Professional Documents

Culture Documents

Api 2005

Uploaded by

Madeline Dacian0 ratings0% found this document useful (0 votes)

325 views2 pagesAPI steel oil / water separators are a gravity differential separation device for removal of free and finely dispersed oil droplets from oily wastestreams. API performance: 100mg / L, 150-micron free, dispersed and non-emulsified oil droplets. API separators can be used singularly or in combination with other treatment processes such as emulsion cracking, DAF and clarifier pretreatment.

Original Description:

Original Title

API 2005

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAPI steel oil / water separators are a gravity differential separation device for removal of free and finely dispersed oil droplets from oily wastestreams. API performance: 100mg / L, 150-micron free, dispersed and non-emulsified oil droplets. API separators can be used singularly or in combination with other treatment processes such as emulsion cracking, DAF and clarifier pretreatment.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

325 views2 pagesApi 2005

Uploaded by

Madeline DacianAPI steel oil / water separators are a gravity differential separation device for removal of free and finely dispersed oil droplets from oily wastestreams. API performance: 100mg / L, 150-micron free, dispersed and non-emulsified oil droplets. API separators can be used singularly or in combination with other treatment processes such as emulsion cracking, DAF and clarifier pretreatment.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Model API

API API Design Oil Water Separators

The API Series oil water separators are designed per the American

Petroleum Institute (API) separator design guidelines.

Pan America Environmental API Series, Features:

steel oil/water separators are a gravity ♦ A-36 carbon steel

differential separation device for removal of ♦ Adjustable water weir

free and finely dispersed oil droplets ♦ Integral oil reservoir

from oily wastestreams. The design follows ♦ Influent diffuser

the American Petroleum Institute’s (API)

#421 Design & Operation of Oil/Water

♦ Expandable effluent chamber

Separators Manual, February 1990. ♦ Sealed/gasketed covers

♦ Internal/external epoxy coatings

API performance: 100mg/L, 150-micron ♦ Lifting lugs

free, dispersed and non-emulsified oil ♦ Flat Bottom

droplets.

♦ Skid mounted

The typical use of the API separator is to ♦ Multi-section cover

reduce inlet loads of oil and suspended

solids in refinery wastewater. Following the Typical applications:

API further treatment may be required, i.e. ♦Groundwater remediation

coalescing oil water separator as a

♦ Mobile separation system

polishing step and treatment of dissolved

organic materials with biological treatment, ♦ DAF/Clarifier pretreatment

and/or other treatment technologies (DAF ♦ Power plant water treatment

etc.). ♦ Refinery process water

♦ Aircraft wash racks

The API steel design is just one of 8 ♦ Machining coolant oil removal

different oil/water separator designs from

Pan America Environmental that can be

♦ Tank farm tank bottoms

used singularly or in combination with other ♦ Vehicle washwater treatment

treatment processes such as emulsion ♦ R.O. Filter pre-treatment

cracking, DAF & clarifier pretreatment. ♦ Oil spill recovery

♦ Trench water treatment

The API can be installed above, flush with

♦ Bilge water treatment

or below grade. Conversion to a DAF can

also be accomplished for flotation where ♦ Hydraulic fluid tank de-watering

needed.

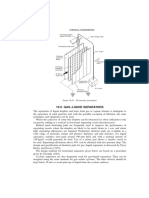

Model API A B

API API Design Oil Water 7 9 14 10

5

3 11

12

5

Separators

13

Gravity Separation 1

2

The API separator separates via gravity and the 3

density differential of liquids per Stokes Law, 6

C

which defines the rise rate of an oil droplet based D E

on its density and size. Typically, the difference 8 F

between the specific gravity of the oil and water is

4

much closer than the specific gravity of the

suspended solids and water. Therefore, the

SECTIONAL SIDE VIEW 4 EFFLUENT END VIEW

design of the API separator is based on the

difference in the specific gravity of the oil to be

separated and the wastewater. Using this criteria Oil

Length Width Height Influent Effluent Oil Drain Oil

results in most suspended solids settling in the Model

Outlet

Chamber

Influent Effluent

Fitting Fitting

Empty Operating Flow

Siz e Siz e Weight Weight Rate

API. API effluent is then treated further in most (Gals) Siz e Siz e

A B C D E F

refinery wastewater treatment plants.

API-15 10'-0" 4'-0" 4'-3" 2'-2" 1'-8" 1'-8" 15 2" 2" 2" 2" 1880 5660 15

Per API guidelines design criteria are: API-25 13-0" 4'-6" 4'-3" 2'-2" 1'-8" 1'-8" 20 3" 2" 2" 3" 2600 6800 25

Depth to width ratio: A minimum depth to width ratio

of 0.3 to 0.5 is specified so that separator does not API-50 16'-0" 4'-6" 4'-3" 2'-2" 1'-8" 1'-8" 25 4" 4" 2" 3" 3200 8365 50

increase droplet rise time to reach the water surface.

API-100 26'-0" 5'-6" 5'-2" 2'-7" 2'-1" 2'-1" 25 6" 6" 3" 3" 6050 20300 100

Length to width ratio: A minimum length to width

ratio of 5:1 is specified for API separators to keep flow API-150 26'-0" 7'-6" 5'-6" 2'-10" 2'-4" 2'-4" 35 6" 6" 4" 4" 8250 29770 150

characteristics homogeneous, reducing short circuiting

effects. API-200 33'-0" 7'-6" 5'-9" 3'-0" 2'-6" 2'-6" 35 6" 6" 4" 4" 10150 41100 200

Maximum channel width and depth: The

API-250 42'-0" 7'-6" 5'-9" 3'-0" 2'-6" 2'-6" 50 8" 8" 4" 4" 12500 52200 250

maximum API separator channel width is 20 ft;

maximum depth is 8 ft. API-300 43'-0" 9'-6" 5'-10" 3'-2" 2'-8" 2'-8" 75 8" 8" 4" 6" 15345 69000 300

Horizontal velocity: Maintaining a horizontal velocity

of no more than 3.0 ft/sec to minimize turbulence and its API-400 50'-0" 9'-6" 5'-10" 3'-2" 2'-8" 2'-8" 75 8" 8" 4" 6" 17660 80130 400

interference with the separation process. API-500 62'-0" 9'-6" 5'-10" 3'-2" 2'-8" 2'-8" 100 10" 10" 4" 6" 21910 99710 500

Influent distributor: Minimization of high influent

velocity into the API separator, and possible short API-600 60'-0" 10'-6" 6'-2" 3'-6" 3'-0" 3'-0" 250 10" 10" 4" 6" 25235 128080 600

circuiting associated with these high velocities, a diffuser

directs flow across the width and depth of the inlet

chamber. Item Qty Description Item Qty Description Item Qty Description Item Qty Description Item Qty Description

Oil droplet size: Most oil droplets in refinery Oil Effluent

1 1 Inlet 4 1 Drain 7 1 Inlet Diffuser 10 1 13 1

wastewaters are 150 micron or larger. The API design Skimmer/Reserv Chamber

standards were based on this droplet. Droplets smaller

2 1 Outlet 5 4 Vent 1" NPT 8 1 Influent Chamber 11 1 Oil Baffle 14 1 Cover

than 150 micron typically escape API separators and

further treatment processes, unless allowances are 3 1 Oil Outlet 6 1 Drain 2" NPT 9 -

Flopak Media

12 1 Water Weir

made in the sizing of the API separator to remove these (option)

smaller particles.

950 N. Rand Rd., Ste 120

Wauconda, IL 60084 USA www.panamenv.com

847-487-9166 Fax: 847-487-9218 www.oil-water-separator.net

panam@panamenv.com

BULLETIN: api05

You might also like

- 3E AND 110H/210H SERIES Canned Motor Pumps: R S P W C I MDocument16 pages3E AND 110H/210H SERIES Canned Motor Pumps: R S P W C I Mari_prasNo ratings yet

- Case Study - Using PipelineStudio To Simulate Pigging Operations On An Indonesian PipelineDocument10 pagesCase Study - Using PipelineStudio To Simulate Pigging Operations On An Indonesian PipelineDan CarrascoNo ratings yet

- Sizing Calculation - AC214312UJ - R0 PDFDocument1 pageSizing Calculation - AC214312UJ - R0 PDFPavendhan PavNo ratings yet

- Appendix A: A.1. Three Phase SeparatorDocument48 pagesAppendix A: A.1. Three Phase SeparatorNhaaaeyNo ratings yet

- Design of Industrial Gravity Type Separators For The Hydrocarbons and Heavy Oil-Water SeparationsDocument5 pagesDesign of Industrial Gravity Type Separators For The Hydrocarbons and Heavy Oil-Water SeparationsCandraNo ratings yet

- LAMPIRAN C Spesifikasi PeralatanDocument89 pagesLAMPIRAN C Spesifikasi PeralatanRahmaisa HarahapNo ratings yet

- كل انواع الفلاش سبريتر الطورين والثلاث اطوار مهمDocument42 pagesكل انواع الفلاش سبريتر الطورين والثلاث اطوار مهمamir loloNo ratings yet

- Design Calculation For Gaseous SystemsDocument16 pagesDesign Calculation For Gaseous Systemsshashi ranjanNo ratings yet

- Rho v2Document1 pageRho v2Myung Ho SynNo ratings yet

- Separator Design: Rev Description Date Prepared by Client ApprovalDocument18 pagesSeparator Design: Rev Description Date Prepared by Client ApprovalUsɱâñ Måâñ100% (1)

- Spray Nozzles Total STDDocument3 pagesSpray Nozzles Total STDDylan RamasamyNo ratings yet

- Calculation of Height of The Siphon SystemDocument2 pagesCalculation of Height of The Siphon SystemHsein WangNo ratings yet

- M=350.17 (γ Wor Γ Gor Ρ γ: 6,000 bbl/dDocument23 pagesM=350.17 (γ Wor Γ Gor Ρ γ: 6,000 bbl/dHoa NguyenNo ratings yet

- CNPCIC Field Production Test Separator GuideDocument18 pagesCNPCIC Field Production Test Separator Guidesalahadine maideNo ratings yet

- Doc. No. 01 - 42 10 002 - OCSDocument36 pagesDoc. No. 01 - 42 10 002 - OCSHerlambang sNo ratings yet

- PH ColumnDocument4 pagesPH ColumnAnonymous oVRvsdWzfBNo ratings yet

- Average TZDocument6 pagesAverage TZvictor javier nuñezNo ratings yet

- Tank FixturesDocument21 pagesTank FixturesASSSSSSSSSSSSNo ratings yet

- KRAL Screw Pumps BrochureDocument28 pagesKRAL Screw Pumps BrochureRené Mora-CasalNo ratings yet

- Three-Phase Separator .: University of KerbalaDocument11 pagesThree-Phase Separator .: University of Kerbalamuhiemin MazinNo ratings yet

- Example 1: Size A 2-Phase Vertical Separator: Job SpecificationsDocument20 pagesExample 1: Size A 2-Phase Vertical Separator: Job SpecificationsagusnnnNo ratings yet

- 12D Series Three Screw PumpsDocument6 pages12D Series Three Screw PumpsJoram Marín HernándezNo ratings yet

- Valve Sizing Calculation8Document2 pagesValve Sizing Calculation8PIDNo ratings yet

- Unlock Separator SizingDocument42 pagesUnlock Separator SizingmortezasabetiNo ratings yet

- Sizing Sheet for 2-phase separator as per API 12J standardsDocument5 pagesSizing Sheet for 2-phase separator as per API 12J standardsWickyNo ratings yet

- Bilge System DesignDocument40 pagesBilge System DesignTegar LanangNo ratings yet

- Section 19Document97 pagesSection 19rahmat mamuriNo ratings yet

- Horizontal Three Phase Separator Sizing CalculationDocument3 pagesHorizontal Three Phase Separator Sizing CalculationDazzy 265No ratings yet

- Velocity and Friction Loss Calculation in PipesDocument4 pagesVelocity and Friction Loss Calculation in Pipesmazzam75No ratings yet

- 3-Phase Sparator Sizing (Vertical and Horizontal)Document30 pages3-Phase Sparator Sizing (Vertical and Horizontal)WickyNo ratings yet

- Separator S-101: Vessel Diameter and HeightDocument29 pagesSeparator S-101: Vessel Diameter and HeightAjeng FadillahNo ratings yet

- 13 - Gas Orifice and Gas Rate CalculationsDocument5 pages13 - Gas Orifice and Gas Rate CalculationsAnik AichNo ratings yet

- pR6-40-10-4 HPDocument2 pagespR6-40-10-4 HPS.DharanipathyNo ratings yet

- 3-Phase Separator Sheet (GPSA)Document12 pages3-Phase Separator Sheet (GPSA)WickyNo ratings yet

- Technological Institute of the Philippines Equipment DesignDocument48 pagesTechnological Institute of the Philippines Equipment DesignJeen AdameNo ratings yet

- PTP 02.2 HandoutDocument29 pagesPTP 02.2 HandoutJayNo ratings yet

- MPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013Document2 pagesMPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013zohaib_farooqNo ratings yet

- CalculationDocument13 pagesCalculationajit kumarNo ratings yet

- ParalDocument9 pagesParalTahirJabbarNo ratings yet

- CNG ADK 3,5 MMSCFD 13 Desember 2019 New Inlet Pressure with Heater After DiDocument1 pageCNG ADK 3,5 MMSCFD 13 Desember 2019 New Inlet Pressure with Heater After Dirandi martaNo ratings yet

- GAS PROPERTIES CALCULATION SHEETDocument56 pagesGAS PROPERTIES CALCULATION SHEETOlumuyiwa FasehunNo ratings yet

- Design 3Document2 pagesDesign 3JOY NATHNo ratings yet

- Calculate Gas Rate Using Choke Equation Texas A & I ModelDocument6 pagesCalculate Gas Rate Using Choke Equation Texas A & I ModelJunaid MateenNo ratings yet

- App 6 CalculationsDocument2 pagesApp 6 CalculationsNizarHamrouniNo ratings yet

- 3 Phase Separators ( Separators') : Design Philosophy: 4 Sections of A SeparatorDocument2 pages3 Phase Separators ( Separators') : Design Philosophy: 4 Sections of A SeparatorPrie TeaNo ratings yet

- Cooling Tower ComparisonDocument4 pagesCooling Tower ComparisonKiran DasNo ratings yet

- 2880LNG LiquefactionDocument64 pages2880LNG LiquefactionKrishna N HNo ratings yet

- Pneumatic Conveying Spreadsheet-ContentDocument27 pagesPneumatic Conveying Spreadsheet-Contentaladdin4dNo ratings yet

- Choosing the right hydraulic separatorDocument3 pagesChoosing the right hydraulic separatoramandaNo ratings yet

- API 12j SizingDocument1 pageAPI 12j SizingAdewunmi OlufemiNo ratings yet

- VGS Vane Separators Are Recommended ForDocument1 pageVGS Vane Separators Are Recommended ForSanthu PeelaNo ratings yet

- Gas Line Pressure LossesDocument4 pagesGas Line Pressure Lossesyash saragiyaNo ratings yet

- Fdocuments - in Separator Sizing SpreadsheetDocument31 pagesFdocuments - in Separator Sizing SpreadsheetGabrielito PachacamaNo ratings yet

- 10.9. Gas Liquid Separators: Chemical EngineeringDocument6 pages10.9. Gas Liquid Separators: Chemical EngineeringsterlingNo ratings yet

- 48" X 15' Three Phase Test SeparatorDocument2 pages48" X 15' Three Phase Test Separatorpraash bhattNo ratings yet

- Horizontal KO PotDocument4 pagesHorizontal KO Pothk168No ratings yet

- Ipa-Water SeparationDocument8 pagesIpa-Water SeparationkashifwarsiNo ratings yet

- Corrugated Plate Separator (CPS) ForDocument2 pagesCorrugated Plate Separator (CPS) Formib_ajayNo ratings yet

- Control of Flow Rates at Startup: GAT2004-GKP-2010.009 September, 2010Document2 pagesControl of Flow Rates at Startup: GAT2004-GKP-2010.009 September, 2010Enyerberht Castañeda BritoNo ratings yet

- Api Oil Water Separators 2013Document6 pagesApi Oil Water Separators 2013adalcayde2514No ratings yet

- DurstDocument7 pagesDurstRahul KatreNo ratings yet

- Lecture Topic: PetroleumDocument5 pagesLecture Topic: PetroleumNikhil TutejaNo ratings yet

- Coordinated Sciences IGSCE 0654 - s12 - QP - 63 PDFDocument20 pagesCoordinated Sciences IGSCE 0654 - s12 - QP - 63 PDFjanovaNo ratings yet

- Biochemical TestsDocument2 pagesBiochemical TestsJacqueline DavisNo ratings yet

- Metabolisme ImmunometabolismDocument25 pagesMetabolisme ImmunometabolismOKE channelNo ratings yet

- CBSE Class 11 and 12 Chemistry Notes The P-Block ElementsDocument45 pagesCBSE Class 11 and 12 Chemistry Notes The P-Block ElementsPrabhuPalanichamy50% (2)

- Water Quality Index Test ResultsDocument11 pagesWater Quality Index Test ResultsSunil BhavsarNo ratings yet

- Aijstpme (2012) 5 (4) 7-20Document14 pagesAijstpme (2012) 5 (4) 7-20maziar60No ratings yet

- Process Analysis of Refinery Crude Charge HeaterDocument21 pagesProcess Analysis of Refinery Crude Charge HeaterNicholas RiveraNo ratings yet

- General PHARMAKOLOGY - Загальна фармакологія - Курс лекцій - изд.2005-215 сDocument219 pagesGeneral PHARMAKOLOGY - Загальна фармакологія - Курс лекцій - изд.2005-215 сSahil Saini100% (4)

- Aspen Exchanger Design and Rating Plate V10: Cold Side DatabankDocument12 pagesAspen Exchanger Design and Rating Plate V10: Cold Side DatabankCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- CEMB 111 Concrete Flexural Strength LabDocument7 pagesCEMB 111 Concrete Flexural Strength LabhamedNo ratings yet

- Air Carbon Arc GougingDocument3 pagesAir Carbon Arc GougingMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Chemical Reactors and Reactor Sizing: Lecturer: Dr. Ayoola A.ADocument14 pagesChemical Reactors and Reactor Sizing: Lecturer: Dr. Ayoola A.AChuka OmeneNo ratings yet

- Cocaine in Blood of Coca ChewersDocument10 pagesCocaine in Blood of Coca ChewersKarl-GeorgNo ratings yet

- Unit 1.5 - Stress and Strain in Lifting EquipmentDocument14 pagesUnit 1.5 - Stress and Strain in Lifting EquipmentnitharsunNo ratings yet

- Chem Book-1Document216 pagesChem Book-1Ergi HoxhaNo ratings yet

- Diffusivity Formula Chart (Infographic)Document3 pagesDiffusivity Formula Chart (Infographic)Safayet AzizNo ratings yet

- CH 8201 PCE AU Question Bank AnswersDocument11 pagesCH 8201 PCE AU Question Bank Answersarulrakk100% (2)

- 管径计算表Document11 pages管径计算表Ascend032No ratings yet

- Triazine DyesDocument30 pagesTriazine DyesRoxanaNo ratings yet

- RADIATION SAFETY FUNDAMENTALSDocument69 pagesRADIATION SAFETY FUNDAMENTALSJay Lawson100% (1)

- The Tensile-Yield Behavior ., of Ship'"S Ee.L: W: S. Owen, B, L Averbach and "Morris Coh&hDocument45 pagesThe Tensile-Yield Behavior ., of Ship'"S Ee.L: W: S. Owen, B, L Averbach and "Morris Coh&hKaung Myat HeinNo ratings yet

- Defect List PDFDocument2 pagesDefect List PDFAnonymous qT80dF24dNo ratings yet

- Hombright S-Id (WD)Document6 pagesHombright S-Id (WD)何恭彥No ratings yet

- Contineous Dyeing of Reactive DyesDocument9 pagesContineous Dyeing of Reactive DyesMohammed Atiqul Hoque ChowdhuryNo ratings yet

- Bm101: Biology For Engineers: Instructor: Yashveer Singh, PHDDocument15 pagesBm101: Biology For Engineers: Instructor: Yashveer Singh, PHDhimanshu singhNo ratings yet

- Science Class 9 Notes SoundDocument1 pageScience Class 9 Notes SoundPriyaprasad PandaNo ratings yet

- Coconut OilDocument12 pagesCoconut OilAniruddh KhalatkarNo ratings yet

- Extended Safety Data Sheet for Agidol-1Document24 pagesExtended Safety Data Sheet for Agidol-1Sekawan CosmeticsNo ratings yet