document: Sulzer_Spec_Trays.doc Page 9 of 18

Sulzer Standard Specification for

Fractionation Trays

Sulzer Chemtech Ltd

Welded chimney trays are normally seal welded directly to the support ring.

Welded chimney trays in towers that are designed for operation at elevated temperatures

with dissimilar material from the vessel are recommended to both evaluate and make pro-

vision for differential expansion using expansion angles around the tray perimeter. Expan-

sion angles are seal welded on site between the chimney tray deck and the tower wall.

3.14 Column manhole

Tray sections shall pass through the specified column manhole I.D. size unless indicated

otherwise.

3.15 Tray supports

The tray manufacturer is responsible for the mechanical design of the tray supports that

are to be welded to the vessel.

The vessel manufacturer is responsible for the supply and installation of all supports that

are welded to the vessel for grassroots towers, unless stated otherwise.

3.16 Tolerances

Trays shall be designed to allow for manufacturing tolerances on both the vessel and the

trays. Allowances shall be made for the vessel shell being out of roundness as limited by

ASME Boiler and Pressure Vessel code Section VIII – Division I.

All tray parts shall be made adjustable so that when installed, the trays and pans will be

within the specified tolerances.

All similar parts shall be interchangeable.

For perforated trays, the number of holes shall be within plus or minus 2% of the number

specified.

The total area of openings elsewhere which may lead to leakage of liquid or vapor shall

not exceed 1% of the total hole area for vapor passage.

3.17 Maximum weight

The weight of any single section of removable tray parts shall not exceed:

1) 35 kg (75 lbs) for vessels up to and including 1.2 m (4ft) diameter and

2) 70 kg (150 lbs) for vessel above 1.2 m (4ft) diameter

Exception shall be made for loose main beams and integrated beams in downcomer.

3.18 Heavy duty trays

If required, heavy-duty trays will be designed based on the loadings as indicated in sec-

tion 3.1. Heavy-duty trays are normally designed with through-bolted downcomer panels.

In addition to a stronger tray (but not as an alternative) explosion doors may be used, in

cases where persistent tray damage has occurred.

Revision: Rev 2.0 April 2008 Document: Sulzer_Spec_Trays.doc Page 10 of 18

Sulzer Standard Specification for

Fractionation Trays

Sulzer Chemtech Ltd

4 Tray fabrication

4.1 Tolerances

The dimensional tolerances on all similar parts shall be such as to make the parts inter-

changeable.

Local depressions and bulges in panels after installation shall not exceed 6 mm (0.25”)

from the nominal plane.

The tilt of fractionating trays shall not exceed 0.15 % of the column diameter.

4.2 Welding

Approved welding processes are SMAW (Shielded Metal Arc Welding), GTAW (Gas

Tungsten Arc Welding), GMAW-P (Pulsed Arc Welding) and Resistance welding.

Welding electrodes or filler metal of a composition similar to the tray material shall be

used.

Welding procedures are available for review in our workshop.

4.3 Sieve and valve hole punching

Punch direction for sieve trays is downward.

For round and for rectangular valves the holes may be punched from either side of the

tray. Same punch direction for movable valves is not required.

Punched hole diameter of sieve trays shall not be smaller than 1.5 times the deck thick-

ness.

4.4 Surface finishing

Trays are manufactured with automated punch press equipment with the use of lubricating

oils and will have some residual oil left on the surface. De-greasing is an extra service that

can be provided for projects that require the removal of residual oil.

Punch press equipment use well maintained dies and tooling along with plasma / laser arc

cutting on some edges.

Goods will be delivered in an “as sheared”, “as punched” and “as cut” condition with no

objectionable burrs.

Welds will only be polished or pickled and passivated on express request by the customer

and agreement by Sulzer. (This may result in additional costs.)

Revision: Rev 2.0 April 2008 Document: Sulzer_Spec_Trays.doc Page 11 of 18

Sulzer Standard Specification for

Fractionation Trays

Sulzer Chemtech Ltd

5 Shop Inspection and testing

5.1 Shop inspection - trial assembly

One tray of each diameter, and of each type, shall be assembled in the shop to the extent

necessary to check fit-up.

A picture of every assembled tray shall be taken and filed for any subsequent quality

checks.

5.2 Leakage test

Welded chimney tray or draw-off sump:

A leakage test for welded chimney trays and draw-off sumps is recommended following

installation by the installer.

Procedure: The chimney tray or draw-off sump will have any drain holes plugged, then the

tray will be filled with water to within 50 mm (2”) of the downcomer overflow or gas riser.

Visual inspection will be performed to observe leakage. Water level should not drop more

than 25mm (1”) in 20 minutes. After testing, the drain hole plugs shall be removed.

Significant leakage should receive weld repair before being placed in service.

Gasketed bubble cap trays:

Gasketed bubble cap trays should be leak tested by the installer subject to client approval.

If deemed necessary, any drain holes should be plugged and the tray will be filled with

water to within 50 mm (2”) of the downcomer overflow or the gas riser, or to 25 mm (1”)

below the bubble cap riser. Water level should not drop more than 25 mm (1”) in 10 min-

utes. After testing, the drain hole plugs shall be removed.

Leakage test is not required for sieve and valve trays.

5.3 PMI Examination (when applicable)

Positive Material Identification (PMI) can be performed for an additional charge on pro-

jects that require this extra service. The cost is dependent on the type of test and the

number of samples tested.

PMI is normally performed by a 3rd party inspector with a Texas Nuclear Analyzer, which

provides material composition, except for carbon content. If required, a portable Spectro-

graph machine can be utilized which provides material composition, including carbon con-

tent.

For bulk materials (sheet, plate, coil, pipe, flanges and weld wire), one (1) PMI test is per-

formed on each material heat prior to the start of fabrication.

For loose materials, the sample size is five (5) pieces of each type of hardware (bolts,

nuts and fasteners) for PMI testing.

5.4 NDE Examination (when applicable)

Non Destructive Examination (NDE) Die Penetrant Testing (PT) can be performed for an

additional charge to confirm the suitability of welds for projects that require this extra ser-

vice.

Revision: Rev 2.0 April 2008 Document: Sulzer_Spec_Trays.doc Page 12 of 18

Sulzer Standard Specification for

Fractionation Trays

Sulzer Chemtech Ltd

A 3rd party inspector performs the test using special developer and UV-light during the

trial assembly.

6 Marking and shipping

6.1 Part marking

All major parts are marked with the part number shown on the assembly drawing with a

marking pencil or metal stamp to permit rapid assembly.

Non-leaded and chloride free paint and/or markers shall be used for marking.

Tray hardware shall be packaged separately from the main tray segments and labeled

with item numbers, which refer to the drawings.

6.2 Standard packaging

Trays are normally shipped in open-sided wood crates. The crate base is a pallet suitable

for handling by forklift. Each crate will be labeled.

The label will indicate:

1) Order number

2) Vessel number

3) Project Name and Number

4) Packing number

5) Size of Packing

6) Net/Gross weight

Carbon steel tray parts are not normally shipped with any rust-ban corrosion inhibitor

unless this service is specifically included in the work scope.

Carbon steel parts are normally shipped in plastic lined or plastic wrapped crates.

6.3 Shipping

Tray components shall be properly packaged to prevent damage during shipping.

7 Tray installation

7.1 Tray manway(s)

Tray manway(s) shall provide a recommended minimum rectangular opening of 350 x 500

mm (13.75” x 20”).

If necessary a smaller opening can be used.

Revision: Rev 2.0 April 2008 Document: Sulzer_Spec_Trays.doc Page 13 of 18

Sulzer Standard Specification for

Fractionation Trays

Sulzer Chemtech Ltd

Manways are normally vertically aligned.

Each assembly, except one piece cartridge trays, post supported trays and other tray

types where manways are not feasible or advantageous, shall have a section or sections

for use as an internal manway. Manways shall be removable from both sides.

If access from one side is impossible, typically with small diameter high capacity trays this

requirement is not applicable.

7.2 Standard connection

Sulzer tray panels are provided with a quick fastening lip-slot connection.

Bolted connections:

Tray bolts shall be tightened, using a calibrated torque wrench, to the Sulzer Installation

instructions and engaged to the full depth of the nuts.

7.3 Tolerances

Tolerances for welded-in supports shall be according to Fig. 1 (page 16) of this docu-

ment.

Outlet weir:

The difference in height between the highest and lowest points of the weir plate top,

measured to a level plane, shall not exceed 6 mm (1/4”).

Height of fixed outlet weir ± 3 mm (±1/8”).

Downcomer Clearance:

Clearance between bottom of downcomer and top of next tray shall not deviate from

nominal clearance by more than ± 3 mm (1/8”).

7.4 Spares for erection

Tray projects include the following spare tray hardware to compensate for installation

losses and shall be as follows:

1) Bolts, nuts and washers, 5%

2) Tray clamps, 5%

3) Gaskets, 25%

4) Movable valves, 2%

Torque: See section 7.2.

Revision: Rev 2.0 April 2008 Document: Sulzer_Spec_Trays.doc Page 14 of 18

Sulzer Standard Specification for

Fractionation Trays

Sulzer Chemtech Ltd

8 Documents

Standard documents include final assembly drawings, installation instructions, bill of mate-

rial, shipping list and bill of lading.

If specified by the client, MTR (Mill Test Reports), WPS (Weld Procedures), PQR (Per-

sonnel Qualification Record), PMI reports and NDE test reports can be provided for pro-

jects where these are performed.

The total weight of the internals per column shall be indicated on the assembly drawing.

On customer request Sulzer shall furnish strength calculations that demonstrate the ade-

quacy of its design to support the specified loads under the applicable deflection criteria.

All documents as stated above will be written in English language.

Revision: Rev 2.0 April 2008 Document: Sulzer_Spec_Trays.doc Page 15 of 18

Sulzer Standard Specification for

Fractionation Trays

Sulzer Chemtech Ltd

Fig. 1: Tolerances for weld-ins in mm (millimeter). Also applicable for two, three and four pass

trays.

Revision: Rev 2.0 April 2008 Document: Sulzer_Spec_Trays.doc Page 16 of 18

Sulzer Standard Specification for

Fractionation Trays

Sulzer Chemtech Ltd

3” & 4” FRI Bubble Cap 6” FRI Bubble Cap

Bubble Cap Size:: 3” 4” 6”

/mm /in /mm /in /mm /in

A Cap diameter (I.D.) 73 2.875 98 3.875 149 5.87

B Cap height 42.5 1.6875 65 2.5 103 4

C Clearance 12.5 0.5 12.5 0.5 12.5 0.5

D Riser height 38 1.5 51 2 83 3.25

G Riser (O.D.) 51 2 70 2.75 105 4

BT Cap thickness 1.5 or 2 16Ga or 1.5 or 2 16Ga or 1.5 or 2 16Ga or

14Ga 14Ga 14Ga

RT Riser thickness 1.5 or 2 16Ga or 1.5 or 2 16Ga or 1.5 or 2 16Ga or

14Ga 14Ga 14Ga

T Panel Thickness 2 or 3 14Ga or 2 or 3 14Ga or 2 or 3 14Ga or

12Ga 12Ga 12Ga

H Slot height - - - - 37 1.2188

I Slot width at bottom - - - - 10 0.5625

K Slot width at top - - - - 6 0.3125

Note: Slot quantity and dimension to be specified by customer or process engineer.

Note: Alternate design with “bridge” in combination with tack welded bolt for double

nuts (as shown on next page) is frequently used.

Fig. 2: Bubble cap dimensions (without gasket).

Revision: Rev 2.0 April 2008 Document: Sulzer_Spec_Trays.doc Page 17 of 18

Sulzer Standard Specification for

Fractionation Trays

Sulzer Chemtech Ltd

3” & 4” FRI Bubble Cap (with gasket) 6” FRI Bubble Cap (with gasket)

Bubble Cap Size:: 3” 4” 6”

/mm /in /mm /in /mm /in

A Cap diameter (I.D.) 73 2.875 98 3.875 149 5.87

B Cap height 42.5 1.6875 65 2.5 103 4

C Clearance 12.5 0.5 12.5 0.5 12.5 0.5

D Riser height 38 1.5 51 2 83 3.25

G Riser (O.D.) 51 2 70 2.75 105 4

BT Cap thickness 1.5 or 2 16Ga or 1.5 or 2 16Ga or 1.5 or 2 16Ga or

14Ga 14Ga 14Ga

RT Riser thickness 1.5 or 2 16Ga or 1.5 or 2 16Ga or 1.5 or 2 16Ga or

14Ga 14Ga 14Ga

T Panel Thickness 2 or 3 14Ga or 2 or 3 14Ga or 2 or 3 14Ga or

12Ga 12Ga 12Ga

H Slot height - - - - 37 1.2188

I Slot width at bottom - - - - 10 0.5625

K Slot width at top - - - - 6 0.3125

Note: Slot quantity and dimension to be specified by customer or process engineer.

Note: Alternate bridge design is also used.

Fig. 3: Bubble cap dimensions (with gasket).

Revision: Rev 2.0 April 2008 Document: Sulzer_Spec_Trays.doc Page 18 of 18

You might also like

- Efficiency Benefits of High Performance Structured Packings: Kevin Bennett, Sulzer Chemtech Mark Pilling, Sulzer ChemtechDocument31 pagesEfficiency Benefits of High Performance Structured Packings: Kevin Bennett, Sulzer Chemtech Mark Pilling, Sulzer Chemtechmisscolgate100% (1)

- DistillationDocument137 pagesDistillationAnonymous lastI7b5No ratings yet

- 000 CG VT 0001Document214 pages000 CG VT 0001Crls Armnd C100% (1)

- Push Valve ExperienceDocument13 pagesPush Valve ExperienceIan Mann100% (1)

- CEeNews2 04 PDFDocument6 pagesCEeNews2 04 PDFJohn AnthoniNo ratings yet

- Vacuum Unit Design and Operation TrainingDocument136 pagesVacuum Unit Design and Operation Trainingsunggwan kim0% (1)

- Schoepentoeter SEPARADORDocument4 pagesSchoepentoeter SEPARADOREsau EstebanNo ratings yet

- Distillation Calculation FormulasDocument21 pagesDistillation Calculation FormulasVaibhav Mishra100% (2)

- Column Internals Regarding-EnDocument44 pagesColumn Internals Regarding-Enmansih457100% (1)

- HP Gas Processes HB 2012Document2 pagesHP Gas Processes HB 2012Syed Mujtaba Ali BukhariNo ratings yet

- Random PackingDocument16 pagesRandom PackingIng Antony MatosNo ratings yet

- Calculate Vent Sizing for Storage TanksDocument5 pagesCalculate Vent Sizing for Storage TanksSteve WanNo ratings yet

- DS-TI Tower InternalsDocument10 pagesDS-TI Tower Internalschris100% (1)

- Sparger Design GuideDocument5 pagesSparger Design GuideShooeibNo ratings yet

- API Operator Manual Practical DistillationDocument17 pagesAPI Operator Manual Practical DistillationUsman NaseemNo ratings yet

- Efficient Vacuum DistillationDocument9 pagesEfficient Vacuum DistillationmishraenggNo ratings yet

- Mass Transfer TechnologyDocument32 pagesMass Transfer TechnologyVasu DevanNo ratings yet

- Sulphur RecoveryDocument8 pagesSulphur RecoveryprthrNo ratings yet

- Rules of Thumb For Process EquipmentDocument4 pagesRules of Thumb For Process EquipmentSaid100% (1)

- Selection of TEMA Type and Thermal Design Optimization of Shell and Tube Heat ExchangerDocument6 pagesSelection of TEMA Type and Thermal Design Optimization of Shell and Tube Heat ExchangerPawan PatilNo ratings yet

- Select The Right ReboilerDocument2 pagesSelect The Right ReboilerSteven A McMurray100% (2)

- 02 - Reactor DesignDocument13 pages02 - Reactor DesignnadNo ratings yet

- 94c Effect of Tray Spacing On Tray Performance AIChE Paper 94cDocument28 pages94c Effect of Tray Spacing On Tray Performance AIChE Paper 94cFranklin Revill100% (1)

- Model A Refrigerated Gas Plant Workshop: ObjectiveDocument25 pagesModel A Refrigerated Gas Plant Workshop: Objectivemiri-256No ratings yet

- IMTPDocument16 pagesIMTPDHAVALESH AMNo ratings yet

- Reboilers & VaporisersDocument17 pagesReboilers & VaporisersKamran MalikNo ratings yet

- (Distillation) - Towers Malfunctions (Kister)Document22 pages(Distillation) - Towers Malfunctions (Kister)Ana Lua100% (1)

- Design of Valve TrayDocument4 pagesDesign of Valve TrayVirendra BhagatNo ratings yet

- Multipass Tray DesignDocument12 pagesMultipass Tray DesignAyoun Ul HaqueNo ratings yet

- TraysDocument23 pagesTraysAmgadNo ratings yet

- Crystallization Process DesignDocument10 pagesCrystallization Process DesignJayakumar PararasuramanNo ratings yet

- Bubble Cap DesignDocument18 pagesBubble Cap Designsanjuct0686% (7)

- Molecular Sieve Sizing Sheet: Input Particle Type Data Particle Type Selection CalculationDocument3 pagesMolecular Sieve Sizing Sheet: Input Particle Type Data Particle Type Selection CalculationreninbabaskiNo ratings yet

- 147047-4 Penex HOT With Methanator SectionDocument375 pages147047-4 Penex HOT With Methanator SectionBn BnNo ratings yet

- Kettle ChoiceDocument5 pagesKettle ChoiceHow Jie WeiNo ratings yet

- Pdvsa 2012 Kgtower-97Document27 pagesPdvsa 2012 Kgtower-97Jose DavalilloNo ratings yet

- Column Hydraulics NotesDocument4 pagesColumn Hydraulics NotessatishchemengNo ratings yet

- 10 - Distillation Revamp Pitfalls To AvoidDocument8 pages10 - Distillation Revamp Pitfalls To AvoidRenato GilbonioNo ratings yet

- Scale Up of Chemical ReactorsDocument51 pagesScale Up of Chemical ReactorsMilton MizrainNo ratings yet

- Glass 110421Document5 pagesGlass 110421Julian MartineliNo ratings yet

- Calculation For Vacuum CondenserDocument0 pagesCalculation For Vacuum Condenserraden_aditiya39No ratings yet

- Fractionation Tray Design HandbookDocument43 pagesFractionation Tray Design Handbookmehul1094150% (2)

- Choosing Trays and Packings For Distillation: Back To BasicsDocument7 pagesChoosing Trays and Packings For Distillation: Back To Basicsmsn1981No ratings yet

- Selection and Design of CondensersDocument27 pagesSelection and Design of Condensersjdgh1986No ratings yet

- ENG-Introduction To Zeolite Molecular SievesDocument20 pagesENG-Introduction To Zeolite Molecular Sieves최우혁No ratings yet

- FCC Revamp Solutions Offer ReliabilityDocument34 pagesFCC Revamp Solutions Offer ReliabilityFederico JanzenNo ratings yet

- Pilling Choosing Trays and Packings For Distillation PDFDocument7 pagesPilling Choosing Trays and Packings For Distillation PDFRajendraNo ratings yet

- Design For Sieve Plate ColumnDocument7 pagesDesign For Sieve Plate ColumnAyushi Jain100% (1)

- Distillation Column Troubleshooting Part IIDocument8 pagesDistillation Column Troubleshooting Part IINishat M PatilNo ratings yet

- Distillation ManualDocument197 pagesDistillation ManualTejas AhalparaNo ratings yet

- Energy and Process Optimization for the Process IndustriesFrom EverandEnergy and Process Optimization for the Process IndustriesNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Industrial Process Scale-up: A Practical Innovation Guide from Idea to Commercial ImplementationFrom EverandIndustrial Process Scale-up: A Practical Innovation Guide from Idea to Commercial ImplementationNo ratings yet

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationFrom EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNo ratings yet

- Reactive Distillation Design and ControlFrom EverandReactive Distillation Design and ControlRating: 1 out of 5 stars1/5 (1)

- Advanced Distillation Technologies: Design, Control and ApplicationsFrom EverandAdvanced Distillation Technologies: Design, Control and ApplicationsNo ratings yet

- ArcelorMittal SPEC GUIDE 20070801Document78 pagesArcelorMittal SPEC GUIDE 20070801SH1961No ratings yet

- Persuasion Is All Around You!: "Can You Hear Me Now?"Document24 pagesPersuasion Is All Around You!: "Can You Hear Me Now?"andy19791No ratings yet

- 1993 Wheatley Et Al Stress and IllnessDocument7 pages1993 Wheatley Et Al Stress and Illnessandy19791No ratings yet

- Mild Vitamin A Deficiency Delays Fetal Lung Maturation in The RatDocument8 pagesMild Vitamin A Deficiency Delays Fetal Lung Maturation in The Ratandy19791No ratings yet

- 12 Affirmations 1005 PDFDocument1 page12 Affirmations 1005 PDFandy19791No ratings yet

- Divine Science 7Document54 pagesDivine Science 7andy19791No ratings yet

- 11 AquaronDocument27 pages11 Aquaronandy19791No ratings yet

- 06 MillerDocument57 pages06 Millerandy19791No ratings yet

- Inborn Errors of Metabolism - Archibald GarrodDocument224 pagesInborn Errors of Metabolism - Archibald Garrodandy19791No ratings yet

- Las Smaw Q3-W1-3Document13 pagesLas Smaw Q3-W1-3Daryl TesoroNo ratings yet

- Invertec 270 SX - 400 SXDocument102 pagesInvertec 270 SX - 400 SXLuisNo ratings yet

- Dec IsoDocument34 pagesDec IsoGuillermo GarciaNo ratings yet

- Svetsaren 2002-2 PDFDocument55 pagesSvetsaren 2002-2 PDFVijo JoseNo ratings yet

- 12 Samss 018Document14 pages12 Samss 018tanveer ahmedNo ratings yet

- Almega PDFDocument151 pagesAlmega PDFTonluck Kaimak50% (2)

- 2) in STN-2 Cycle Time Is OUT As Loading Time Is More in Both Fixture Than Welding TimeDocument1 page2) in STN-2 Cycle Time Is OUT As Loading Time Is More in Both Fixture Than Welding TimeKARTICK PRASADNo ratings yet

- Aws-A5 32 PDFDocument26 pagesAws-A5 32 PDFCGRRNo ratings yet

- 222Document24 pages222Houman Hatamian100% (1)

- Pamphlet TG-X SeriesDocument2 pagesPamphlet TG-X SeriesrajeshNo ratings yet

- Outokumpu Forta H-Series BrochureDocument20 pagesOutokumpu Forta H-Series BrochurehamzahachmiNo ratings yet

- EFC Publication 16 3rd Edition PDFDocument53 pagesEFC Publication 16 3rd Edition PDFНаталья100% (2)

- Steel - Tips - Electroslag Welding Facts For Structural Engineers - Final Submission-Copy-1Document47 pagesSteel - Tips - Electroslag Welding Facts For Structural Engineers - Final Submission-Copy-1Harshit100% (1)

- Pec pdf1Document11 pagesPec pdf1Delmark Dionisio LusterioNo ratings yet

- Unclassified Ad Number Limitation Changes TODocument22 pagesUnclassified Ad Number Limitation Changes TOnitharsunNo ratings yet

- Painting & Sand Blasting ReportDocument41 pagesPainting & Sand Blasting ReportAshwani Dogra89% (9)

- Vendor - Directory 0121 Final NEW 040121Document207 pagesVendor - Directory 0121 Final NEW 040121CE CERTIFICATENo ratings yet

- Case StudyDocument18 pagesCase StudyJALPANo ratings yet

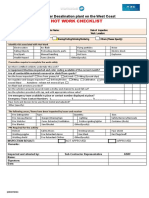

- Hot Work Checklist: Saline Water Desalination Plant On The West CoastDocument1 pageHot Work Checklist: Saline Water Desalination Plant On The West CoastBRC HSE Dept.No ratings yet

- Insignia Ns-lcd37 Lc-37ha37 SM (ET)Document40 pagesInsignia Ns-lcd37 Lc-37ha37 SM (ET)meng798651No ratings yet

- HASTELLOY C-276 Alloy PDFDocument16 pagesHASTELLOY C-276 Alloy PDFvtbkNo ratings yet

- Influence of Welding Position on T-Joint Strength of Mild Steel Fillet Welds Using FCAWDocument7 pagesInfluence of Welding Position on T-Joint Strength of Mild Steel Fillet Welds Using FCAWIan NikoNo ratings yet

- IS 1161 Steel Tubes Structural PurposeDocument9 pagesIS 1161 Steel Tubes Structural PurposeAnuradhaPatraNo ratings yet

- Formula SAE Frame Assembly GuideDocument7 pagesFormula SAE Frame Assembly GuideafhamNo ratings yet

- Magnelis Book ENDocument56 pagesMagnelis Book ENNima SharifiNo ratings yet

- BPW Original-Spare Parts. Mechanical SuspensionsDocument70 pagesBPW Original-Spare Parts. Mechanical SuspensionsMunzir HammamNo ratings yet

- Reyco Manual Axle Model 21B & 21-Y MediaDocument36 pagesReyco Manual Axle Model 21B & 21-Y Mediahebert perezNo ratings yet

- Preview Aws Wit W 2008Document7 pagesPreview Aws Wit W 2008James BashamNo ratings yet

- 90203-1085DEB Arc Welding Operation Manual (D Series)Document178 pages90203-1085DEB Arc Welding Operation Manual (D Series)Ihcene BoudaliNo ratings yet