Professional Documents

Culture Documents

Flooding & Floating

Uploaded by

boyo17meiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flooding & Floating

Uploaded by

boyo17meiCopyright:

Available Formats

JCT Research, Vol. 1, No.

3, July 2004

Flooding and Floating in Latex Paint

Huang Ying,† Cheng Jiang, Wen Xiufang, and Yang Zhuoru—South China University of Technology*

Flooding and floating are problems in many paint applications. If pigment concentration is uniform on the surface but not

through the thickness of the film, one refers to ‘flooding’ (horizontal separation). If, however, concentration differences are

visible across the surface of the paint film, one refers to ‘floating’ (vertical separation). In this article, the influence of pig-

ment, filler, additives, and processing conditions on the flooding and floating of colored latex paint were investigated. It was

discovered that too broad a distribution of pigment and filler particle size can lead to flooding and floating. Different lev-

els of pigment (TiO2) or filler (kaolin) loading cause diverse degrees of flooding and floating. Waterborne coatings that do

not exhibit flooding or floating may show these conditions when diluted. Using dispersants or thickeners with hydrophobic

constituents, increasing viscosity, reducing surface tension, etc., all help to prevent or reduce flooding and floating.

Comparison tests revealed little influence of processing conditions on flooding or floating.

Keywords: Flooding, floating, latex paint, exterior wall coating

W

hen pigment and emulsion dispersions in wa- (2) Flow currents within the film9-10—In the wet film, as

terborne paint are not stable, asymmetric sepa- water volatilizes, the temperature, surface, and interfacial

rations can take place. They are often accompa- tension will decline, more hydrophilic pigments will be

nied by flocculation. If there is sufficient dissociation and carried with water to the surface, and Bénard cells are

flocculation, stripe or grid patterns can be seen on films. formed.11 Bénard cells in a wet film are illustrated in Figure

This defect is called color floating. In other cases, the sep- 3. Bénard cells will persist until the coating is too viscous

arations are rather regular, pigments concentrate on the for the particles to move. In many cases, flooding and

surface, causing a uniform color difference from the nor- floating are more likely to occur in humid circumstances

mal paint. This is called flooding. Floating may be looked than in dry air. Increasing the viscosity and reducing the

upon as a vertical separation of pigments, and flooding as surface tension of the system can alleviate flooding and

a horizontal separation. Figures 1 and 2 show floating in floating.12

a latex paint and its conversion to flooding with the ad- (3) The emulsion used—Binder, like pigment, requires sur-

dition of silicon oil. Flooding and floating occur during factants for dispersion and stabilization. If the emulsion

the application of colored latex paint.1 They complicate and color paste are not compatible, or if the emulsion or

color matching, waste color paste or pigment, and can color paste is deprived of surfactants, the stability of the dis-

hurt appearance, flow and leveling, hiding power, tint persion will be reduced, and flooding and floating may ap-

strength, gloss, and the resistance of the paint film to wa- pear.13 So testing compatibility between emulsion and color

ter and alkali.2-4 paste before production is essential. Methods for assessing

It is widely accepted that there are many components pigment dispersion have been compared by Van et al.14

and factors that influence flooding and floating. Among

these factors are:

(1) Stability of pigment and emulsion dispersion—

Inorganic pigments in aqueous coatings have been inves-

tigated using atomic force microscopy and microprobe an-

alyzers.5 Dispersability of organic pigments aggregation

degree has been determined,6 and rheological, electroki-

netic properties and surface chemistry of waterborne dis-

persions have also been studied.7-8 When excessive floccu-

lation and precipitation occur, flooding and floating

happen. So absorbing suitable dispersants on pigments

and forming an optimum absorption layer will exert a Figure 1—Floating and flooding defects. (A) floating, (B) normal,

beneficial influence on flooding and floating resistance. (C) floating converts to flooding after silicon oil is added.

*Research Institute of Chemical Engineering, Guangzhou, 510640, China.

†Author to whom correspondence should be addressed. Voice/fax: 86.20.87112057.807; huangying77@21cn.com.

www.coatingstech.org July 2004 213

H. Ying et al.

EXPERIMENTAL

Materials

Primal AC-261, from Rohm and Haas, was used as

emulsion. CPS Monicolor universal color pastes were used

for color. Dupont TiO2, kaolin from Jinyang in ShanXi,

China, and talc from Longguang in GuangXi, China were

used as pigment and fillers. Henkel and BYK additives

were used as dispersants and defoamers, etc.

Instruments

An MP200A electronic scale from Shanghai, China and

a GFJ-0.4 high speed dispersing plant in Shanghai, China

were used to produce the paint. A 480KU viscometer from

Sheen Instruments Ltd., U.S. and a Brookfield DV-II vis-

cometer from Brookfield Engineering Laboratories, U.S.,

ICI cone and plate viscometer from Research Equipment

Ltd., a QXD-25 to QXD-150 fineness of grind gauge from

Tianjin, China, a tensionmeter 70535 surface tension ap-

paratus from CSC-Dunouy, and a WGG-B three-angle dig-

ital glossmeter from Fujian, China were used to evaluate

and survey the experiments.

Experimental Design

Figure 2—Illustrating diagrams of floating and flooding defects. (A)

normal, (B) floating, (C) floating converts to flooding after silicon The acrylate emulsion and color paste were tested for

oil is added. compatibility. First, the emulsion and color paste were

blended at a 50:1 ratio. After storage at 50°C for 30 days, the

fineness was measured. If the fineness was below 30 µm, the

(4) Application conditions—Humidity, temperature, and emulsion and color paste were considered compatible. If

processing are also influential.15 the fineness was above 50 µm, they were considered incom-

patible. If it was between 30 and 50 µm, they were consid-

A variety of approaches have been used to alleviate

ered partially compatible. Other ingredients were let-down

flooding and floating, such as forming coflocculates,16-17

and the latex paint was produced. Paint was applied on the

using leveling agents,18 or adding shear thickeners.19

substrate (asbestine plank) to form films and flooding and

However, how the essential components in latex paint in-

floating of the wet films were evaluated.

fluence the defects of flooding and floating has seldom

been reported. To study how pigment and filler influence flooding and

floating, we designed the following experiments:

In this article, the influence of pigment, filler, addi-

tives, and processing conditions on flooding and floating (1) Different amounts of TiO2 (4, 10, 23 wt%) and var-

is studied. Correlative measures to prevent or alleviate ious amounts of monoazo red (0.1, 0.5, 1, 2, 5, and 10

flooding and floating are also proposed. wt%), were added to the basic paint.

Figure 3—Bénard cells in wet film. Figure 4—Floating in paint with different titanium.

214 July 2004 JCT Research

Flooding and Floating in Latex Paint

Table 1—Compatibility of Acrylate Emulsion and Color Paste

Emulsion and Color Paste Only Coatings with Other Ingredients

Bin stability Fineness

Color Paste (50°C, 30 days) µm)

(µ Compatibility Inside Surfacea

Anthraquinone red............ Uniform 28 Compatible Uniform Red floating at the brim2, flooding2

Monoazo red .................... Uniform 21 Compatible Uniform Floating4, flooding3

Indian red ......................... Uniform 30 Compatible Uniform Floating1, flooding1

Quinoline yellow............... Uniform 26 Compatible Uniform Floating1, flooding1

Monoazo yellow ............... Uniform 22 Compatible Uniform Floating1, flooding1

Disazo yellow.................... Uniform 25 Compatible Uniform Floating2, flooding1

Ferrite yellow .................... Uniform 29 Compatible Uniform Floating2, flooding1

Brown iron oxide .............. Uniform 28 Compatible Uniform Floating1, flooding1

Phthalocyanine green ....... Uniform 28 Compatible Uniform Floating4, flooding3

Phthalocyanine blue.......... Uniform 26 Compatible Uniform Blue floating at the brim2, flooding2

Quinacridone violet .......... Uniform 23 Compatible Uniform White floating1, flooding1

Delphine violet ................. Uniform 25 Compatible Uniform White floating1, flooding1

Carbon black .................... Flooding2 40 Partially compatible Uniform Floating4, flooding3

(a) Note 1, 2, 3, 4 indicate the degree of floating and flooding: 1 = slightest, 4 = most severe; the same coding scheme is used in all tables.

Table 2—Influence of Titanium Content on Flooding and Floating

Flooding and Floating Condition

TiO2 Content 4 wt% 10 wt% 23 wt%

Color paste 0.1 Floating2, flooding2 Uniform Floating2, flooding2

content (wt%) 0.5 Floating2, flooding2 Uniform Floating2, flooding2

1 Floating1, flooding1 Floating1, flooding1 Floating2, flooding2

2 Floating1, flooding1 Floating1, flooding1 Floating3, flooding3

5 None Floating2, flooding2 Floating3, flooding3

10 None Floating2, flooding2 Floating4, flooding4

(2) Using a formulation with 10 wt% TiO2 in the basic (6) Three types of thickeners were used to increase vis-

paint, colored by 0.1 wt% monoazo red, we added 5, 10, cosity: cellulose QP-4400, acrylic CR2, and polyurethane

and 15 wt% water to dilute the paint and stored it natu- SN-612. We adjusted the viscosity between 85–95 KU with

rally for seven days. the three thickeners; QP-4400 was added before other in-

gredients, while CR2 and SN-612 were added in the last

(3) With no change to the other ingredients in the paint,

phase of production. They were all colored by 0.1 wt%

we used differing kaolin contents; the kaolin contents used

monoazo red and carbon black.

were: 8, 11, and 14, and 17 wt%, colored by monoazo red

and carbon black both at 0.1 wt%. (7) To see whether processing affects flooding and

floating of coating, we added 0.1 wt% monoazo red in the

(4) We produced three groups of paint with kaolin and coating in four different ways: (a) Dispersed with titanium

talc of various particle sizes, TiO2, and other ingredients as under high speed agitating; (b) Added after high speed ag-

above: itation dispersion of titanium and filler, and before emul-

(a) kaolin (38 µm) + talc (38 µm)

(b) kaolin (38 µm) + talc (10 µm)

(c) kaolin (10 µm) + talc (10 µm)

(d) kaolin (2 µm) + talc (10 µm)

All were colored with monoazo red and carbon black,

both at 0.1 wt%.

(5) Several groups of surfactants were investigated to re-

veal how the surfactants influence flooding and floating:

(a) 0.8 wt% SN-Dispersant 5040

(b) 0.8 wt% SN-Dispersant 5027

(c) 0.2 wt% SN-Dispersant 5040 + 0.6 wt% SN-Dispersant

5027

Other ingredients were unchanged; the formulations

were colored by monoazo red and carbon black, both at

0.1 wt%, and then brushed. After the films dried, we

measured the brightness and saturation to compare dis- Figure 5—The floating results of carbon black with different kaolin

persion stability. contents.

www.coatingstech.org July 2004 215

H. Ying et al.

Table 3—Flooding and Floating Difference of Latex Paint Diluted with Water

Flooding and Floating Condition

Dilution ratio ............................................... 5 wt% 10 wt% 15 wt%

0.1 wt% paste + 10 wt% TiO2 ..................... Flooding1, floating1 Flooding2, floating 3 Flooding3 , floating4

sion addition; (c) Added after the basic paint is produced, for the preparation of light tint paint, 8–13% TiO2 content

that is, the last in order; and (d) Color paste premixed latex is used for the preparation of a medium shade coat-

with emulsion, then added into the paint in the usual or- ing, and < 4% TiO2 content latex is used in deep color pro-

der. Flooding and floating were evaluated for each after duction. To summarize, high TiO2 makes flooding and

natural and accelerated storage at 50° for 30 days. floating worse, especially with high paste content. The 10

wt% level may not be the optimum, but it certainly is bet-

ter than the others at low paste content.

RESULTS AND DISCUSSION The effect of dilution with water on flooding and float-

ing is shown in Table 3.

Influence of Emulsion

It is observed that, when a nonfloating paint is diluted

The results of the compatibility experiment of acrylate with water, flooding and floating may occur, or their

emulsion and color paste are shown in Table 1. severity may increase. When more water is added to the

It can be seen that most color pastes are compatible paint, the dispersants are diluted and there is compara-

with the emulsion, except that carbon black paste is par- tively less dispersant available to stabilize the pigment.

tially compatible. However, in the paint produced with The paint becomes more hydrophilic, so lipophilic com-

the same emulsion and different paste, flooding and float- ponents are more likely to phase separate. Last, but by no

ing appear in varying degrees, in which monoazo red and means least, the decrease of viscosity makes the move-

carbon black paint are most severe. That is why we chose ment of particles easier. The addition of water also tends

monoazo red and carbon black paste for the following ex- to raise the surface tension, inducing more severe Bénard

periments. In the case of quinacridone violet and del- cell flows.

phine violet, white color floats on the surface. It can be The influence of kaolin content on flooding and float-

concluded that, in most cases, the emulsion is not the ing is shown in Table 4, and the floating results of carbon

main cause of flooding and floating. black are plotted in Figure 5.

The main component of kaolin is Al2O3•2SiO2•2H2O. It

Influence of Pigments and Fillers has some other names, such as hydrated aluminum sili-

The influence of TiO2 content on flooding and floating cate, China clay, white bole, etc. It can engender

is shown in Table 2 and Figure 4. It can be seen that paints thixotropic structure, form a kind of spatial network struc-

with different TiO2 content differ in flooding and floating. ture, and prevent aggregation of pigment particles, thus

This is because pigment particles vary in hydrophilicity. alleviating flooding and floating.

While a volatile component like propylene glycol which is It is found that there is an optimum content of kaolin.

used as a cold-resistant agent evaporates, it carries rather Increasing concentration favors dispersion stability, but

more lipophilic particles to the surface, so the scission of makes dispersion difficult. Application properties and

color emerges. Usually, 20–30% TiO2 content latex is used gloss are impaired at high concentrations. Based on Table

Table 4—Influence of Kaolin Content on Flooding and Floating

Kaolin Content 8 wt% 11 wt% 14 wt% 17 wt%

Carbon black ..............Film status after natural setting Floating1 Floating1 Floating1 Floating2

for one week flooding2 flooding1 no flooding floating2

Film status after accelerated Floating3 Floating2 Floating1 Blocking

storage for one month flooding3 flooding2 no flooding

Monoazo red ..............Film status after natural setting Floating2 Floating1 Floating1 Floating2

for one week flooding2 flooding1 no flooding floating2

Film status after heat Floating3 Floating2 Floating1 Blocking

accelerating storage for one month flooding3 flooding2 no flooding

Table 5—Influence of Particle Size on Flooding and Floating

Test Item .................................. Kaolin (38 µm) Kaolin (38 µm) Kaolin (10 µm) Kaolin (2 µm)

+talc (38 µm) +talc (10 µm) +talc (10 µm) +talc (10 µm)

Monoazo red (0.1 wt%)........... Floating3, flooding2 Floating3, flooding1 Floating1, no flooding None

Carbon black (0.1 wt%) ........... Floating3, flooding3 Floating2, flooding1 Floating1, no flooding None

216 July 2004 JCT Research

Flooding and Floating in Latex Paint

Table 6—Influence of Dispersants on Flooding and Floating

Dispersants Flooding and Floating Surface Tension (dyn/cm)

Carbon black ...... 5027 (0.8 wt%) Floating1, flooding1 34.5

5040 (0.8 wt%) Floating2, flooding2 41.5

5027 (0.6 wt%) + 5040 (0.2 wt%) None 37.1

Monoazo red ...... 5027 (0.8 wt%) Floating1, flooding1 34.3

5040 (0.8 wt%) Floating1, flooding2 41.8

5027 (0.6 wt%) + 5040 (0.2 wt%) None 37.0

Table 7—Influence of Different Thickeners on Flooding and Floating

Thickener

QP4400 CR2 SN-612

Content............... 1.5 wt% 1.2 wt% 1 wt%

Viscosity .............. 92.1 92.3 91.8

Monoazo red....... Floating3, flooding3 Floating1, flooding1 Floating2, flooding2

Carbon black ....... Floating3, flooding3 Floating1, flooding1 Floating3, flooding3

4, 14 wt% is a comparatively effective dosage. In practice, surface tension. For the higher steric hindrance and lower

several fillers are often used in combination to meet per- surface tension, 5027 is good at alleviating flooding and

formance requirements. floating; but 5040 has higher dispersing efficiency when

Small particle size tends to alleviate flooding and float- used alone, so the use of both shows the best effect.

ing. According to Stokes’ law, the velocity of spherical par- Sedimentation can be adjusted by increasing viscosity.

ticles sinking in a liquid is given by: CR2 is an acrylic thickening agent; a schematic of its struc-

ture is shown in Figure 6. Its hydrophilic “segment” coa-

V = D(dpi–dbi)r2/η lesces with water to thicken, and its lipophilic segment’s

hydrophobic function keeps the particles detached, and

where V: velocity; D: proportional constant; η: viscosity;

forms a steric network, thus controlling flooding and

dpi: density of pigment; dbi: density of binder; r: pigment

floating. It can be seen from Table 7 that steric hindrance

radius. This equation indicates that sinking velocity de-

plays an important role in the control of flooding and

creases when the particle size decreases, or the difference

floating.

between pigment and binder density is reduced, or binder

viscosity increases. The effect of particle size on flooding QP4400 is a kind of hydroxyethylcellulose from

and floating is shown in Table 5. Cellosize, and SN-612 is another hydroxyethylcellulose

from Henkel Ltd. Hydroxyethylcellulose is widely used in

paint. However in this case, it is less effective in reducing

Influence of Additive Agents floating, for CR2 is more similar in structure to and com-

The influence of dispersants on flooding and floating is patible with the dispersants. So, the compatibility be-

shown in Table 6. SN-Dispersant 5040 is a special polysodium tween thickener and dispersant is very important.

carboxylate dispersant for latex paint. SN-Dispersant 5027 The influence of different viscosities (adjusted using

is a polyammonium carboxylate with higher molecular CR2, since it is the most effective thickener among the

weight than 5040. 5027 is more lipophilic and has lower three) on flooding and floating is elucidated in this exper-

Table 8—Influence of Viscosity on Flooding and Floating

CR2 content.......................... 0.8 wt% 0.85 wt% 0.9 wt% 0.95 wt%

Viscosity (KU) ....................... 89 94 103 112

Monoazo red........................ Floating3, flooding3 Floating2, flooding2 Floating1, flooding1 Floating1, flooding1

Carbon black........................ Floating3, flooding3 Floating3, flooding3 Floating1, flooding1 Floating1, flooding1

Table 9—Influence of Processing on Flooding and Floating

Processing 1 2 3 4

Monoazo red After natural

setting (3 days) None Almost none Floating1, flooding1 Floating1, flooding1

After natural

setting (7 days) Almost none Almost none Floating1, flooding1 Floating1, flooding1

After accelerated storage

for 1 month Floating2, flooding2 Floating2, flooding2 Floating2, flooding2 Floating2, flooding2

www.coatingstech.org July 2004 217

H. Ying et al.

(4) Processing conditions have little influence on

flooding and floating.

To sum up, reducing the surface tension, forming spa-

tial network structure, decreasing the particle size, mini-

mizing the difference between pigment and binder den-

Figure 6—Structure scheme of CR2.

sity, and increasing viscosity are helpful in preventing

flooding and floating.

iment; the results can be seen in Table 8. It is found that

higher viscosity reduces flooding and floating. References

(1) Graystone, J.A., Surface Coatings International, (80)11: 516-522

(1997).

Influence of Processing (2) Fujitani, T., Prog. Org. Coat., 29, 97-105 (1996).

(3) Guner, F.S., Gumusel, A., Calica, S., and Erciyes, A.T., “Study of

It can be seen from Table 9 that processing has little in-

Film Properties of Some Urethane Oils,” JOURNAL OF COATINGS

fluence on flooding and floating. In practice, color paste is TECHNOLOGY, 74, No. 929, 55 (2002).

added as process number 3 according to the principles of (4) Schoff, C.K., “Surface Defects: Diagnosis and Cure,” JOURNAL OF

convenience, speediness, and economy. COATINGS TECHNOLOGY, 71, No. 888, 56 (1999).

(5) Somasundaran, P. and Krishnakumar, S., Colloids Surf. A, 123-

124, 491-513 (1997).

CONCLUSIONS (6) Daescu, C., Dye and Pigments, Vol. 38, No. 1-3, pp.173-180, 1998.

(7) Huynh, L. and Jenkins, P., Colloids Surf. A, 190, 35-45 (2001).

In this article, flooding and floating in latex paint were (8) Morris, G.E., Skinner, W.A., Self, P.G., Smart, R. St. C., Colloids

studied and the causes were summarized from the aspect Surf. A, 155, 27-41 (1999).

(9) Visschers, M., Laven, J., and van der Linde, R., “Film Formation

of components. Ways to alleviate flooding and floating in

from Latex Dispersions,” JOURNAL OF COATINGS TECHNOLOGY, 73,

waterborne coatings were explored. The following conclu- No. 916, 49 (2001).

sions can be drawn: (10) Lofflath, F. and Gebhard, M., “Rheological Changes During the

Drying of a Waterborne Latex Coating,” JOURNAL OF COATINGS

(1) Generally, color pastes are compatible or partially

TECHNOLOGY, 69, No. 867, 55 (1997).

compatible with the emulsion. However, in the paint pro- (11) Hester, R.D. and Squire, D.R. Jr., “Rheology of Waterborne

duced with the same emulsion and different paste, flood- Coatings,” JOURNAL OF COATINGS TECHNOLOGY, 69, No. 864, 109

ing and floating appear in various degrees. So, emulsion is (1997).

not the main cause of flooding and floating. (12) Weidner, D.E., Schwartz, L.W., and Eley, R.R., Colloid Interface

Sci., 179, 66-75 (1996).

(2) Paints with different pigment or filler contents dif- (13) Brown, R.F.G. et al., Prog. Org. Coat., 30, 185-194 (1997).

fer in flooding and floating conditions. It is because pig- (14) Van, S.T., Velamakanni, B.V., and Adkins, R.R., “Comparison of

ment particles are different in hydrophilic property and Methods to Assess Pigment Dispersion,” JOURNAL OF COATINGS

lipophilic nature. Usually, 20–30% TiO2 content latex is TECHNOLOGY, 73, No. 923, 61 (2001).

used for preparing light tint paint; 8-13% TiO2 content la- (15) Schwartz, L.W., Roy, R.V., and Eley, R.R., Colloid Interface Sci.,

234, 363-374 (2001).

tex is used for preparing a medium shade coating; and < 4% (16) Volz, H.G., Prog. Org. Coat., 33, 101-107 (1998).

TiO2 content latex is used in deep colored paint production. (17) Reuter, E., Silber, S., and Psiorz, C., Prog. Org Coat., 37, 161-167

Reducing the surface tension, increasing the viscosity, and (1999).

using finer particles help to prevent flooding and floating. (18) Eley, R.R. and Schwartz, L.W., “Interaction of Rheology,

Geometry, and Process in Coating Flow,” JOURNAL OF COATINGS

(3) Steric hindrance in both dispersants and thickeners TECHNOLOGY, 74, No. 932, 43 (2002).

plays an important role in the control of flooding and (19) Strivens, T.A., Paint and Surface Coatings: Theory and Practice, 2nd

floating. ed., Woodhead Pub. Ltd., 1999.

218 July 2004 JCT Research

You might also like

- BASF Brochure Packaging Everyday LifeDocument23 pagesBASF Brochure Packaging Everyday LifeKiệt ĐỗNo ratings yet

- ExtendersDocument33 pagesExtenderssbttbsNo ratings yet

- Kronos Grades ListDocument20 pagesKronos Grades ListKarbonKale100% (1)

- Chlorinated-Polyethylene-Rubber 6 PDFDocument4 pagesChlorinated-Polyethylene-Rubber 6 PDFAsit RayNo ratings yet

- Next Generation HEUR Technology CoatingsTech March2014Document9 pagesNext Generation HEUR Technology CoatingsTech March2014Arturo Antonio Matencio ArroyoNo ratings yet

- Catalogo Aditivos AfconaDocument44 pagesCatalogo Aditivos AfconaMaleja HerediaNo ratings yet

- Li Edaplan Metolat Dispersing TechnologyDocument15 pagesLi Edaplan Metolat Dispersing TechnologyPulbere NeagraNo ratings yet

- MODAFLOWDocument24 pagesMODAFLOWuzzy2100% (1)

- Calculating Technique For Formulating Alkyd Resins: Progress in Organic Coatings September 1992Document22 pagesCalculating Technique For Formulating Alkyd Resins: Progress in Organic Coatings September 1992Naresh KumarNo ratings yet

- Dirt-Pickup Resistance Inlowt Elastomeric Coatings: Robert Sandoval, PH.DDocument31 pagesDirt-Pickup Resistance Inlowt Elastomeric Coatings: Robert Sandoval, PH.Dichsan hakimNo ratings yet

- Jan 2010 Oxylink Updated Sales Presentation PDFDocument44 pagesJan 2010 Oxylink Updated Sales Presentation PDFdainguyenlamNo ratings yet

- Dispersing AgentsDocument6 pagesDispersing AgentsEdward MenezesNo ratings yet

- Ropaque HP-1096Document6 pagesRopaque HP-1096Manuel XhireNo ratings yet

- 7020P Version 7thDocument1 page7020P Version 7thDuc NguyenNo ratings yet

- Elementis Selector Chart AdditiveDocument14 pagesElementis Selector Chart AdditiveEugene Pai100% (1)

- Basic Science For Students of Paint TechnologyDocument44 pagesBasic Science For Students of Paint TechnologysondeadorNo ratings yet

- Four Steps to Effective Pigment Dispersions: Starting from ScratchDocument5 pagesFour Steps to Effective Pigment Dispersions: Starting from ScratchEyad AlsheiikhNo ratings yet

- Rheofibre - BasfDocument2 pagesRheofibre - BasftheshadowknightNo ratings yet

- 01 - 2K PU SB Auto Refinish & Ind Systems 08-10Document67 pages01 - 2K PU SB Auto Refinish & Ind Systems 08-10محمد عزتNo ratings yet

- Functions of Dispersing Additives in InkDocument71 pagesFunctions of Dispersing Additives in InkBoonyarit LurdgrienggraiyingNo ratings yet

- Rust Preventative GuideDocument11 pagesRust Preventative GuideEduardo Fuentes Renner100% (1)

- RP4036 PDFDocument5 pagesRP4036 PDFA MahmoodNo ratings yet

- Zinc FreeDocument8 pagesZinc FreeDuc NguyenNo ratings yet

- Coating Ingredient Effects On RheologyDocument50 pagesCoating Ingredient Effects On RheologydougNo ratings yet

- Huber's Alumina Trihydrate (ATH) A Versatile Pigment For Coatings, Inks, Adhesives, Caulks and Sealants ApplicationsDocument5 pagesHuber's Alumina Trihydrate (ATH) A Versatile Pigment For Coatings, Inks, Adhesives, Caulks and Sealants ApplicationsdewanibipinNo ratings yet

- Primal ICC 3Document2 pagesPrimal ICC 3hongducxxxNo ratings yet

- Akzo Nobel's Duomeen TDO: PointDocument1 pageAkzo Nobel's Duomeen TDO: PointさいとはちこNo ratings yet

- Eastman Product For Ink and CoatingDocument28 pagesEastman Product For Ink and CoatingshikhajainNo ratings yet

- Pergut EDocument17 pagesPergut ECesar MartinezNo ratings yet

- RosinDocument42 pagesRosinVingiu Katre100% (1)

- Omnova Coatings PresentationDocument12 pagesOmnova Coatings PresentationNatalia Rodriguez100% (1)

- Epoxy Curing Agents - Americas PDFDocument74 pagesEpoxy Curing Agents - Americas PDFMuhammad FahadNo ratings yet

- Guide For High Performance CoatingsDocument34 pagesGuide For High Performance Coatingsro snNo ratings yet

- Opti FloDocument11 pagesOpti FloAna QuintanaNo ratings yet

- Solvent Evap RateDocument2 pagesSolvent Evap RateBoro TerakolNo ratings yet

- BYK Rheology AdditivesDocument127 pagesBYK Rheology AdditivesAlbertNo ratings yet

- Iriotec - 8850 - EMD - TDS (For US and Canada) PDFDocument2 pagesIriotec - 8850 - EMD - TDS (For US and Canada) PDFxy2zjgNo ratings yet

- Resin Solubility ChartDocument7 pagesResin Solubility ChartLaboratorio InkctechNo ratings yet

- 1.1.6 Rust ConvertersDocument1 page1.1.6 Rust ConvertersRey Luis TehNo ratings yet

- 24 391 01 Coatings and Inks Additive Selection GuideDocument16 pages24 391 01 Coatings and Inks Additive Selection GuideLong An DoNo ratings yet

- 3 Binders For Eco FormulationsDocument80 pages3 Binders For Eco FormulationsCarolinaMaria Consonni100% (1)

- Cril at 4830Document4 pagesCril at 4830ForeverNo ratings yet

- 3m FluosufactantDocument4 pages3m Fluosufactantuzzy2No ratings yet

- BASF Technical Guide For PUDocument40 pagesBASF Technical Guide For PUshikhajainNo ratings yet

- Product Fact Sheet: Emulsogen TS 200Document2 pagesProduct Fact Sheet: Emulsogen TS 200Arturo Hernández100% (1)

- Short Dispersion Guideline For Orion Carbon Black Pigments in Coatings. Technical Information TI 1375Document12 pagesShort Dispersion Guideline For Orion Carbon Black Pigments in Coatings. Technical Information TI 1375Bandana DholeNo ratings yet

- Coating Technology HandbookDocument4 pagesCoating Technology HandbookvaducNo ratings yet

- Classification of PaintsDocument2 pagesClassification of Paints9440864459No ratings yet

- Ethylene Glycol: Product GuideDocument34 pagesEthylene Glycol: Product Guidectopher63No ratings yet

- UC-1226 UCAR Waterborne Vinyl Resin Dispersion AW-875 For Inks Coatings and Adhesives PDFDocument24 pagesUC-1226 UCAR Waterborne Vinyl Resin Dispersion AW-875 For Inks Coatings and Adhesives PDFchayanunNo ratings yet

- Rust ConverterDocument2 pagesRust ConvertergabictbNo ratings yet

- CW January 2014Document66 pagesCW January 2014Stephanie NorrisNo ratings yet

- BASF industrial+Metal+CoatingsDocument12 pagesBASF industrial+Metal+CoatingsMaria Eugenia CiveiraNo ratings yet

- DSM Ind. Wood 2Document11 pagesDSM Ind. Wood 2RutherfordNo ratings yet

- Fundamentals of Waterborne Resin TechnologyDocument4 pagesFundamentals of Waterborne Resin TechnologyvaducNo ratings yet

- Self-Cleaning Materials and Surfaces: A Nanotechnology ApproachFrom EverandSelf-Cleaning Materials and Surfaces: A Nanotechnology ApproachWalid A. DaoudRating: 5 out of 5 stars5/5 (1)

- Polymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3From EverandPolymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3No ratings yet

- Handbook of Vinyl FormulatingFrom EverandHandbook of Vinyl FormulatingRichard F GrossmanRating: 3 out of 5 stars3/5 (1)

- Acrylic & Methacrylic AdhesivesDocument6 pagesAcrylic & Methacrylic AdhesivesparsonadhesivesNo ratings yet

- Acrylic & Methacrylic AdhesivesDocument6 pagesAcrylic & Methacrylic AdhesivesparsonadhesivesNo ratings yet

- Acrylic & Methacrylic AdhesivesDocument6 pagesAcrylic & Methacrylic AdhesivesparsonadhesivesNo ratings yet

- Talc For Wall Paint - WallpaintDocument9 pagesTalc For Wall Paint - Wallpaintboyo17meiNo ratings yet

- 2011 035 - CR - Evaluation of Various UV StabilizationxDocument10 pages2011 035 - CR - Evaluation of Various UV Stabilizationxboyo17meiNo ratings yet

- Paints and Coatings - How Surfactants Can Advance New DevelopmentsDocument9 pagesPaints and Coatings - How Surfactants Can Advance New Developmentsboyo17meiNo ratings yet

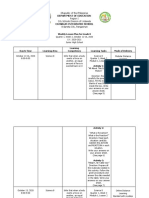

- Weekly lesson plans for Grade 8 and 10 science and MAPEH subjectsDocument14 pagesWeekly lesson plans for Grade 8 and 10 science and MAPEH subjectsMark Jay BongolanNo ratings yet

- 5 Paint TypesDocument136 pages5 Paint TypesManohar Seetharam100% (1)

- Fall/Winter 2013-2014 Frontlist CatalogDocument478 pagesFall/Winter 2013-2014 Frontlist CatalogConsortium Book Sales & DistributionNo ratings yet

- Mariupol - Trifold BrochureDocument1 pageMariupol - Trifold BrochureAnna GumenyukNo ratings yet

- Nude (Art)Document23 pagesNude (Art)karina AlvaradoNo ratings yet

- Design History (Swin)Document9 pagesDesign History (Swin)Thư Giang MinhNo ratings yet

- Manual - Lego Ironman MK42 PapercraftDocument2 pagesManual - Lego Ironman MK42 Papercrafthicaro_leandroalonso756167% (6)

- Giorgio Morandi (Art Ebook)Document136 pagesGiorgio Morandi (Art Ebook)untalsebas100% (1)

- Graduate Thesis on Tschumi's "Architecture and DisjunctionDocument2 pagesGraduate Thesis on Tschumi's "Architecture and DisjunctionhusnaabharinaNo ratings yet

- Toa Ngma FinalDocument7 pagesToa Ngma FinalbandhuarushiNo ratings yet

- Denotation and ConnotationDocument6 pagesDenotation and Connotationkellyting90No ratings yet

- Chapter 1Document53 pagesChapter 1Kaynine Kiko50% (4)

- NCTIABE'19 RESEARCH PAPER (Anishma, Abisekha, Bala Kaleeswaran, Anisha)Document6 pagesNCTIABE'19 RESEARCH PAPER (Anishma, Abisekha, Bala Kaleeswaran, Anisha)Anishma AyyappanNo ratings yet

- The Manual of ArmsDocument124 pagesThe Manual of ArmsDave Niescior100% (11)

- PowerPointHub-Science Learning-3B8QqADocument24 pagesPowerPointHub-Science Learning-3B8QqAsungi kyuNo ratings yet

- Heavy Planet - Bong Hits From The Astral Basement - Heavy Planet E-BookDocument129 pagesHeavy Planet - Bong Hits From The Astral Basement - Heavy Planet E-Book__arsalNo ratings yet

- Itl 518 Project Based Learning Template 1Document24 pagesItl 518 Project Based Learning Template 1api-431944437100% (1)

- (Contemporary French and Francophone Cultures 27) Edward Welch, Joseph McGonagle - Contesting Views - The Visual Economy of France and Algeria-Liverpool University Press (2013)Document245 pages(Contemporary French and Francophone Cultures 27) Edward Welch, Joseph McGonagle - Contesting Views - The Visual Economy of France and Algeria-Liverpool University Press (2013)guzel nsm100% (1)

- Pma XT Sp0013Document47 pagesPma XT Sp0013memo_uniNo ratings yet

- 3rd Quarter STUDY NOTES For AnimationDocument2 pages3rd Quarter STUDY NOTES For AnimationBerry BlueNo ratings yet

- The Chevalier D'eon and His Worlds: Gender, Espionage and Politics in The Eighteenth CenturyDocument54 pagesThe Chevalier D'eon and His Worlds: Gender, Espionage and Politics in The Eighteenth CenturyContinuum0% (1)

- Oxford Solutions Intermediate Oxford Solutions Intermediate Progress Test Answer Key BDocument13 pagesOxford Solutions Intermediate Oxford Solutions Intermediate Progress Test Answer Key BAngelinsss2374% (19)

- Kerala State Rutronix: Question CodeDocument2 pagesKerala State Rutronix: Question CodefcmitcNo ratings yet

- Bop RepairDocument13 pagesBop Repairnjava1978100% (1)

- The Practice Chart for Intention Centered Yoga and Art TherapyDocument16 pagesThe Practice Chart for Intention Centered Yoga and Art TherapyBalázs TóthNo ratings yet

- Lesson Plan: Block PrintingDocument1 pageLesson Plan: Block PrintingarianamoonNo ratings yet

- Paints SlidesDocument24 pagesPaints SlidesMian Afzaal 72No ratings yet

- Franz MarcDocument14 pagesFranz MarcSandmansNymphetNo ratings yet

- Classical, Medieval and Renaissance Art Periods Cheat SheetDocument1 pageClassical, Medieval and Renaissance Art Periods Cheat SheetmistyofNo ratings yet

- DeKalb FreePress: 4-14-17Document20 pagesDeKalb FreePress: 4-14-17Donna S. SeayNo ratings yet